Document 11895863

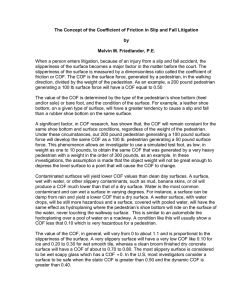

advertisement

Analyzing Nonskid for Naval Applica4ons Bri$any Preston 24” square test panel Nonskid is a mul--­‐use coa-ng used to increase maneuverability on the decks of ships and to prevent corrosion and wear of the decks. It is made of aluminum oxide in a polymer matrix . Impact: Confidence in the equipment provided to the fleet is necessary for proper opera-on, safety of equipment and crew, and maintenance. This tes-ng will determine whether there was a difference between the old and new products, possible reasons for the difference, and offer sugges-ons for future work. Objec4ve: Determine whether the new 96 % aluminum oxide content performed to the same coefficient of fric-on (CoF) standards as the old 86 % aluminum oxide content. Determine what the results from the new rota-ng arm CoF meter mean. Approach: Roll rough and flat 96 % and 86 % Al2O3 panels. CoF measured made on all panels under wet, oily, and dry condi-ons. Surface energy, hardness and roughness readings compared for each type of nonskid. Contact: Dr. Michel Barsoum Materials Science and Engineering E-­‐mail: barsoumw@drexel.edu Phone: (215) 895-­‐2338 Mentor: Jeffrey Duckworth Code 614, NSWC Philadelphia, PA jeffrey.w.duckworth@navy.mil