2015-2016 Material Handling Student Design Competition ACME Shoes Facility Design Case Overview

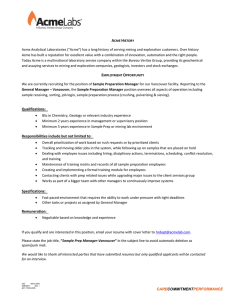

advertisement

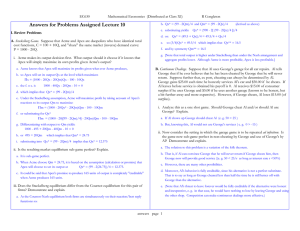

2015-2016 Material Handling Student Design Competition ACME Shoes Facility Design Case Overview As a wholesale footwear distributor, ACME provides popular athletic footwear for varying sizes of customers. ACME’s current distribution center (DC) in Outwest, AZ, is at capacity for both storage and throughput. In addition, the current location is landlocked and restricts growth inplace. Thus, a new location is required. The current Outwest lease expires in July 2017, and ACME wants to leave the facility no later than the end of 2016, to provide time for decommissioning. Demand for their products is increasing, and ACME is anticipating 7% annual unit growth into the future. Current operations are mostly manual, with minimal automation. ACME is seeking a solution for a new facility that will accommodate growth through 2021. ACME wants to explore alternative solutions that are cost justified and will result in more efficient, more flexible, and less complex operations. They have provided information on current processes, current productivity rates, stock keeping units (SKUs), outbound flow (by orders, lines, and SKUs), labor assumptions, and future state design requirements. The current operation is to be considered the baseline for analysis purposes. The goal is to implement a new DC with minimal risk and no negative impacts on their customers. ACME desires to stay in or near Outwest, AZ, and will be securing land in the area. In summary, ACMS’s existing DC is at capacity with no room to expand and an expiring lease. They are anticipating 7% annual unit growth through at least 2021. Thus, ACME requests your team to design a new, cost-justified DC to support business projections through 2021. Sponsored by: www.CICMHE.org www.mhi.org/OFS www.fortna.com