Production of Pure Hydrogen from a Source of Waste er

advertisement

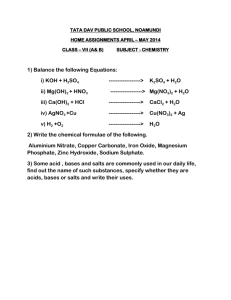

Production of Pure Hydrogen from a Source of Waste sing Solid O ide Membrane Electrolyzer Electrol er and Steam using Oxide Soobhankar Pati Kyung Joong Yoon Srikanth Gopalan Uday B. Pal Materials Science & Engineering ECS 215 ECS 215th Conference, San Francisco May 24 May 24 ‐‐ 30th, 2009 OUTLINE OF THE PRESENTATION y Hydrogen as an energy carrier ? y Conventional Solid Oxide Steam Electrolyzers (SOSE) y Novel Solid Oxide Membrane (SOM) Electrolyzer y Experiment y Process model for the SOM Electrolyzer y Evaluation of experimentally obtained data using the process model d l y Some ongoing experiments to improve the efficiency ELECTROLYSIS: CONVENTIONAL SOLID OXIDE STEAM ELECTROLYZER (SOSE) Air (O2 , N2) O2 (g) 2eO + O Æ O2(g) Porous anode O2‐ Æ O + 2e‐ V Electrolyte H2O(g) + 2e‐ Æ H2(g) + O2‐ Porous cathode H2O (g) H (g) 2 2e- Partial pressure of oxygen in air (pO2)air > Partial pressure of oxygen in H2-H2O (pO2)H2O/H2 60 – 70% of the energy = THERMODYNAMIC BARRIER Natural gas* THERMODYNAMIC BARRIER REDUCTANT AT THE ANODE Coal Hydrocarbon waste t PROBLEM: Conventional SOSE is not equipped to use reductants (waste, coal, etc.) *J. Martinez‐Frias, Ai‐Quoc Pham and S. M. Aceves: Int. J. of Hydrogen Energy, 2003, vol.28, pp 483‐90 CONFIGURATION: SOLID OXIDE MEMBRANE (SOM)ELECTROLYZER Reductant (R) (Coal, Hydrocarbon waste) RO(g) Syn gas Syn‐gas 2e- Liquid metal anode (Sn1, Ag2, Cu3) [O]LMA + R Æ R Æ RO(g) RO( ) O2‐ Æ [O]LMA + 2e‐ V O2‐ Electrolyte (YSZ) H2O(g) + 2e‐ Æ H2(g) + O2‐ Porous cathode (Ni‐YSZ, Cu‐YSZ) H2 (g) 2e- H2O(g) 1 , 2 Charge transfer at the YSZ/Anode interface LIQUID METAL ANODE 3 1 2 3 Reaction interface for oxidation of reductant by the [O] y [ ]LMA T. Ramanarayanan and R.A. Rapp: Metall. Trans. B,3, 3239 (1972) T. H. Etsell and S. N. Flengas, Metall. Trans. B, 2, 2829 (1971) A. Krishnan, U. Pal and X. Lu: Metall. Trans. B, 36,463 (2005) ADVANTAGES : SOLID OXIDE MEMBRANE (SOM) ELECTROLYZER 1.2 200 0.9 H2O (g) ( ) = H2(g) ( ) + 1/2 O2(g) ( ) 100 06 0.6 o ΔE (Voltss) ΔGo (kJ / mol) SOSE 0.3 Operating Temperature 0 0.0 SOM -0.3 H2O (g) + C = H2(g) + CO (g) -100 400 600 800 1000 1200 o Temperature ( C ) If h d If hydrocarbon waste (HC) is used , b (HC) i d H2O(g) + (HC) Æ H2(g) + H2O(g) + CO(g) ‐ Electrochemical conversion of H2O(g) High purity H2 ‐ Efficient way of converting energy value in waste EXPERIMENTAL SET UP: ELECTROCHEMICAL PERFORMANCE Ni-YSZ S cathode ~ 90 m ~ 10% porous YSZ electrolyte ~ 2 mm Operating Temperature : 1000 O ti T t 1000oC ELECTROCHEMICAL CHARACTERIZATION AND PERFORMANCE ELECTROCHEMICAL CHARACTERIZATION: OPEN CIRCUIT POTENTIAL Open circuit potential (Eeq)*,** Cathodic gas composition : poO2(a) [C/CO(g) equilibrium] 3 % H 2O - H 2 10 % H2O - H2 20 % H2O - H2 40 % H2O - H2 Measured Values (V) -0.050 3.999 × 10-19 - 0.120 -0.154 - 0.207 A negative open circuit potential (OCP) indicates the process is spontaneous OCP of SOSE (0.89 V) >> OCP SOM electrolyzer (-0.207 V) : 40%H2O – H2 * J. Martinez‐Frias, Ai‐Quoc Pham and S. M. Aceves: Int. J. of Hydrogen Energy, 2003, vol.28, pp 483‐90. ** P. Soral, U. Pal, H. Larson and B. Schroeder: Metall. Trans. B, 1999, vol.30, pp 307‐21. ELECTROCHEMICAL CHARCTERIZATION: POTENTIODYNAMIC SCAN 5 40% H2O 2 4 Current (A)) C 10% H2O 0.3 3% H2O 3 0.2 2 1 0 -0.5 Mass transfer limited 0.0 0.5 1.0 1.5 Curren nt Density (A/cm ) 04 0.4 20% H2O 2.0 2.5 3.0 0.1 3.5 Potential (V) Current density increased with increase in steam content in the cathodic gas feed Mass transfer limitation was observed only at 3% H2O content ~ Unavailability of H2O(g) at the TPBs ELECTROCHEMICAL PERFORMANCE: POLARIZATION MODEL DEVELOPMENT Open circuit potential (Eeq) Ohmic Polarization ( : = i Rohm ohm) : ohm Activation Polarization ( act) Rohm : YSZ , Electrodes, Contact, Lead wire (ne=2, α=1/2) : (Anode + Cathode) Concentration Polarization ( conc) : Cathodic concentration polarization Anodic concentration polarization ELECTROCHEMICAL PERFORMANCE: CURVE FITTING Open Ohmic loss Circuit Potential Measured Activation polarization Cathodic conc. polarization i0 : Fitting parameter Impedance spectroscopy Anodic conc. polarization : Literature value* kc (Mass transfer coeff. of dissolved oxygen yg (Eff i bi (Effective binary diffusivity) diff i i ) in the liquid tin anode) : Fitting parameter : Fitting parameter Maximum of 2 fitting parameters used for the curve fitting * T. Ramanarayanan and R.A. Rapp: Metall. Trans. B, 1972, vol.3, pp 3239‐46 Appropriate assumption ELECTROCHEMICAL PERFORMANCE: IMPEDANCE SPECTROSCOPY 2 Zreal(Ω-cm ) 5 10 15 20 30 35 40 3% H2O 1.6 4 X 10-2 Hz 10% H2O 16 12 1 Hz 0.8 8 0.4 4 4000 Hz 0.0 0.5 1.0 1.5 2.0 Zreal(Ω) 2 40% H2O - Zimag(Ω-cm ) 20% H2O 1.2 - Zimag(Ω) 25 0 2.5 3.0 3.5 4.0 High frequency intercept : Ohmic resistance* : Independent of steam content** g q y p p Overlap of charge transfer resistance and diffusional (Warburg) impedance at higher frequencies *** * J.R. Macdonald : Impedance Spectroscopy, John Wiley, New York,NY,1987 ** M. A. Laguna‐Bercero, S. J. Skinner and J. A. Kilner, J. of Power Sources, doi:10.1016/j.jpowsour.2008.12.139,(2009) *** S. Britten and U. Pal, Metall. and Mat. Transactions B, 31, 733 (2000) ELECTROCHEMICAL PERFORMANCE: CURVE FITTING (40% H2O in cathodic gas) Open O Ohmic loss Oh i l Circuit Potential Activation polarization A i i l i i i0 : Fitting parameter Measured Cathodic conc. polarization h d l Insignificant Anodic conc. polarization A di l i i kc: Fitting parameter Measured (Imp. Spectra) 3.5 A3.0 3SSUMPTION 0 : Cathodic concentration polarization ( conc, c ) is negligible* ) is negligible Potentiial (V) 2.5 ‐ Mass transfer limitation not observed ‐ SOM electrolyzer is electrolyte supported with thin Ni‐ YSZ cathode 2.0 1.5 1.0 0.5 0.0 -0.5 0 1 2 3 4 Fitting parameters Curve fitting results Exchange current (i0 ) 1.00A Mass transfer f coefficient ff ( kc) ( k 0.00056 cm/sec 5 Current (A) * M. Ni, M.K.H. Leung and D.Y.C. Leung: Int. J of Hyd. Energy, 2007, vol. 32, pp 2305‐13 ELECTROCHEMICAL PERFORMANCE: CURVE FITTING (3% H2O in cathodic gas) Open Ohmic loss Circuit Potential Activation polarization Measured Cathodic conc. polarization Cathodic conc polarization kc : Independent 0f cathodic gas comp.* i0 : Fitting parameter : Fitting parameter Measured (Imp. Spectra) kc : 40 % curve fitting (0.00056 cm/sec 3% H2O 2.0 Anodic conc. polarization Anodic conc polarization Curve Fitted Pote ential (V) 1.5 1.0 0.5 0.0 Fitting parameters Curve fitting results Exchange current (i0 ) 0.12 A Effective Binary Diffusivity ( DeffH2‐H2O ) 0.025 cm2/sec 0.0 0.3 0.6 0.9 1.2 1.5 1.8 Current (A) *S. Yuan, K.C. Chou, U. Pal: J. Elec. Soc.,1994, vol. 141, pp. 467‐74 ELECTROCHEMICAL PERFORMANCE: CURVE FITTING ( 10 % and 20 % H2O) Open Ohmic loss Circuit Potential p Activation polarization p Cathodic conc. polarization kc : 40 % curve fitting (0.00056 cm/sec i0 : Fitting parameter Measured p Anodic conc. polarization :Independent of cathodic gas comp.* Measured (Imp. Spectra) 3 10 % H2O :3% curve fitting (0.025 cm2/sec) 20 % H2O Pote ential (V) 2 Curve Fitted 1 0 0 1 2 3 Cathode gas composition Exchange current (i0) 10 % H2O – H2 0.26 A 20 % H2O – H2 0.68 A 4 Current (A) R. B. Bird, W. E. Stewart and E. N. Lightfoot: Transport Phenomena, 2nd ed., John Wiley & Sons, New York, 2002 ELECTROCHEMICAL PERFORMANCE : ACTIVATION POLARIZATION Cathode g gas Exchange current (i0) composition 3 % H2O – H2 0.12 A 10 % H2O – H2 0.26 A 20 % H2O – H2 0.68 A 40 % H2O – H2 1.00 A 3% H2O Ac ctivation pola arization (V) 0.4 10% H2O 20% H2O 0.3 H2O content 40% H2O => Surface coverage of H S f f H2O (g) at TPB’s O ( ) TPB’ 02 0.2 0.1 0.0 0 1 2 3 Current (A) 4 5 Provides additional sites for the charge transfer reaction ELECTRO. PERFORM.: CATHODIC CONC. POLARIZATION (40% H2O) is composition independent 3.5 Total polarization Cathodic conentration polarization Polarrization (V) 3.0 25 2.5 2.0 1.5 Cathodic concentration polarization 1.0 0.5 1% of the total overpotential 0.0 -0.5 0 1 2 3 4 5 Current (A) Cathodic concentration polarization is insignificant at 40% H2O : Consistent with our initial assumption ELECTRO. PERFORM.: IMPEDANCE SPECTROSCOPY IN SUPPORT OF POLARIZATION MODELING Cathodic gas composition :40 % H2O Equivalent circuit describing the SOM electrolyzer 2 Zreal (Ω-cm ) 0 5 10 15 20 25 30 20 Cathodic gas composition 40 % H2O O-H H2 Curve fitted 1.5 16 -2 -Zimag (Ω) 1.0 0 12 Rohm = 0.585 Ω Rct = 0.061 Ω 8 1 Hz 0.5 10 Hz 4000 Hz 4 0 0.0 0.5 1.0 1.5 2.0 2.5 Zreal (Ω) At small activation polarization At small activation polarization, Polarization modeling CNLS Fitting Oh i Loss Ohmic L (Rohm) 0 58Ω 0.58Ω 0 585Ω 0.585Ω Charge transfer resistance (Rct,c) 0.054Ω 0.061 Ω 2 CNLS Fitting Results: -Zimag(Ω-c cm ) 4.0 X 10 Hz ELECTROCHEMICAL PERFORMANCE: VARIOUS POLARIZATION LOSSES 3% Steam content 40% Steam content 3.5 2.0 1.5 Conc. polarization(Cathode) Activation polarization 1.0 Ohmic loss (Electrodes, Contact, Current collector)) 05 0.5 Total Polarizatio T on (V) Conc. polarization(Anode) Tottal Polarization n (V) Conc. polarization ( Anode) Activation pol. 3.0 2.5 Ohmic loss ( Electrode, Current collector) 2.0 1.5 1.0 Ohmic loss ( YSZ electrolyte) 0.5 Ohmic (YSZ electrolyte) 0.0 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 0.0 0 1 2 3 4 Current (A) Current (A) At 3% H2O the ohmic part ≈ Overpotential due to electrode processes At 40% H2O ohmic resistance is 80.5% of the total polarization p Electrodes, Contacts, Current collector 52 % of the ohmic loss YSZ electrolyte resistance 48 % of the ohmic loss Ohmic loss due to the dominates the performance loss: ‐ Molybdenum current collectors on the anodic side ‐ SOM electrolyzer design ( Electrode supported) 5 SUMMARY The potential of hydrogen production from steam using a solid oxide membrane electrolyzer with a liquid anode was demonstrated. l t l ith li id d d t t d Thermodynamic barrier was lowered using a reductant in the liquid metal anode. U Using an electrolyte supported design and applying only 2.0 i l t l t t d d i d l i l 2 0 V , a current density of t d it f 2 0.5 A/cm was achieved. Polarization modeling results thus showed that the performance is rate‐controlled by the ohmic loss. h h i l Experimental study and modeling will form the basis for redesigning the SOM electrolyzer to improve its efficiency and for investigating various types of waste feed.