Production of Clostridium difficile toxin in a medium

advertisement

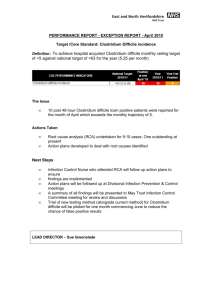

Production of Clostridium difficile toxin in a medium totally free of both animal and dairy proteins or digests The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Fang, Aiqi, Donald F Gerson, and Arnold L Demain. “Production of Clostridium difficile toxin in a medium totally free of both animal and dairy proteins or digests.” Proceedings of the National Academy of Sciences 106.32 (2009): 13225-13229. © 2009 National Academy of Sciences As Published http://dx.doi.org/10.1073/pnas.0906425106 Publisher United States National Academy of Sciences Version Final published version Accessed Wed May 25 18:19:20 EDT 2016 Citable Link http://hdl.handle.net/1721.1/54821 Terms of Use Article is made available in accordance with the publisher's policy and may be subject to US copyright law. Please refer to the publisher's site for terms of use. Detailed Terms Production of Clostridium difficile toxin in a medium totally free of both animal and dairy proteins or digests Aiqi Fang1, Donald F. Gerson2, and Arnold L. Demain3 Department of Biology, Massachusetts Institute of Technology, Cambridge, MA 02139 In the hope of developing a vaccine against Clostridium difficile based on its toxin(s), we have developed a fermentation medium for the bacterium that results in the formation of Toxin A and contains no meat or dairy products, thus obviating the problem of possible prion diseases. Particular preparations of hydrolyzed soy proteins, especially Soy Peptone A3, have been found to replace both the meat/dairy product tryptone in the preparation of working cell banks and seed media, and NZ-Soy BL4 does the same in the fermentation medium. These replacements yield even higher toxin titers. fermentation medium 兩 TcdA 兩 Toxin A C lostridium difficile is a Gram-positive, spore-forming, anaerobic, and toxigenic bacterium that causes antibioticassociated diarrhea and pseudomembranous colitis, which can be fatal. The organism is widely spread and can be found in soil, rivers, river bank mud, lakes, hay, farm animals, swimming pools, raw vegetables, and surfaces of residential homes and hospitals. Although C. difficile is normally a harmless environmental organism, antibiotic therapy has led to its causation of human morbidity and mortality. The disease usually occurs in intensive care units, surgical wards, and hematology/oncology units, particularly affecting patients over 60 years of age. Disease can occur when the normal intestinal colonic flora are disrupted by therapy with antibiotics or antitumor agents, and ingested C. difficile spores germinate in the colon. Vegetative cells grow rapidly, fill empty niches and form toxins, usually causing fever, nausea, anorexia, diarrhea, flatulence, and malaise, sometimes causing death (1). C. difficile causes 25% of the cases of antibiotic-associated diarrhea and cases in hospitalized patients number greater than 3.5 million per year (2, 3). In Canada, an epidemic was reported to have occurred in 2004 in which over 600 deaths occurred in Quebec alone (4). Such disruption enables the organism to become established in the colon where it produces 2 high molecular weight toxins, the causative agents of the illness. Toxins A (TcdA) and B (TcdB) are polypeptide cytotoxins of molecular weight 308 and 270 kDa, respectively, with a great difference in activity. Toxin A also acts as an enterotoxin, causing accumulation of fluid in ligated intestinal loops. Both toxins are members of a family of glucosyltransferases that glycosylate proteins of the Rho family of small GTP-binding proteins using a UDP-intermediate (5). The toxins are encoded by 2 separate but closely linked genes (tcdA and tcdB) that, together with 3 other ORFs, form part of a short chromosomal 19.6-kb region known as the ‘‘toxigenic element’’ or ‘‘pathogenicity locus.’’ The genes have been described by Rupnik et al. (6). They are highly homologous and likely evolved by duplication. Toxins A and B are produced simultaneously in C. difficile strain VPI 10463 (ATCC 43255) in a ratio of 3:1, respectively (7). They begin to be formed during the exponential phase of growth, increase in production as cells enter the stationary phase (8), and are usually released from the cell between 36 and 72 h of culture. The toxins can be released earlier by sonication or by use of a French press. www.pnas.org兾cgi兾doi兾10.1073兾pnas.0906425106 It is hoped that toxin(s) of C. difficile will be used to develop a vaccine against the organism. Media for growth and toxin formation of C. difficile typically contain animal and dairy byproducts as sources of protein, peptides, amino acids, and other nutrients required for growth (9). Manufacturers of such media have used complex ingredients such as casein digests and meat extracts to maximize production of the toxins. However, such toxin preparations could be contaminated with animal or dairy proteins. Thus, it is possible that some preparations could contain undesirable contaminants such as the prion causing bovine spongiform encephalopathy (BSE; Mad Cow Disease) or antigenic peptides that stimulate anaphylactic reactions and other undesirable immune reactions in immunized hosts. Rolfe and Finegold (10) studied a number of media for growth of C. difficile and formation of toxin. The best media for toxin production contained chopped meat, or brain heart infusion, or protease peptone. Since protease peptone is a peptic digest of animal tissue, all 3 media contain animal products. No toxin was detected after growth in a medium containing an amino acid mixture instead of animal products. When non-animal/non-dairy peptones were used, such as phytone or yeast extract, the toxin titers were markedly lower, that is, 12.5 or 25%, respectively, of the titer with chopped meat or brain heart infusion. Al Saif and Brazier (11) used a medium containing horse blood for production of Toxin A. Braun et al. (12) used alkaline trypticase yeast extract-mannitol medium. Other investigators have used cooked meat, brain heart infusion (13), tryptone (14), and trypticase (15). Trypticase and tryptone are digests of a dairy protein, that is, casein, prepared with an enzyme preparation obtained from the animal pancreas (pancreatic juice). As a result of the above problems, there is a real need for an improved medium lacking both animal and dairy products for development of a vaccine. With our experience in developing a soy-based process for preparation of tetanus toxin (16–19), we decided to address this need and attempt to develop a high-level production process for C. difficile toxin totally lacking animal and dairy products. The successful result is described in this paper. Results Comparison of Production Media Containing Tryptone Peptone. Tryp- tone peptone (also called tryptone) is a pancreatic digest of casein. The enzyme mixture used to prepare it is from the pancreas, that is, the gland of vertebrates, and usually comes Author contributions: A.L.D. designed research; A.F. performed research; A.F., D.F.G., and A.L.D. analyzed data; and A.L.D. wrote the paper. The authors declare no conflict of interest. Freely available online through the PNAS open access option.. 1Present address: 5626 RFD, Long Grove, IL 60047-8248. 2Present address: PnuVax, Inc., 134 Albert St., Kingston, ON, Canada K7L 3V2. 3To whom correspondence should be addressed at the present address: Charles A. Dana Research Institute for Scientists Emeriti (R.I.S.E.), HS-330, Drew University, Madison, NJ 07940. E-mail: ademain@drew.edu. PNAS 兩 August 11, 2009 兩 vol. 106 兩 no. 32 兩 13225–13229 APPLIED BIOLOGICAL SCIENCES Contributed by Arnold L. Demain, June 10, 2009 (sent for review May 1, 2009) Table 1. Comparison of culture media containing animal/dairy products for growth and Toxin A production Medium TYM (control) TYG TY TNB Maximum growth, OD Maximum toxin A, ng/mL 0.97 1.05 0.95 0.71 27 26 2,500 2,520 from the hog. A number of tryptone-containing media used by other workers were compared for ability to support toxin production. Table 1 shows that 2 of the media (TY and TNB) supported high toxin production whereas the other 2 (TYM and TNG) were poor. There did not seem to be a correlation between growth and production. TY was chosen as the animal/dairy type medium as a control to examine the possible use of vegetable protein digests. Ability of Soy Peptones to Replace Tryptone Peptone for Toxin Production. Using the TY medium as a tryptone control, we tested a number of vegetable peptones for production (Table 2). The control medium supported good toxin production as expected. Many of the vegetable media also supported excellent toxin production but the leader was medium NZS-BL7 (containing NZ-Soy BL7) which yielded more than twice as much toxin A as the animal/dairy control TY medium. The other very good media were NZS (containing NZ-Soy), NZS-BL4 (containing NZ-Soy BL4), and VP No. 1 (containing Vegetable Peptone No. 1). The results thus show that the toxin production ability of tryptone can be replaced and even exceeded by vegetable digests. Effects of Carbon Sources Added to a Soy-based Medium. The marked differences between the different animal/dairy based media (Table 1) with respect to support of toxin formation prompted us to test the effect of carbon sources. In this case, we added them to soy-based medium HS. This medium contained Hi-Soy at 30 g/L, yeast extract at 20 g/L, and sodium thioglycolate at 1 g/L. Results are shown in Table 3. It is obvious that addition of 10 g/L glucose or mannitol markedly inhibited production whereas 1 g/L glycerol had no effect. The negative effects of glucose or mannitol obviously were the cause of the poor toxin formation observed in media TYM and TYG in Table 1. Performance in medium TNB was good despite its content of glucose because glucose concentration was only 1/10 of what it was in TYM and TYG. Elimination of Animal/Dairy Products from the Seed Medium and the Medium Used To Prepare Working Cell Bank. In the above experi- ments, the medium used for preparation of the WCB and the seed media for fermentation was TYM medium containing the animal/dairy product tryptone. Since there is a danger of carryover of tryptone into the fermentation medium, studies were undertaken to replace this problematic constituent by the use of vegetable products in the seed medium. Vegetable products were tested as replacements for the tryptone of TYM in the seed media. The media were identical to TY with the exception that a vegetable digest was used to replace tryptone. Various fermentation media were used in these experiments. They included NZS-BL4 and VP No. 1 and a third medium, SPA3 containing Soy Peptone A3. To start, VP No.1 was compared to TYM as seed medium and tested in fermentation medium VP No. 1, containing Vegetable Peptone No. 1. The results showed that toxin production with the vegetable seed medium was only 26% of that with tryptone. In a second experiment, toxin production in NZ-Soy BL4 was also found to be poorer than TYM as seed medium (53% of tryptone control). In a third experiment, 11 vegetable peptones (HY-Soy, NZ-Soy, NZ-Soy BL4, NZ-Soy BL7, SE 50M, WGE 80M, Plant Peptone E1, Vegetable P No. 1, Soy Peptone Type II, Soy Peptone Type AC, and Soy Peptone Type AB) were compared to tryptone in the seed medium, and also modifications were made in the NZ-Soy BL4 seed medium such as increasing the NZ-Soy concentration from 24 g/L to 48 and 96 g/L, and changing initial pH of the medium from 6.8 to 7.5 and 8.5. Fermentation was done in the NZ-Soy BL4 production medium. All 11 peptones failed to duplicate the performance of tryptone as protein digest in the seed medium. The vegetative seed media gave toxin titers varying from 28% to 41% of that of the tryptone seed. The best vegetable replacement was NZ-Soy BL4. None of the above modifications to the NZ-Soy BL4 vegetable seed Table 2. Comparison of tryptone-containing medium TY with media containing vegetable products as fermentation media Medium TY (Control) VP AMI SE-M WGE-M B1 HST HS SPF SPSL CNE SPAB WGE-BT SPII SPAC SE VP No.1 NZS-BL4 NZS NZS-BL7 Maximum peptone Maximum growth, OD Toxin A, ng/mL Tryptone Vegetable peptone AMISoy SE-70M WGE 80M Plant peptone E1 Hy-Soy T Hy-Soy Soy peptone type F Soy peptone type SL CNE-50M Soy peptone type AB WGE 80BT Soy peptone type II Soy peptone type AC SE 50M Vegetable peptone No. 1 NZ-Soy BL4 NZ-Soy NZ-Soy BL7 0.88 1.07 Insoluble 0.55 Insoluble 0.66 Insoluble 0.70 0.39 0.54 0.72 0.76 Insoluble 0.65 0.76 0.80 0.74 0.81 0.97 Insoluble 5,240 288 3,500 3,500 3,650 3,766 4,100 4,144 4,250 4,346 4,348 4,512 4,800 5,069 5,073 5,789 8,941 8,997 9,068 13,036 13226 兩 www.pnas.org兾cgi兾doi兾10.1073兾pnas.0906425106 Fang et al. Table 3. Effect of addition of glucose, mannitol, and glycerol to the fermentation medium on toxin production Medium Maximum vegetable peptone Maximum growth, OD Toxin, ng/mL Hy-Soy Hy-Soy Hy-Soy Hy-Soy Hy-Soy 0.66 0.90 0.84 0.68 0.81 3,820 244 158 3,820 140 HS HS ⫹ Gluc* HS ⫹ Mann† HS ⫹ Glyc‡ HS ⫹ Mann† ⫹Glyc‡ medium allowed it to equal the activity of the animal/dairy seed; they yielded only 39% to 51% of the toxin of controls. The best vegetable seed medium was NZ-Soy BL4 modified by raising its pH to 7.5. A fourth experiment was done using 13 vegetable peptones as seed media adjusted to pH 7.5. These included AMI Soy, Hy-Soy T, SE 50MK, WGE 80BT, SE 70BT, SE 70M (DMV), CNE-50M (DMV), Soy Peptone A1, Soy Peptone A2, Soy Peptone A3, Plant Peptone ET 1, Wheat Peptone E1, and NZ-Soy BL4. Again none was able to equal the activity of tryptone as seed media. The range of toxin titers reached was 32% to 59% of the TYM seed titer. Finally in the fifth experiment, we compared performance of a working cell bank grown with tryptone (TYM) vs. that grown in a vegetable medium containing Soy Peptone A3. Surprisingly, we found that the working cell bank produced with Soy Peptone A3 performed much better in vegetable seed and fermentation media than did the tryptone-grown cell bank (Table 4). This was confirmed in a second test also shown in Table 4. Furthermore, the addition of an iron source to the second stage seed further stimulated toxin formation whereas adjustment of the second stage seed from pH 7.5 to 8.5 had a mild stimulatory effect. Scale Up from Test Tubes into 1-L Fermentors and a 1-L WAVE Bioreactor. Up to this point, all of our work had been done in 16 ⫻ 100-mm unagitated test tubes containing 8 mL media under a gaseous atmosphere of 80% nitrogen, 10% hydrogen, and 10% carbon dioxide. To begin to scale-up the production process, we studied formation of toxin in 1-L bottles and a 1-L WAVE Bioreactor containing 800 mL NZ-Soy BL4 fermentation medium. A WAVE bioreactor ( GE Healthcare , Life Sciences) consists of a 1-L presterilized disposable bag system capable of sterile additions and sampling that is placed on a rocker apparatus providing gentle mixing (20). In this case, the WAVE was operated in anaerobic conditions as described for the Coy chamber above. The bottles were inoculated with 4 mL second stage seed grown in Soy Peptone A3, closed with foam plugs and incubated statically in the anaerobic chamber containing an 80%N2/10%H2/10%CO2 atmosphere at 37 °C⫹/-1 °C for 5 days. As seen in Table 5, toxin was produced in the 1-L bottles at 72% of the production level achieved in test tubes. In the WAVE Bioreactor, production almost equaled that in test tubes. We repeated the experiment, this time adding reduced iron powder to the second stage seed medium. In all 3 types of reactor, toxin titers were increased by the iron addition (thus confirming the results on iron addition in the previous section), and this time, performance in bottles was 88% that in tubes whereas in the WAVE Bioreactor production was virtually the same as in tubes. Discussion The interference in toxin formation that we observed when adding glucose or mannitol to the fermentation medium can be explained by the observation that expression of promoters of the tox genes is repressed by rapidly used carbon sources (8, 21). The tox genes are positively regulated by the product of the txeR gene that is just upstream of the tox gene cluster (22). Product TXE is a 22-kDa protein containing a potential C-terminal helix-turnhelix DNA binding motif that is repressed by glucose. Before our studies commenced, the fermentation media used to grow C. difficile and to produce toxins contained complex animal/dairy additives such as tryptone peptone, chopped meat, Table 4. Comparison of working cell bank (WCB) prepared in Soy-Peptone A3 medium vs. WCB prepared in TYM and effect of iron sources and pH in second stage seed medium Fermentation WCB prep medium Seed medium Seed growth, OD Medium Growth, OD Toxin, ng/mL Test1 TYM SPA3 TYM SPA3 1.10 1.03 Test2 NZ-SoyBL4 NZ-SoyBL4 0.86 0.76 5,568 12,288 TYM SPA3 (pH 7.5) SPA3 (pH 7.5) SPA3 (pH 7.5) SPA3 (pH 7.5) SPA3 (pH 7.5) TYM SPA3 (pH 7.5) SPA3 (pH 7.5) ⫹ Fe powder SPA3 (pH 7.5) ⫹ FeSO4 SPA3 (pH 7.5) ⫹ Fe gluc SPA3 (pH 8.5) 1.13 1.10 *** 1.05 1.02 1.10 NZ-SoyBL4 NZ-SoyBL4 NZ-SoyBL4 NZ-SoyBL4 NZ-SoyBL4 NZ-SoyBL4 0.77 0.73 0.71 0.75 0.75 0.73 6,944 10,752 14,208 12,160 13,184 11,944 ***, insoluble, no OD readings made. All WCB preparation media and seed media contained 12 g/L yeast extract, 10 g/L mannitol, 1 g/L glycerol and 12 g/L of a peptone. Peptones: TYM contained tryptone; SPA3 contained Soy Peptone A3. Fermentation medium: NZ-Soy BL4 medium contained 20 g/L of yeast extract, 1 g/L sodium thioglycolate and 30 g/L NZ-Soy BL4. Modifications to SPA3 such as adding iron sources or increasing pH were done to 2nd stage seed only. Fe powder ⫽ reduced iron powder at 0.5 g/L; FeSO4 ⫽ FeSO4䡠7H2O at 0.04 g/L; Fe gluc ⫽ ferrous gluconate at 0.2 g/L. Fang et al. PNAS 兩 August 11, 2009 兩 vol. 106 兩 no. 32 兩 13227 APPLIED BIOLOGICAL SCIENCES *Glucose at 10 g/L. †Mannitol at 10 g/L. ‡Glycerol at 1 g/L. Table 5. Scale-up of vegetable peptone process into 1-L bottles and 1-L WAVE Bioreactor Fermentation Tubes Seed Medium OD* Toxin, ng/mL SPA3 0.76 12,288 SPA3 ⫹ Fe powder** 0.71 14,208 Bottles OD WAVE Bioreactor Toxin, ng/mL OD Toxin, ng/mL 1.03 Test 2 8,896 1.03 11,392 0.70 12,544 0.70 14,464 Test 1 Fermentation medium: NZ-Soy BL4 *, Growth; **, Fe powder ⫽ reduced iron powder at 0.5 g/L added to 2nd stage seed. cooked meat, brain heart infusion, horse blood, trypticase, etc. Such preparations might yield toxoid containing undesirable contaminants such as the prion causing bovine spongiform encephalopathy (BSE; Mad Cow Disease) or antigenic peptides that stimulate anaphylactic reactions and other undesirable immune reactions in immunized hosts (23). When non-animal/ non-dairy peptones were used by others, such as phytone or yeast extract, the toxin titers were markedly lower, that is, 12.5 or 25% respectively of the titer with animal/dairy products. In our work, we were able to completely replace tryptone in both the first stage and the second stage seed medium and in the fermentation medium with vegetable peptones. Our initial experiments were done using a working cell bank prepared with tryptone, and we realized that even this small amount of tryptone might result in carryover of this undesirable additive into the fermentation medium and possibly the final toxoid. We were then able to substitute Soy Peptone A3 to prepare working cell banks. As a result, we now have a process for production of C. difficile toxin that is completely free of animal and dairy products, from the WCB at the beginning of the process all of the way to the end. Our vegetable-based process avoids medical problems and yields Toxin A titers even higher than that with tryptone. The medium was shown to be scaleable from test tubes into 1-L bottles and the 1-L WAVE Bioreactor, and thus should be excellent for the beginning of studies involving scale up into larger production fermentors. The process we recommend uses Soy Peptone A3 at pH 7.5 for preparing WCBs and in first stage seed, Soy Peptone A3 at pH 8.5 and supplemented with 0.5 g/l reduced iron powder for second stage seed, and NZS BL4 medium at pH 6.8 as fermentation medium. The reason we tested the effect of iron sources was their importance for anaerobic organisms (24) and especially in production of tetanus toxin (17). When tetanus toxin is made by fermentation with C. tetani, the traditional source of iron has been insoluble reduced iron powder, that is, elemental iron of molecular weight 55.85, that removes oxygen from the system by forming FeO2 (rust). In our previous work, other inorganic iron sources failed to replace reduced iron powder for growth or tetanus toxin formation. The one that came closest was ferrous ammonium sulfate. The organic iron sources ferric citrate and ferrous gluconate were more active than the inorganic compounds but could not completely replace reduced iron powder. Combinations of activated charcoal with soluble iron sources such as ferrous sulfate, ferric citrate, and ferrous gluconate showed increased activity and the last-named combination almost replaced reduced iron powder. It thus appeared that the traditional iron source, reduced iron powder, plays a double role in supporting tetanus toxin formation, that is, releasing soluble sources of iron and providing an insoluble surface. The reason that effective toxin production would require an insoluble material is unknown to us at this time but it could be to provide a surface for growth, or for the adsorption of some unidentified inhibitory compounds in the medium or produced during 13228 兩 www.pnas.org兾cgi兾doi兾10.1073兾pnas.0906425106 growth. In the present work, we also noted a positive effect of reduced iron powder and ferrous gluconate on C. difficile toxin production when added to second stage seed medium. In conclusion, this work has resulted in a practical and effective way to product Toxin A from C. difficile without the use of animal- or dairy-derived media components for the production of a toxoid vaccine for this difficult nosocomial pathogen. Materials and Methods Microorganism. The organism used as master cell bank (MCB) was C. difficile strain VPI10463 (also known as ATCC 43255), cell bank lot #95L02 from Cryonix Inc. After receipt, we stored it before use at ⫺80 °C. All media used doublydistilled water. Anaerobic Growth. Operations were done in a Coy anaerobic chamber (CoyLab Prods Inc.) in an atmosphere of 80% N2 ⫹ 10% CO2 ⫹ 10% H2. The chamber incorporates a palladium catalyst that, in conjunction with the H2, maintains oxygen below 5 ppm. Growth Media. The TYM (tryptone-yeast extract-mannitol) medium, used to prepare working cell banks (WCBs) and seed medium for fermentation, contained per liter 24 g of Difco tryptone peptone, 12 g yeast extract, 10 g mannitol, and 1 g glycerol and was adjusted to pH 6.8 (25). Makeup per liter for other media was as follows: TY medium: 30 g Difco tryptone peptone, 20 g yeast extract, and 1 g sodium thioglycolate (26); TYG medium: 30 g Difco tryptone peptone, 20 g yeast extract, 10 g glucose, and 1 g thioglycolate (26); TNB medium: 200 g Difco Bacto tryptose, 1 g glucose, 2 g Na2HPO4, and 1 g KNO3 (14). All media were adjusted to pH 6.8 before autoclaving. Peptones. Sources of the protein hydrolysates used were as follows. Difco BD was the source of Tryptone (a pancreatic digest of casein). Organotechnie, Techniscience provided Plant Peptone E1 and Plant Peptone ET1 (non-animal enzymatic/non-dairy digests of potato protein), Wheat Peptone (non-animal/ enzymatic digest of wheat protein), SoyPeptone A1, Soy Peptone A2 and Soy Peptone A3 (non-animal/non-dairy enzymatic digests of non-GMO soy meal). Oxoid supplied Vegetable Peptone 1 (a non-animal/non-dairy enzymatic digest of non-GMO pea flour). Marcor was the source of non-animal/non-dairy soy digests Soy Peptone Type II, Soy Peptone Type AC, Soy Peptone Type AB, Soy Peptone Type SL, Soy Peptone Type F. DMV International provided SE 50M, SE 70BT, SE-70M (non-animal/non-dairy enzymatic digests of soy), WGE 80BT, WGE 80M (non-animal/non-dairy enzymatic digests of wheat gluten), and CNE-50M (non-animal/non-dairy enzymatic digest of cottonseed). Sheffield was the source of Hy-Soy, Hy-Soy T, NZ-Soy, NZ-Soy BL4, NZ-Soy BL7, and AMISoy (non-animal/non-dairy enzymatic hydrolysates of soy). Working Cell Bank (WCB). We prepared the WCB by placing 100 mL TYM in a 160-mL Corning Milk Dilution Bottle (narrow mouth with screw cap), autoclaving for 30 min and cooling in the anaerobic chamber. One milliliter of MCB was used to inoculate this first stage TYM bottle that was incubated for 24 h at 35 °C ⫾ 1 °C. The latter was used to inoculate a second stage TYM bottle that was incubated similarly. Finally, sterile glycerol was added to this second stage growth with gentle mixing to a final concentration of 30% by volume. This preparation was divided into 1.5-mL portions in sterile microcentrifuge tubes and these WCB vials were stored at ⫺80 °C until used. Seed. To prepare seed, 10 mL TYM was added to each step-1 seed tube (16 ⫻ 150 mm) and 40 mL to each 125-mL DeLong Bellco culture flask step-2 seed Fang et al. Toxin Production. Production media were dispensed at 8 mL per each 16 ⫻ 100 mm fermentation tube. Three tubes were used for each variable. Tubes were autoclaved, and each was inoculated with 80 L step-2 seed, and incubated in the anaerobic chamber at 35 ⫾ 1 °C for 5 days. A fourth tube was uninoculated and served to standardize the Turner Spectrophotometer for growth measurements at 660 nm every 24 h. Toxin Assay. Fermented broth was placed in a 15-mL centrifuge tube, and centrifuged at 3,000 ⫻ g for 30 min at 4 °C. The supernatant fluid was filtered through a membrane filter with a 0.45-m pore size. Toxin A production was measured on the filtrate by the capture ELISA method (Sandwich ELISA) (27). 1. Songer JG (2004) The emergence of Clostridium difficile as a pathogen of food animals. Anim Health Res Rev 5:321–326. 2. Johnson S, et al. (1990) Nosocomial Clostridium difficile colonisation and disease. Lancet 336:97–100. 3. McFarland LV, Mulligan ME, Kwok RY, Stamm WE (1989) Nosocomial acquisition of Clostridium difficile infection. N Engl J Med 320:204 –210. 4. Warny M, et al. (2005) Toxin production by an emerging strain of Clostridium difficile associated with outbreaks of severe disease in North America and Europe. Lancet 366:1079 –1084. 5. Voth DE, Ballard JD (2005) Clostridium difficile toxins: Mechanism of action and role in disease. Clin Rev Microbiol 18:247–263. 6. Rupnik M, et al. (2005) Revised nomenclature of Clostridium difficile toxins and associated genes. J Med Microbiol 54:113–117. 7. Karlsson S, Burman LG, Akerlund T (1999) Suppression of toxin production in Clostridium difficile VPI 10463 by amino acids. Microbiology 145:1683–1693. 8. Dupuy B, Sonenshein AL (1998) Regulated transcription of Clostridium difficile toxin genes. Mol Microbiol 27:107–120. 9. Holbrook, WP, Duerden BL, Deacon AG (1977) The classification of Bacteroides melaninogenicus and related species. J Appl Bacteriol 42:259 –273. 10. Rolfe RD, Finegold SM (1979) Purification and characterization of Clostridium difficile toxin. Infect Immun 25:191–201. 11. al Saif N, Brazier JS (1996) The distribution of Clostridium difficile in the environment of South Wales. J Med Microbiol 45:133–137. 12. Braun M, et al. (2000) Detection of the ADP-ribosyltransferase toxin gene (cdt A) and its activity in Clostridium difficile isolates from Equidae. FEMS Microbiol Lett 184:29 –33. 13. Onderdonk AB, Low BR, Bartlett JG (1979) Effect of environmental stress on Clostridium difficile toxin levels during continuous cultivation. Appl Environ Microbiol 38:637– 641. 14. Haslam SC, et al. (1986) Growth of Clostridium difficile and production of toxins A and B in complex and defined media. J Med Microbiol 21:293–297. 15. Osgood CP, Wood NP, Sperry JF (1993) Nutritional aspects of cytotoxin production by Clostridium difficile. Appl Environ Microbiol 59:3985–3988. Fang et al. Goat anti-Toxin A (TechLab, Cat # T1001) at 1 g/mL in carbonate-bicarbonate buffer (pH 9.8 ⫾ 0.1) was used at 100 L/well to coat the plate and the plate was kept at 4 °C overnight. The plate was blocked with 200 L/well of 2.5% Non-Fat Dry Milk buffer in 0.05 M phosphate-buffered saline (PBS) (blocking buffer) at 37 °C for at least 60 min, then washed. Culture supernatant fluids, standards, and controls were prepared using the blocking buffer, added at 100 L/well, and incubated at 37 °C for 1 h. The second antibody, mouse anti-Toxin A IgG (Acambis, MPA22), was incubated at 100 L/well at 37 °C for 1 h. The detection antibody was goat anti-mouse IgG coupled to alkaline phosphatase (Southern Biotech, Cat# 1030 – 04). Diethanoloamine (Sigma Cat# D-2286104) and disodium p-nitrophenyl phosphatase (PNPP), Sigma Cat# N-9389, was the substrate. The wash buffer was 0.05 M PBS plus 0.05% Tween 20. A Fusion Universal Microplate Analyzer (Packard) was used to read the plates with filters of 405 and 490 nm. Assays were performed at 3 and 5 days of growth, and the maximum figure is reported in this work. ACKNOWLEDGMENTS. We thank Acambis Inc. for providing a grant to carry out these studies. 16. Demain AL, Gerson D, Fang A (2005) Effective levels of tetanus toxin can be made in a production medium totally lacking both animal (e.g., brain heart infusion) and dairy proteins or digests (e.g., casein hydrolysates). Vaccine 23:5420 –5423. 17. Demain AL, Gerson DF, Kole M, Fang, A (2006) The role of reduced iron powder in the fermentative production of tetanus toxin. Appl Microbiol Biotechnol 73:55–59. 18. Fang A, Gerson DF, Demain AL (2006) Menstrum for culture preservation and medium for seed preparation in a tetanus toxin production process containing no animal or dairy products. Lett Appl Microbiol 43:360 –363. 19. Demain AL, George S, Kole M, Gerson DF, Fang A (2007) Tetanus toxin production in soy-based medium: Nutritional studies and scale-up into small fermentors. Lett Appl Microbiol 45:635– 638. 20. Mikola M, Sato J, Amanullah A (2007) Evaluation of a novel Wave bioreactor cellbag for aerobic yeast cultivation. Bioproc Biosyst Engr 30:231–241. 21. Hundsberger T, et al. (1997) Transcription analysis of the genes tcdA-E of the pathogenicity locus of Clostridium difficile. Eur J Biochem 244:735–742. 22. Mani N, Dupuy B (2001) Regulation of toxin synthesis in Clostridium difficile by an alternative RNA polymerase sigma factor. Proc Natl Acad Sci USA 98:5844 – 5849. 23. Wisher M (2002) Biosafety and product release testing relevant to replication- competent oncolytic viruses. Cancer Gene Ther 9:1056 –1061. 24. Scott JP, Brandly CA (1932) The use of reduced iron for the cultivation of anaerobic organisms. J Bacteriol 26:1–7. 25. Thomas WD, Giannasca PJ, Zhang Z, Lei W, Monath TP (2005) Active immunization against Clostridium difficile disease. US Patent 6969520. 26. Garnier T, Cole ST (1986) Characterization of a bacteriocinogenic plasmid from Clostridium perfringens and molecular genetic analysis of the bacteriocin-encoding gene. J Bacteriol 168:1189 –1196. 27. Redound SC, et al. (1985) Detection of Clostridium difficile enterotoxin (toxin A) by ELISA and other techniques, In Isolation and Identification of Microorganisms of Medical and Veterinary Importance, eds Collins CH and Grange JM (Society of Applied Bacteriology Technical Series No. 21, Academic, London), pp 237–250. PNAS 兩 August 11, 2009 兩 vol. 106 兩 no. 32 兩 13229 APPLIED BIOLOGICAL SCIENCES bottle. These were autoclaved at 121 °C for 30 min. The Step-1 seed tube was inoculated with 1 mL WCB culture and incubated at 35 ⫾ 1 °C for 24 h in the anaerobic chamber. The step-2 seed bottle was inoculated with 1 mL step-1 seed culture and incubated at 35 ⫾ 1 °C for 24 h. Growth was measured in a Turner Spectrophotometer (model 330) at optical density (OD) of 540 nm.