Department: Physics & Technology Academic Year: 2014-2015

advertisement

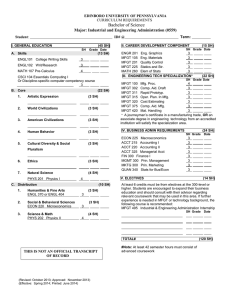

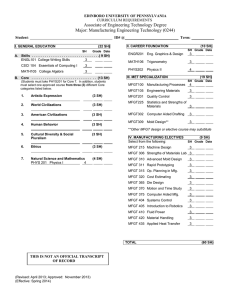

Department: Physics & Technology Summary of Assessments for: Objective Number 1. 2. 1. 2. 3. Associates of Applied Science (AAS) Assessment Method (ie Portfolios, Pre/Post Test, Focus Groups, Surveys, etc.) Math placement Where Assessed? (ie Course, Sequence of Courses, other) By appointment Criteria used to measure level of performance. (ie scoring scales, rubrics) Standard testing Pre/Post worksheets to assess aptitude MFGT 201 Track employment status MFGT 298 Competency in students understanding of quality control concepts Assessment embedded in final exam. Students needs to display competency 3. Objective Number Academic Year: 2014-2015 Sampling strategy, if appropriate When is data collected? Beginning and completion of program Beginning and completion of MFGT 201 Post-graduation and continuing Summary of Data Students’ scores will be compared to measure improvement rate. Strengths/Concerns evident in the data N/A Developing test N/A Used employment statistics to measure student’s competency to enter an applied science environment. This was easy to administer, student contact has to be maintained to be effective. Based on the above data, what changes do you propose? Continually develop instruments for measuring objectives. (The AAS is a newer program with only about 12 part and full time students enrolled this academic year.) Program: Associate of Engineering Technology (Manufacturing Objective Number 1. 2. Assessment Method (ie Portfolios, Pre/Post Test, Focus Groups, Surveys, etc.) Where Assessed? (ie Course, Sequence of Courses, other) Criteria used to measure level of performance. (ie scoring scales, rubrics) Assessed student assignments metal working skills against the national standards NIMS certificate Pre/Post worksheets to assess aptitude MFGT 100 NIMS Standards Throughout semester on a two year rotation when the class is offered ENGR 201 Competency in technical drawing layout and reading Beginning and end of semester Part of Final Exam MFGT 105 Assessment embedded in final exam. Students needs to display competency End of semester 3. Objective Number Engineering Technology) Sampling strategy, if appropriate When is data collected? Summary of Data No data to report, class is taught on a two year rotation Strengths/Concerns evident in the data No data to report, class is taught on a two year rotation 2. Used final exam to measure student engineering design competency Exit survey: (23 responses) With an average score of 87 and a standard deviation of 3.4 Concern: as engineering software evolves, it may be difficult to benchmark program success over time 3. Used final exam to measure student competency Exit survey: (21 responses) With a average score of 85 and a standard deviation of 4.1 This was easy to administer with the independent instrument may be better utilized to better capture the student knowledge base at the beginning of the semester and their comprehension level at the end of the course. 1. Students seem to be knowledgeable in the field of engineering materials. Based on the above data, what changes do you propose? Continue to improve the specific instrument in MFGT 105 for measuring the students understanding of the strength and properties of various materials used in manufacturing. Based on the above data, what changes do you propose? Continually develop a set of more specific instruments as Engineering Materials evolve and add nanotechnology to curriculum. Program: Industrial Engineering Administration (IdEA) Objective Number 1. Assessment Method (ie Portfolios, Pre/Post Test, Focus Groups, Surveys, etc.) Assessed student assignments metal working skills against the national standards NIMS certificate Where Assessed? (ie Course, Sequence of Courses, other) MFGT 100 2. University math placement exam Separate testing environment (both) 3. Part of Final Exam MFGT 105 4. Pre/Post worksheets to assess aptitude ENGR 201 Objective Number Criteria used to measure level of performance. (ie scoring scales, rubrics) NIMS Standards Sampling strategy, if appropriate When is data collected? Throughout semester on a two year rotation when the class is offered Math placement test Beginning and end of enrollment Assessment embedded in final exam. Students needs to display competency Competency in technical drawing layout and reading End of semester Beginning and end of semester Summary of Data No data to report, class is taught on a two year rotation Strengths/Concerns evident in the data No data to report, class is taught on a two year rotation Waiting for test results (12 responses) N/A Used final exam to measure student competency Exit survey: (21 responses) With a average score of 85 and a standard deviation of 4.1 This was easy to administer, But an independent instrument may be better utilized to better capture the student knowledge base at the beginning of the semester and their comprehension level at the end of the course. 1. 2. 3. 4. Used final exam to measure student engineering design competency Exit survey: (23 responses) With an average score of 87 and a standard deviation of 3.4 Students seem to be knowledgeable in the field of engineering materials. Concern: as engineering software evolves, it may be difficult to benchmark program success over time Based on the above data, what changes do you propose? Continue to improve the specific instrument in MFGT 105 for measuring the students understanding of the strength and properties of various materials used in manufacturing. Based on the above data, what changes do you propose? Continually develop a set of more specific instruments as Engineering Materials evolve and add nanotechnology to curriculum. Summary of Assessments for: Industrial Engineering Administration (BSIEA) Objective Number Assessment Method (ie Portfolios, Pre/Post Test, Focus Groups, Surveys, etc.) Where Assessed? (ie Course, Sequence of Courses, other) Criteria used to measure level of performance. (ie scoring scales, rubrics) Sampling strategy, if appropriate When is data collected? Course entrance (freshmen) ENGR 201 Mechanical Drawing Skill Test* Traditional Freshmen Course exit project (freshmen) MFGT 100 NIMS Standards** Traditional Freshmen End of first week of classes every year starting Fall 2011 Every other year starting Fall 2011 3 Exit Field test (Sophomores) Separate testing environment (both) Internally generated test 4 Exit Field test (Seniors) Internally generated test 5 Exit math test (Seniors) Separate testing environment (both) Separate testing environment (both) Students completing MFGT301 Graduating students Graduating students 1 2 6 7 Math placement test Every year starting Spring 2012 Every year starting Spring 2012 Every year starting Spring 2012 Business Business * Fifty question online test to evaluate competency of knowledge base for mechanical drawing developed by The University of Central Missouri. ** The National Institute for Metalworking Skills (NIMS) is the only ANSI accredited developer of precision manufacturing skill standards and competency assessments. Based on the above data, what changes do you propose? 1. Continue to revamp the pedagogy in ENGR 201 and MFGT 302 to capture the new engineering design software.