St. Louis Community College Physical Facilities Prepared By: Risk Management Department

St. Louis Community College

Physical Facilities

Prepared By: Risk Management Department for the

Grounds, Housekeeping, HVAC, Maintenance & Shipping & Receiving Departments

1

Table of Contents

Guideline No.

2

Title

Personal Protective Equipment

Fluorescent Bulbs

5 Bloodborne Pathogen Exposure

Control Plan

6 Lockout/Tagout

7 Accident & Incident Reporting

9 Hazardous and Special Waste

Management

10 Hot

2

Physical Facilities

No. 1

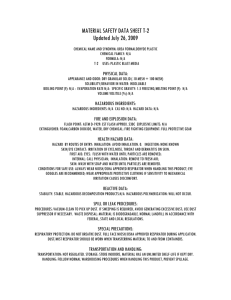

Subject: Hazard Communication Program

Overview: St. Louis Community College is committed to protecting worker health and safety while working around hazardous chemicals. As a result, the college has developed and implemented a Hazard Communication or

"Employee Right to Know" program. The purpose of the program is to inform employees about the chemical and physical hazards they face in the workplace.

The Hazard Communication Standard has five basic requirements for employers. They are as follows:

• Develop and maintain a written plan

• Maintain a list of hazardous chemicals used in the workplace

• Ensure containers of hazardous chemicals are labeled

• Maintain Material Safety Data Sheets for hazardous chemicals used in the workplace

• Provide employee training

These items are described in the following guideline:

Safety

Guidelines:

A written Hazard Communication Program has been developed for the

Physical Facilities areas at each campus. The written program describes how each campus will comply with the requirements of the hazard communication standard. The requirements are summarized below:

Written Plan: The written plan is developed and maintained by the

District Safety Specialist. The written plan is kept in the Physical

Facilities office area and must be made available to all Physical Facilities employees.

3

Page 2

Hazardous Chemical List: A list of all hazardous chemicals used in the workplace must be maintained. The list should be kept as the Table of

Contents for the Material Safety Data Sheets. The written Hazard

Communication Program describes who is responsible at each campus for maintaining the list.

Container Labels: Chemical manufacturers are responsible for labeling containers of hazardous chemicals. However, employers are responsible to ensure that manufacturer labels remain legible and in good condition.

In addition, any time an employee transfers a chemical from its original container to a new container, an appropriate label must be placed on the container. The label must include the chemical name and the appropriate hazard warnings (NFPA diamond with appropriate numbers). Appendix A of the Hazard Communication Program includes a description of container labels.

Material Safety Data Sheet: Employers are responsible for maintaining

Material Safety Data Sheets for each hazardous chemical used on site.

The written Hazard Communication program details who is responsible for obtaining and maintaining MSDSs for each campus.

Training: The District Safety Specialist is responsible for providing employee Hazard Communication Training for the Physical Facilities employees.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Date: March 15, 2000

4

Physical Facilities

No. 2

Subject: Personal Protective Equipment

Overview: In an effort to eliminate or minimize hazards to Physical Plant workers, St.

Louis Community College requires employees to wear suitable personal protective equipment for tasks where injury could occur. It should be noted that personal protective equipment should only be used after all engineering controls and other methods to eliminate or minimize the hazard have been implemented.

St. Louis Community College has established guidelines for the following types of personal protective equipment (where necessary):

• Eye and Face Protection

• Hand Protection

• Hearing Protection

• Foot Protection (where necessary)

• Electrical Protective Equipment

• Respiratory Protection**

Safety

Guidelines:

The following pages provide guidelines on selecting and using proper personal protective equipment while conducting work activities in the

Physical Plant area. The requirements are divided by department and by type of protective equipment.

**Respiratory protection guidelines are detailed in a separate "Safety Guideline."

See Safety Guideline No. 3 - Respiratory Protection for information on proper respirator selection and usage.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Revision Date: July 24, 2001

5

Required Personal Protective Equipment

Housekeeping

Eye Protection

• Chemical splash goggles must be worn when pouring or mixing chemicals. Safety glasses with side shields may be worn when spraying liquid chemicals in small quantities.

• Chemical splash goggles must be worn when there is the possibility that liquid chemicals could be splashed or sprayed into the eyes.

• Safety glasses with side shields must be worn when working overhead to prevent particles from falling into the eyes.

NOTE: Prescription glasses are not a substitute for safety glasses. Employees required to wear prescription glasses must wear goggles or safety glasses (as needed) over prescription glasses.

Hand Protection

• Chemical resistant gloves must be worn when working with cleaning chemicals.

(Refer to the Material Safety Data Sheet for each chemical for specific guidelines on protective gloves.)

Other Protective Equipment

Back Supports:

• Back supports should be worn when conducting frequent and/or heavy lifting activities.

6

Required Personal Protective Equipment

Grounds

Eye Protection

• Safety glasses with side shields must be worn when working with power equipment, including:

Mowers Blowers

Trimmers Chippers

Snow blowers

• Safety glasses with side shields AND a protective face shield must be worn when working with the following equipment:

Chain Saw

Grinder

• Chemical splash goggles must be worn when mixing, pouring, or spraying liquid chemicals including pesticides, herbicides, fuels, etc. Safety glasses with side shields may be worn when spraying liquid chemicals in small quantities.

• Safety glasses with side shields must be worn when working overhead to prevent particles from falling into the eyes.

NOTE: Prescription glasses are not a substitute for safety glasses. Employees required to wear prescription glasses must wear goggles or safety glasses (as needed) over prescription glasses.

Hand Protection

• Chemical resistant gloves must be worn when working with liquid chemicals including pesticides, fungicides, herbicides, fuels, etc. (Refer to the Material Safety

Data Sheet for each chemical for specific guidelines on protective gloves.)

• Leather or cotton gloves should be worn during activities where there is a possibility that hands could be subject to cuts, abrasions, and/or scrapes. IMPORTANT:

Always select gloves that will not pose an additional hazard such as getting caught in moving equipment or impairing the ability to operate the equipment controls.

7

Required Personal Protective Equipment

Grounds (continued)

Hearing Protection

• The following hearing protection must be worn when operating the following equipment:

Ear Plugs with NRR of 30 or higher or Ear Muffs with NRR of 25 or higher

Bob Cat Trimmers

Mowers Backhoe

Lawn Sweeper

Or when conducting activities where the noise level is 85 decibels or greater.

Ear Plugs with NRR of 30 or higher AND Ear Muffs

Chipper

Chain saw

Back pack blowers

NOTE: Stereo headphones are NOT a suitable substitute for hearing protection and are not to be worn when operating equipment.

Other Protective Equipment

Back Supports:

• Back supports should be worn when conducting frequent and/or heavy lifting activities.

8

Required Personal Protective Equipment

Maintenance

Eye Protection

• Safety glasses with side shields must be worn when working with power tools.

• Safety glasses with side shields AND a protective face shield must be worn when using the grinder.

• Chemical splash goggles must be worn when mixing, pouring or spraying liquid chemicals such as solvents, fuels, etc. Safety glasses with side shields may be worn when spraying liquid chemicals in small quantities.

• Safety glasses with side shields must be worn when working overhead, such as changing light bulbs, working on ceiling tiles, etc. to prevent particles from falling into the eyes.

• Safety glasses with side shields AND face shields with the appropriate protective filter lens must be worn when welding. See Attachment A for filter lens guidelines.

NOTE: Prescription glasses are not a substitute for safety glasses. Employees required to wear prescription glasses must wear goggles or safety glasses (as needed) over prescription glasses.

Hand Protection

• Chemical resistant gloves must be worn when working with liquid chemicals including fuels, solvents, paints, etc.

• Leather or cotton gloves should be worn during activities where there is a possibility that hands could be subject to cuts, abrasions, and/or scrapes. IMPORTANT :

Always select gloves that will not pose an additional hazard such as getting caught in moving equipment or impairing the ability to operate the equipment controls.

• Welding gloves must be worn when conducting welding operations.

9

Required Personal Protective Equipment

Maintenance (continued)

Hearing Protection

• Hearing protection (foam ear plugs with NRR of 30 or higher and/or ear muffs with a

NRR of 25 or higher) must be worn when operating power tools or other equipment or when conducting activities where the noise level is greater than 85 decibels.

NOTE: Stereo headphones are NOT a suitable substitute for hearing protection and are not to be worn when operating equipment.

Foot Protection

• Protective toe guards or steel-toed shoes must be worn when working in areas where heavy objects can be dropped or rolled on to the feet.

Other Protective Equipment

Welding Equipment:

• Fire resistant protective clothing, such as jackets or aprons, and gauntlet gloves must be worn when conducting welding operations.

• Welding helmets must be worn during all arc welding operations.

Note: Always ensure there is good ventilation in areas where welding is conducted.

Back Supports:

• Back supports should be worn when conducting frequent and/or heavy lifting activities.

10

Required Personal Protective Equipment

HVAC

Eye Protection

• Safety glasses with side shields must be worn when working with power tools or while performing operations where there is the potential for flying particles.

• Safety glasses with side shields AND a protective face shield must be worn when operating the grinder.

• Chemical splash goggles must be worn when mixing, pouring or spraying liquid chemicals such as acids, bases, bactericides, cleaners, etc. Safety glasses with side shields may be worn when spraying liquid chemicals in small quantities.

• Safety glasses with side shields must be worn when working overhead to prevent particles from falling into the eyes.

• Safety glasses with side shields AND face shields with the appropriate protective filter lens must be worn when welding. See Attachment A for filter lens guidelines.

NOTE: Prescription glasses are not a substitute for safety glasses. Employees required to wear prescription glasses must wear goggles or safety glasses (as needed) over prescription glasses.

Hand Protection

• Chemical resistant gloves must be worn when working with liquid chemicals including cleaners, acids/bases, fuels, solvents, etc.

• Leather or cotton gloves should be worn during activities where there is a possibility that hands could be subject to cuts, abrasions, and/or scrapes. IMPORTANT :

Always select gloves that will not pose an additional hazard such as getting caught in moving equipment or impairing the ability to operate the equipment controls.

• Welding gloves must be worn when conducting welding operations.

11

Required Personal Protective Equipment

HVAC (continued)

Hearing Protection

• Hearing protection (foam ear plugs with NRR of 30 or higher and/or ear muffs with a

NRR of 25 or higher) must be worn when:

Operating power tools and other equipment

Working around the chiller units

Or when conducting activities where the noise level is greater than 85 decibels.

NOTE: Stereo headphones are NOT a suitable substitute for hearing protection and are not to be worn when operating equipment.

Foot Protection

• Protective toe guards or steel-toed shoes must be worn when working in areas where heavy objects can be dropped or rolled on to the feet.

Other Protective Equipment

High Voltage Equipment:

• High voltage gear including arc helmet, coat, gloves, and sleeves must be worn when working with high voltage.

Welding Equipment:

• Fire resistant protective clothing, such as jackets or aprons, and gauntlet gloves must be worn when conducting welding operations.

• Welding helmets must be worn during all arc welding operations.

Note: Always ensure there is good ventilation in areas where welding is conducted.

Back Supports:

Back supports should be worn when conducting frequent and/or heavy lifting activities.

12

ATTACHMENT A

Filter Lenses for Protection Against Radiant Energy

Operation

Shielded Metal

Arc Welding

Gas Metal Arc

Welding and Flux

Cored Arc

Welding

Gas Tungsten

Arc Welding

Air Carbon

Arc Cutting

Plasma Arc

Welding

Electrode Size

(Inches)

Arc Current Minimum

Protective*

Less than 3/32 Less than 60 7

3/32-5/32 60-160 8

5/32-8/32 160-250 10

More than 8/32 250-550 11

Less than 60 7

Light

Less than 50

Less than 500

Less than 20

8

10

6

Plasma Arc

Cutting

Torch Brazing

Light**

Medium** 300-400 9

Heavy** 400-800 10

Less than 300 8

3

Torch Soldering 2

Carbon Arc Welding 14

Gas Welding

Light Under 1/8

Medium 1/8-1/2

Heavy Over ½

Oxygen Cutting

Under 3.2

3.2-12.7

Over 12.7

4

5

6

Light Under 1

Medium 1-6

Under 25

25-150

3

4

Heavy Over 6 Over 150 5

* As a rule of thumb, start with a shade that is too dark to see the weld zone (the darkest lens carries a value of 10). Then go to a lighter shade which gives sufficient view of the weld zone without going below the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow or sodium line in the visible light of the (spectrum) operation.

** These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the workpiece.

13

Physical Facilities

No. 3

Subject: Personal Protective Equipment - Respiratory Protection

Overview: St. Louis Community College is committed to providing a safe work environment for all employees. During certain working conditions, it may be necessary for employees to wear a respirator to prevent overexposure to airborne contaminants.

St. Louis Community College has developed a respiratory protection program to protect the health of employees exposed to respiratory hazards. Employees who voluntarily choose to wear respirators for operations where they are not specifically required must also follow the requirements of the college’s written respiratory program as detailed in this guideline.

The written respiratory program includes detailed information on the following:

• Activities requiring respirators;

• Respirator selection and use;

• Medical evaluations;

• Fit test procedures;

• Employee training; and

• Supervisor and employee responsibilities;

The requirements of the written program are summarized in the following safety guideline.

Safety

Guidelines:

A written respiratory protection program has been developed for the following departments at each campus: Grounds, Maintenance, HVAC,

Housekeeping and Shipping & Receiving. The written program describes procedures for required respirator usage as well as voluntary respirator usage. The requirements are summarized below:

14

Page 2

Required Use & Respirator Selection:

Respirators are required to be worn for the following:

Department Operations Type

Grounds

Department

Large scale application of pesticides, herbicides, insecticides, and fungicides

• 3M 6000 Series

• Half Face Air

Purifying with a boom sprayer or other large sprayers (does not include spot application

Respirator

• 3M 6001

Organic Vapor with small bottles)

•

Cartridge

5N11 N95 Prefilter

It should be noted that respirator usage for these operations is a precautionary measure and is not based on an overexposure condition.

Employees who are required to wear respirators must complete the following:

• Medical evaluation;

• Fit Test; and

• Training.

Voluntary Respirator Use:

Employees who voluntarily wear respirators for activities other than those noted above are also subject to portions of the respiratory protection program as follows:

Respirators with a Tight Fitting Facepiece (e.g., half face or full face air purifying respirators with cartridges)

• Medical evaluation; and

• Sign a copy of the information regarding voluntary respirator use (Attachment A).

Dust Masks

• Sign a copy of the information regarding voluntary respirator use (Attachment A).

15

Page 3

Medical Evaluations:

Employees who are required or voluntarily wear air purifying respirators

(not including dust masks) must complete a medical evaluation prior to wearing the respirator in the workplace. The medical evaluation must include completion of a medical questionnaire that is reviewed by a

Professional Licensed Health Care Provider.

The medical evaluation must be scheduled during normal work hours at one of the following locations:

Concentra

1212 South Grand 7927 N. Lindbergh Blvd.

St. Louis, MO 63104 Hazelwood, MO 63042

Meramec

Concentra

1709

636/349-6850

To schedule a medical evaluation:

1. Contact the appropriate Concentra facility and schedule a respirator physical.

2. Obtain a Treatment Authorization Form from the Safety Specialist.

3. The Concentra physician will provide the Safety Specialist with documentation of whether or not the employee is medically able to wear a respirator. Note: All medical information provided to the physician will be kept confidential and will not be provided to the college.

4. Once the employee is medically approved to wear a respirator, the

Safety Specialist will contact the employee to schedule respirator fit testing and training.

16

Page 4

Respirator Fit Testing:

Employees who are required to wear a respirator with a tight fitting facepiece (not including dust masks) are required to be fit tested as follows:

• Prior to being allowed to wear the respirator;

• Annually; and

• When there are changes in the employee’s physical condition that could affect respirator fit.

Respirator Training:

Employees who are required to wear respirators or who voluntarily choose to wear respirators must be trained prior to conducting any activities where respirators are required. Employees will be trained annually or as needed.

Responsibilities under the Respiratory Protection Program:

Supervisor, Buildings & Grounds at each campus is responsible for ensuring that the respiratory protection program is implemented in his/her areas. This includes the following:

• Ensure employees are properly trained, fit tested and medically evaluated as required by the plan;

• Ensure required respirators and accessories are available to employees who require them;

• Enforce proper use of respiratory protection;

• Monitor work areas and operations to identify respiratory hazards; and

• Ensure that any voluntary respirator usage is identified and employees complete the necessary medical evaluation, fit testing and training.

17

Page 5

Supervisor, Maintenance and HVAC at each campus is responsible for ensuring that the respiratory protection program is implemented in his/her areas. This includes the following:

• Monitor work areas and operations to identify respiratory hazards; and

• Ensure that any voluntary respirator usage is identified and employees complete the necessary medical evaluation, fit testing and training.

Employees are responsible for wearing the respirator in accordance with the training and instruction received from their supervisor and/or the

Safety Specialist. Employees must also:

• Care for and maintain their respirator;

• Inform their supervisor if there are any problems with the respirator; and

• Inform their supervisor if there are any additional respiratory hazards that they feel are not adequately addressed.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Date: January 7, 2002

18

ATTACHMENT A

Information for Employees Who Voluntarily Wear a Respirator

19

INFORMATION FOR EMPLOYEES USING RESPIRATORS WHEN NOT REQUIRED

UNDER THE STANDARD

(29 CFR 1910.134 - Appendix D)

To the Employer:

The statement below must be read to all employees using respirators when not required under

OSHA’s Respiratory Protection Standard.

To the Employee:

Your employer is required to ensure that you read the statement below if you are wearing a respirator when it is not required under OSHA’s Respiratory Protection Standard.

Information for Employees Using Respirators When Not Required Under 29 CFR 1910.134

Respirators are an effective method of protection against designated hazards when properly selected and worn. Respirator use is encouraged, even when exposures are below the exposure limit, to provide an additional level of comfort and protection for workers. However, if a respirator is used improperly or not kept clean, the respirator itself can become a hazard to the worker.

Sometimes, workers may wear respirators to avoid exposures to hazards, even if the amount of hazardous substance does not exceed the limits set by OSHA standards. If your employer provides respirators for your voluntary use, or if you provide your own respirator, you need to take certain precautions to be sure that the respirator itself does not present a hazard.

You should do the following:

1. Read and heed all instructions provided by the manufacturer on use, maintenance, cleaning and care, and warnings regarding the respirator’s limitations.

2. Choose respirators certified for use to protect against the contaminant of concern. NIOSH, the

National Institute for Occupational Safety and Health of the U.S. Department of Health and

Human Services, certifies respirators. A label or statement of certification should appear on the respirator or respirator packaging. It will tell you what the respirator is designed for and how much it will protect you.

3. Do not wear your respirator into atmospheres containing contaminants for which your respirator is not designed to protect against. For example, a respirator designed to filter dust particles will not protect you against gases, vapors, or very small solid particles of fumes or smoke.

4. Keep track of your respirator so that you do not mistakenly use someone else's respirator.

Employee Information

Employee Name:

I certify that I have read and understand the above statement regarding Use of Respirators when not required under the OSHA Respiratory Protection Standard.

_______________________________________________ ______________________

(Signature) (Date)

20

Physical Facilities

Subject: Management of Used Fluorescent Bulbs

Overview: Used light bulbs, including fluorescent, neon, high-pressure sodium, highintensity discharge, mercury vapor and metal halide lamps may contain toxic metals such as mercury, cadmium and lead.

According to the Missouri Department of Natural Resources, unbroken mercury-containing lamps pose a minimal threat to human health and the environment. However, when mercury-containing lamps are broken, mercury vapor and other toxic metals can be released.

As a result, spent mercury-containing lamps are considered a hazardous waste and must be carefully managed in accordance with Missouri

Department of Natural Resources regulations.

The following guideline provides details on how to properly manage these wastes to ensure the health and safety of students, staff and the environment.

Safety

Guidelines:

"Green" Bulbs

Used bulbs with green end caps do not

No. 4 contain regulated levels of mercury or other metals. Bulbs with green end caps (Phillips Alto Bulbs) may be placed in the solid waste trash dumpster.

Hazardous Bulbs

Used bulbs that do not have the green end caps are assumed to be a hazardous waste. These bulbs CANNOT be crushed or placed in the trash dumpster. These bulbs must be kept in tact and sent for recycling as follows:

21

Page 2

• Place used bulbs in original package or other secure container;

• Store the bulbs in an area and manner that will protect them from breakage or other damage;

• Clearly label the outside of the container or box with the words "Used

Mercury-Containing Lamps" and the date that accumulation of used bulbs began. The blank label on the attached page may be copied and affixed to the container.

• Contact the College-selected bulb recycler to pick up used bulbs for recycling.

• Obtain a receipt or other shipping paper documenting the shipment of bulbs. (Note: A Hazardous Waste Manifest is not required for bulbs sent off site for recycling.)

Broken Bulbs

Broken bulbs (other than the "green" bulbs) CANNOT be recycled and must be managed as a hazardous waste as follows:

• Place the broken bulb in a sealed plastic bag and place the bag in a secure container, such as a drum;

• Label the container with the following words:

Hazardous Waste

Waste Mercury Containing Lamps

Accumulation Start Date: _______________

• Contact the Risk Management Department at extension 5120 to arrange a hazardous waste disposal pick-up.

• Obtain a copy of the Hazardous Waste Manifest form from the waste management company. Please forward all manifest copies to the Risk

Management Department at the Cosand Center.

Notes:

1. Do not deliberately break or crush fluorescent lamps. Do not use small commercially available drum-type fluorescent lamp crushers for the hazardous lamps. Use of these devices is considered illegal treatment of a hazardous waste.

2. Solid waste landfills have a right to refuse specific wastes and may refuse to accept the "green" bulbs. Check with the solid waste hauler for their specific policies.

22

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Date: April 17, 2000

23

Universal Waste - Used Bulbs

Container Label

All containers of used hazardous bulbs must be properly labeled. The following blank label may be copied and affixed to the outside of the box or container in which the used bulbs are stored. (Note: This label is to be used only for bulbs that are intact and are being sent for recycling.)

Used Mercury-Containing Lamps

Accumulation Start Date: ____________________

24

Physical Facilities

No. 5

Subject: Bloodborne Pathogen Exposure Control Plan

Overview: The purpose of the Bloodborne Pathogen Exposure Control Plan is to protect workers from the risk of exposure to bloodborne pathogens such as the Human Immunodeficiency Virus (HIV) and the Hepatitis B Virus

(HBV).

The Bloodborne Pathogen Exposure Control Plan covers all employees who could be “reasonably anticipated” as the result of performing their job duties to contact blood and other potentially infectious materials. (It should be noted that “Good Samaritan” acts such as assisting a co-worker with a nosebleed would not be considered occupational exposure.)

•

•

•

The basic requirements of the Bloodborne Pathogen Exposure Control

Plan are as follows:

• Develop and maintain written Exposure Control Plan;

• Identify employees who could be exposed to potentially infectious materials;

• Establish personal protective equipment and work practice requirements for affected employees;

Provide affected employees with Hepatitis B Vaccination;

Provide employee training; and

Provide employees who have been exposed to potentially infectious materials with a follow-up medical evaluation.

The following guideline provides details on how to properly implement the elements of the Bloodborne Pathogen Exposure Control Plan to ensure the health and safety of students and staff.

25

Page 2

Safety

Guidelines:

A written Bloodborne Pathogen Exposure Control Plan has been developed for St. Louis Community College. The written program provides information on how to protect employees who are exposed to potentially infectious materials. The requirements and contents of the plan are summarized below:

Written Plan: The written plan is maintained by the District Risk

Manager. A copy of the written plan is kept in the following areas:

• Physical Facilities Office Area

• Campus Nurse's Office

Affected Employees: Employees covered by the Exposure Control Plan include the following:

• Allied Health Faculty

• Athletic Trainer

• Child Development Center Staff

• Housekeepers

• Nurse

• Police Officer

• Certain Maintenance Staff

Protective Equipment and Work Practice Requirements: The written

Bloodborne Pathogen Exposure Control Plan provides detailed information on appropriate protective equipment such as eye protection, gloves, etc. and work practices to prevent exposure to bloodborne pathogens.

Hepatitis B Vaccination: All employees in occupations that are reasonably anticipated to be exposed to potentially infectious materials are offered a Hepatitis B Vaccination. The Hepatitis B Vaccinations are administered by the Campus Nurse. Any affected employees who decline the vaccination must sign a waiver form.

26

Page 3

Training: The District Safety Specialist is responsible for coordinating employee Bloodborne Pathogen Training for St. Louis Community

College employees. The training is provided on an annual basis.

Post-Exposure Procedures: Any time an employee has had an exposure to a potentially infectious material, they must be provided with a confidential medical evaluation and follow-up. The post-exposure procedures are described in the written plan.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Date: June 9, 2000

27

Physical Facilities

No. 6

Subject: Lockout/Tagout

Overview: The Lockout/Tagout Program is designed to protect employees from hazards of servicing and maintenance of machines and equipment in which the unexpected energization or start up of the machines or equipment could cause injury to employees.

The Lockout/Tagout Program provides detailed guidelines for Physical

Plant employees in two categories:

• Authorized employees

• Affected employees.

Authorized Employees are employees who are authorized to take equipment out of service for maintenance or repair. They are authorized to apply lockout and/or tagout equipment in order to deenergize the equipment for service. This category primarily includes power plant and maintenance staff.

Affected Employees are employees who work with or around the equipment or machines that will be locked or tagged out for service. This category can include all other Physical Plant staff, including Grounds, Housekeeping and Warehouse employees.

The primary components of the Lockout/Tagout program include the following:

• Written Lockout/Tagout Program,

• Written Lockout/Tagout procedures,

• Lockout/Tagout equipment, and

• Employee training.

The following guideline provides details on how to properly implement the elements of the Lockout/Tagout Program to ensure the health and safety of students and staff.

28

Page 2

Safety

Guidelines:

Written Plan: The written plan is developed and maintained by the

District Risk Manager. A copy of the written plan is kept in the following areas:

• Physical Facilities Office Area

• Risk Management Office

The written plan provides detailed information on all components of the

Lockout/Tagout Program.

Written Lockout/Tagout Procedures: The written Lockout/Tagout

Procedures are provided in Appendix A of the written plan. The procedures provide step by step information on how to deenergize machines and equipment and how to properly lockout and tagout the equipment. All "Authorized" employees are required to understand and follow the written Lockout/Tagout Procedures any time equipment is locked or tagged out for service.

The following procedures are provided in Appendix A of the written plan:

Procedure

#

1

2

Type of Equipment/Machine

Electric Only Equipment

Electrical and Air Equipment

3 Boilers

4 Compressors

5 Expansion

6 Forklift

7 Building Transformers, High Voltage Switches, or High

Voltage Cable

29

Page 3

Lockout/Tagout Equipment: Lockout/Tagout equipment is available in all Physical Facilities areas. "Authorized" employees must have access to locks, tags, and other equipment. Types of equipment include valve covers, plug covers, single pole block out devices, wall switch lockout devices, circuit breaker lockout devices and multiple lock hasp devices.

Appendix B of the written plan provides directions on use for several types of lockout equipment.

Employee Training: The District Safety Specialist is responsible for coordinating lockout/tagout training for Physical Plant employees. The type of training provided will be dependent upon whether the employee is an "Authorized" or "Affected" employee.

"Authorized" employees will be trained in how to implement the

Lockout/Tagout procedures. The "Affected" employees will be provided with a general overview of Lockout/Tagout. They will be instructed to never attempt to remove a lock or tag or operate a piece of equipment that is locked or tagged out.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Date:

30

Physical Facilities

No. 7

Subject: Accident & Incident Reporting

Overview: St. Louis Community College is committed to providing a safe workplace for all employees. In order to minimize accidents and to prevent recurrence of similar accidents, St. Louis Community College has developed an accident and incident reporting system.

The purpose of the report is to monitor the accidents and incidents that occur in Physical Plant operations to establish safety policies, select safety equipment, and develop training as necessary to enhance work safety and prevent similar incidents throughout the district.

A sample of the Accident Report Form is provided in Attachment A.

A sample of the Employee Accident & incident Investigation Report is provided in Attachment B.

The following guideline provides details on the Accident & Incident

Reporting System.

Safety

Guidelines:

Accident & Incident Reporting Process:

If the Campus Nurse is on duty:

1. The injured employee must make a reasonable attempt to contact his/her supervisor, then report to Campus Health Services for assistance.

2. The Campus Nurse contacts the employee’s supervisor to notify them that the employee has been injured, documenting the date and time that the supervisor was contacted.

31

3. The supervisor is responsible for investigating and correcting any hazardous equipment or working conditions that may have caused or contributed to the accident/injury.

4. The Campus Nurse fills out the Accident/Injury Report form.

5. Within 24 hours of the accident/incident, the Campus Nurse faxes the first page ONLY of the completed Accident/Injury Report form to:

• The employee’s supervisor,

•

•

The Human Resources Department, and

The Risk Management Department.

6. The employee’s supervisor must complete the “Supervisor’s Comments” section of the form and fax it to the Risk Management Department at x5453.

7. Within 24 hours of the accident/incident, the employee’s supervisor must complete the Employee Accident & Incident Investigation Report and fax it to the Risk Management Department at x5453. Copies of the report are to be forwarded to:

• Risk Management Department

• Human Resources Department

• Supervisor File Copy

8. Following treatment, the Campus Nurse obtains the diagnosis/work statement from the physician and documents status on the Accident/Injury

Report form.

9. Note: Injured employees must provide a written release from the physician before returning to work. A copy of the release must be provided to the work supervisor AND the Campus Nurse.

If the Campus Nurse is NOT on duty:

1. The injured employee must make a reasonable attempt to contact his/her supervisor, then contacts Campus Police for assistance.

2. Campus Police contacts the employee’s supervisor to notify him/her that the employee has been injured, documenting the date and time that the supervisor was contacted.

32

3. The supervisor is responsible for investigating and correcting any hazardous equipment or working conditions that may have caused or contributed to the accident/injury.

4. Campus Police fills out the first page of the Accident/Injury Report form.

5. Within 24 hours of the accident/incident, Campus Police faxes the first page ONLY of the completed Accident/Injury Report form to:

• The Campus Nurse,

•

•

•

The employee’s supervisor,

The Human Resources Department, and

The Risk Management Department

6. The employee’s supervisor must complete the “Supervisor’s Comments” section of the form and fax it to the Risk Management Department at x5453.

7. Within 24 hours of the accident/incident, the employee’s supervisor must complete the Employee Accident & Incident Investigation Report and fax it to the Risk Management Department at x5453. Copies of the report are to be forwarded to:

• Risk Management Department

• Human Resources Department

• Supervisor File Copy

8. Following treatment, the Campus Nurse obtains the diagnosis/work statement from the physician and documents status on the Accident/Injury

Report form.

9. Note: Injured employees must provide a written release from the physician before returning to work. A copy of the release must be provided to the work supervisor AND the Campus Nurse.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

33

ATTACHMENT A

Accident Report

34

ATTACHMENT B

Employment and Incident Investigation Report

35

Physical Facilities

No. 8

Subject: Forklift Operations

Overview: Forklifts are often used at St. Louis Community College to assist with moving large items. St. Louis Community College wants to ensure that all activities involving forklifts are conducted in a safe manner.

In order to prevent accidents and injuries related to forklift operations, St.

Louis Community College has developed a Forklift Operations Safety

Program which covers activities in the Physical Facilities areas.

Safe operation of forklifts involves several elements, including the following:

• Employee Training; Driver Evaluation and Licensing;

• Forklift Inspections; and

• Forklift Operations.

Each of these elements is addressed in detail in the following guideline.

Safety

Guidelines:

Employee Training, Driver Evaluation and Licensing:

No employee will be allowed to operate a forklift unless they have successfully completed training. (Note: Training must have been completed after December 1999.)

Upon completion of classroom training, forklift drivers will be required to complete a written test as well as demonstrate their ability to operate the forklift by passing a hands on evaluation.

36

Page 2

Employees who successfully complete the training program will be provided with a certification documenting that they have completed the required training and are eligible to operate the forklift.

Refresher Training

Employees will be required to complete refresher training when:

• The operator has been observed operating the vehicle in an unsafe manner;

• The operator has been involved in an accident or near-miss incident;

• The operator has received an evaluation that reveals that the operator is not operating the truck safely;

• The operator is assigned to drive a different type of forklift; or

• A condition in the workplace changes in a manner that could affect safe operation of the truck.

Reevaluation

St. Louis Community College will evaluate each forklift operator's performance at least once every three years. However, if an operator has previously received training in a topic, additional training in that topic is not required if the operator has been evaluated and found competent to operate the truck safely.

Forklift Inspections:

All St. Louis Community College forklifts must be inspected before each use. An inspection checklist is attached to each forklift and must be reviewed by the operator prior to each use.

Forklift Operations:

Forklifts must be operated in a safe manner. All operators must abide by the following:

General Operating Practices

• Forklifts must be operated at a speed that will allow the forklift to be brought to a stop in a safe manner;

• Trucks must not be driven up to anyone standing in front of a bench or other fixed object;

• Unauthorized personnel are not permitted to ride on forklifts, unless the truck is specifically designed to accommodate a passenger.

37

Page 3

• When a forklift is left unattended or the operator is 25 feet or more away from the vehicle:

1. The forks must be fully lowered;

2. Controls must be placed in neutral;

3. Power must be shut off;

4. Brakes must be set;

5. Wheels must be blocked if the truck is parked on an incline.

• When the operator of a forklift is dismounted and within 25 feet of the forklift still in his/her view:

1. The forks must be fully lowered;

2. Controls must be placed in neutral; and

3. The brakes must be set.

Loading/Unloading of Trucks or Trailers

• When unloading a truck or trailer, the brakes of the vehicle must be set and wheel blocks must be in place to prevent movement of the vehicle.

• Fixed jacks must be used to support a semitrailer during loading or unloading when the trailer is not coupled to a tractor.

• The flooring of trucks and trailers must be checked for breaks and weakness before they are driven into.

Traveling

• Forklift operators must slow down and sound the horn at cross aisles and other locations where vision is obstructed.

• If the load being carried obstructs forward view, the driver must travel with the load trailing.

• Operators must look in the direction of, and keep a clear view of the path of travel.

• Operators must avoid running over loose objects on the floor or roadway surface.

• Grades must be ascended or descended slowly.

• When ascending or descending grades in excess of 10 percent, loaded trucks must be driven with the load upgrade.

• On all grades, the load and load engaging means must be tilted back if applicable, and raised only as far as necessary to clear the road or floor surface.

If you have questions regarding these guidelines, please contact the Risk Management

Department at extension 5120.

Date: September 7, 2000

38

Physical Facilities

No. 9

Subject: Hazardous Waste/Special Waste Disposal

Overview: St. Louis Community College is committed to ensuring that all hazardous chemicals are managed in a manner that protects human health and safety and the environment. Hazardous chemicals are used for many purposes in the Maintenance, HVAC, Grounds and Housekeeping Departments.

Some wastes generated by these departments can be considered hazardous wastes. As such, these wastes must be properly managed to comply with

State and Federal Law as well as Missouri Department of Natural

Resources and St. Louis Metropolitan Sewer District requirements.

The following guideline provides details on how to properly manage wastes.

Safety

Guidelines:

The methods of waste management include the following:

• Hazardous waste - e.g., solvents, oil based paints, pesticides, cleaners;

• Special Waste - e.g., used oil, oil filters, oil dry, lead acid batteries, shop rags, aerosol cans;

• Universal Waste - e.g., fluorescent bulbs;

• Nonhazardous waste - e.g., cleaners, pesticides; and

• General refuse - non liquid, non hazardous debris.

Hazardous Waste Disposal

The Resource Conservation and Recovery Act (RCRA) regulates hazardous wastes. Unneeded hazardous materials become regulated hazardous wastes once they are no longer usable or when a decision is made to discard them. This is an important item to note since RCRA defines strict time limits on storage of these materials once they have been declared a "Waste."

39

Page 2

Once the material becomes a waste, it must be determined whether or not that material meets the definition of a hazardous waste. In general, hazardous wastes are materials that are ignitable, toxic, corrosive or reactive. The information on the manufacturer's label or the Material

Safety Data Sheet can help in determining whether or not a material is a hazardous waste.

If you need assistance in making this determination or if it is uncertain if the material is a hazardous waste, contact the Risk Management

Department at extension 5120.

Note: There are very specific requirements for hazardous waste management and disposal. In addition, there can be significant penalties for noncompliance with the waste management regulations.

Therefore, if there is any doubt as to how to handle or dispose of a waste material, contact the Risk Management at extension 5120 for further assistance.

Hazardous Waste Management Procedures

Container Labels

Once a material has been determined to be a hazardous waste, the material must be placed in a compatible container that is securely closed and labeled. The label must include the following information:

HAZARDOUS WASTE

Federal Laws Prohibit Improper Disposal

If found, contact the nearest police or public safety authority or the U.S. Environmental Protection Agency

St. Louis Community College

Appropriate Address

Accumulation Start Date - the date that the waste was placed in the container.

Description of the waste

Preprinted hazardous waste container labels can be obtained by contacting the Risk Management Department.

40

Page 3

Storage Requirements

• Containers of hazardous waste must be securely closed, labeled and stored on a pallet. Storage areas must be inspected at least weekly while waste is stored on site. The inspection must be documented on the form provided in Attachment A.

• Hazardous wastes cannot be stored on site for more than 180 days.

• Each campus cannot have more than 2,200 pounds (approximately 275 gallons) of hazardous waste on site at any one time.

• Once hazardous waste has been generated and placed into storage, contact the Risk Management Department at extension 5120 to arrange for a waste pickup.

• The waste may only be picked up by a licensed hazardous waste transporter, using a hazardous waste manifest and sent to a permitted hazardous waste facility.

Special Waste Management Procedures

Used Oil

Used oil includes engine oil, as well as oils used for lubrication/cutting oil, heat transfer, hydraulic power or insulation in dielectric transformers.

• Used oil must be placed in a compatible container or tank that is securely closed and labeled.

• The container or tank must be labeled with the words "Used Oil."

• The used oil must be sent off site for recycling or recovery using a licensed transporter.

Oil Filters

• Every effort should be made to remove excess oil from oil filters - this can be done by crushing or puncturing the oil filters and allowing them to drain.

• Oil filters should be placed in a container that is closed and labeled

"Oil Filters" or something similar.

• Oil filters should be sent off site for recycling or proper disposal.

Oil Dry

Important: If oil dry or other absorbent material is used to clean up spills of hazardous waste (for example, gasoline or solvent), then the oil dry must be managed as a hazardous waste.

41

Page 4

• Oil dry that is used to clean up spills of oil may be placed in the trash dumpster ONLY IF:

-The oil dry does not contain any unabsorbed liquid.

-The oil dry does not contain any hazardous waste.

Lead Acid Batteries

• Lead acid batteries must be sent to a battery reclaimer/recycler or to a permitted hazardous waste management facility.

• When stored on site, batteries must be stored on a pallet.

• Batteries must be stored indoors when possible or in a manner that prevents any leakage from impacting the surrounding soil or water.

Shop Rags

Shop rags that are used with a hazardous waste such as a solvent, paint thinner or gasoline, must be managed according to the following:

• Rags sent off site for laundering are not considered a waste and should be managed in accordance with the laundry company guidelines.

• If rags are discarded, a hazardous waste determination must be made - if that rag was used with certain solvents, paint thinner, or gasoline, it is considered a hazardous waste.

Aerosol Cans

Disposal of aerosol cans containing hazardous materials (for example, if the nozzle breaks or the product is no longer useful) must comply with the following:

• Small quantities of aerosol cans (2 or 3 on an infrequent basis) can be placed in the trash.

• If there are large quantities of cans to be discarded, recycling is the preferred management method. Contact the Risk Management

Department to have the materials picked up.

Universal Waste - Fluorescent Bulbs

(not including Phillips Alto green tip bulbs)

Fluorescent bulbs contain small amounts of mercury and are considered a hazardous waste. However, if the bulbs are sent off site for recycling, they can be managed under less stringent Universal Waste requirements instead of the hazardous waste requirements.

42

Page 5

The Universal Waste requirements are as follows:

• Bulbs must be stored in a manner to prevent breakage - it is recommended that they be stored in the original box.

• The box must be labeled as follows:

UNIVERSAL WASTE

USED MERCURY CONTAINING LAMPS

St. Louis Community College

Appropriate Address

Accumulation Start Date - the date that the waste was placed in the container.

(Contact the Risk Management Department for Universal Waste labels.)

• Bulbs must be sent off site for recycling within one year of the accumulation start date.

• Retain receipt of shipment of bulbs to a recycling facility.

Important: If bulbs are broken or are to be disposed of - they must be managed as a hazardous waste.

Non Hazardous Waste Management Procedures

Some liquid wastes do not meet the definition of a hazardous waste, yet they cannot be disposed of down the drain because they exceed metropolitan Sewer District limits.

Examples of non hazardous wastes can include non hazardous solvents contaminated with oil and grease, some pesticides and fungicides, certain cleaning chemicals.

• Place the material in a securely closed container;

• Label the container with a description of the contents;

• Contact the Risk Management Department to arrange to have the material picked up by an appropriate waste management company.

43

Page 6

General Refuse

Solid materials that do not meet the definition of a hazardous waste and have not been contaminated with a hazardous waste may be disposed of in the general refuse.

If you have questions regarding these guidelines, please contact the Risk

Management Department at extension 5120.

Date: November 9, 2000

44

ATTACHMENT A

Hazardous Waste Inspection Checklist

45

WEEKLY

HAZARDOUS WASTE CONTAINER

INSPECTION CHECKLIST

All hazardous waste containers are stored in their proper location

All hazardous waste containers are labeled as follows:

HAZARDOUS WASTE

Federal Laws Prohibit Improper Disposal

If found, contact the nearest police or public safety authority or the U.S. Environmental Protection

Agency

St. Louis Community College

Appropriate Address

Accumulation Start Date - the date that the waste was placed in the container.

Description of the waste

Hazardous waste containers are in good condition (no leaks, rust, dents, etc.)

Hazardous waste containers are closed with the lid, lock ring and/or bung is secure.

Hazardous waste containers are stored on a pallet or otherwise elevated so that leaks can be detected.

Comments:

________________________________ ______________________________

Inspector's Name (Please Print) Inspector's Signature

46

Physical Facilities

No. 10

Subject: Hot Work

Overview: St. Louis Community College is committed to protecting students, staff and property from fire hazards. Hot work activities at the college could pose a fire hazard if not conducted in a safe manner. Hot work activities include welding, cutting, grinding, soldering, and other activities that produce heat or sparks. Hot work is conducted by the Maintenance,

HVAC and Grounds departments as well as by outside contractors.

The following guideline provides details on how to properly implement the hot work permit system to ensure the health and safety of staff, students, and property.

Safety

Guidelines:

A Hot Work Permit System must be used to monitor all hot work operations. Exception: Hot work operations conducted in a designated hot work area do not require a Hot Work Permit.

The following describes the Hot Work Permit System to be used at St.

Louis Community College.

Step 1: Is there another method (other than hot work) that could be used to complete the project?

Step 2: Obtain a Hot work Permit from the Fire Safety/Hot Work Supervisor

(see Attachment A)

47

Page 2

Supervisor:

• Review the checklist on the Hot Work Permit, and mark off boxes to indicate precautions are in place;

- Ensure sprinklers, fire extinguishers, etc. are available and in working order;

- Remove any flammable or combustible liquids, oily rags, etc. from the area;

- Remove or protect combustible contents, construction materials, etc. in the area; and

- Ensure that wall and floor openings are protected.

• Indicate on the Hot Work Permit if work is being conducted by an employee or a contractor;

• Complete the date, location, nature of job and name of person doing hot work;

• Sign the hot work permit;

• Note the date and time that the Hot Work Permit expires. (This is the estimated time to complete the project, but must be no longer than one shift);

• Indicate the name and phone number for an emergency contact on the back of the permit;

• Issue part 2 to the person doing the Hot Work;

• Keep part 1; and

• Assign a Fire Watch .

Step 3: Conduct Hot Work

Worker:

• Ensure that a fire watch is present;

• Post Hot Work Permit in the work area;

• Conduct the Hot Work.

Fire Watch:

• Ensure that fire extinguishing equipment is readily available and you are trained in its use;

• Familiarize yourself with the means/procedure of promptly reporting a fire and sounding an alarm in the event of a fire.

• Watch for fires in all exposed areas, and try to extinguish them only when obviously within the capacity of the equipment available, or otherwise sound the alarm.

48

Step 4: Hot Work Completion

Worker:

• Notify the supervisor that the hot work project is completed.

Page 3

Fire Watcher:

• Remain in the area for 60 minutes after completion of the hot work;

• After 60 minutes, sign the Hot Work Permit; and

• Notify the supervisor that you are leaving the area.

Supervisor:

• Assign someone to monitor the hot work area periodically for the next four hours;

• After four hours, sign the Hot Work Permit – Final Checkup section; and

• Remove Hot Work Permit and file.

Contractors: All contractors conducting hot work on St. Louis Community College property must agree to follow the steps outlined in this Hot Work Safety

Guideline. Contractors must review and sign below indicating they have reviewed the document and will work in accordance with the guideline.

Any time contractors are conducting hot work, the St. Louis Community

College employee responsible for contractor oversight must serve as the

Fire Safety/Hot Work Supervisor.

If you have questions regarding these guidelines, please contact the Risk

Management Department at extension 5120.

Date: May 15, 2001

CONTRACTOR SIGNATURE

I have read the St. Louis Community College Safety Guideline No. 10 –

Hot Work, and agree that all hot work will be conducted in accordance with the guideline.

__________________________________________

(Name – Please Print)

__________________________________________ _______________

(Signature) (Date)

49

ATTACHMENT A

SAMPLE HOT WORK PERMIT

50