Effect of salmon plasma protein on Pacific whiting surimi gelation

advertisement

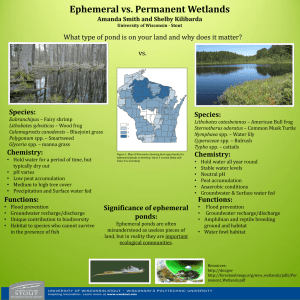

Effect of salmon plasma protein on Pacific whiting surimi gelation under various ohmic heating conditions Fowler, M. R., & Park, J. W. (2015). Effect of salmon plasma protein on Pacific whiting surimi gelation under various ohmic heating conditions. LWT-Food Science and Technology, 61(2), 309-315. doi:10.1016/j.lwt.2014.12.049 10.1016/j.lwt.2014.12.049 Elsevier Accepted Manuscript http://cdss.library.oregonstate.edu/sa-termsofuse 1 1 Effect of Salmon Plasma Protein on Pacific Whiting Surimi Gelation under Various 2 Ohmic Heating Conditions 3 4 Matthew R Fowler, Jae W Park 5 6 7 Oregon State University Seafood Research and Education Center 8 2001 Marine Dr Rm 253, Astoria, OR 97103, USA 9 10 Corresponding Author: 11 Jae W Park 12 (503) 325-4531 Ext #3 13 Jae.park@oregonstate.edu 14 15 16 17 To be submitted to LWT- Food Sci and Tech 2 18 ABSTRACT: 19 The effect of salmon blood plasma (SPP) on the gelation of Pacific whiting surimi under 20 different ohmic heating conditions was investigated. SPP was found to significantly increase gel 21 strength in gels heated ohmically to and held at 60° for 30 min followed by heating ohmically to 22 90°C. SPP at a level of 1 g/100g was also found to increase gel strength in gels held at 25°C for 2 23 h prior to ohmic heating. This increase was not seen in gels where EDTA was added to inhibit 24 the activity of endogenous transglutaminase (ETG). SPP also created a more pronounced setting 25 effect as measured by dynamic rheology and SDS-PAGE. SPP was found to effectively inhibit 26 protease activity through TCA-soluble peptide analysis. Scanning electron microcopy revealed a 27 loosely arranged gel network caused by protease enzymes. It was reversed by the addition of 28 SPP as well as setting at 25oC due to ETG. 29 30 31 Keywords: salmon plasma, surimi gelation, ohmic heating, transglutaminase, protease 3 32 Highlights: 33 • Various ohmic heating rates effectively isolated enzyme activity in surimi 34 • Salmon plasma protein effectively inhibited protease in Pacific whiting surimi 35 • Salmon plasma protein increased gel strength during setting 36 • Salmon plasma protein is an effective inhibitor at low levels (0.5 g/100g or less) 37 4 38 Introduction 39 In the United States, surimi is made from two types of fish: Alaska pollock (AP) and Pacific 40 whiting (PW). Unlike AP, PW contains a high amount of protease enzymes that degrade the 41 quality of the surimi gel when heated slowly (Klesk, Yongsawatdigul, Park, Viratchakul, & 42 Virulhakul, 2000). The major protease enzymes found in PW are cathepsins B, H, and L. After 43 PW has gone through the rinsing step of surimi manufacturing, most of cathepsin B and almost 44 all of cathepsin H proteases are removed. However, cathepsin L, a protease associated with 45 myofibrillar proteins, is not removed during the washing process and was found to be the main 46 protease responsible for degradation of the surimi gel (An, Weerasinghe, Seymour, & 47 Morrissey, 1994). Cathepsin L is a heat activated cysteine protease, having an optimum 48 temperature of around 55-60°C (Seymour, Morrissey, Peters, & An, 1994; Visessanguan, 49 Benjakul, & An, 2003). Incubating PW surimi around this temperature range for 30 min before 50 heating to 90oC will result in a complete disappearance of the myosin heavy chain as well as an 51 inability to form a gel network (Morrissey, Wu, Lin, & An, 1993; Rawdkuen, Benjakul, 52 Visessanguan, & Lanier, 2007a). Surimi that is heated at a slow rate (such as in a water bath) 53 also suffers protoeolytic degradation (Yongsawatdigul, Park, Kolbe, Dagga, & Morrissey, 1995). 54 In the past, bovine blood plasma (BPP) was added to PW surimi as a protease inhibitor. This 55 practice was discontinued however due to public fear of Bovine Spongiform Encephalopathy 56 (BSE). Since then, BPP has been replaced by dried egg white (DEW), which contains mainly 57 serine protease inhibitors (Yongswatdigul, Hemung, & Choi, 2014). Since DEW is not as effective 58 as BPP at inhibiting cysteine proteases, such as cathepsin L (Yongswatdigul et al., 2014), finding 59 an alternative inhibitor that can be used at small concentrations would be beneficial. Blood 5 60 plasma from other sources, such as pork (Benjakul, Srivilai, & Visessanguan, 2001; 61 Visessanguan, Benjakul, & An, 2000) and chicken (Rawdkuen et al., 2007a; Rawdkuen, Lanier, 62 Visessanguan, & Benjakul, 2004, 2007b), have been found to be effective inhibitors of protease 63 enzymes found in surimi. 64 In addition to protease inhibitors, blood plasma also contains other proteins that may enhance 65 the gelation of surimi. Blood plasma proteins such as fibrinogen exhibit their own gelling ability 66 upon heating (Davila, Pares, Cuvelier, & Relkin, 2007). Also, blood plasma has been shown to 67 contain endogenous transglutaminase (ETG) enzymes (Lorand, 2007). ETG is a naturally 68 occurring enzyme in PW and other species of fish. ETG is a calcium dependent enzyme that 69 mediates covalent cross linking of myofibrillar proteins, resulting in a higher gel strength (An, 70 Peters, & Seymour, 1996). Since endogenous PW and AP ETG has an optimum temperature of 71 around 25°C, leaving surimi paste at room temperature for 1 or 2 hr before heating results in 72 stronger gels. This ETG mediated formation of non-disulfide covalent cross links before heating 73 is known as “setting”. Addition of calcium and calcium containing compounds to surimi has 74 been shown to increase the effect of setting (Lee & Park, 1998) and the addition of calcium 75 chelating compounds, such as EDTA, has been shown to completely inhibit setting (Kumazawa, 76 Numazawa, Seguro, & Motoki, 1995). Since blood plasma contains ETG, it may also contribute 77 to the setting phenomenon when added to surimi in sufficient amounts. 78 The activity of these two different types of enzymes (proteases and ETG), pose a problem when 79 evaluating the quality of PW surimi gel. Traditionally, surimi is heated in a water bath to 90°C 80 before conducting gel texture measurement. This slow heating allows for the activity of both 81 ETG (enhances gel strength) and proteases (lowers gel strength). Surimi crabstick, however, is 6 82 manufactured in a thin sheet under gas and/or steam heating, which quickly deactivates both 83 types of enzymes and does not allow for any activity beyond 75oC. Therefore, these testing 84 methods do not accurately assess the quality of the surimi seafood being produced in a thin 85 sheet under fast heating. Rapid heating methods, such as ohmic heating, allow for a better 86 assessment of surimi containing protease enzymes (Yongsawatdigul et al., 1995). The objective 87 of this study was to isolate the activities of both proteases and ETG at various heating rates 88 under ohmic heating, and evaluate the effect of salmon plasma protein (SPP) on the gelation of 89 PW surimi in combination with these enzymes. 90 91 2. Materials and Methods 92 2.1. 93 Pacific whiting surimi (FA grade) without the addition of egg white, 2 months old, was obtained 94 from American Seafoods (Seattle, WA, USA) and kept at -30°C until used. Protein markers and 95 other electrophoresis chemicals were purchased from Bio-Rad Laboratories (Hercules, CA, 96 USA). All other chemicals used were of reagent grade. Materials 97 98 2.2. Collection of salmon blood and preparation of plasma 99 Whole blood was collected at the Klaskanine Fish Hatchery (Astoria, OR, USA) from female 100 Chinook salmon immediately before roe collection. Blood was collected from bleeding fish 101 into bottles containing 3.8g/100mL sodium citrate (as an anti-coagulant), and gently mixed at a 102 ratio of 9:1 (mL:mL) blood to sodium citrate (Li, Lin, & Kim, 2008; Rawdkuen et al., 2007b). 103 Blood was kept on ice and transported back to the Oregon State Seafood Laboratory (Astoria, 7 104 OR, USA) where it was centrifuged for 15 min at 1,500 × g at 4°C using a Beckman J6-MI 105 centrifuge (Beckman Coulter, Fullerton, CA, USA). The supernatant was then lyophilized in a 106 Labconco freeze drier (Kansas City, MO, USA) and regarded as salmon plasma protein (SPP). SPP 107 was stored at -80°C until used. Samples were not stored longer than 3 months. 108 109 2.3. Surimi gel preparation 110 Paste and gels were prepared according the method of Poowakanjana, Mayer, and Park (2012) 111 with various heating methods. Partially thawed surimi was chopped at 1,800 rpm for 1 min 112 using a silent cutter (UM 5 universal, Stephan Machinery Corp, Columbus, OH, USA). After a 113 2g/100g addition of salt, surimi was chopped for an additional 1 min at 1,800 rpm. Moisture 114 content was then adjusted to 78g/100g using ice. At this time SPP (0, 0.5 or 1 g/100g) as well as 115 EDTA (0 or 0.1 g/100g) was added. A preliminary study conducted in our laboratory indicated 116 that 0.1 g/100g EDTA was sufficient to completely inhibit ETG activity in PW surimi (data not 117 shown). Following the addition of ice and other dry ingredients, surimi was chopped again for 1 118 min at 1,800 rpm. Chopping was then continued at 3,600 rpm under vacuum (40-60 kPa) for an 119 additional 3 min and a total chopping time of 6 min. Care was taken so that the final 120 temperature of the surimi paste was less than 15°C. Paste was packed in a polyethylene bag 121 and subjected to vacuum to remove any air pockets developed during packing. The paste was 122 then stuffed into a 15 cm x 3 cm nylon tube. 3 different heating methods were used: 1. Ohmic 123 (rapid) heating to 90°C at a voltage gradient of 12.62 V/cm with settings of 250 V and 10 kHz to 124 prevent the activity of both ETG and proteases (OH); 2. Ohmic heating to 60°C followed by 125 ohmically holding at 60°C for 30 min before ohmically heating to 90°C to prevent the activity of 8 126 ETG and maximize the activity of proteases (60/OH); and 3. Holding in a 25°C water bath for 2 h 127 (to maximize the activity of ETG) followed by ohmic heating to 90°C to prevent the activity of 128 proteases (25/OH). Two sausages were made per heating method. Following heating, gels were 129 placed in a plastic bag, submerged in ice water for 15 min, and stored overnight at 4°C. 130 131 2.4. Oscillatory dynamic measurement 132 Surimi paste was subjected to a temperature sweep using a CVO rheometer (Malvern 133 Instruments Ltd., Worcestershire, UK) using a cone (4° and 40 mm diameter) and plate 134 geometry with a gap of 150 μm. Surimi gels prepared as described above were thinly cut to a 135 thickness of 2 mm and subjected to a frequency sweep using parallel plate geometry (20 mm 136 diameter) and a gap of 1 mm. Surimi gel (3 cm diameter) was trimmed to 2 cm using a small 137 knife and moisture trap containing a moistened sponge was used to minimize drying of sample. 138 Temperature sweeps were conducted from 10 °C-90 °C at a heating rate of 2 °C/min at a fixed 139 frequency of 0.1 Hz. Frequency sweeps were conducted from 0.1 to 10 Hz at a fixed 140 temperature of 25 °C. A shear stress of 50 Pa, determined by stress sweep to be in the linear 141 viscoelastic region, was used. 142 143 2.5. Fracture gel evaluation 144 The day after heating, gels were removed from refrigerated storage and held at room 145 temperature for 2 h prior to testing. Gel samples were cut into 30 mm lengths and the breaking 146 force (g) and penetration distance (mm) were determined using a texture analyzer (TA-XT plus, 9 147 Texture Technologies Corp, NY, USA). Gels were punctured with a spherical probe (5 mm 148 diameter) at 1 mm/sec. 149 150 2.6. Color analysis 151 L*, a*, and b* values of surimi gels were determined from 30 mm samples using a Minolta 152 colorimeter (CR-310; Minolta Camera Co. Ltd., Osaka, Japan). The instrument was standardized 153 using a Minolta calibration plate and a Hunter Lab standard hitching file according to the 154 method of Park (1994). Whiteness was calculated using the equation L*-3b*. 155 156 2.7. Determination of TCA soluble peptides 157 Eighteen mL of 5 g/100mL trichloroacetic acid (TCA) was added to 2 g of sample followed by 158 homogenization for 2 min at 15,000 rpm using a Tissue Tearor homogenizer (Biospec Products 159 Inc., Bartlesville, OK, USA). Homogenate was then held at 4 °C for 1 h before centrifugation at 160 8,000 × g for 5 min using a Sorvall RC-5B centrifuge (DuPont Instruments, Newton, CT, USA). 161 The TCA-soluble peptide content of the supernatant was measured by the method of Lowry et 162 al. (1951) using tyrosine as a standard and expressed as μmol tyrosine/ g sample. Samples were 163 measured in triplicate. 164 165 2.8. SDS PAGE 166 Surimi gels were examined for protein patterns based on their molecular weight according to 167 the method of Laemmli (1970). Gels were solubilized in 5g/100mL sodium dodecyl sulfate at 90 168 °C according to the method of Morrissey et al. (1993). A 4g/100mL acrylamide stacking gel and 10 169 10g/100mL acrylamide separating gel were used. Gels were fixed and stained in 0.125g/100mL 170 Coomassie R-250 (Bio-Rad, Richmond, CA, USA), and de-stained in a 50mL/100mL methanol, 171 10mL/100mL acetic acid solution. Molecular weights of bands were determined by comparison 172 to a molecular weight standard (Protein Plus All Blue, Bio-Rad Laboratories, Hercules, CA, USA). 173 174 2.9. Scanning electron microscopy 175 Gels were cut into 2 mm x 2 mm sections and rinsed two times in distilled water for 30 min 176 prior to fixing for 2 hr in a 0.1 mol/L cacodylate buffer containing 2.5g/100mL glutaraldehyde 177 and 1g/100mL paraformaldehyde. Samples were then dried through serial acetone dilutions 178 (10, 30, 50, 70, 90 and twice in 100%) followed by critical point drying. Samples were then 179 coated with gold and palladium (40:60 ratio) and examined in a Quanta 600 FEG field emission 180 scanning electron microscope (FEI Inc., Hillsboro, OR). This microscopy work was done at the 181 Oregon State University Electron Microscope Facility (Corvallis, OR, USA). 182 183 2.10. Statistical analysis 184 Data were subjected to analysis of variance (ANOVA). Comparison of means was carried out by 185 Tukey test (Ramsey & Schafer, 2012). Statistical analysis was done by Sigma Plot software 186 package (Sigma Plot 12.5, Systat Software Inc, San Jose, CA, USA). Two batches were made for 187 each treatment and all experiments were repeated. 188 189 190 11 191 3. Results and Discussion 192 3.1. 193 The maximum elastic modulus (G’) of surimi heated at 2°C/min decreased as more SPP was 194 added (Fig 1A-1C). Visessanguan et al. (2000) found that the addition of pork plasma protein to 195 Pacific whiting actomyosin also decreased G’. It was postulated that this was due to plasma 196 proteins having different thermal stabilities and gelation properties than fish muscle proteins. 197 The formation of two different gel networks (plasma protein and fish protein) with different 198 properties may lead to the observed decrease in G’. However, for pastes with 0.5g/100g SPP 199 (Fig 1B) and 1g/100g SPP (Fig 1C), the maximum G’ was higher for samples containing no EDTA 200 than samples containing EDTA. This difference was not observed in the control containing no 201 SPP. The difference between samples with and without EDTA is attributed to the setting effect 202 due to the action of ETG. This activity, however, may be offset by proteases active in the control 203 paste that are inhibited in the samples containing SPP. Therefore, the influence of setting 204 during heating at 2°C/min is more pronounced when SPP is added. In addition, ETG and calcium 205 present in SPP may serve to enhance the setting effect. Yin & Park (2014) found that adding 206 calcium containing nano scale fish bone to surimi also increased gel strength. 207 Rheological properties of the final gel were also evaluated by frequency sweep (Fig 1D). The G’ 208 of the control sample held at 60°C before ohmic heating showed a significantly higher 209 frequency dependence than the control sample ohmically heated directly to 90°C. Samples 210 containing both 0.5g/100g SPP and 1g/100g SPP and held at 60°C before ohmic heating showed 211 similar frequency dependence as the control heated to 90°C. G’ values of less cohesive gels 212 exhibit higher frequency dependency. Therefore, G’ increases at a higher rate as frequency Oscillatory rheology 12 213 increases than is observed in a more cohesive gel (Picout & Ross-Murphy, 2003). These results 214 indicate that adding SPP to surimi to inhibit proteases lead to a less frequency dependent, more 215 cohesive gel network in the finished product. 216 217 3.2. Fracture gel evaluation 218 Both breaking force (Fig 2A) and penetration distance (Fig 2B) of 60/OH gels were greatly 219 increased by the addition of 0.5g/100g and 1g/100g SPP with or without the addition of EDTA 220 (P<0.05). There was no difference for this heating method between 0.5g/100g and 1g/100g 221 SPP. This heating condition maximized the action of endogenous proteases while minimizing 222 the activity of ETG to less than 10% (Park, Ooizumi, & Hunt, 2014). This indicates SPP at a level 223 of 0.5g/100g is sufficient for inhibiting protease activity and no added benefit in this regard is 224 seen from increasing concentration. 225 Compared to OH gels, 25/OH gels without EDTA showed a greater breaking force and 226 penetration distance (P<0.05). This heating method was favored by ETG and the activity of 227 protease enzymes was not significantly noted. Therefore, this increase of gel strength is due to 228 the setting phenomenon. In addition 25/OH gels without EDTA and containing 1g/100g SPP 229 showed the highest breaking force and penetration distance of all samples (P<0.05). It may be 230 postulated that transglutaminase present in SPP contributed additionally to enzyme-mediated 231 covalent cross linking during settings. Both OH and 25/OH gels containing no SPP decreased 232 moderately and significantly, respectively, in breaking force and penetration distance when 233 EDTA was added (P<0.05). EDTA chelates calcium, which in addition to being a cofactor for ETG 234 may also play other roles in gelation (Lee & Park, 1998). However, both OH and 25/OH gels 13 235 containing EDTA showed a higher breaking force and penetration distance with the addition of 236 SPP as compared to the control (P<0.05), indicating a significant role of SPP as a gel enhancer. 237 In addition to transglutaminase being present in SPP, it may also be a source of additional 238 calcium (Heaton & Pomare, 1974; Maye, Keaton, Hurst, & Habener, 1979), leading to greater 239 gel strength. 240 241 3.3 242 Whiteness decreased markedly as SPP concentration increased (P<0.05) (Fig 3D). Increase in 243 SPP was also associated with a lower L* value (less lightness) (Fig 3A), more negative a* value 244 (more redness) (Fig 3B) and a higher b* value (more yellowness) (Fig 3C). The decrease in color 245 quality is due to hemolysis in the blood plasma. When blood is collected and plasma is 246 processed, damage to the red blood cells can result in plasma containing a pinkish hue as 247 opposed to a straw yellow color (Field, Elvehjem, & Juday, 1943; Li et al., 2008). In addition, as 248 salmon is a cold water species, blood plasma may exhibit lower thermal stability and therefore 249 be more susceptible to hemolysis than blood plasma from mammals. This issue may be partly 250 intervened by the fact that SPP is needed only at very low levels (maximum of 0.5g/100g as 251 shown by the results in Fig 2) in order to prevent proteolysis in PW surimi. It is suggested 252 however that further studies be conducted to determine collection and processing methods 253 that will reduce hemolysis. In addition, 60/OH gels showed greater L* values, less negative a* 254 values, and higher b* values than other gels (P<0.05). However, overall whiteness was not 255 affected by heating conditions. 256 Color gel analysis 14 257 258 3.4 TCA soluble peptide content 259 At a TCA concentration of 5g/100mL, all proteins except for small oligopeptides are insoluble 260 (Yvon, Chabanet, & Pelissier, 1989). Since small peptides are the result of the action of 261 endogenous proteases on PW muscle, the protein content in the 5g/100mL TCA supernatant 262 after centrifugation is related to total protease activity in the surimi. Control 60/OH gels with or 263 without EDTA had significantly higher TCA soluble peptide content compared to other gels 264 (P<0.05) (Fig 4). The addition of SPP to these gels showed a significant decrease in TCA soluble 265 peptide content (P<0.05). There was no difference between 0.5g/100g and 1g/100g SPP. 266 Besides 60/OH gels, no difference was seen in TCA soluble peptide content between other 267 treatments and 60/OH gels containing SPP. This confirms the fact that an SPP concentration of 268 0.5g/100g is sufficient to inhibit protease activity and no additional inhibition is seen from 269 increasing concentrations. In addition, this confirms that the fast heating treatments (OH and 270 25/OH) effectively eliminate protease activity. 271 272 3.5 SDS PAGE 273 For OH gels, there was no discernible difference in protein pattern between gels prepared 274 without EDTA (Fig 5A) and gels with EDTA (Fig 5B). Among this group, SPP also had no 275 noticeable effect on protein pattern. This is because the OH treatment eliminated the activity of 276 both protease enzymes and ETG, therefore there was no setting effect or degradation of the 277 myosin heavy chain. For the 25/OH samples, however, a protein band is visible in the high 278 molecular weight range (>250 kDa) for gels treated without EDTA that is not present for gels 15 279 treated with EDTA (dotted line in Fig 5A). Yin and Park (2014) found that ETG-mediated cross 280 linking in surimi led to the appearance of high molecular weight bands. This band is due to the 281 crosslinking of myosin heavy chain proteins, leading to higher molecular weight proteins 282 (Kamath, Lanier, Foegeding, & Hamann, 1992). The disappearance of this band in the EDTA 283 samples confirms the inhibition of ETG by EDTA. The high molecular weight band is also darker 284 for 1g/100g SPP than the control, indicating that SPP might have played a role in the setting 285 phenomenon as transglutaminase is one of various proteins present in blood plasma (Folk, 286 1980). 287 The 60/OH group showed no difference between samples with and without EDTA. In this 288 treatment, only protease enzymes are active and the action of ETG was eliminated. This heating 289 treatment completely destroyed the myosin heavy chain band in the control samples due to the 290 activity of proteases. When SPP was added at 0.5g/100g however, the myosin heavy chain band 291 remained intact. Increasing SPP concentration did not affect the intensity of the myosin heavy 292 chain band. This confirms that 0.5g/100g SPP is sufficient to inhibit proteases and prevent 293 myosin heavy chain degradation. 294 295 3.6 Scanning electron microscopy 296 The 60/OH gel with no SPP added showed the greatest number of voids and the least compact 297 structure among the samples tested (Fig 6B). This is consistent with the results from the 298 puncture test as well as the TCA-soluble peptides. This confirms that protease enzymes active 299 at this temperature serve to break up and weaken the gel structure. 60/OH gel with 1g/100g 300 SPP (Fig 6E) showed a significantly more orderly and continuous gel structure with less voids 16 301 than the 60/OH gel with no SPP present, indicating effective inhibition of protease enzymes. 302 However, there were a greater number of voids present in this gel than in the OH gels (Fig 6A 303 and 6D), indicating residual protease activity. 25/OH gels without and with 1g/100g SPP (Fig 6C 304 and 6F, respectively) had a more compact and continuous structure compared to OH gels 305 without and with 1g/100g SPP (Fig 6A and 6D, respectively). This is due to the addition of extra 306 covalent cross linking in the gel structure due to the action of ETG. In addition, 25/OH gel with 307 1g/100g SPP had a more compact structure with less voids than the 25/OH gel without SPP. 308 This may be due to transglutaminase present in SPP in addition to ETG of surimi, leading to 309 additional cross linking during setting. 25/OH sample containing no SPP and 0.1g/100g EDTA 310 (Fig 6G), had a greater number of voids than the OH samples. The purpose of EDTA addition 311 was to chelate calcium in order to prevent the activity of ETG. However, these results indicate 312 that calcium may play other roles in gelation in addition to being a cofactor for ETG. 313 314 4. Conclusion 315 SPP was found to effectively inhibit endogenous proteases in PW surimi at levels as low as 316 0.5g/100g. Higher concentrations of SPP may also aid in transglutaminase-mediated gel setting, 317 leading to an increase in gel strength. However, increasing SPP concentrations also led to a 318 decrease in the elastic modulus as well as a decrease in whiteness. This balance must be kept in 319 mind when formulating surimi with SPP. Holding at 25°C before ohmic heating was found to 320 optimize ETG activity while controlling protease activity. Rapidly heating to and holding at 60°C 321 before ohmic heating to 90°C was found to optimize protease activity while minimizing ETG 322 activity. 17 323 324 5. Acknowledgment 325 This research was supported by a scholarship (2013 NPRD Graduate Research Award) from the 326 North Pacific Research Board (Anchorage, AK). We are thankful for Teresa Sawyer of the 327 Oregon State University Electron Microscope Facility (Corvallis, OR) for her assistance with the 328 scanning electron microscopy. 329 330 REFERENCES 331 332 333 334 335 336 337 338 339 340 341 342 343 344 345 346 347 348 349 350 351 352 353 354 355 356 An, H., Peters, M. Y., & Seymour, T. A. (1996). Roles of endogenous enzymes in surimi gelation. Trends in Food Science & Technology, 7(10), 321-327. An, H., Weerasinghe, V., Seymour, T. A., & Morrissey, M. T. (1994). Cathepsin Degradation of Pacific Whiting Surimi Proteins. Journal of Food Science, 59(5), 1013-1017. Benjakul, S., Srivilai, C., & Visessanguan, W. (2001). Porcine plasma protein as proteinase inhibitor in bigeye snapper (Priacanthus tayenus) muscle and surimi. Journal of the Science of Food and Agriculture, 81(10), 1039-1046. Davila, E., Pares, D., Cuvelier, G. r., & Relkin, P. (2007). Heat-induced gelation of porcine blood plasma proteins as affected by pH. Meat Science, 76(2), 216-225. Field, J. B., Elvehjem, C. A., & Juday, C. (1943). A study of the blood constituents of carp and trout. Journal of Biological Chemistry, 148(2), 261-269. Folk, J. E. (1980). Transglutaminases. Annual Review of Biochemistry, 49(1), 517-531. Heaton, K. W., & Pomare, E. W. (1974). Effect of bran on blood lipids and calcium. The Lancet, 303(7846), 49-50. Kamath, G. G., Lanier, T. C., Foegeding, E. A., & Hamann, D. D. (1992). Nondisulfide covalent cross linking of myosin heavy chain in setting of Alaska Pollock and Atlantic Croaker surimi. Journal of Food Biochemistry, 16(3), 151-172. Klesk, K., Yongsawatdigul, J., Park, J. W., Viratchakul, S., & Virulhakul, P. (2000). Gel Forming Ability of Tropical Tilapia Surimi as Compared with Alaska Pollock and Pacific Whiting Surimi. Journal of Aquatic Food Product Technology, 9(3), 91-104. Kumazawa, Y., Numazawa, T., Seguro, K., & Motoki, M. (1995). Suppression of surimi gel setting by transglutaminase inhibitors. Journal of Food Science, 60(4), 715-717. Laemmli, U. K. (1970). Cleavage of Structural Proteins during the Assembly of the Head of Bacteriophage T4. Nature, 227(5259), 680-685. Lee, N., & Park, J. W. (1998). Calcium compounds to improve gel functionality of Pacific whiting and Alaska pollock surimi. Journal of Food Science, 63(6), 969-974. 18 357 358 359 360 361 362 363 364 365 366 367 368 369 370 371 372 373 374 375 376 377 378 379 380 381 382 383 384 385 386 387 388 389 390 391 392 393 394 395 396 397 398 399 Li, D. K., Lin, H., & Kim, S. M. (2008). Effect of rainbow trout (Oncorhynchus mykiss) plasma protein on the gelation of Alaska pollock (Theragra chalcogramma) Surimi. Journal of Food Science, 73(4), C227-C234. Lorand, L. (2007). Crosslinks in blood: transglutaminase and beyond. The FASEB Journal, 21(8), 1627-1632. Lowry, O. H., Rosebrough, N. J., Farr, A. L., & Randall, R. J. (1951). Protein measurement with the Folin phenol reagent. The Journal Of Biological Chemistry, 193(1), 265-275. Maye, G. P., Keaton, J. A., Hurst, J. G., & Habener, J. F. (1979). Effects of plasma calcium concentration on the relative proportion of hormone and carboxyl fragments in parathyroid venous blood. Endocrinology, 104(6), 1778-1784. Morrissey, M. T., Wu, J. W., Lin, D., & An, H. (1993). Protease Inhibitor Effects on Torsion Measurements and Autolysis of Pacific Whiting Surimi. Journal of Food Science, 58(5), 1050-1054. Park, J. W. (1994). Functional protein additives in surimi gels. Journal of Food Science, 59(3), 525-527. Park, J. W., Ooizumi, T., & Hunt, A. L. (2014). Ingredient technology for surimi and surimi seafood. In J. W. Park (Ed.), Surimi and Surimi Seafood (3 ed.). Boca Raton, FL: CRC Press. Picout, D. R., & Ross-Murphy, S. B. (2003). Rheology of biopolymer solutions and gels. TheScientificWorld Journal, 3, 105-121. Poowakanjana, S., Mayer, S. G., & Park, J. W. (2012). Optimum chopping conditions for Alaska pollock, Pacific whiting, and threadfin bream surimi paste and gel based on rheological and Raman spectroscopic analysis. Journal of Food Science, 77(4), E88-E97. Ramsey, F., & Schafer, D. (2012). The Statistical Sleuth: A Course in Methods of Data Analysis (3 ed.). Stamford: Cengage Learning. Rawdkuen, S., Benjakul, S., Visessanguan, W., & Lanier, T. C. (2007a). Effect of cysteine proteinase inhibitor containing fraction from chicken plasma on autolysis and gelation of Pacific whiting surimi. Food Hydrocolloids, 21(7), 1209-1216. Rawdkuen, S., Lanier, T. C., Visessanguan, W., & Benjakul, S. (2004). Chicken plasma protein: Proteinase inhibitory activity and its effect on surimi gel properties. Food Research International, 37(2), 156-165. Rawdkuen, S., Lanier, T. C., Visessanguan, W., & Benjakul, S. (2007b). Cysteine proteinase inhibitor from chicken plasma: Fractionation, characterization and autolysis inhibition of fish myofibrillar proteins Food Chemistry, 101(4), 1647-1657. Seymour, T. A., Morrissey, M. T., Peters, M. Y., & An, H. (1994). Purification and characterization of Pacific whiting proteases. Journal of Agricultural and Food Chemistry, 42(11), 24212427. Visessanguan, W., Benjakul, S., & An, H. (2000). Porcine plasma proteins as a surimi protease inhibitor: effects on actomyosin gelation. Journal of Food Science, 65(4), 607-611. Visessanguan, W., Benjakul, S., & An, H. (2003). Purification and characterization of cathepsin L in arrowtooth flounder (Atheresthes stomias) muscle. Comparative Biochemistry and Physiology Part B: Biochemistry and Molecular Biology, 134(3), 477-487. Yin, T., & Park, J. W. (2014). Effects of nano-scaled fish bone on the gelation properties of Alaska pollock surimi. Food Chemistry, 150, 463-468. 19 400 401 402 403 404 405 406 407 408 409 410 411 412 Yongsawatdigul, J., Park, J. W., Kolbe, E., Dagga, Y., & Morrissey, M. T. (1995). Ohmic heating maximizes gel functionality of Pacific whiting surimi. Journal of Food Science, 60(1), 1014. Yongswatdigul, J., Hemung, B. O., & Choi, Y. J. (2014). Proteolytic Enzymes and Control in Surimi. In J. W. Park (Ed.), Surimi and Surimi Seafood (3 ed., pp. 141-167). Baco Raton, FL: Taylor and Francis. Yvon, M., Chabanet, C., & Pelissier, J. P. (1989). Solubility of peptides in trichloroacetic acid (TCA) solutions hypothesis on the precipitation mechanism. International Journal of Peptide and Protein Research, 34(3), 166-176. 20 FIGURES 80000 80000 Elastic modulus (Pa) 100000 Elastic modulus (Pa) 100000 60000 40000 20000 A 60000 40000 20000 0 B 0 10 20 30 40 50 60 70 80 90 10 Temperature (°C) 20 30 40 50 60 70 80 90 Temperature (°C) 100000 10000 80000 Elastic modulus (Pa) Elastic modulus (Pa) 413 414 415 416 417 418 419 420 421 422 423 424 425 426 427 428 429 430 431 432 433 434 435 436 437 438 439 440 441 442 443 444 445 446 447 448 60000 40000 20000 C 0 10 20 30 40 50 60 Temperature (°C) 70 80 D 1000 90 0.1 1 Frequency (Hz) Figure 1 – Elastic (Storage) modulus of Pacific whiting surimi paste as affected by temperature sweep and 0, 0.5 and 1g/100g SPP additions (A, B, and C, respectively) and gel as affected by frequency sweep (D) after various treatments. without EDTA with EDTA Control OH Control 60/OH 0.5g/100g SPP 60/OH 1g/100g SPP 60/OH 10 21 449 600 452 453 454 Breaking Force (G) 451 500 400 300 200 100 0 A Penetration Distance (mm) 450 20 18 16 14 12 10 8 6 4 2 0 B 455 456 457 458 459 460 461 462 463 464 465 466 467 468 469 470 471 472 473 Figure 2 - Breaking force (A) and penetration distance (B) of Pacific whiting surimi gel as affected by SPP concentration, EDTA, and heating method. Error bars represent the standard deviation of 6 determinations. control 0.5g/100g SPP 1g/100g SPP 22 474 475 85 476 80 A B -3 a* 75 L* 477 -4 -2 70 478 -1 65 60 0 483 484 485 486 487 488 489 490 491 492 493 494 495 496 497 498 499 500 501 502 503 504 505 506 507 508 509 510 8 80 b* 6 4 2 0 C Whiteness (L*-3b*) 479 480 481 482 60 D 40 20 0 Figure 3 - L* (A), a* (B), b* (C), and whiteness (D) values of Pacific whiting surimi gels as affected by SPP concentration, EDTA, and heating methods. Error bars represent the standard deviation of 6 determinations. 23 μmol tyrosine/g sample 2 1.5 1 0.5 0 511 512 513 514 515 516 517 518 519 520 521 522 523 524 525 526 527 528 529 530 531 532 533 534 535 536 537 538 539 540 Figure 4 - TCA soluble peptide contents in Pacific whiting surimi gel as affected by SPP concentration, EDTA, and heating method. Error bars represent the standard deviation of 3 determinations. 24 541 542 543 544 545 546 547 548 549 550 551 552 553 554 555 556 557 558 559 560 561 562 563 564 565 566 567 568 569 570 571 572 573 574 Figure 5 - SDS PAGE pattern of surimi gels without (A) and with (B) 0.1g EDTA/100g as affected by SPP concentration and heating methods. MW=molecular weight marker, C=control, 0.5=0.5g/100g SPP, 1=1g/100g SPP, MHC=myosin heavy chain, Ac=Actin, 20-250=molecular weight in kDa. 25 575 576 577 578 579 580 581 582 583 584 585 586 587 588 589 590 591 592 593 594 595 596 597 598 599 600 601 602 603 604 605 606 607 608 609 610 611 612 613 614 615 616 OH 60/OH 25/OH A B C D E F Control 1g/100g SPP G Control EDTA Figure 6 – Scanning electron microscope image of surimi gels. A = Ohmic heating with no SPP added; B = 60°C holding for 30 min followed by ohmic heating with no SPP added; C = 25°C holding for 2 hr followed by ohmic heating with no SPP added; D = Ohmic heating with 1g/100g SPP added; E = 60°C holding for 30 min followed by ohmic heating with 1g/100g SPP added; F = 25°C holding for 2 hr followed by ohmic heating with 1g/100g SPP added; G = 25°C holding for 2 hr followed by ohmic heating with no SPP added and 0.1g EDTA/100g. Magnification = 10,000x.