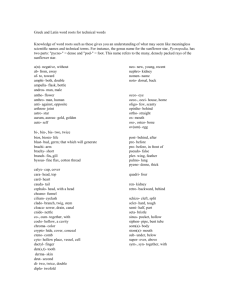

Chloride Treatment using Hollow Fiber Supported Liquid Membranes EUROPEAN PROJECT SEMESTER 2013

advertisement

1 Chloride Treatment using Hollow Fiber Supported Liquid Membranes EUROPEAN PROJECT SEMESTER 2013 The Team Tobias Slusarek, Germany Markus Hofmeister, Germany Rafal Madaj, Poland William Strömbäck, Finland 2 3 an alternative “ Develop desalination technique for the Abrera drinking water treatment plant. Explore the working principle Up-scale “ Chemistry economics it to industrial use Compare the technique to conventional ones competitive technology Table of Contents I. Water Shortage II. The need for an alternative technique III. Hollow Fiber Supported Liquid Membranes I. Working principle II. Experimental part and results IV. Up-scaling to industrial use V. Perspectives VI. Conclusions 4 Water Shortage – The General Problem The demand for fresh water constantly increases More than 1.3 billion people are suffering from water shortage The main cause is the growing world’s population Three basic approaches to solve the problem 5 http://wewastetime.files.wordpress.com/2010/06/agbardesert.jpg I. I. Water Sho Salinity 6 Chloride contamination Content of dissolved salts Maximum chloride concentration set by the EU is 250 mg/l (98/83/EC) Exceeding this limit would cause a bad taste and a higher corrosion rate El Llobregat has a chloride concentration between 300mg/l and 500mg/l [Cl-], mg/l 500 400 300 200 100 0 EU standard El Llobregat I. Water Sho The need for an alternative technique Reverse osmosis 7 Electrodialysis reversal Driving force Pressure Electric potential gradient High energy consumption Hollow Fiber Supported Liquid Membranes as an energy-saving alternative II. The need for an alternative tech Hollow Fiber Supported Liquid Membranes Hollow fiber http://www.pall.com/images/Graphic-Arts/crossflow_filtration_figure9.jpg 8 Supported liquid membranes Pores filled with an organic liquid containing carrier molecules (Aliquat® 336) Barrier between two aqueous phases III. Hollow Fiber Supported Liquid Memb Transport process Heat transfer 9 chloride ions transfer Extraction Diffusion Stripping III. Hollow Fiber Supported Liquid Memb Investigation strategy • Determination of the equilibrium constant • Aliquat® 336 preparation Aliquat® 336 Flat sheet membranes • First impression of the technique • Determination of the diffusional transport constant 10 • Desired continuous process • More complex Hollow fibers washing III. Hollow Fiber Supported Liquid Memb Experimental set-up [Cl-] initial ≈ 600 mg/L Vfeed >> Vstripping Chloride evolution measured Different Aliquat® 336 concentrations 11 III. Hollow Fiber Supported Liquid Memb Results of the HFSLM - experiment 12 EU standard III. Hollow Fiber Supported Liquid Memb Achievements Effectiveness proved Determination of most efficient operating conditions Very general MATLAB model for up-scaling 13 III. Hollow Fiber Supported Liquid Memb Up-scaling process 14 Agència Catalana de l' Aigua. Planta dessalinitzadora de la conca del Llobregat. Generalitat de Catalunya, 2009. IV. Up-scaling to industr Current treatment steps 15 Technologies, GE Power & Water - Water & Process. Trihalomethanes (THM) Precursor Reduction of Surface Water by EDR Technology: Abrera Drinking Water Treatment Plant, Barcelona Spain. General Electric Company, 2010. Pretreatment Desalination Electrodialysis Reversal (8 Modules) Splitted flow Possible replacement by HFSLM IV. Up-scaling to industr Technical questions 16 Split the flow or treat all 4m3/s ? Concurrent or countercurrent flow? What are best flow conditions? What concentration of bicarbonate should be used? Concurrent flow Countercurrent flow IV. Up-scaling to industr Economic aspects Number of modules Pumping system Bicarbonate concentration 17 The price we pay is not a production price! IV. Up-scaling to industr Results 18 35556 modules Subject Price arranged paralelly Modules 534 mil € treating 4m3/s in countercurrent flow Electricity per year 600 000 € Sodium bicarbonate for 1st year 30.5 mil € Sodium bicarbonate for next year 3.9 mil € Cleaning costs for 1m³ of stripping phase 0.058 € IV. Up-scaling to industr Comparison with competitive techniques 0,160 € 0,140 € Electricity costs to produce 1m3 of clean water 0,300 € Overall costs of producing 1m3 of clean water 0,270 € 0,139 € 19 0,250 € 0,263 € 0,230 € 0,120 € 0,200 € 0,100 € 0,150 € 0,080 € 0,059 € 0,060 € 0,100 € 0,040 € 0,020 € 0,020 € 0,050 € 0,000 € 0,000 € RO EDR HFSLM RO EDR HFSLM IV. Up-scaling to industr Summary Lower electricity and maintenance costs Better quality of water due to bicarbonate addition 20 High equipment purchase costs Cost efficient only down to 200 ppm of [Cl-] Requires additional support from competitive technique IV. Up-scaling to industr Improvement potential Economy 21 Estimated costs for 1m³ of cleaned water of scale 0,30 0,25 0,20 0,15 0,10 0,05 0,00 RO EDR HFSLM V. Perspe Improvement potential 22 Developing special membranes for desalination Investigations Technique on other counter ions almost unexplored V. Perspe Further investigations Up-scale or down-scale Clean only drinking water Explore the functionality for higher chloride concentrations 23 New markets like China or India Long-term study about Aliquat® 336 side effects Aliquat® 336 is really harmful for all kinds of living organisms V. Perspe Conclusions 24 The Hollow Fiber Supported Liquid Membrane technique works Competitive to other techniques The energy consumption is even less sustainable! It is possible to use this technique without electricity The implementation costs have to be reduced VI. Conc 25 Thank you for your attention.