Document 11549982

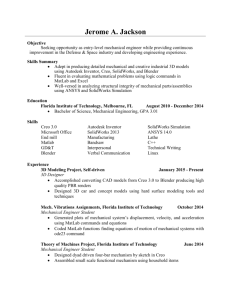

advertisement

Joshua Benz BSME, UC Berkeley jrbenz09@gmail.com PROFILE Over four years of manufacturing experience from project management to product development and sustaining. Areas of expertise include electro-mechanical systems, injection molding, computer-aided modeling, and process optimization. EXPERIENCE PARKER HANNIFIN ENG MATLS GRP | SAN DIEGO, CA DESIGN ENGINEER APR. 2014 TO PRESENT Design composite sealing systems for diesel & industrial markets. Responsibilities and accomplishments: • Seal Design o Design to market/industry standards: CAD, FEA, Customer/concurrent engineering o Market outreach to major industry customers: Cummins, CAT, Navistar o Ownership of ECR – ECO process for 100+ active products OCT. 2012 TO NOV. 2013 PARKER HANNIFIN FILTRATION | BALTIMORE, MD DEVELOPMENT ENGINEER II Develop & sustain standard product nitrogen generators (ISO 9001, 14001). Product sampling & data analysis for new material validation. Responsibilities and accomplishments: • System Development o Design and qualification to food/beverage industry standards o Programming in electrical (PLC) and pneumatic (mechanical response) logic o Prototype electromechanical data collection system (8 sensors, AC/DC) • Optimization o Ownership of ECR – ECO process for 10+ generator assemblies (60+ drawings) o Manage cross-functional team of five in planning/executing wellness initiatives PRECISION CASTPARTS CORP. | San Leandro, CA PRODUCT ENGINEER MARCH 2010 to SEP. 2012 Manage new product development for Structural Castings Division (ISO 9001) from workflow setup to casting configurations, flow-down of quality requirements in aerospace and biomedical industries. Manufacturing processes utilizing various materials - rapid prototype polymers (SLA), wax, ceramic, and corrosion-resistant alloys. Responsibilities and accomplishments: • Mechanical Design o Advanced SolidWorks tools for model construction and design modifications o Tool & fixture design (dimensional validation, machine shop experience) o Product qualification (NDT, GD&T, grain-structure) to SAE international standards o ECR – ECO ownership on 200+ active designs o Contractor for US DoD end-use product o FEA simulation for solidification stress, heat & mass transfer analyses 1 of 2 o Customer & vendor interface: concurrent engineering aimed at DFM o DOE/Six-sigma to reduce manufacturing costs & product variability • Project Management Process improvements translated to $500k annual cost savings Meet or exceed quarterly NPI project goals (typ. 25 products/year) Supervise foundry (7 direct reports) in recovering $1M manufacturing deficit Algorithm recognition for iterative solutions to reduce repetitive labor o Manufacturing workflow optimization: 5-S, Kaizens, Lean, cellular workspaces o o o o • Technical Communication o Custom & standard manufacturing work instructions/techniques (pictorial & written) o Train operators on quality control & safety procedures • Business Management o Increase primary account sales two-fold o Procure 30+ production alloys, totaling $12M annually o Build standing customer relationships (Honeywell Aerospace, GE, Capstone Turbine) IMPAX LABORATORIES | HAYWARD, CA MECHANICAL ENGINEER - INTERN JUNE 2008 to DEC. 2008 Hands-on intern, reported to Director of Maintenance. Active role in maintenance department for FDA-regulated facility, including standard work, design, and procedure composition. • Pharmaceutical Machinery Troubleshooting • SOP Composition & Contractor Training • GMP/Pharmaceutical Tool & Equipment Design EDUCATION UNIVERSITY OF CALIFORNIA - BERKELEY, CA | 2009 Mechanical Engineering Bachelor of Science (BSME) CHABOT COLLEGE - HAYWARD, CA | 2007 Engineering Associate of Science CERTIFICATIONS • • PROFESSIONAL ENGINEER-IN-TRAINING 2011: CA Certification No. EIT 145065 CERTIFIED SOLIDWORKS ASSOCIATE 2007: ID No. C-BLHFB2H2R4 SOFTWARE EXPERTISE • • • • OFFICE UTILITY………….…...Excel | PowerPoint | Project | Word | Outlook | Lotus Notes MAINFRAME SYSTEMS...........Java [MSSv] | Cisco [Escala] CAD/FEA.………………..…..Inventor | AutoCAD | SolidWorks | ProCAST MATHEMATICAL MODELING….Matlab | LabView | Excel 2 of 2