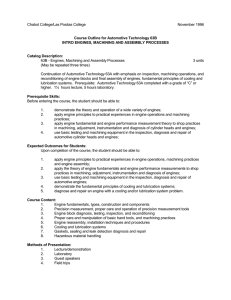

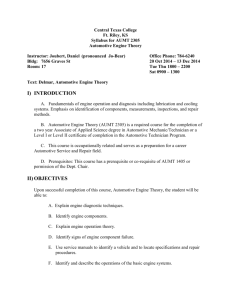

Chabot College/Las Positas College November 1996 Course Outline for Automotive Technology 63A

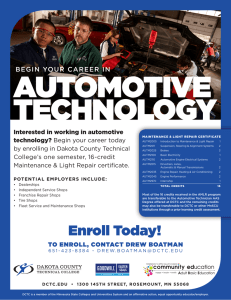

advertisement

Chabot College/Las Positas College November 1996 Course Outline for Automotive Technology 63A INTRODUCTION TO ENGINES AND MACHINING PROCESSES Catalog Description: 63A - Introduction to Engines and Machining Processes (May be repeated three times) 3 units Diagnosis, inspection, and repair of various engine types; machining operations, use of instruments and automotive machinist equipment in repairing engines and cylinder head reconditioning. Prerequisite: Automotive Technology 50 or 55, and 60B completed with a grade of “C” or higher. Strongly recommended: Industrial Technology 61 and 74 or equivalent (may be taken concurrently). 1½ hours lecture, 5 hours laboratory. Prerequisite Skills: Before entering the course, the student should be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. evaluate concepts, techniques, principles and legal requirements for shop and agency practices; evaluate various methods used to achieve a profitable, well organized shop or agency; recognize the basic elements to plan, organize and direct a business towards established objectives; diagnose and repair basic automotive electrical/electronic systems; demonstrate skills in problem solving, testing and repairing electrical components; use basic electrical testing equipment in diagnosis and repair of electrical/electronic circuits and components; demonstrate skills using diagnostic testing equipment to troubleshoot and repair more complex automotive circuits and components; understand safety procedures and ramifications of handling hazardous waste materials; identify and access service information in shop manuals and computer-stored systems. Expected Outcomes for Students: Upon completion of the course, the student should be able to: 1. demonstrate the theory and operation of a wide variety of engines; 2. apply engine principles to practical experiences in engine operations and machining practices; 3. apply engine fundamental and engine performance measurement theory to shop practices in machining, adjustment, instrumentation and diagnosis of cylinder heads and engines; 4. use basic testing and machining equipment in the inspection, diagnosis and repair of automotive cylinder heads and engines; Course Content: 1. Engine fundamentals, types, construction and components 2. Engine diagnosis, inspection and repair 3. Engine performance measurement and adjustment 4. Precision measurement, proper care and operation of precision measurement tools 5. Metals identification, mechanical and physical properties 6. Fastening devices and operations 7. Proper care and manipulation of basic hand tools 8. Engine removal, disassembly, and cleaning techniques and procedures 9. Cylinder head diagnosis, testing, inspection, and reconditioning 10. Hazardous material handling Chabot College Course Outline for Automotive Technology 63A, page 2 November 1996 Methods of Presentation: 1. Lecture/demonstration 2. Laboratory 3. Guest speakers 4. Field trips Methods of Evaluating Student Progress: 1. Class participation 2. Performance of laboratory task list and projects 3. Homework assignments 4. Quizzes, midterm and final examinations Textbook(s) Typical: Automotive Engines, Diagnosis, Repair, Rebuilding, Tim Gilles, Delmar Publishers Special Student Materials: Safety glasses and shop/safety clothing rsj a:\wpfiles\AT63A.96