Appendix C Review of the States of the Art and Practice

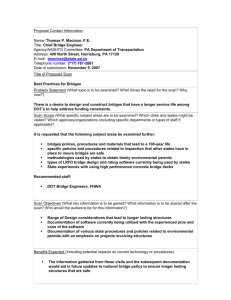

advertisement