23-Sep-2010 1 ISPE - Pellet Coating Process D. W. Staggs

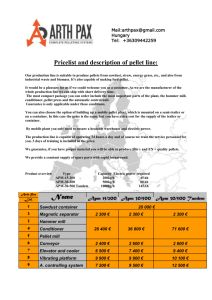

advertisement

23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 1 Fluid Bed Pellet Coating Process: An Exercise in Process Engineering Fundamentals Darrell Staggs, P.E. Associate Engineering Consultant Process Engineering Center Coated Pellet Formulation 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 3 Understanding the Process Technology The pellets are spray-coated with layer after layer of other materials, including API, while being blown around inside the MP10, a large stainless-steel vessel that works something like a giant hot-air corn popper, said Nic Chornet, team leader for manufacturing at IndyDry. MQ News 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 4 Fluidized Bed Pellet Coating The Basics 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 5 Define the Process Critical Process Parameters •Suspension T, Mill Speed, Product T during Coating Everything Else • • • • • • • • Solution / Suspension Preparation Air Preparation and Delivery Solution / Suspension Delivery Droplet Formation Pellet Transport and Coating Film Formation and Drying Pellet Classification … 70+ Variables 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 6 The Mass Balance Solids Applied Water Evaporation Coating Efficiency Pellet Potency 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 7 Pellet Coating Layers A Consistent Quality Product Sugar Core API Subcoat Enteric Color Analysis of Spheres SEM and Image Analysis Eric Olson 6/30/03 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 8 Pellet Coating Integrated Unit Operations Suspension Makeup Baghouse Pump Skid Filter Skid Coater CIP System 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 9 DEFINE the Process Process Thermodynamics - Air Preparation and Drying 0% =4 RH 0.0320 RH RH =8 0.0340 =6 0% 0% Psychrometric Chart 0.0280 0.0260 Exhaust 40 C 48% RH h = 90 kJ/kg ⎯⎯→ 0.0240 0.0220 0.0200 h = 70 kJ/kg ⎯⎯→ 0.0180 30 C 60% RH 0.0160 0.0140 De 8 hu C m de id w if y pt Humidity Ratio (kg H2O per kg dry air) 0.0300 RH = 20% Dr yin g h = 50 kJ/kg⎯⎯→ 0.0120 0.0100 0.0080h = 30 kJ/kg ⎯⎯→ Heat Inlet 80 C 0.0060 0.0040 0.0020 0.0000 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 Dry Bulb Temperature (C) 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 10 100 Process ThermodynamicsIncreased Inlet Air T 0% =4 Exhaust 40 C 60% RH 0.0300 0.0280 0.0260 h = 90 kJ/kg ⎯⎯→ 0.0240 0.0220 Dr yin g 0.0200 h = 70 kJ/kg ⎯⎯→ 0.0180 30 C 60% RH 0.0160 0.0140 De 8 hu C m de id w if y pt Humidity Ratio (kg H2O per kg dry air) RH 0.0320 RH RH =8 0.0340 =6 0% 0% Psychrometric Chart RH = 20% h = 50 kJ/kg⎯⎯→ 0.0120 0.0100 0.0080h = 30 kJ/kg ⎯⎯→ Heat 0.0060 Inlet 95 C 0.0040 0.0020 0.0000 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 Dry Bulb Temperature (C) 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 11 100 Process Thermodynamics- Favorable Coating Conditions vs. System Capacity 0% =4 RH 0.0320 RH RH 0.0340 =6 0% =8 0% Psychrometric Chart 0.0300 Humidity Ratio (kg H2O per kg dry air) 0.0280 0.0260 h = 90 kJ/kg ⎯⎯→ 0.0240 AHU + Coating 95 Inlet, 8 D.P. 0.0220 0.0200 h = 70 kJ/kg ⎯⎯→ 0.0180 RH = 20% 0.0160 0.0140 h = 50 kJ/kg⎯⎯→ 0.0120 0.0100 0.0080h = 30 kJ/kg ⎯⎯→ 0.0060 0.0040 0.0020 0.0000 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 Dry Bulb Temperature (C) 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 12 100 Process Thermodynamics: Conclusions Evaporative Capacity AND Relative Humidity Environment Increase with increasing Inlet Temperature BUT, That does NOT fully define the coating environment. 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 13 Sustain the Process Equipment Qualification How to QUALIFY a Precision Coater™? All Columns performing equally Air Flow Distribution • Atomization Air Control • Spray Rate Control • Temperature Response • 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 14 Temperature Mapping a Precision Coater™ 100 95 Column Inlet T vs. Inlet Air T vs. Set Point vs. Time 90 TC1 TC2 TC3 TC4 TC5 TC6 TC7 TC8 TC9 TC10 Setpoint Inlet Temp 85 75 70 65 60 96 55 95.5 50 9:10:05 9:38:53 10:07:41 10:36:29 11:05:17 11:34:05 TC2 94.5 12:02:53 TC3 94 TC4 Time Column Inlet T Variability TC1 95 Temp, C Temp, C 80 TC5 93.5 TC6 93 TC7 92.5 TC8 92 TC9 TC10 91.5 Setpoint 91 TT5209B 90.5 90 13:14:53 13:17:46 13:20:38 13:23:31 13:26:24 13:29:17 13:32:10 13:35:02 13:37:55 Time 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 15 23-Sep-2010 D. W. Staggs 8RD04 8RD05 8RD30 8RF93 8RF94 8RF95 8RF96 8RF98 8RF99 8RH26 8RH28 8RF97 8RH29 8RH30 8RH31 8RJ82 8RL13 8RL14 8RL15 8RL53 8RL54 8RL55 CT506492 CT507303 DTS23810 DTS23818 CT507304 CT508801 7RA52 7RA53 7RA54 7RH05 7SG37 7RH06 7SG28 7SG29 7SG30 7SG31 7SG32 7SG33 7SG34 7SG35 7SG36 7SG38 8RD01 8RD02 Oversize Pellets, kg Improve the Process - Secondary Loop The Problem: Pellet Agglomeration Coating=Active Control Chart Individual Measurement of Oversize Pellets, kg 160 150 140 130 120 110 100 90 80 70 60 50 UCL=56.54 40 30 20 10 Avg=16.82 0 Lot ISPE - Pellet Coating Process 16 Duloxetine Pellet Coating Process Pellet AGGLOMERATION Wet Pellets Inadequate Drying Diffusion Limiting Drying Curve API (compare to talc) Air Flow Air distribution Bed vs. Column Poor Spray Large Droplets High Relative Humidity Environment High Spray Rate Low Exhaust Temperature Air flow maldistribution Spray Nozzle Atomization Air Low Pressue Slurry Properties Delivery System Water Leak Solids Concentration variability Condensation Viscosity Mis-Alignment Nozzle Tip Wear Data: UofC Spray tests Insert size Free Moisture Plate pluggage HPMC? control valve clearance / shear API solids prop's API solids prop's Outside Air Leak Cold Surface Low Flow Pellet Distribution column loading Aeration Low Pellet Circulation Fouled nozzle Low Energy Input Tank/ Agitator design / operation API solids prop's Solids "Flooded" Column UC spray data Air flow rate Particle Size Distribution Inlet Temperature Aspect Ratio Low initial temperature Crystal Habit and Morphology DWS 1-Sep-2004 Agglomeration Mechanisms rev-3.vsd 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 17 Spray Nozzle Testing Spray Using MP-10 Nozzle for API Solution Studies On The Spray Pattern of Nozzles Used In Niro MP-10 And MP-1 Precision Coaters November 12, 2004 J. Zhou Process Engineering Center 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 18 Improve the Process Pellet Agglomeration Fundamental Process Changes: Atomization Air P Coating=Active Control Chart • Initial Inlet airIndividual T Measurement of Oversize Pellets, kg • Initial Air Flow • 160 150 140 130 120 Oversize Pellets, kg 110 100 90 80 70 60 UCL=56.54 50 40 30 20 Avg=16.82 10 8RD04 8RD05 8RD30 8RF93 8RF94 8RF95 8RF96 8RF98 8RF99 8RH26 8RH28 8RF97 8RH29 8RH30 8RH31 8RJ82 8RL13 8RL14 8RL15 8RL53 8RL54 8RL55 CT506492 CT507303 DTS23810 DTS23818 CT507304 CT508801 7RA52 7RA53 7RA54 7RH05 7SG37 7RH06 7SG28 7SG29 7SG30 7SG31 7SG32 7SG33 7SG34 7SG35 7SG36 7SG38 8RD01 8RD02 0 Lot 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 19 Process Engineering Fundamentals “There is no result in nature without a cause; understand the cause and you will have no need of the experiment. “ “Therefore O students study mathematics and to not build without foundations.” “He who thinks little makes many mistakes.” Leonardo Da Vinci 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 20 The Fluid Bed Pellet Coating Process Questions? 23-Sep-2010 D. W. Staggs ISPE - Pellet Coating Process 21