“TECHNOLOGY OF THE FUTURE” Using Disposables to Build a Flexible Manufacturing Capacity

advertisement

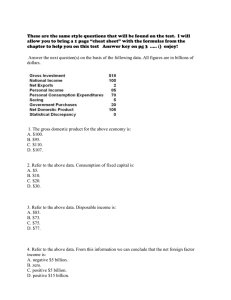

“TECHNOLOGY OF THE FUTURE” Using Disposables to Build a Flexible Manufacturing Capacity San Francisco / Bay Area ISPE Vendor Night 28 February, 2008 Geoffrey Hodge, VP Process Development & Technology, Xcellerex Outline • Introduction • Case Study: 1000L perfusion culture in a disposable bioreactor • Concept: A new platform approach to fast, flexible, turnkey manufacturing • Case Study: Flexible mAb facility • Strategic manufacturing options • Conclusions and Q&A INTRODUCTION The need for speed (and flexibility) Strategic Outlook Industry Growth New Technology Smaller Markets Cost Pressures • 15% annual avg. • Better process yields • Fewer blockbusters • Health care reform • >20 approved mAbs • Potent compounds • Personalized medicine • Biogenerics • >150 mAbs in clinic • Drug delivery • Genetic diagnostics • Follow-on drugs • Genomics impact Capacity shortage (captive capacity) Smaller batch sizes Smaller R&D budgets . Need for more efficient PD & fast, flexible and inexpensive manufacturing capacity Advantages of Single Use Systems Reductions in: • Cleaning • Sterilization • Engineering cost • Equipment lead time Lead to • Utility requirements • Validation • Quality / Regulatory burden • Space • Labor • Waste generation Improvements in: • Manufacturing quality • Capital investment • Facility buildout time • Cycle time • Flexibility • Environmental impact • COGS CASE STUDY 1000L perfusion in a disposable bioreactor Project Overview Goal: reproduce client bench scale process in XDR disposable bioreactor first at 200L then at 1000L scale SCALE LOCATION DAYS HARVESTS 10L Client 27 22 200L Xcellerex 28 22 1000L Xcellerex 19 12 XDR-200 Disposable Bioreactor System Disposable Bag Assembly (incl. Filters & Tubing) Jacketed Stainless Steel Support Tank View Ports PLC or Delta V Controller Integrated Acid/Base, Feed Pumps Probe Port Eccentric Bottom Mag. Drive Agitator Temperature Control Unit XDR Disposable Bioreactor Overview Disposable Assembly • All product contact surfaces single-use except sensors • No assembly required within sterile barrier • USP Class VI films & components, low endotoxin, low particulate, non-cytotoxic materials Bioreactor Hardware and Controls • Turnkey, fully integrated with DeltaV or PLC process controller • Stirred tank design — bottom magnetic drive agitation, integrated sparger • Jacketed tank — 30-45 minute heat-up • 5:1 turndown ratio (operates at 20% volume) Confidential ® CentriTech LAB Disposable Centrifuge Perfusion Schematic Harvest Perfusion out Perfusion in pump pump CentriTech XDR Cell concentrate return ® XDR 200 Disposable Bioreactor & CentriTech LAB ™ XDR™200 CentriTech® LAB Challenges for 1000L Scale • Medium supply • Made in XDM™1000 • New filter welded daily • Filtered into 1 of 3 1000L holding bags • Connectivity • Aseptic components welded • “Daisy-chained” holding bags – FIFO drain & fill • Process control • Tuning feed pump & load cell 1000L Scale Perfusion Layout Centritech Cell I® disposable continuous centrifuge Harvest hold bag and chilled tank XDR™-1000 disposable bioreactor (1000L working volume) Load cell controlling medium feed pump Daisy-chained 1000L media hold bags & holders 1,000L disposable media mixing system (XDM-1000) Viable Cell Density 10.00 6 x 10 cells/mL Viable cell density, 12.00 8.00 6.00 4.00 10 L glass XDR-200 disposable XDR-1000 disposable 2.00 0.00 -10.0 -5.0 0.0 5.0 10.0 15.0 20.0 25.0 Days in Production, Days Viable cell density in XDR at 200 and 1000L scale comparable to client 10L benchtop Cell Viability 100.0 Viability, % 90.0 80.0 70.0 10 L glass 60.0 XDR-200 disposable XDR-1000 disposable 50.0 -10.0 -5.0 0.0 5.0 10.0 15.0 20.0 25.0 Days in Production, Days Cell viability in XDR at 200 and 1000L scale comparable to client 10L benchtop Cumulative enzyme production per liter bioreactor working volume Enzyme Productivity 0.0 5.0 10.0 15.0 Cumulative enzyme production Cumulative Productivity 10 L glass XDR-200 disposable XDR-1000 disposable 20.0 Specific Productivity 25.0 Days in Production, Days Volumetric and specific productivity in XDR at 200 and 1000L scale comparable to client 10L benchtop data 10 L glass XDR-200 disposable XDR-1000 disposable 0 From Yin, BioProcessing Challenges for Large Scale Disposable Bioreactors, IBC BioPharm Production Week, Boston, Oct. 2007 20 40 60 80 100 120 140 160 Integrated viable cell density, million cells/mL * day 180 200 ™ FLEXFACTORY : A Novel Platform for Biomanufacturing The Requirements Design a biomanufacturing capability to: • • • • • • Minimize capital cost Be rapidly constructed Handle a wide range of processes Be flexible and quickly reconfigurable Assure a high level of product quality Minimize labor and operating cost The Concept An integration of emerging technologies • • • • Disposable bioprocess components Microenvironments (modular clean spaces) Process automation Electronic batch records Advantages of Disposables • Heavy use of disposables allows the FlexFactory manufacturing platform to operate without utilities • Additional advantages: • • • • Cleaning Sterilization Engineering Equipment lead time • • • • Validation Quality / Regulatory Space Labor Advantages of Microenvironments • • • • Save space Decrease HVAC complexity Portable and reconfigurable Greater protection of product from human contamination Advantages of Process Automation and Electronic Batch Records • Reduce manual operations • Reduce labor • Reduce chance for human error • Increase opportunity for data collection and process control • Enable on-line tools Traditional Manufacturing Plant WFI CIP Buffer Storage Cleaning Records Sterilization Records Validation & Maintenance Records Production SOPs Batch Records Deviations, CAPAs HVAC Clean Steam Purification Air Locks & Hallways Air Locks & Hallways Cell Culture Air Locks & Hallways Air Locks & Hallways Buffer / Media Prep Air Locks & Hallways Air Locks & Hallways PW Form / Fill Specifications Manufacturing Reports Replacing Stainless w/ Disposables… WFI CIP Buffer Storage Cleaning Records Sterilization Records Validation & Maintenance Records Production SOPs Batch Records Deviations, CAPAs HVAC Clean Steam Purification Air Locks & Hallways Air Locks & Hallways Cell Culture Air Locks & Hallways Air Locks & Hallways Buffer / Media Prep Air Locks & Hallways Air Locks & Hallways PW Form / Fill Specifications Manufacturing Reports …Eliminates Utilities Cleaning Records Sterilization Records Validation & Maintenance Records Production SOPs Batch Records Deviations, CAPAs Cell Culture Purification Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways HVAC Form / Fill Specifications Manufacturing Reports Adding Microenvironments… Cleaning Records Sterilization Records Validation & Maintenance Records Production SOPs Batch Records Deviations, CAPAs Cell Culture Purification Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways Air Locks & Hallways HVAC Form / Fill Specifications Manufacturing Reports Air Locks & Hallways …Eliminates Cleanrooms & Complex HVAC Cell Culture Purification Form / Fill Cleaning Records Sterilization Records Validation & Maintenance Records Production SOPs Batch Records Deviations, CAPAs Specifications Manufacturing Reports Adding E-Batch Records & Automation… Cleaning Records Sterilization Records Validation & Maintenance Records Production SOPs Batch Records Deviations, CAPAs Air Locks & Hallways eFactory™ Cell Culture Purification Form / Fill Specifications Manufacturing Reports Air Locks & Hallways …Eliminates Paper, Provides Electronic Data & Web Access Through Secure Portal eFactory™ Cell Culture Purification Form / Fill Operators work in “gray space” and can move easily from one unit op to another between upstream and downstream or between products FlexFactory Plant Air Locks & Hallways ™ eFactory™ Cell Culture Purification Form / Fill Operators work in “gray space” and can move easily from one unit op to another between upstream and downstream or between products Technology Assessment • Economics of operation • Commissioned model from BioPharm Services • Cost of disposables more than offset by capital savings, decreased utilities / water • Engineering study • Commissioned study w/ PFI to examine cost and timing of facility construction • Capital cost < 50% of traditional design • Construction timeline of 1 year CASE STUDY Construction cGMP mAb Facility Proof of Concept: Fully Disposable Process • 10 L Wave disposable bioreactor scale • Typical mAb process • All product components disposable • All media & buffers provided / made in bioprocess bags • All process intermediates stored in bioprocess bags • All product contact components, including sensors, fully disposable Technology Feasibility Prototypes • • • • Built prototype units for 100L scale Operated with typical mAb process Worked out design and operability issues Collected EM data The Challenge January 2002: Need cGMP mAb by year end Facility construction Design & fabrication Validation Manufacturing campaign Drug substance release testing Fill Drug product release testing Drug product release Distribute to clinic Start clinical trial Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov The challenge: Design, build & validate a facility in less than 6 months Dec The Project • Two parallel tracks – facility and modules • Facility • Identified CMO with expansion space • Unused portion of warehouse • 600 sq. ft. • Constructed open 10K cleanroom • HVAC, electrical only • No pipes or other utilities The Project • Modules • Designed and fabricated off-site • Process equipment purchased • Partial integration of equipment and modules done off-site • Commissioning done off-site • Final integration, IQ/OQ done on-site The Results • Facility and modules completed and validated in <6 months • GMP production started June 10th • Six batches of bulk drug substance manufactured at 100% success rate • Produced in campaigns—upstream batches completed, modules swapped, purification completed • Clinical trial started in December, 2002 Xcellerex FlexFactory™ Today - 200, 1,000L working volume disposable stirred tank bioreactors - Disposable downstream processing (except columns) - Modular clean environments - Rapid deployment portability to customer site - Simple clean room facility - No CIP or SIP systems - 50% reduction in capital cost - 70% reduction in time to build - 25% lower operating costs STRATEGIC IMPACT Eliminating the Buy vs. Make Decision Capital Investment Risk Product Development Life Cycle Phase I (12 months) • Safety Clinical Development Timeline (6-7 years) Phase II (24 months) Phase III (24 months) • Dose Finding • First Efficacy • Pivotal Trials Plant investment decisions must be made long before product approval Product Launch Filing & Review (18 months) Lead-Time for Building a Commercial Plant (~4 years) Design (12 months) Construction (24 months) Validation (12 months) Can organization support “Make” strategy if product fails? Current Buy vs. Make Dilemma Buy (CMO) Make (Build) • No capital expense • Fast access to Pro capacity • No cost between projects • • • • Builds capability Strategic asset Control of projects Flexibility • Loss of control • Does not build Con internal capability • • • • Capital expense Long lead time Risk Maintenance cost when idle New Possibilities • Problem: Buying CMO capacity is a fast, low capital option, but money spent does not build company assets • Ideal Solution: • Buy CMO capacity when risk / uncertainty is high, cash is low • Quickly establish in-house capacity when risk is low, high product / pipeline demands certain “Buy and Take” Manufacturing Portable turnkey manufacturing platform enables a new solution to the buy vs. make dilemma Xcellerex / CMO Customer Facility design, build validate FlexFactory™ modules design, build, validate Xcellerex / CMO Customer contract mfg., training ™ Customer FlexFactory The Ultimate Tech Transfer Re-qualify / cal, start GMP mfg. CONCLUSIONS Conclusions • Competition and market pressures will increase pressure on drug cost • Manufacturing will increasingly be viewed as a strategic asset • Disposables offer opportunities for flexibility and cost savings in manufacturing capacity Conclusions FlexFactory uses disposables for a platform approach with several advantages over traditional facility designs: ™ Facility • >50% less capital cost • Short lead time: 1 yr (vs. 3-4 for traditional) • Rapid capacity expansion • Delays capital spend • Portable, flexible • Space savings, no utilities Operations • Reduced labor • No SIP / CIP • Mobility between unit ops • Process automation & EBR • Improved quality • No chance of cross-contamination • On-line control & QA • Rapid turnaround • Enables “buy & take” option for moving from outsourced manufacturing to in-house capacity Thank You 170 Locke Drive, Marlborough, MA 01752 www.xcellerex.com