b Sb with variable starting Zn compositions

advertisement

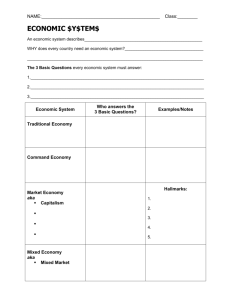

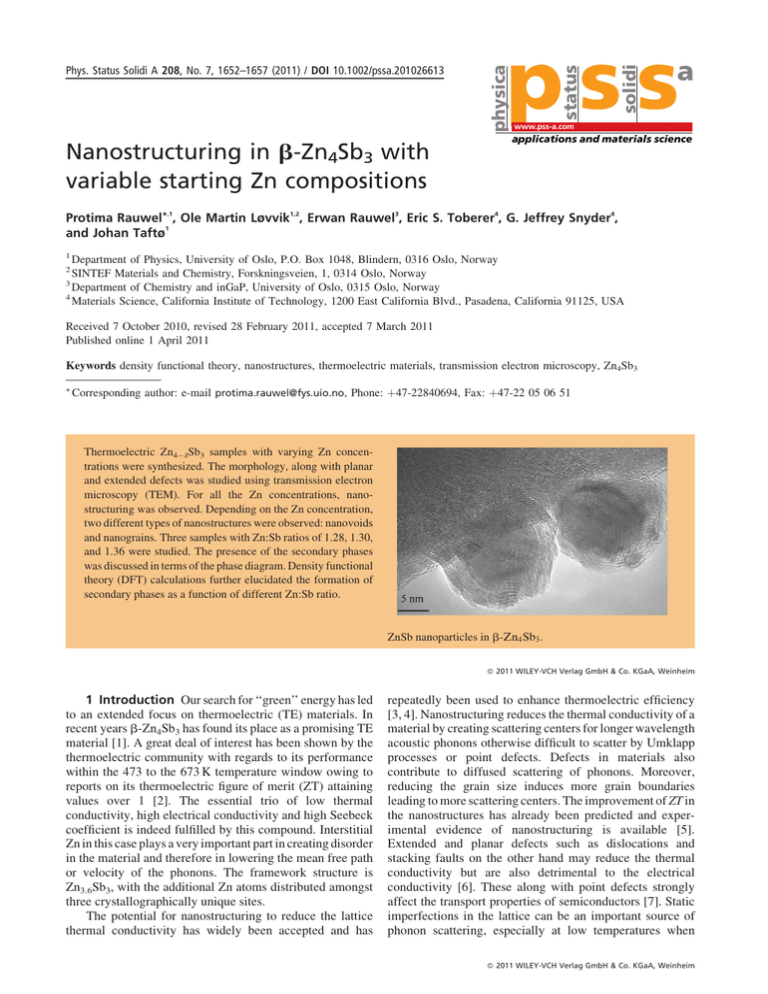

1,2 3 status a www.pss-a.com applications and materials science Nanostructuring in b-Zn4Sb3 with variable starting Zn compositions ,1 solidi pss physica Phys. Status Solidi A 208, No. 7, 1652–1657 (2011) / DOI 10.1002/pssa.201026613 4 4 Protima Rauwel* , Ole Martin Løvvik , Erwan Rauwel , Eric S. Toberer , G. Jeffrey Snyder , 1 and Johan Taftø 1 Department of Physics, University of Oslo, P.O. Box 1048, Blindern, 0316 Oslo, Norway SINTEF Materials and Chemistry, Forskningsveien, 1, 0314 Oslo, Norway 3 Department of Chemistry and inGaP, University of Oslo, 0315 Oslo, Norway 4 Materials Science, California Institute of Technology, 1200 East California Blvd., Pasadena, California 91125, USA 2 Received 7 October 2010, revised 28 February 2011, accepted 7 March 2011 Published online 1 April 2011 Keywords density functional theory, nanostructures, thermoelectric materials, transmission electron microscopy, Zn4Sb3 * Corresponding author: e-mail protima.rauwel@fys.uio.no, Phone: þ47-22840694, Fax: þ47-22 05 06 51 Thermoelectric Zn4dSb3 samples with varying Zn concentrations were synthesized. The morphology, along with planar and extended defects was studied using transmission electron microscopy (TEM). For all the Zn concentrations, nanostructuring was observed. Depending on the Zn concentration, two different types of nanostructures were observed: nanovoids and nanograins. Three samples with Zn:Sb ratios of 1.28, 1.30, and 1.36 were studied. The presence of the secondary phases was discussed in terms of the phase diagram. Density functional theory (DFT) calculations further elucidated the formation of secondary phases as a function of different Zn:Sb ratio. ZnSb nanoparticles in b-Zn4 Sb3 . ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 1 Introduction Our search for ‘‘green’’ energy has led to an extended focus on thermoelectric (TE) materials. In recent years b-Zn4Sb3 has found its place as a promising TE material [1]. A great deal of interest has been shown by the thermoelectric community with regards to its performance within the 473 to the 673 K temperature window owing to reports on its thermoelectric figure of merit (ZT) attaining values over 1 [2]. The essential trio of low thermal conductivity, high electrical conductivity and high Seebeck coefficient is indeed fulfilled by this compound. Interstitial Zn in this case plays a very important part in creating disorder in the material and therefore in lowering the mean free path or velocity of the phonons. The framework structure is Zn3.6Sb3, with the additional Zn atoms distributed amongst three crystallographically unique sites. The potential for nanostructuring to reduce the lattice thermal conductivity has widely been accepted and has repeatedly been used to enhance thermoelectric efficiency [3, 4]. Nanostructuring reduces the thermal conductivity of a material by creating scattering centers for longer wavelength acoustic phonons otherwise difficult to scatter by Umklapp processes or point defects. Defects in materials also contribute to diffused scattering of phonons. Moreover, reducing the grain size induces more grain boundaries leading to more scattering centers. The improvement of ZT in the nanostructures has already been predicted and experimental evidence of nanostructuring is available [5]. Extended and planar defects such as dislocations and stacking faults on the other hand may reduce the thermal conductivity but are also detrimental to the electrical conductivity [6]. These along with point defects strongly affect the transport properties of semiconductors [7]. Static imperfections in the lattice can be an important source of phonon scattering, especially at low temperatures when ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim Original Paper Phys. Status Solidi A 208, No. 7 (2011) phonon–phonon scattering becomes very weak. Imperfections can take the form of impurities, mass fluctuations, point defects, dislocations, stacking fault, lattice disorder (glass or amorphous structures) and crystal grain boundaries [8]. At high temperatures large concentrations of lattice imperfections are required in order to produce significant effects above that of phonon–phonon scattering [9]. The introduction of irregularities in the lattice by alloying often brings about sufficient disorder to produce phonon scattering at high temperatures and is vital to the improvement of the performance of thermoelectric materials [10]. As mentioned above, b-Zn4Sb3 possesses a high density of Zn interstitials leading to significant scattering of short wavelength phonons [11]. Here we describe how additional structural disorder viz. nanostructures can be introduced through appropriate synthetic conditions and characterized by transmission electron microscopy (TEM). In this work we study the morphology and microstructure of b-Zn4Sb3 around stoechiometric synthesis compositions. We have also performed density functional theory (DFT) calculations and consequently discuss the observed nanoparticle phases with reference to these calculations and to the phase diagram in this paper. 2 Experimental 2.1 Synthesis The samples were prepared with a starting composition of 56.2, 56.5 and 57.2 at.% Zn and are called sample A, B, C, respectively. The elements were directly reacted in a fused-silica ampoule sealed under vacuum (105 Torr). The melt was heated for 8 h at 800 8C before being water quenched. The resulting ingot was ball milled for 4 h, hot pressed at 350 8C for 1 h. Fine homogenous powders were obtained by mechanical alloying under argon in a SPEX Mixer/Miller 8000 series mill for a total of 3 h. The powder was hot pressed under argon at 350 8C for 1 h. Finally, it was annealed without stress for 2 h at 350 8C. 2.2 Characterization The sample was characterized by X-ray diffraction to determine the crystal structure on a Philips XPERT MPD diffractometer operated at 45 kV and 40 mA. Scanning electron microscopy (SEM) images were recorded on a Quanta 200FEG, FEI. TEM studies were carried out on a JEM2010F disposing a point to point resolution of 1.9 Å. 2.3 Density functional theory Theoretical calculations based on DFT were performed to elucidate the atomic and energetic properties of the Zn4Sb3 phase. The Vienna ab initio Simulation Package (VASP) [12, 13], employing the projector augmented wave method [14] and the PBE generalized gradient approximation was used. A plane wave cut-off of 300 eV was used for the relaxations, while 500 eV was used for the total energy calculations. The k-point density was at least 0.25 Å1. Together with a criterion for self-consistence of 105 eV change of total energies we www.pss-a.com 1653 obtained relative energies with less than 1 meV error originating from numerical sources. Similarly, the forces were converged to less than 0.05 eV/Å. The relaxations allowed simultaneous changing of atomic positions, unit cell shape and cell size. 3 Results Table 1 recapitulates the various secondary phases as observed from X-ray diffraction studies. When an excess of Zn was used to synthesize Zn4Sb3 as is the case for sample C one observes a Zn metal impurity phase. For the sample prepared with a starting Zn:Sb ratio of 1.30 (sample B) no secondary phases were observed. For the sample with Zn:Sb starting ratio of 1.28 (sample A) a ZnSb secondary phase was detected. The Seebeck coefficient, thermal and electrical conductivity of all the three samples have been studied and the present study at hand will focus on the structural properties at the nano- and microscales [15]. Our discussion will be as follows: first the ideal case of Zn:Sb of 1.30 corresponding to a composition of Zn3.9Sb3will be presented (sample B) followed by the result of decreasing the Zn:Sb ratio (sample A). Finally, the effect of excess of Zn (sample C) on the microstructure during the synthesis will be shown and discussed. TEM and SEM analyses performed on sample B with a Zn:Sb ratio of 1.30 did not allow the detection of a secondary phase and subsequently confirms the XRD results. After checking for probable secondary phases using TEM, morphological characterization was carried out. Figure 1a is a low magnification TEM image of sample B with different shades of gray. The white spots on the image correspond to voids in the material with an average size of around 8 nm. The SEM image presented in Fig. 1b shows dark spots corresponding to larger voids at the microscale present in the sample. EDX (Fig. 1c) performed on one of the voids in the SEM image (Fig. 1b) gave no other element other than Zn and Sb. The elemental quantification performed estimated a Zn:Sb ratio of around 1.30. These voids were detected not only at the grain boundary but also within the grain. The higher magnification TEM image highlights the faceting of these voids in Fig. 1d. One reason for the formation of these voids could be an incomplete densification of the material when hot pressed after ball milling. Another explanation for the formation of these nanovoids could be related to the reabsorption of the Zn precipitates into the Zn4Sb3 matrix leaving behind an agglomeration of Zn vacancies. In fact, Zn precipitates into the b-Zn4Sb3 matrix when cooling down from melt with Zn:Sb ratios starting from 1.30 (see DFT section). The size of the precipitates is determined by the rate Table 1 Secondary phases as obtained from X-ray diffraction for the three samples observed [15]. Zn:Sb 1.280 (sample A) 1.300 (sample B) 1.360 (sample C) secondary phase ZnSb none Zn ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim solidi status physica pss a 1654 Figure 1 (online color at: www.pss-a.com) (a) TEM image of a Zn4Sb3 sample having Zn:Sb ratio of 1.30 (sample B). (b) SEM image of sample B. (c) EDX spectra performed in a void shown in (b). (d) Higher magnification TEM image of the voids. of quenching [16]. Moreover, on account of the retrograde solubility of Zn in the b phase, at some intermediate temperature the Zn is reintegrated into the matrix leaving behind voids [17]. In the case of sample A having a Zn:Sb ratio of 1.28, XRD detected a ZnSb second phase (Table 1). TEM analyses not only allowed the confirmation of this impurity phase but also the study of its morphology. The ZnSb secondary phase is present in nonnegligible quantities in sample A as a whole. Figure 2a shows the ZnSb nanoparticles whose average size is around 10 nm. A HRTEM image of a 16 nm ZnSb nanoparticle is shown in Fig. 2b. In the inset, the power spectrum confirms the ZnSb phase. The particle in this image is oriented along the h101i zone axis of the Pbca space group with lattice parameters a ¼ 6.20 Å, b ¼ 7.74 Å, and c ¼ 8.10 Å. SEM images recorded on sample C also confirm the presence of the second phase (lighter zones) (Fig. 2c). The EDX spectra (not shown here) confirmed the presence of only Zn and Sb with a ratio of 1:1. SEM study on sample C also pointed out to its rather high porosity (pores are black). The phase boundary between ZnSb and b-Zn4Sb3 was studied using HRTEM. Figure 2d exhibits a clean phase boundary without any amorphous phases. It was also characterized as being semi-coherent as a large number of misfit dislocations compensating for the lattice mismatch were observed. The b-Zn4Sb3 grain boundaries (not shown here) are also free of amorphous phases. The presence of crystal grain boundaries provides another possibility for phonon damping. As for the b-Zn4Sb3 sample C with a Zn:Sb ratio of 1.36, the X-ray spectra detected a second phase and further confirmed the secondary phase as a Zn impurity. The latter ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim P. Rauwel et al.: Nanostructuring in b-Zn4Sb3 Figure 2 (a) TEM images of ZnSb nanoparticles in sample C with a Zn:Sb ratio of 1.28, inset is the corresponding SAED of the nanoparticles. (b) High resolution image of a ZnSb nanoparticle. Inset shows the power spectrum of the nanoparticle. (c) SEM image sample C. (d) Phase boundary between a ZnSb grain and a b-Zn4Sb3 grain. crystallizes in the form of nanoparticles shown in Fig. 3a which is in accord with a recently published work [18]. Figure 3a is a TEM image taken from a crushed sample dispersed in ethanol and supported by a carbon grid. In this Figure 3 (online color at: www.pss-a.com) Sample A with Zn:Sb ratio of 1.36. (a) TEM image of sample A crushed. (b) Higher magnification image of (a). (c) Stacking faults. The a lattice parameter of the Zn4Sb3 phase is indicated (d) extended defects, dislocations. Black arrows point out to a few of the Zn metal nanoparticles. www.pss-a.com Original Paper Phys. Status Solidi A 208, No. 7 (2011) zone, nanosized Zn grains are protruding from the Zn4Sb3 micrometric grain. Figure 3b is a high magnification image consisting of isolated Zn nanoparticles. The TEM image highlights the faceting of the nanoparticles. The average size of the Zn metal particles is around 8 nm. In small grains, no defects were observed. Moreover, no impurities on the grain boundary nor at the triple point were observed. However in the ion milled sample large grains (200 mm) along with planar and extended defects were observed. In Fig. 3c two edge dislocations are observed. These two edge dislocations are numbered (1) and (2) in Fig. 3c. Edge dislocation (1) is characterized by an extra (010) plane inserted at ½ (120) whereas edge dislocation (2) is the result of an extra (100) plane inserted at ½ (1–20). The glide planes of both dislocations are at 608 to each other. Extended defects were also observed in the sample. Figure 3d is one such example of dislocations in the Zn4Sb3 sample containing an excess of the Zn element. Transmission electron microscopy specimens were prepared in two ways for this study. The first method consisted of crushing the bulk sample and mixing the powder in ethanol with the help of an ultrasonic bath. A drop of the suspension was then placed on a holey carbon grid for observation. The second method required mechanical thinning of the sample followed by ion milling to obtain electron transparency. TEM observations on both samples gave the same morphology. Nanostructuring was observed irrespective of the TEM sample preparation technique. Ion beam thinning induces local heating and is a source of artifacts in TEM observations as reported by Lensch-Falk et al. [19]. They observe nanoparticles of Ag2Te precipitates in thermoelectric PbTe due to ion milling and have attributed it to the high mobility of Ag due to local heating. This is an important point for the b-Zn4Sb3 sample with a Zn:Sb ¼ 1.36 1655 containing Zn nanoparticles as Zn has a very high mobility in this material and can form Zn clusters [20]. In our case, since we have used both techniques, we can safely eliminate the contribution of artifacts. In our study, nanoparticle morphology was observed and size distribution histograms were plotted for the crushed samples while observation of defects and grain boundaries were carried out on ion-milled samples. Scanning electron microscopy images acquired point out to the presence of Zn in Fig. 4a. The dark spots correspond to the Zn metal. Various EDX spectra were acquired and quantified from various zones of Fig. 4a. Zone 1 is a Zn precipitate free zone and the corresponding EDX spectra after quantification indicates that it is indeed Zn4Sb3 (Fig. 4c). Zones 2 and 3 are the ones with Zn impurities and their corresponding EDX spectra show the presence of Zn along with negligible amounts of Sb (Fig. 4b and d). The average size of the Zn precipitates at this scale is about 1 mm. The ground state thermodynamic stability of the Zn4Sb3 phase was assessed by DFT calculations. The Zn content was varied by changing the amount of interstitial Zn in the atomistic models. No interstitial Zn corresponds to a Zn:Sb ratio of 1.2; then only the crystallographic Zn1 site is occupied. Higher Zn concentrations were achieved by filling the interstitial sites Zn2, Zn3, and Zn4 introduced in the experimental study by Snyder et al. [1]. Combinations of two interstitial sites along with a Zn1 vacancy were also investigated, and it was found that such defect clusters represented the most stable configurations. The resulting energetic of interstitial Zn formation (compared to Zn6Sb5 and pure Zn) is shown in Fig. 5. It is evident that interstitial Zn is thermodynamically stable below a Zn:Sb ratio of approximately 1.32, while it is unstable above this ratio. There also seems to be a thermodynamic minimum around Figure 4 (online color at: www.pss-a.com) SEM study on sample A with Zn:Sb ratio of 1.36 (a) SEM image, (b) EDX from zone 3, (c) EDX from zone 1 (d) and EDX from zone 2. www.pss-a.com ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim solidi status physica pss a 1656 Figure 5 (online color at: www.pss-a.com) The ground state thermodynamic stability of Zn4Sb3 with respect to decomposition to the model without interstitial Zn (with a Zn:Sb ratio of 1.2) and pure Zn. Several different possibilities of including the Zn were tested, using combinations of the crystallographic interstitial sites Zn2, Zn3, and Zn4 [1] as well as clusters of Zn vacancies and interstitial sites (see text for details). The dashed curve is drawn as a guide to the eye only, and has been fitted to the lowest energy (most stable) models. A positive DH (above the dashed line) implies that the phase is unstable with respect to pure Zn and Zn6Sb5. the Zn:Sb ratio 1.27; however since the curve is rather flat at the bottom and since there are many sources of error, the safest conclusions that one can draw from the shape of the curve in Fig. 5 is that the ratios between 1.23 and 1.30 are the most stable from the theoretical point of view. This suggests that when the Zn:Sb ratio at the starting point is larger than 1.30 one should expect a mixture of Zn and Zn4Sb3 from the calculations. On the low side of the Zn:Sb ratio (<1.23), there seems to be on the other hand a thermodynamic driving force for the formation of additional interstitial Zn, moving towards a Zn4Sb3 phase with a Zn:Sb ratio of 1.23. This must be accompanied by the formation of ZnSb in order to balance the reaction. It should be mentioned here that additional calculations (not shown here) demonstrate that all the Zn4Sb3 phases are unstable with respect to decomposition into ZnSb and Zn at 0 K, similar to what was previously predicted for models Zn13Sb10 (Zn:Sb ¼ 1.3) and Zn6Sb5 (Zn:Sb ¼ 1.2) by Mikhaylushkin et al. [21]. All these calculations neglect temperature and entropy, which are most probably the main reasons for stability of Zn4Sb3 in this region of the phase diagram. Nevertheless, these results can be seen as a rationalization for the formation of ZnSb phase at low ZnSb ratios and for the formation of Zn at higher ratios. The calculations predict that the Zn4Sb3 phase should exhibit a range of Zn:Sb ratios, tentatively between 1.23 and 1.30. One can expect significant changes in this region on including in the calculations parameters such as temperature, entropy, increase of unit cell size, etc. 4 Discussion The three samples being investigated have compositions corresponding to 56.2, 56.5, and 57.2 at.% Zn. The final heat treatment was at 350 8C under the limit of creation of high temperature Zn4Sb3 phases. Our ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim P. Rauwel et al.: Nanostructuring in b-Zn4Sb3 study shows that the crystallization of phases in the samples are heavily dependant on the starting Zn:Sb ratio. In fact, for a low Zn:Sb ratio (Zn:Sb < 1.30), i.e., 56.2 at.% Zn, we observe a phase separation and the presence of ZnSb embedded in the Zn4Sb3 matrix. This is consistent with the DFT calculations. Moreover, Zn4Sb3 remains stable for a Zn:Sb ratio of 1.30 where no splitting of phases is visible. However, an increase in the Zn:Sb ratio to 1.36 induces a phase separation or in other words the nanocrystallization of Zn particles. This observation is supported by DFT calculations where one predicts a Zn metal phase separation for Zn:Sb ratios exceeding 1.32. The study therefore indicates that no phase separation should occur between Zn:Sb ratios of 1.30:1.32. Pedersen et al. [22] have also observed this phase separation on substituting Zn with Hg. However in their study along with Zn and ZnSb precipitates they also observe Hg precipitates at the micrometer scale due to the limited solubility of Hg in the b-Zn4Sb3 structure. With respect to the phase diagram [23], the presence of a ZnSb secondary phase in sample A for a starting Zn:Sb ratio of 1.28 puts it to the left hand side of the single phase field. For the Zn:Sb ratio of 1.30 (sample B) where no second phase was detected, places the material in the single phase field. Lastly, with regards to sample C with a Zn:Sb ratio of 1.36 where Zn impurity is present in nonnegligible quantities, one would position it on the right hand side of the single phase field of the Zn–Sb phase diagram. The morphology of the three samples as observed on the SEM images was also different. Sample A possesses the highest porosity among the 3. Sample compactness has known to affect the thermopower of Zn4Sb3 [24]. The nanosized secondary phases and voids present in the TEM images also have microsized counterparts present in the SEM images. The precipitation of the secondary phases starts with small agglomerates of Zn or ZnSb atoms in the early stages giving rise to nanometric size precipitates. Over time the nanometric precipitates grow and coalesce to form micrometric precipitates. For the first time we have demonstrated that the phase separation in Zn4Sb3 not only occurs at the microscale but also at the nanoscale in the form of nanovoids, ZnSb, or Zn nanoparticles as a function of the Zn:Sb starting ratio. The thermoelectric performance of the Zn4Sb3 containing nanostructures has already been published. For a Zn:Sb starting ratio of 1.36 an excess of Zn not only induces a Zn secondary phase but also extended defects in the sample. Moreover, both the ZnSb and Zn secondary phases are highly crystalline. The grain boundaries and phase boundaries observed in this study are semi-coherent and highly crystalline. 5 Conclusion In conclusion three different Zn concentrations were studied (56.2, 56.5, and 57.2 at.% Zn). TEM studies showed that for different starting Zn concentrations secondary phases and nanovoids appear during the synthesis of Zn4Sb3. The presence of these secondary phases such as ZnSb and Zn with varying Zn concentrations are also www.pss-a.com Original Paper Phys. Status Solidi A 208, No. 7 (2011) predicted by DFT calculations. The electron microscopy studies also demonstrated that phase separation was not only occurring at the micrometer scale but also at the nanometer scale with the self-insertion of these nanoparticles or nanovoids within the Zn4Sb3 matrix. Acknowledgements Ole Bjørn Karlsen is thanked for fruitful discussions. The Norwegian Research Council and Marie Curie-PERG05-GA-2009-249243 are thanked for financial support. References [1] G. J. Snyder, M. Christensen, E. Nishibori, T. Caillat, and B. B. Iversen, Nature Mater. 3, 458–463 (2004). [2] T. Caillat, J. P. Fleurial, and A. Borshchevsky, J. Phys. Chem. Solids 58, 1119–1125 (1997). [3] L. D. Hicks and M. S. Dresselhaus, Phys. Rev. B 47, 16631– 16634 (1993). [4] L. D. Hicks, T. C. Harman, X. Sun, and M. S. Dresselhaus, Phys. Rev. B 53, 10493–10496 (1996). [5] A. l. Guéguen, P. F. P. Poudeu, C.-P. Li, S. Moses, C. Uher, J. He, V. Dravid, K. M. Paraskevopoulos, and M. G. Kanatzidis, Chem. Mater. 21, 1683–1694 (2009). [6] N. Peranio, O. Eibl, and J. Nurnus, J. Appl. Phys. 100, 114306–114310 (2006). [7] R. Berman, in: Thermal Conduction in Solids (Clarendon Press, Oxford, 1976). [8] D. L. Medlin and G. J. Snyder, Curr. Opin. Colloid Interface Sci. 14, 226–235 (2009). [9] A. F. May, E. Flage-Larsen, and G. J. Snyder, Phys. Rev. B 81, 125205–125211 (2010). www.pss-a.com 1657 [10] N. Mingo, D. Hauser, N. P. Kobayashi, M. Plissonnier, and A. Shakouri, Nano Lett. 9, 711–715 (2009). [11] C. J. Vineis, A. Shakouri, A. Majumdar, and M. G. Kanatzidis, Adv. Mater. 22, 3970–3980 (2010). [12] G. Kresse and J. Hafner, Phys. Rev. B 47, 558–561 (1993). [13] G. Kresse and J. Furthmüller, Phys. Rev. B 54, 11169–11186 (1996). [14] G. Kresse and D. Joubert, Phys. Rev. B 59, 1758–1775 (1999). [15] E. S. Toberer, P. Rauwel, S. Gariel, J. Tafto, and G. Jeffrey Snyder, J. Mater. Chem. 20, 9877–9885 (2010). [16] T. Ikeda, V. A. Ravi, and G. J. Snyder, Acta Mater. 57, 666– 672 (2009). [17] G. Pomrehn, E. S. Toberer, G. J. Snyder, and A. Van de Walle, Phys. Rev. B 83, 094106–094111 (2011). [18] O. Prytz, A. E. Gunnaes, O. B. Karlsen, T. H. Breivik, E. S. Toberer, G. J. Snyder, and J. Tafto, Phil. Mag. Lett. 89, 362– 369 (2009). [19] J. L. Lensch-Falk, J. D. Sugar, M. A. Hekmaty, and D. L. Medlin, J. Alloys. Compd. 504, 37–44 (2010). [20] E. Chalfin, H. X. Lu, and R. Dieckmann, Solid State Ion. 178, 447–456 (2007). [21] A. S. Mikhaylushkin, J. Nylen, and U. Haussermann, Chem. Eur. J. 11, 4912–4920 (2005). [22] B. L. Pedersen, H. Birkedal, E. Nishibori, A. Bentien, M. Sakata, M. Nygren, P. T. Frederiksen, and B. B. Iversen, Chem. Mater. 19, 6304–6311 (2007). [23] X. J. Liu, C. P. Wang, I. Ohnuma, R. Kainuma, and K. Ishida, J. Phase Equilib. 21, 432–442 (2000). [24] B. L. Pedersen, H. Birkedal, B. B. Iversen, M. Nygren, and P. T. Frederiksen, Appl. Phys. Lett. 89, 242108–242110 (2006). ß 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim