Field Niotes INFORMATION SYSTEM

advertisement

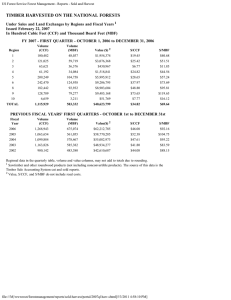

ENGINEERING TECHNICAL FIELD NOTES DATA INFORMATION TECHNICAL RETRIEVAL PROFESSIONAL REPORTS MANAGEMENT DEVELOPMENT SYSTEM VOLUME Field Concrete Method the HP 9 NUMBER 7 Niotes Bridge 1 of Marking Boundarytines Using 25 Calculator Minimum-CastNetwork Design 1 Timber Transport Washington FOREST SERVICE JULY 1977 R5T US - ýnnra.cRGý U.S. DEPARTMENT OF AGRICULTURE UýS ENGINEERING FIELD NOTES Volume Information 9 Number 7 has been developed for guidance of employees publication its and its Department of Agriculture-Forest Service contractors and State agencies. The Department of Agriculture assumes no contained this respon-sibility of the United cooperating in States Federal for the interpretation or use The of trade firm or use convenience of any The that or service may be text in the by as FSM or policy except engineers and engineering not intended in this publication by the United States is official its own employees. for the information and endorsement or approval Department of Agriculture to the exclusion suitable. publication must not be construed names corporation by other than Such use does not constitute an of the reader. product of others of this information exclusively the represents recommended personal Because references. technicians opinions or approved should of the respective procedures of the type read each of material in the publication issue however for engineers. FOREST SERVICE U.S. DEPARTMENT OF AGRICULTURE Washington D.C. mandatory author and instructions 20013 this publication all is TO READERS OF INVITATION FIELD NOTES reader Every author potential a is of an article for Field Notes. If you have news a item or accu-rate short you would article publication Material in Field submitted to share with like we Service engineers you invite to send it for Notes. the to Washington Office publication for be reviewed should by the Washing-ton respective Office Regional and of informative may material submitted however short articles Field Notes is the list ask number of Washington Each all to 7113. material submitted All be should illustrations The length to original of pages typewritten several the drawings or photos. Forests your Office copies FSM sentences items are preferred. double-spaced timely technically current and Forest Manager Office directly Service retirees. or the sent to your office. Regional to are Information Copies of back issues Regional Station all you If not currently Coordinator are also and on the to increase available from the Office. Region questions short several is Service-wide engineers distributed from the Washington Area Headquarters mailing vary the information to from or news and white black interest be typed Office should glossy to see that has an Information Coordinator and material for publication. The whom to Coordinators R-1 Bill McCabe R-4 Ted R-2 Royal M. Ryser R-5 Jim McCoy R-3 Bill R-6 Kjell R-8 Bob Bowers Coordinators Strohschein should direct questions Bakke concerning Forest Engineering Staff Telephone L. D.C. should submit both Smith R-9 Norbert R-10 Frank Muchmore WO Al Colley format editing publishing dates and other Service Attn Gordon P.O. Box 2417 Washington personnel are Wood problems to USDA field Rm. 1108 RP-E Rome or Rita E. Wright 20013 Area Code 703-235-8198 CONCRETE TINKER TOY BRIDGE Ed Larson Staff Engineer Region 5 A road crossing on Eltapom Creek Shasta-Trinity NF was selected for a Because of the unique type of prefabricated concrete bridge figure 1. Forest Service traditional concept that timber purchaser-built bridges must be of a type to allow construction by loggers and bridge builders the R-5 Engineering Structures Section designed concrete sections. Figure 1. a concrete bridge composed of precast The EZtapom Bridge Shasta-Trinity showing the completed bridge. NF The basic design objective was to provide a durable and economical logging road crossing that would be easier for a purchaser to construct than our The original concept used a familiar treated-timber Tinker Toy bridges. modified concrete crib wall in the configuration of a rectangle with the long The superstructure was parallel to the stream for the abutments. deck 32 feet 1.2192 prestressed panels 10.354 long and 4 feet precast wide. Four panels were placed side by side with 12-inch 30.45 cm precast curbs bolted to the top of the exterior panels leaving a minimum 14-foot Cast-on-site 4.267 roadway as shown in cross section figure 2. was specified to form a bearing seat for the deck panels and to help con-crete sides m m 1 m /6 O 0 4Orya 5/-741 Unit. 7O E/. /off TL2 99723 /Z Weariny SUýfdce ýVrnrn. 9e E ýPcrýd in-cluded Figure 2. A cross section of the bridge at the center of the span. It was realized that this design as abutment units together. was not the ultimate design. the timber sale contract However and obtainable from concrete to be functional was judged readily precast tie the in it suppliers. Hilfiker Pipe Company of Eureka California was contacted by the Timber The Purchaser to furnish precast components for the Forest Service design. of had a wall Hilfiker Company recently developed retaining system precast concrete facial sections with dead-men anchorage into the embankment. They proposed to modify the Forest Service abutment design using special footing blocks and abutment and wingwall sections similar to their anchor wall facial sections. All members including the superstructure were fastened This scheme together with tie rods placed through inserts cast in the units. the eliminated all need for casting concrete at site. and trucked Fabrication was done at the Hilfiker plant at Eureka California work Site for the substructure was performed by a three-man to the jobsite. A Massey Fergueson 80 Backhoe Loader crew one operator and two laborers. The precast concrete foundation and abutment was used for the excavation. panels were placed with an Austin Western 410 Senior Hydraulic Crane having a 60-foot 18.288 boom figure 3. Backfilling was done with the Massey Fergueson and was compacted with Wacker Tampers. m m The prestressed deck panels were delivered to the job on 40-foot 12.172 in semi-trailers. Mr. Hilfiker has indicated that he will use logging trucks Each panel 4 feet 1.2192 wide the future to increase maneuverability. and 32 feet 9.754 long weighed 19400 pounds 8801.84 kg. They were 18144 kg capacity placed with an Austin Western Crane and a 40000-pound m m 2 Lima shovel mounted on rubber m a 24-foot 7.315 the deck panels. tires and for loading logs. A five-man crew placed were the shovel operator and oiler. heal boom set up The two extra men 4 Figure 3. Abutment of placement. panels were in place the three-man crew placed the curbs on tightened all bolts. and grouted deck keys and bolt holes figure Total field erection time for the project was 2 weeks. Prior to logging 4. traffic use an asphalt leveling and wearing surface is to be placed on the After the the deck deck deck. Figure 4. The completed bridge 3 facing upstream north. intends to restrict use of design to the 30- or 40-foot respectively We are span range for the present. construction costs at 85 estimating percent of conventional treated timber Region 5 9.144 m and 12.192 m this designs. 4 A METHOD LINES BOUNDARY CALCULATOR MARKING THE HP 25 OF USING Dennis Moonier Stanislaus National Forest Region 5 INTRODUCTION calcu-lator. note-keepers with a procedure to accomplish cadastral surveys by using the HP 25 or HP 25C electronic pocket programmable The HP 25 and HP 25C are basically the same instrument except for This continuous memory the continuous memory capability of the HP 25C. capability offers the advantage of being able to turn the calculator off This means and on and still retain the program and memory information. 1 that the traverse can be computed as outlined in steps through 5 in the calculator procedure while the traverse is being run as part of the This is a discussion concerned normal responsibilities. Although the procedure is designed specifically for the HP 25 and HP 25C it can be adapted for use with any whether programmable or not. calculator The advent of the pocket calculator has provided a tool for the surveyor to use with survey methods of establishing straight lines that have previously involved long and cumbersome office calculations--calculations that can now This gives the surveyor more be done easily by the surveyor in the field. latitude in determining the survey method used to accomplish a task the fastest easiest and most accurate way possible. BASIC CONCEPT The task to be accomplished is getting a true ground between two land monuments. There are 1. 2. basically two ways to line accomplish the established on the task Run a straight random line on a predetermined bearing and then correct to the true line by the amount of error in the random line and run the corrected bearing back or Traverse an irregular course between the two points and inverse the true line bearing and distance. Offsets from the traverse the line then be calculated. to true can angle points 5 In the easiest and most economical method is the traverse method natural and man-made obstructions can easily be circulvented. general because PROCEDURE Refer to the diagram figure Y FOR THE TRAVERSE METHOD 1 F 5.80 505.57 208.00 I Ft. 92 53 17 E II 143.00 a D I 37 24718 95.00 B N Ft. Ft. Offset distance C I 138 26 12 100.00 1025 151 Solar 140 00 Ft. B I 00 100 Ft. point Azi 265 00 00 X A 0 Bearing axis Note 1 2 Figure 1. of True Line-amount the Y must be rotated to compute These relationships of the circle Diagram not to offsets hold true for any quadrant scale Diagram for traverse method. 6 1. line 2. at or near point A and point A is computer. A solar observation point solar the is taken to azimuth of be-come B C D E F Angles and distances aia measured to each point The traverse points should be set along the along the traverse. general direction of the true line taking advantage of the easiest Care must be taken however not to routes for lines of sight. vary too much from the true line as the offset distances can too difficult with which to work. The terrain and vegetation of the area will control this aspect of the job as well as the distances between traverse points. Heavy brush or timber with steep varying slopes will tend to demand short distances between traverse points and small offset distances. Open country with gentle slopes will allow long distances between traverse points and larger offset distances. With experience the will learn to determine the best traverse course. survey crew Coordinates 0.00 0.00 coordinates are computed are B 4. The bearing and of 5. In 3. for established at point A and each successive point then C D E F. bear-ing distance the true line can now be calculated. order to calculate the offsets to the true line from the traverse line all you need to do is rotate the Y axis to the of the true line and recalculate the coordinated of each The X coordinate then becomes the offset distance. traverse point. CALCULATOR PROCEDURE Note 1. This procedure is for use with a HP 25 calculator. For use with other calculators variations will need to be applied. See figures 2 and 3. 2. All angles are input 3. Refer to HP 4. Letters in parentheses represent calculator means recall memory register number 7. 25 as station angles measured to the program form enclosed 7 Program HP 25 or HP 25C calculator and then switch PRGM. 1. for programming right. key strokes. key strokes i.e.. to RUN mode--press Rcl f Input and store azimuth of beginning solar--solar point to point A is the correct direction. Variations can be made if the solar is Press not taken along this line. --H and sto 1.. G 7 HP-25 Program Form Offsets Title Switch to PRGM mode DISPLAY 5 02 g then key PRGM lines boundary Y . 00 01 Q press posting KEY ENTRY CODE LINE marking and for in Page Z T COMMENTS mAl R1C Azimuth 05 00 06 51 4 0 B 01 1 3 10 14 15 R/S 09 f- 1 A AB Y coord D R 25 12 14 Sto 74 3 00 40 4 07 Y Gto 00 Rc 4 Rc 77 17 06 g 18 32 19 74 C R ZAB X coord Y coord E X coor coor F X coon Y coor X coor Y coor X coord tan R3 A coord.V R coord Y X R Y coord CHS -R Y coord F X coor R/S C 5 00 -. H 21 51 22 31 Enter 23 4 33 f 24 3 01 S 1 25 3 00 GTO 00 27 28 - Re R 5 6 -R C R C R Y AC - R -R C 4 coord coor C-26 20 2 coord coor X F 71 16 A B AZ 1 ve A A O8 13 REGISTERS 4 31 04 09 2 R o 03 07 of the program. C - 1 coord - R f X coor Y coor R coor 7 R - - R C ----- -- -- - - NOTES 29 30 A Traverse B 1800 C Beginning D Traverse Angles 31 32 33 34 Solar 35 36 Distance 37 AZ 38 Azimuth of Traverse 39 Line 40 R 41 Bearing line 42 43 44 45 46 47 48 49 HEWLETT Figure 2. HP-25 PACKARD Program Form 8 front side. of true HP-25 Program Form Title Offsets for Dennis Programmer STEP marking and Moonier - in Key 2 Store 3 Inpt 4 Input 5 Record X coordinate 6 Record Y coordinate 7 Re eat steps Program as many times solar Azi to Angle Traverse Feet 4 5 Compute boundary lines 6 as USFS 0 IIII 0 u 00 000 II 0 00 ii 0 00 u rý 0 II0 00 0 0 0 Gý II rý 0 0 II-ýO 0 0 0 000 0 0 00 00 00 0 000 0000 00 0 000 0 00 00 000 00 00 000 0000 000 000 10 ecord 11 Input R/S Decimal R/S enTreesoma Rcl X-coord 12 Repeat 13 ecord e Y-nonrd Rcl Rcl IP/ý Bearing Bearing z 0 stes34 offsets Figure of IlIII__X -J distance Solar 2 L-l-I N LýJ Compute of OUTPUT DATA/UNITS KEYS Sto 9 2 Page NF - distance -napdad 8 INPUT DATA/UNITS INSTRUCTIONS 1 posting Stanislaus Distance HMS -1 0 Bgearing H Decimal IIýýI X-coord 3. HP-25 Program Form 9 back side. of 2. 3. Input angle to the right to the traverse line. The Press R/S. display is the cumulative azimuth. For the actual azimuth of the line subtract as many 360 as possible. This information may or may not be desired. Press R/S. Input distance. Display is the number of entries that have been put into the registers. The cumulative X and Y coordinates of the traverse point can be manually recalled. Press and the X coordinate is displayed. Rcl Press Rcl and the Y coordinate is displayed. 4 4. To get 7 to the ending station repeat steps 2 and 3 as often as necessary. 5. You are now ready to compute the distance between the beginning and ending points of the traverse. The following method is only one of the many possible ways to obtain the distance and employs the use of the Pythagorean x2 theorem i.e. R2 y2. Press 4 sto 6 Rcl 7 G x2 Rcl 6 Rcl g x2 V X coordinate on paper Record Y coordinate on X from the beginning to ending station. Note The signs of the X and Y coordinates quadrant the bearing of the true line is. X paper _ distance Display is the Record will tell you in what Y NE - SE SW NW - - _ 1 4 line--press GTO R/S. line in decimals of Display bearing degrees so convert to degrees minutes and seconds by pressing Record the bearing. H.MS. Press -.H to convert back to decimals of degrees. To obtain the bearing of is the of the true the true f G - 6. - Note Disregard the sign there only for calculator displayed with the See manipulation. form. 10 bearing since line 18 of it program is The following steps pertain to getting the offset distances. the beginning solar azimuth in the same manner as step 1. Input Press R/S. Display is the solar azimuth algebraically added to the rotation of the Y axis. 7. 2 Repeat steps 3 and 4 and record on paper the coordinate each traverse point. The X coordinate is the offset distance the traverse point to the true line. 8. at from OFFSET PROCEDURE coord-inate the offsets should be staked while convenience and less confusion traveling in the same direction as the traverse was run. For true line is in any northerly direction NE or NW a positive means to offset to the left and a negative coordinate means to offset to the right--on a bearing that is perpendicular to the bearing of the true line. If the true line is in any southerly direction SE or SW a positive coordinate means.to offset to the right and a negative coordinate means to offset to the left--on a bearing that is perpendicular to the bearing of the true line. If the equipment used to set the offsets will vary from a cloth tape and land compass to a steel chain or EDME and transit or theodelite depending on the offset distance terrain and vegetation. The Example see figure 4 cal-culator. Azimuth of line point A to solar 850000. 1800000 Refer to step PI A B C 1 1400000 1511025 1382612 Coordinates of PI F Offsets to true PI ft. D 100.00 ft. E 95.00 ft. F X 5.80 Y N 505.60 2471837 925317 - the 143.00 ft. 208.00 ft. line 0.00 ft. D 54.93 ft. ft. E 149.24 ft. C 96.65 ft. F 0.00 ft. the into feet 69.89 of input 505.57 B left 2650000 03927E A The offsets are the 2650000 100.00 A to F A to F Bearing of line Distance of line is point 850000 must be Therefore of Calculator Procedure. the positive therefore random line on a bearing 11 offset to the of N true 892033W. line is to -TRAVERSE _ _ FOREST T Stanislaus R. STATION M FILE No. CASE NAME DIRECTION - FORM 7150 Cadastral Proposed PAGE Surveys Article for BY Field Notes N 4q N 16 _M 10 nn 25 _L E N 25 23 23 N 41 55 131E 143.00 N 45 11 30 208.00 W F Bearing Distance Corrected of o line A line to A 34 E EAST X 0.00 0.00 70.71 70.71 166.75 98.56 252-A S7-83 to N F 0 39 7 358.98 153.37 505.57 5.80 E 505.60 Offset earings A 20 1977 95.00 E 44 30 1 100.00 D N Y OF Moonier 100.00 C W March DATE NORTH DISTANCE A B 1 Dennis u.uu 0.00 71.52 69.89 100.00 B N 15 30 59 E 100.00 N 26 02 49 W 95.00 N 41 15 47 E 143.00 N 45 50 56 W 208.00 C D E F Figure 4.. 9f 253.22 54.93 360.72 149.24 505.60 0.00 An example traverse form. 12 6 168.87 - Dist MINIMUM-COST NETWORK Peter DESIGN FOR Wong T.A.G. WaZZy TIMBER TRANSPORT Cox Shasta-Trinity NF I. INTRODUCTION Transportation planners at National Forests are faced with determining the Timber transport is composed least cost road system for timber transport. of two elements the path from the sale to the mill and the path from the When it is planned that existing roads be mill to the appraisal point. then used with no reconstruction or construction calculating the least cost path from each sale through a mill to the appraisal point would result When road projects are under in the most economic use of the network. construction cost and reduction the trade-off between analysis consideration in haul cost due to road construction for all timber sales can become based on a network mind boggling. In this paper a case study is presented model proposed by Dr. Malcolm Kirby for analysis program transshipment The transshipment model is being this minimum-cost design problem. solving If so it will tested to assure that it is useful for field operations. This model will handle a larger then be developed for implementation. network than the timber travel model and this paper illustrates what the analysis would do. II. STATEMENT OF THE PROBLEM The problem is to maximize the net value lumber value at appraisal points less all costs subject to satisfying a given total lumber demand where the material is transported on a proposed road network first as logs and The intended network then as lumber after being processed at the mills. and roads. Flow on the network is proposed may include both existing the of An truck is assumed to take measured in MBF logs and lumber. empty of loaded The include the truck. costs hauling logging opposite path and construction costs if lumber manufacturing environmental protection proposed roads are selected. Hauling cost includes the road maintenance fee. Also one standard of road is used and a single time period is assumed. Kirby Malcolm A Transshipment Model for Timber Transportation Planning First Draft Management Sciences Staff PSW U.S. Forest Service Berkeley California January 1977. 13 III. INPUT TO THE MODEL Shasta-Trinity Transshipment model is applied to a transportation system planning problem for a timber compartment analysis at the Big Bar District of the National Forest. long-span and helicopter logging Short-span considered for that area. Each logging system would are being systems entail a slightly different road system due to different locations of timber landing and geometric requirements for handling various sizes of The feasibility of combining the three logging systems is being equipment. studied. For simplicity only the network design problem for helicopter All timber available is to be harvested in the same logging is presented. time period. The road system under consideration is shown figure 1. Timber volume of are available at helicopter There are three mills and road construction and in 5511 MBF 4430 MBF 1585 MBF and 10375 MBF landing nodes 18 19 22 and 28 respectively. recon-struction two The cost of the seven appraisal points. projects are described in table 1. 1.--Construction Table projects Cost$ Between nodes Project a 12 b 17 c 17 d 19 e 24 f 21 g 21 ýý--ý ý- 4900 19 18 2800 24 440050 ý-ý--- - and costs 21 148500 28 115400 24 64700 22 184150 protec-tion elements included in the analysis are logging environmental timber value at appraisal log and lumber hauling mill manufacturing points and road construction and maintenance. These costs are summarized and 3. in tables Hauling plus maintenance cost for link i-.j represents the round trip cost of a loaded truck going from i-.-j and an -i. empty truck from j Cost 1 2 Table Logging 2.--Cost elements $70/MBF cost $10/MBF LEnvironmental protection Mill $60/MBF manufacturing Timber $170/MBF value 14 p MBF 10375 Mill Burnt Ranch 28 10 i 5 2 42 40 39 O 41 6 35 11 33 17 34 M.-38 - 36 34 37 Appraisal 1/ 3 32 31 29 Pt. Arcata 88 30 44 4 43 9 7 f 2110 b 551 --- 12 i T 1 MBF 14 % ---- 8 gy 1 1585 W- 13 --- 22 28 15 19 4430 25 26 MBF 12 O MBF 16 17 Ln 18 O 31 23 21 Mill Mill Hyampon Hayfork 24 22 20 12 Directional Link from 30 12 ý 12 --E-.-p a ý Link No. 35 Project Appraisal a No. 19 landing with 4430 MBF MBF Figure 1. Pt. Redding 19 Helicopter 4430 8 30 Construction Node 19 to 19 Schematic network for helicopter Logging. Table 3.--Network Round Link From No. node 1 28 2 10 3 24 4 17 5 24 6 28 7 To Haul node Log -y -- Round cost Lumber Link From To No. node node 5.301 1.044 23 28 5.301 1.044 24 7 17 11.616 5.022 25 8 10.332 4.641 26 7 2.761 1.238 27 19 24 3.797 1.537 28 12 -- 28 cost $/MBF maint. 10 24 -i trip maintenance haul 31 -. -- - Haul trip $/MBF Maint. cost Log Lumber 13.459 2.829 14.122 3.249 7 18.629 8.434 8 21.145 9.166 7 31 12 8.011 3.503 19 7.361 3.336 12 0.869 0.381 8 0.822 0.371 28 1 4.830 0.951 29 8 1 28 4.830 0.951 30 12 9 24 21 1.897 0.830 31 11 12 1.882 0.818 24 1.746 0.789 32 12 11 1.738 0.762 22 3.789 1.694 33 17 11 2.805 1.237 21 4.493 1.869 34 11 17 2.670 1.207 21 3.770 1.698 35 11 8.216 3.712 19 5.015 2.069 36 9 9.408 4.088 0.995 0.228 37 8 5.106 2.288 1.177 0.267 38 9 10 21 11 21 12 22 13 19 14 21 15 22 16 --ý 1 22 1 - 33 17.670 3.480 39 9 1 17.670 3.480 40 10 27.978 5.510 41 34 27.978 5.510 42 10 14.670 3.200 43 17 14.196 2.891 44 18 17 1 18 33 19 33 20 35 21 33 -- 31 22 31 --ý 33 35 -- 33 IV. Traffic 8 -. -ý -- 9 11 -- - 9 8 7.507 2.955 10 3.816 1.800 -ý 9 4.704 2.044 --- 10 31.983 6.299 34 31.983 6.299 - 18 3.081 1.392 17 3.081 1.392 MATHEMATICAL LOGIC to flow over Haul cost is considered the any set of links. and the costs any length of road having the same characteristics of loading and unloading are treated as separate factors. The logic is based on the conservation of flow that is the total amount of timber same is free for flowing into conservation a node of from a harvest must equal the amount of timber flowing out. This flow principle also is used to evaluate total timber moving node through a mill node and to an appraisal node. main-tenance objective of this analysis is to delineate routes and construction projects where net value is maximized after costs of haul and road and construction are subtracted. The 16 A further explanation of the mathematical formulation is given in Section VII - MATHEMATICAL FORMULATION APPENDIX at the end of this paper. RESULTS V. OF ANALYSIS From figure 1 we can see that there are numerous ways of transporting the Even for this small problem log from each sale via the mills to the market. The result from the hand be analysis by time-consuming. doing may quite model is shown on the analyses using transshipment computer prototype should be 2. It shows that and b a 124 l9 figure projects implemented. sale but only The output the 17-l8 does log and not lumber explicitly give the paths used by each volume on each link. However the user would not usually have much difficulty in determining the paths from the The paths for this case study are shown in table 4. All link volumes. As far as timber was transported via mill node 10 to appraisal point 34. the net value of the solution is concerned it does not matter which paths used the timber the timber volumes on the links are sales provided by for this case with the solution. A of the cost breakdown agree summary is in. table 5. It shows that the minimum cost road study given by using the timber available has a net value of $263540. system Table Sale Sale to 18 18 19 19 22 22 28 28 4.--Selected paths mill Mill -17 -11 --a- 12 -.8 -P-9 -ý10 -12 -8 -9 -10 -1 -28 -10 --10 Table Hauling Lumber Hauling Road cost protection 34 10 34 10 34 - 1533100 219010 247800 - 1314100 137950 7700 cost log manufacturing cost 34 10 $3723200 cost Environmental 10 point 5.--Solution cost breakdown Timber value Logging to appraisal cost lumber construction Net value Once 263540 one can readily perform the data for the problem are established For sensitivity analyses to reflect the uncertainties in the input values. example we can check the stability of the solution if some of the road project costs or timber volume available are changed. 17 Mill Burnt Ranch 10375 MBF 10 11960 26 m 11 5511 17 b co 18 cn 34 5511 5511 MBF 22 a -----E------------Arcata p Appraisal Pt. 9941 4430 12 1 g 4430 MBF 00 21901 Lumber volume direction 34 10 9941 0 12 Log volume direction a Selected MBF in of loaded truck MBF in of loaded truck road construction project a 19 Figure 2. Minimum-cost network. 58s M8F O The mixed integer mode of the Functional Mathematical Programming System available at the USDAs Fort Collins Computer Center was used to obtain the solution. The cost of the computer run was about $3.50. VI. CONCLUSION A method is given for designing an efficient road system for transporting timber from one or more timber sales. The model considers all possible From all paths between each sale and each appraisal point via each mill. possibilities the most economic combination of paths for all sales is selected. The most economic combination means the highest economic value for timber less the costs of road construction logging environmental lumber manufacturing and hauling. The road projects to be protection constructed and the log and lumber volume on each road segment are obtained from the model. We hope that this method can eliminate the widely practiced method of sale-by-sale transportation planning which is responsible for the large mileage of inefficient road system existing in many National Forests today. MATHEMATICAL FORMULATION VII. The transshipment formulation for multicommodity fixed cost elements are given below. APPENDIX flow with variable and Notations Xij amount of Z-th commodity traversing directional link i --.j where Z 1 for log and 2 for lumber commodity flow is measured in MBF of timber. Z. Nt the set this of is the demand terminal nodes for commodity Z. set of all mill nodes. For Z 2 this For 1 Z is the set of all appraisal nodes. NS the set set of of all For supply nodes for commodity Z. sale nodes. For Z 2 this is the Z set 1 of this is the all mill nodes. S1 Vý Aij timber volume available net at sale node J. timber volume generated supply node at node commodity Z. j or received demand re-quired node i ---.j and j----iare constructed 0 otherwise. only applies to a link where construction is it can be used. These variables are defined as 0-1 integer variables. 1 if road links This variable before hij round trip hauling commodity Z. We cost $/MBF assumed loaded 19 i-j directional link for truck would go from i -.j and over empty truck from haul cost. _P-i. total hauling cost CH construction pij or for Road maintenance commodity reconstruction ij total. construction CP Zj for cost set is included cost in the Z. of all unordered pairs construction or reconstruction are the NP links such i that projects. and reconstruction logging environmental protection -j -j and i -i. j and j -i project cost. cost $/MBF for sale node j respectively. ej CL C J total logging and environmental protection cost for all sales. E manufacturing mk total CT cost $/MBF cost CP CL for mill node CE lumber value vj at CH. CH total lumber value at all CV k. appraisal nodes. appraisal node j $/MBF. avail-able total net value CN lumber value - all costs. constant which is equal from all sales. the a a D total lumber demand at appraisal points. to twice total timber volume Formulation 0 kXjk iXij - 0 Sý 0 i Xij - k Xik -Vi 0 Ns j 4 j cNs U Nt 1 jN1 N2UN2 j j c j e Ns N2 20 2 E l X k jk j k XJk - i Xij -VI i ij V1 k - E 5 6 0 J 7 c ijhii 0 Xj i Z ij ij Np A ij CH ij - ZJV-ýl. CL s .EN 4 D Xij J NS j Z jEN1 V2 E jENt jEN22 E E 3 Z t V2 E j Nt k kcN1 jEN1 kENt E V1 V E 0 j 1V CE c for ij NP 8 9 0 0 10 0 11 12 Q s - kEN1 mkvk 13 0 CM t ZcHCpcLcE-cT0 jcN2tujVj C c V C T - C CV N 14 15 0 16 0 Objective Function Maximize Net Value - max CN 21 17 1 con-servation An explanation of the formulation follows. Constraint is the of flow equations for log transport. For a node which is neither a sale nor mill node the total amount of timber flowing to the node must The timber volume out of the sale node equal the volume flowing from it. minus the volume into the node cannot exceed the amount of timber available. Note that a supply node sale can also be a transshipment node i.e. flow supply node as well as from it. Similarly for a mill or amount of log going into a mill node must be more than amount going out. is permitted to a appraisal the or equal node- to the The conservation of flow restrictions for lumber haul is contained in constraint The mill nodes serve as demand nodes for log transport and nodes for lumber transport. Since the amount of log terminating as supply at a-mill is a variable we can only require the difference between the of and amount of lumber flowing out into the mill to be less than the 2. amount of log available at the mill. For an appraisal node lumber into the node must be more than out of the node. 3 the amount of 4 Constraints and are for calculating the amount of timber that flows into the demand and supply nodes respectively. The total amount of log volume harvested at all sale nodes is the same as the total volume at all mill nodes according to Constraint says that the amount of log at mill nodes is the same as the lumber volume at all appraisal nodes. and are not necessary since they are automatically The total amount of lumber at all appraisal nodes must equal the demand D by The specified total lumber demand must not exceed total Constraint insures that a road project is implemented log available. if a non-zero timber is assigned to it. to are Equations Con-straints satis-fied. 6 5 6 5. account-ing 7. 8 9 14 hauling logging equations for summing up total project construction environmental protection mill manufacturing and total cost respectively. The total lumber value is calculated by 15. defines the Equation net value as timber value minus hauling construction logging and The objective function is to maximize net value protection costs. environ-mental 16 as given in 17. 22 WASHINGTON TECHNOLOGICAL OFFICE NEWS IMPROVEMENTS Heyward T. Taylor Assistant Director INTERNATIONAL CONFERENCE ON LOW-VOLUME ROADS 1979 the Transportation Research Board TRB will hold an international conference on low volume-roads. Mr. Adrian Pelzner of the Forest Service is chairman of the TRB Planning Committee that is making plans and Another Forest Service employee serving on arrangements for the conference. the Planning Committee is Martin Everitt R-2. The decisions plans and made the Committee outlined below. by are arrangements Planning In WO Name International Conference on Low-Volume Roads Place Iowa State University Ames Iowa Date August 19-23 1979 Sunday-Thursday Sponsorship TRB Task Force A2T57 on Low-Volume Roads along with a wide array of cooperators. Theme Operating and managing low-volume roads. emphasize costs and practical aspects. Anticipated Attendance Over 500 23 The conference will Format Conference low-volume 1. Welcome 2. Keynote by Iowa State officials. address by prominent individual associated with roads. 3. General sessions with invited speakers. 4. Theme-oriented sessions with attendees choosing from several concurrent workshops. Selected papers will be presented to open these sessions and followed by group discussions to formulate conclusions and recommendations. 5. Session on international aspects of low-volume roads. 6. Field trips--attendees choose 7. Session on low-volume from several different options. technology transfer and information exchange on roads. 8. theme-oriented General summary session with reports from concurrent sessions. Social Activity Mid-conference Call for Iowa Corn Boil. Papers Flyers requesting theme oriented papers and pre-registration information will be distributed by TRB. Both formal papers published and informal presentations unpublished will be solicited. Devel-opment Post Conference Tours be coordinated by World Bank Agency for International National Association of Country Officials and Iowa Association. Engineers To Proceedings Volume Conference will be fully documented and a proceedings volume will be published by TRB through its normal publication procedures. Each attendee will receive conference registered a proceedings volume. Over 7000 copies of the 1974 Workshop on Low-Volume Roads have been distributed. An even larger distribution is anticipated for this 1979 conference. 24 cost-efficient con-ference. Conference on Low Volume Roads will be an important meeting for all The Forest Service administers an extensive low-volume road system it is important this system be managed and operated in a therefore and practical manner--which is exactly the theme of the 1979 Since many of you have responsibilities and knowledge that directly relates to the theme of this conference you are encouraged to share your and an offer for a formal paper or an knowledge experience by submitting informal presentation. We plan to make a Servicewide distribution of the TRB The 1979 of us. Call the flyers become available. Also future issues of Field the Notes will latest information on speakers Engineering give papers and other details of the conference. We ask that you be on the lookout for this information and assess what contribution you can make. for Papers when 25 CONSULTATION AND C.R. Assistant REVIEW STANDARDS Weller Director OF ROAD AND BRIDGE PRECONSTRUCTION ACTIVITY Background During the summer of 1976 29 projects were audited in three additional projects were reviewed to a lesser extent. Regions and 31 Servicewide preconstruction engineering practices were the primary subject of these reviews with sampling conducted in Regions 1 The Road and and 9. Bridge Preconstruction Activity was selected for review because recent 6 In some by the Forest Service significantly affected that work. work has been from the Office to the design delegated Regional cases All units had made Forests or from the Forests to Zones and Districts. adjustments in their programs to handle an increased engineering workload changes Congres-sional facil-ities timber sale contracts. addition raised concerns In inquiries had being developed. audits reviews recent about the costs and and standards of Objective The objectives of this review were determine if current direction established standards and for Roads and Preconstruction guidelines Bridge procedures and to assure that a meets resource adequate facility management and objectives 1. To 2. To develop an action plan which will eliminate or deficiencies. improve Conclusions Three general broad areas in need of 1. Communications 2. Design 3. Management analysis procedures and activities improvement were identified and quality that other documentation and affect preconstruction 26 practices. on Report and Action Plan A detailed report covering the review teams findings and conclusions and an action plan are being prepared and will be published as an Engineering The action plan covers specific corrective actions to be Management Report. carried out over the next 2 years. Preconstruction Beryl Johnston Engineer in the WO will be coordinating work on various items of the Action Plan. 27 OPERATIONS Harold L. Strickland Assistant Director RESOURCE INFORMATION DISPLAY SYSTEM RIDS result of the Systems Development Action Planning Team Report SDAPT that computer mapping needs of the Forest Service be scrutinized and that short term and long term strategies be developed for As a it was recommended computer mapping. assigned this responsibility to Engineering. In turn Director Howlett assigned responsibility to the Geometronics Development Group in the Washington Office. The Chief M.R. Establishing a Project Team for RIDS within the Geometronics Development Group has taken considerable time and effort but a team is now on board consisting of the following personnel Tom George - Project Leader Ed Chapman Roger Pelletier George Holguin These people have had experience in computerized mapping systems within the Forest Service and with other government agencies. As set by Chief the the goal of this project is Provide computer mapping tools for field personnel to utilize in support of their various tasks. The emphasis of these tools will be on using the computer to derive and display information from maps rather than summarize on the cartographic project itself. from above although Geometronics is mainly interested in this project will not be all photogrammetric and cartographic products that concerned about the cartographic aspects of the map products. This As can be seen Computer mapping as used in RIDS project refers to computer assisted and spatial display of resource information analysis retrieval storage from existing maps. 28 does not mean. that cartographic information will not be considered or used as part of the RIDS project. To meet the objectives goal have Chief short-range established by the been established. and long-range main-tainable Short Range To put together from existing Forest Service computer mapping systems a system which will be usable by the field and by RIDS. The existing systems which RIDS will investigate GRID for the short term are POLYGON MIADS2 WRIS R2MAP PLOT R3MAP COMLUP MAPIT CONGRID To make a study of where the Forest Service should be in the Long Range of area computer mapping in the1980s and to obtain a unified system to meet these needs.. In the system long or range RIDS may obtain develop the existing system contract for a new This decision has not yet been system in-house. an made. A meeting between the RIDS team and 15 developers and users of existing Forest Service systems was held during May. Since then the RIDS team has been busy analyzing the various existing Forest Service systems so that it can start on a system which incorporates the best of the existing computer mapping programs. Although Engineering at the Region and Forest level probably will not be directly involved with this development effort it may be involved in the preparation of input data to any computer mapping system which evolves from the RIDS project. We will attempt to keep the field informed of the progress of the RIDS project through periodic reports in the Field Notes as well as by informal newsletters to those in the field who are directly involved. you would like more information on the RIDS project or have comments or contact Project Leader Tom George FTS telephone 235-8184. suggestions If 29 U.S. GOVERNMENTS PRINTING OFFICE 1977 0-241-426/4