Document 11448444

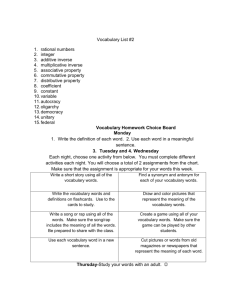

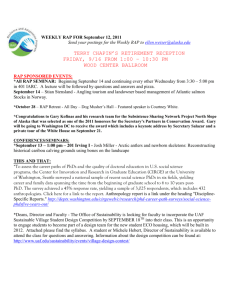

advertisement