Cross-Industry Freight Derailment Working Group Interim Progress Report Version 3.4

advertisement

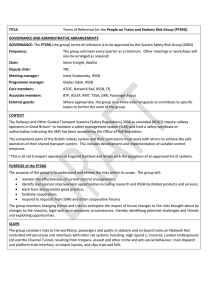

Cross-Industry Freight Derailment Working Group Interim Progress Report Version 3.4 Copyright © RAIL SAFETY AND STANDARDS BOARD LTD. 2016 ALL RIGHTS RESERVED This publication may be reproduced free of charge for research, private study or for internal circulation within an organisation. This is subject to it being reproduced and referenced accurately and not being used in a misleading context. The material must be acknowledged as the copyright of Rail Safety and Standards Board and the title of the publication specified accordingly. For any other use of the material please apply to RSSB's Head of System Safety for permission. Any additional queries can be directed to enquirydesk@rssb.co.uk. This publication can be accessed by authorised audiences, via the SPARK website: www.sparkrail.org. Written by: Lynne Collis, System Safety Engineer, and Gareth Tucker, Vehicle Dynamics Engineer, RSSB Published: February 2016 Issue Version Date First issue Draft 6 November, 2015 Updated draft issued to ORR 3.3 21 December, 2015 ORR comments taken into account, Update issued. 3.4 28 January, 2016 Cover image courtesy of RAIB report 21/2014 Derailment at Primrose Hill/Camden Road West Junction 15 October 2013; noted in that report as courtesy Network Rail. 1 Introduction.......................................................................................1 1.1 Background ......................................................................................................................1 1.2 The Cross-Industry Freight Derailment Working Group ..................................1 1.3 Methodology ...................................................................................................................1 1.4 Link to RAIB recommendations ................................................................................4 2 Progress report..................................................................................5 2.1 Action 1: Risk Analysis................................................................................................ 5 2.1.1 Output from the First Bowtie Workshop..................................................................................... 5 2.1.2 Changes in the rail industry over the last 10 years ..............................................................10 2.2 Action 2: XIFDWG .......................................................................................................10 2.3 Action 3: Programme plan ...................................................................................... 10 2.4 Action 4: Regular reporting to ORR ...................................................................... 11 2.5 Action 5: ORR contact with other enforcing authorities...............................11 2.6 Action 6: ORR/RSSB meeting to discuss risk acceptance .............................12 3 Further activities in progress by XIFDWG ............................14 3.1 Consider an additional wavelength for the assessment of track twist ...14 3.2 Loading guidance for vehicle testing ..................................................................14 3.3 Consider limiting offset loading conditions ...................................................... 15 3.4 Establish existing levels of offset loading on wagons ...................................15 3.5 Rules and regulations for the loading of containers...................................... 16 4 Future governance arrangements..........................................17 5 References .......................................................................................18 6 Abbreviations .................................................................................20 Appendix A: List of group members...........................................21 Appendix B: Relevant RAIB recommendations......................22 Appendix C: XIFDWG work streams and projects – December 2015.................................................................................27 Cross-Industry Freight Derailment Working Group Interim Progress Report 1 Introduction 1.1 Background On 5 December 2014 Ian Prosser, HM Chief Inspector of Railways, sent a letter to several key companies in the rail industry [1] requesting that the industry work collectively to address concerns about freight train derailment relating to the combinational effects of track condition, vehicle sensitivity to track geometry and asymmetric loading of containers. Specifically, the ORR invited the infrastructure manager and the freight industry to work together with RSSB and others, to: 1 Define the current track, vehicle and load system 2 Define how these three elements interact 3 Describe the current risk controls in place 4 Detail the gaps in those risk control systems 5 Specify the measures required in the short, medium and long term to reduce those risk gaps so far as is reasonably practicable 6 Implement those measures 1.2 The Cross-Industry Freight Derailment Working Group In response to the ORR letter [1], Freight Technical Committee proposed a cross-industry working group should be set up to oversee the work needed. The cross-industry freight derailment working group (XIFDWG) was therefore set up, facilitated by RSSB, with representatives from: Network Rail, freight operators, Interfleet, Huddersfield University, Lloyds Register Rail, ORR and RSSB. A full list of current members is included in Appendix A. An ORR facilitated seminar followed on 6 March where the key actions were discussed and agreed [4]. 1.3 Methodology The work of the cross-industry group follows a structured process, in accordance with the industry guidance on safety related decision making and risk management, Taking Safe Decisions [2]. Taking Safe Decisions is built RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 1 around key regulatory requirements that duty holders must comply with, in particular the Common Safety Method for Monitoring and the Common Safety Method on Risk Evaluation and Assessment (CSM RA)[3]. Figure 1 - The Taking Safe Decisions Risk Management Framework According to that process when a safety concern has been identified, analysis is required to understand the nature of the problem, and identify options that can be considered to reduce any identified risk. Appropriate application of risk acceptance criteria is necessary in order to understand whether there are any measures which are necessary. Following the identification of options to progress, any necessary changes to the railway and its operation are made, and necessary monitoring arrangements put in place to monitor the impact of the change. This process is consistent with the ORR request for industry activity. At the ORR-hosted meeting on 6 March 2015, six actions for the XIFDWG were agreed [4]. These actions are described below. As the Programme Plan and related activities are further developed (see Section 2.3) this will result in a restructured approach to reporting progress on activities, however for this report, progress is presented against each of these six actions (in Sections 2.1 to 2.6). 2 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 Action 1: The industry to review its understanding of the hazards and risks associated with container freight train derailments to ensure a common understanding of the effectiveness of current risk control measures, and identify improvements to reduce the risk as low as reasonably practicable. a This review to be approached from a first principles system perspective. b The review should be based on detailed risk analysis supported by bow tie assessment. The existing SRM/PIM provides information that can form part of this review. The initial basic bow tie analysis presented in ORR’s paper is a potential starting point [1]. c The review should include consideration of what has changed or is changing on the railway that could change the industry understanding of the way in which these types of derailment can occur and the way they are modelled and assessed. d The risk analysis work should take account of views and inputs from organisations outside the rail sector with responsibilities for forwarding, loading and handling of freight containers e This links to the cross-industry working group (XIFDWG) proposals 1&2 (See below) to update the risk assessment and identify changes to the railway. Action 2: The XIFDWG should lead this work as it provides a good forum for taking the actions from this meeting forwards as it already includes specialist railway infrastructure (track), rolling stock and risk expertise. a The XIFDWG to consider, at their next meeting, how to better understand the hazard created by the load, and determine the Group’s approach on engaging with the container industry (for example Associated British Ports (ABP), Maersk, Freightliner Roads, Rail Freight Group (RFG)) to assist in gaining this understanding. The objective here is for the XIFDWG to be able to fully take account of the load aspect in their review of the hazards and risks associated with container freight train derailments. Action 3: The proposed work by XIFDWG was presented at the meeting, taking account of item 1 above, and was accepted as forming the basis of a work programme. a The next meeting of the XIFDWG will review the proposed work in light of the discussions and agreed actions at the 6 March meeting and develop/scope out a work programme. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 3 Action 4: The XIFDWG would provide ORR with formal written progress reports in 6 months and 12 months with consideration being given to holding a second industry meeting at the 12 month report back stage to review progress. Action 5: The ORR to contact other enforcing authorities (for example VOSA, MCA, HSE) to discuss potential opportunities for seeking improvements in the packing, weighing and loading of containers across the container delivery chain and feedback to the XIFDWG. Action 6: ORR and RSSB to meet and discuss wider issues regarding safety decision making, Taking Safe Decisions Issue 2 and the linkages between the Safety Risk Model, risk assessments and managing risks so far as is reasonably practicable. 1.4 Link to RAIB recommendations The Rail Accident Investigation Branch (RAIB) has made a number of recommendations to various industry parties in relation to a number of the freight train derailments that have recently occurred [Appendix B]. The Rolling Stock and Infrastructure standards committees proposed that the crossindustry group (XIFDWG) should consider these recommendations in its work. Workstreams underway as part of the XIFDWG will provide information that supports those to whom RAIB recommendations are addressed, in closing them. The approach being taken by the XIFDWG is that it will consider the recommendations and, in undertaking the task set for it by the ORR, it will endeavour to provide any relevant information to support members in addressing their particular recommendations. However, we stress that it is for those particular organisations, rather than the XIFDWG, to address the recommendations with the regulator. Appendix B lists RAIB recommendations relevant to the activities of the group, for which a mapping is to be undertaken. This mapping will seek to clearly establish exactly which aspects of which recommendations are to be considered as part of the XIFDWG activity. Early discussions in the XIFDWG confirmed that there are two issues which are best considered separately. The first focus of the group would be on freight train derailment relating to the combinational effects of track condition, vehicle sensitivity to track geometry and asymmetric loading. The second issue would be cyclic top and vehicle response to such track inputs. 4 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 2 Progress report As outlined in the process described in Figure 1, having identified a safety concern there is a need to analyse and understand the issue and evaluate options around the need for further risk controls. Initial focus has therefore been on undertaking of risk analysis to fully understand the nature of the problem, the sufficiency of current controls, and options to supplement or improve them. 2.1 Action 1: Risk Analysis Work to produce a complete and accurate ‘bow-tie’ model of the relevant risk controls is well advanced and nearing completion. This work is being undertaken to identify potential gaps in the control framework leading to further work to evaluate the potential need for further controls. Work undertaken so far has focussed on three related areas. These are: Review of the original risk assessment carried out for PPR 691 [5]. Bowtie risk analysis regarding track twist, combinations of track faults, wagon faults and offset loads of containers and hopper wagons. Investigation of the feasibility of quantified assessment of combinatory risk relating to the above. 2.1.1 Output from the First Bowtie Workshop RSSB risk experts have reviewed the assumptions and base data used in the original risk assessment carried out for PPR691. This work has been used as an input to the bowtie risk workshop. The first Bowtie risk workshop was undertaken on 23 July 2015. It included representatives from Network Rail, freight operating companies, ORR and RSSB. The draft bowtie provided by ORR [1] was taken into account. The output of the workshop was recorded in the draft bowtie diagram, to be completed at the second Bowtie workshop. The output comprised: An updated, bowtie risk assessment diagram dealing with freight derailment, due to track twist, combinations of track faults, wagon faults and offset loading with relation to container trains and hoppers [14]. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 5 A list of inadequate or potential controls for further assessment and prioritisation [15]. These outputs are discussed below, but are currently only in draft form, as a second bowtie risk assessment workshop will be undertaken in March 2016 to complete the work. All statements made are therefore subject to review by the second bowtie workshop. Controls associated with each threat were assessed for efficacy. Whereas the input bowtie had significant numbers of unknown controls, these were defined in the XIFDWG bowtie, as shown in Figures 2 and 3. In addition, the XIFDWG bowtie identified potential controls which could be put in place. The graphs in Figures 2 and 3 show the relative completeness of the bow-tie derived by the ORR and the one derived by the XIFDWG, and compare their assessed effectiveness levels. A number of points have arisen so far, which are presented in the following sub-sections. For the avoidance of doubt, these points are the output of the first bowtie workshop [14] and [15], and are therefore subject to further review. 6 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 Figure 2 - ORR bowtie controls Figure 3 - XIFDWG Bowtie Controls 2.1.1.1 Track twist The measures of control considered focused chiefly on inspection and measurement of track twist and combinations thereof. Existing measures include: Track recording vehicle Measurement via MPV (multi-purpose vehicle) Inspection from the cab of in-service trains Trackside inspection. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 7 The efficacy of these measures was discussed. The workshop found potential new threats, not included in the ORR input bowtie, concerning the twist on switches and crossings, as these are generally not measured by track recording vehicles, most of which stop recording at low speed. There is currently one MPV available, which focuses on track measurement on switches and crossings. Another key point is the difficulty of diagramming recording vehicle movements via all switches and crossings, and all lines. The use of in service trains for inspections was discussed. It is easier for inspection staff to access the cabs of passenger trains, due to their station stopping patterns, but it was noted that, if it is possible to use freight trains for cab inspections, these would cover freight only lines. A further potential measure of fitting track twist measurement equipment to in service freight locomotives was included. It was noted that trackside inspections have become more difficult, due to the move away from red zone working. It was also recorded that there is a workstream reviewing the wavelength of track twist measurement, which will need to be taken into account once results are available. 2.1.1.2 Wagon faults New potential controls regarding wagon faults include: Development of guidelines on conditions for testing, with reference to partial, asymmetric and shifts in loads. Modification to suspension of existing vehicles to improve tolerance to track twists that are outside of the maintenance limits. 2.1.1.3 Offset loads The key issue with asymmetric loading of container wagons is that the problem is essentially multi-modal in nature. Containers may originate in other countries, or may be loaded with no regard for guidelines available for the loading of rail containers. If transported by sea, the containers may be subject to considerable lateral and longitudinal forces. International loads may be customs sealed, preventing the freight operating company from inspecting the load. The Safety of Life at Sea (SOLAS) regulations, coming into force in July 2016, [6] are intended to control gross load weights, but will not take into account offset loads. Risks associated with transferring rejected rail freight containers 8 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 to road were highlighted, as it was perceived as undesirable merely to transfer the risk from rail to road rather than developing or improving controls to prevent such containers arriving at rail heads. Overcoming the operational challenges presented by rejecting containers at rail heads will also be critical. A potential control was also noted, that ORR should liaise with other regulatory bodies, such as the IMO and HSE. Further potential controls were discussed regarding measurement of loads, including Network Rail’s GOTCHA trackside monitoring system, for subsequent discussion. These are described in Sections 3.3, 3.4 and 3.5 of this report, and include more detail on investigation into controls on the loading of containers and measurement of loads. It should be noted that this work has been further developed since the above workshop of July 2015, as represented by Sections 3.3, 3.4 and 3.5. 2.1.1.4 Work in progress A key next step is to complete the bow-tie analysis. When this work is complete, work to evaluate whether further controls are necessary can begin. The completion of this work is therefore on the critical path to progress and will represent a key milestone in the programme plan, when developed (Section 2.3). As outlined in the framework of Figure 1, further work to implement any necessary controls would then follow. A second bowtie workshop will be undertaken in early 2016 (now scheduled for 3 March 2016). This will refine the bowtie model and will consider means of prioritising potential controls, or those which could be improved, as well as providing a broader freight operating company input. In addition, expertise from organisations outside the rail sector on forwarding, loading and handling of freight containers has been arranged to contribute to the risk analysis. The output of the bowtie workshop will permit review and update of the RSSB and TRL report on container loading [5]. The Institute of Rail Research at the University of Huddersfield (IRR) has been asked to review the feasibility of quantified risk assessment, combining risks of track twist, wagon faults and offset loads. A key issue is the difficulty of obtaining adequate data for quantification. Additional work is being planned (discussed in section 2.6) to further quantify the numbers of unevenly loaded containers and the severity of the loading RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 9 offset; this will also aid the understanding of the level of risk. Analysis will be undertaken in accordance with the principles of Taking Safe Decisions, and using the risk acceptance criteria set out in the CSM RA. 2.1.2 Changes in the rail industry over the last 10 years Identification of changes to the railway over last 10 years and in the future, considering wagon types, type and volumes of freight carried and numbers of derailments. IRR has reviewed records of freight train derailments for the last 10 years, along with records of the fleet sizes of freight wagons and the number of miles run by each wagon type. This has allowed an assessment of the propensity for derailment per wagon mile and how that has changed in the last 10 years. 2.1.2.1 Work in progress Work is on-going to further refine these results and Network Rail are obtaining further Actual traffic (ACCTRAF )data to enable this analysis. Further work is still required to identify differences in type of freight carried during the last 10 years and investigate a link between freight type and derailment risk for container wagons. 2.2 Action 2: XIFDWG The XIFDWG is meeting regularly1 with good representation from the industry and specialist knowledge of railway infrastructure (track), rolling stock and risk. It has arranged its activities into seven workstreams as presented at the ORR meeting on 6 March 2015 [4]. The workstreams have been further developed into individual projects as shown in Appendix C. In future these will be reported on separately. 2.3 Action 3: Programme plan The programme plan will be tabled at meetings of the XIFDWG for endorsement. The plan will explain how the detailed planning and design of all aspects of this on-going programme will be undertaken. It will address: Timescales and dependencies between the workstreams. Resources required and where they will be sourced from. During this stage, resources already assigned to each of the workstreams will also be included. 1 The XIFDWG met on 29 January, 23 Feb, 10 April, 3 June, and 23 September 2015. [16]. 10 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 Boundaries, assurance and governance arrangements that will be applied and within which the team will work during the programme definition stage. Confirmation of membership of the working group and its subgroups. Schedule of activities to complete the programme plan. Estimated effort and costs associated with delivering the plan. Risk register to capture and actively manage the risks to the programme 2.4 Action 4: Regular reporting to ORR This is the first interim report providing a high level overview of the activities undertaken by XIFDWG to date. The timing of further reports will be discussed at the next meeting of the XIFDWG in February 2016. 2.5 Action 5: ORR contact with other enforcing authorities To raise wider industry awareness in February 2015 (prior to the ORR industry meeting on 6 March 2015) ORR gave a presentation to the HSE logistics industry forum on recent freight container train derailments highlighting the container loading aspect of these derailments. Subsequently ORR has: Held initial discussions with the Health and Safety Executive (HSE), Marine and Coast Guard Agency (MCA), Vehicle and Operator Services Agency (VOSA), Port Skills and Safety (PSS) with regards to the issue of asymmetric container loading. Given a presentation on asymmetric container loading to International Cargo Handling Coordination Association (ICHCA), container weighing seminar in September 2015. 2.5.1 Work in progress These early discussions have identified that there is interest in, and recognition of the issue, and understanding that it has potential to affect road modes of transport as well as rail. However the issue is not high in the wider ranging priorities across the transport and logistics sectors. They are open to further discussions on the topic but currently the lack of evidence on the scale and degree of asymmetric loading within the container transport sector are likely to make it difficult to attract resource against other more visible and evidence based issues such as declaration of container gross weight, overloading and load security. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 11 The loading research work proposed and potential of data from the GOTCHA system (Project item 7.1) should provide evidence on the scale and degree of asymmetric loading of container wagons, which could be used to inform future discussions with HSE et al. To provide a forum directly linked to the XIFDWG it was agreed at the XIFDWG on 23 September to create a container loading subgroup including freight operators, HSE, VOSA, DFT, MCA and other agencies. 2.6 Action 6: ORR/RSSB meeting to discuss risk acceptance Initial conversations between the industry and ORR, following the letter from HM Chief Inspector of Railways [1], led to some debate about how risk information is used to set duty holder management priorities. Initially the industry queried whether the level of residual risk associated with freight train derailments, as estimated in the Safety Risk Model [7] justified a significant industry initiative in this area, given the range of other risks that the industry is currently dealing with on a strategic basis, such as the risk from signals passed at danger, and the risk of injuries at the platform train interface. The regulator was clearly of the view that, as there was the potential for a major accident, this itself justified action. The ORR’s Enforcement Maturity Model was presented as a justification for why the industry needed to take action. The industry has a consensus on such matters, captured in ‘Taking Safe Decisions’ [2] and various supporting documents. A meeting about safety decision-making was held on 14 May between David Keay, Colin Greenslade and Lee Collins of the ORR; and Colin Dennis and George Bearfield of RSSB [8]. At this meeting the attendees sought to reaffirm that position, remind all parties of the key principles and to clarify the basis by which future work would be undertaken. In summary the key conclusions of the meeting were that: Freight train derailments pose the potential to cause catastrophic high consequence events, albeit this is estimated to occur at low frequency. However given the recent occurrences of freight train derailments and that incidents will put pressure on both the relationships and reputation that operators enjoy, over and above their legal duties, the validity of those estimates and the need for further consideration should be recognised. There is a need for the industry to seek to establish the efficiency and effectiveness of current controls, and whether there are any gaps in them. 12 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 This is a separate, complementary, activity to the use of risk acceptance criteria to identify the need for additional controls. The ORR Enforcement Management Model criteria, which were presented at the meeting on 6 March 2015, are not duty holder risk acceptance criteria in accordance with the regulation for the common safety method on risk evaluation and assessment [9] and should not be presented or interpreted as such. They are a guide to regulatory activity and prioritisation. To make informed decisions the industry uses statistical approaches to support risk estimation. Such risk assessments include the impact of the failure of managed control measures as well as circumstantial factors like train loading and train frequency, and their impact on, for example, the risk from secondary collisions following a derailment. A number of further actions were identified which are being tracked for closure as part of the broader programme of work. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 13 3 Further activities in progress by XIFDWG In parallel with work to analyse and fully understand the problem, additional activities have been undertaken. Not all of these activities will be able to be fully completed until the initial work to analyse and understand the sufficiency of risk control measures is complete. However, work has begun in anticipation of likely future work. 3.1 Consider an additional wavelength for the assessment of track twist Potential benefits that could be gained from adding an additional longer wavelength track twist measurement and criteria. Network Rail has carried out an initial review of track data to identify the wavelength content of twist defects on their network. Further work is planned in conjunction with IRR to investigate the benefits of an additional, longer wavelength for the assessment of track twist. XIFDWG has discussed alternative lengths of twist assessment used on European mainline railways and also London Underground. 3.2 Loading guidance for vehicle testing Review of existing loading guidance provided for vehicle testing. A study has been initiated to use multi-body vehicle dynamics simulation (using the Vampire software) to investigate the safety margin in the GM/ RT2141 Safety against Derailment on Twisted Track Assessment Method [10]. The specification for this work is currently in development. A sub-group has been set up to support this activity. The initial phase of the work, based on a vehicle model of the FEA and FSA wagons, will be carried out by IRR. A further phase will widen the study to include more vehicle models; and options for further research by RSSB are being explored. 14 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 The outputs of this study will allow XIFDWG to consider the need for testing container or hopper wagons in an asymmetrically loaded condition. 3.3 Consider limiting offset loading conditions Assess need and feasibility of testing and computer simulations of existing wagons to establish limiting offset loading conditions and related wheel unloading limits. This will build on the results of the modelling work described above to consider limits that might be appropriate for offset loading conditions for testing and permitted wheel unloading under such loads. The International Union of Railways (UIC) project ‘Harmonization – Running Behaviour and Noise Measurement Sites’ (HRMS)[17], completed in December 2014, was a project to suggest a common approach to defining and using monitoring systems placed on the trackside to monitor trains, including train noise emissions, Wheel Impact Load Detectors (WILD) and Weight in Motion (WIM) systems. The HRMS project suggested in-service limits for offset loading of rail vehicles. These suggested limits will be taken into account by XIFDWG when considering limits for offset loading. 3.4 Establish existing levels of offset loading on wagons Analysis of GOTCHA measurements to establish existing wagon uneven load profiles. Work is on-going with Network Rail to confirm whether or not the current implementation of GOTCHA provides robust data for this purpose, as distinct from its primary aim of detecting impact forces. Once the data is known to be fit for the analysis of vehicle load distribution then a review of more GOTCHA data (in addition to the work carried out by the Freight Technical Committee Asymmetric loading intermodal group in 2013) will commence to look at trends on different routes, traffic flows, and vehicle types. Additionally options for further research by RSSB are being explored for work to directly measure the level of offset loading of containers from port cranes. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 15 3.5 Rules and regulations for the loading of containers Investigate the rules and regulations around the loading and verification of containers as a wider transport issue and how well they are implemented. XIFDWG suggest the existing guidelines such as the IMO Guidelines for packing of cargo transport units (CTUs) are adequate [11], however, the problem is they are very difficult to enforce. XIFDWG would like the HSE to investigate options to enforce these packing guidelines and/or train the packers of CTUs appropriately in their use. It is important to recognise that this is a multimodal transport system problem, and so the risk associated with carrying these unevenly loaded containers is not exclusive to rail. The ORR has taken an action to liaise with the HSE to discuss this. 16 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 4 Future governance arrangements At the meeting of the XIFDWG on 23 September 2015 Colin Dennis stepped down as Chairman of the group, and Mick James stepped down as the Freight Technical Committee representative; both have made significant contributions to establishing the group and both have now retired from RSSB. RSSB Director of System Safety, George Bearfield, has taken over as Chairman of the group, and Neil Halliday of RSSB has taken over as the Freight Technical Committee representative. The XIFDWG currently reports to the Freight Technical Committee, which in turn feeds back relevant findings to the Rolling Stock Standards Committee and Infrastructure Standards Committee. In advance of the next meeting of the group, a review of the governance arrangements of the group is to be undertaken. With the publication of the Industry Health and Safety Strategy in early 2016 there will be renewed thought around the co-operative arrangements for managing safety under the RSSB facilitated System Safety Risk Group. The linkage of this key project to that industry activity will be considered. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 17 5 References 18 1 Letter from Ian Prosser to Network Rail, Freightliner, GBRF, DB Schenker, DRS, Colas, RSSB, RAIB and HSE, titled ‘Recent freight derailment: The interaction of track, vehicles and freight container loads, and potential areas for improvement’, 5 December 2014. 2 Taking Safe Decisions, http://www.rssb.co.uk/risk-analysis-and-safetyreporting/risk-analysis/taking-safe-decisions, RSSB. 3 Not used 4 Recent freight derailments: The interaction of track, vehicles and freight container loads, and potential areas for improvements. Rail Industry Meeting, - Friday 6 March 2015 5 PPR691 ‘Potential risk to road and rail transport associated with asymmetric loading of containers’, RSSB and TRL 2014 6 Maritime and Coastguard Agency MG530 Guidance on the implementation of the SOLAS VI Regulation 2 amendment requiring the verification of the gross mass of packed containers, 2015 7 Safety Risk Model, http://www.rssb.co.uk/safety-risk-model/safety-riskmodel 8 Note of ORR/RSSB meeting about safety decision making, 14 May 2015 a 9 Common safety methods for Risk assessment, http://www.era.europa.eu// Core-Activities/Safety/Safety-Management-System/Pages/RiskAssessment.aspx 10 GM/RT 2141 Resistance of Railway Vehicles to Derailment and Roll-Over, RSSB, 2009 11 IMO / ILO / UN ECE Code of practice for packing cargo transport units. www.unece.org/fileadmin/DAM/trans/doc/2014/itc/ id_07_CTU_Code_January_2014.pdf 12 RAIB report 21/2014 Derailment at Primrose Hill / Camden Road West Junction, 15 October 2013 13 RAIB report 11/2015 Freight train derailment at Angerstein Junction, 2 April 2014 RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 14 Draft bowtie diagram, from XIFDWG Bowtie Workshop of 23 July 2015 [unpublished] a 15 Draft Issues List, from XIFDWG Bowtie Workshop of 23 July 2015 [unpublished] a 16 XIFDWG Minutes of Meeting for 29 January, 23 Feb, 10 April, 3rd June, and 23 September 2015. a 17 Overview of HRMS Project, InnoRail, http://innorail.hu/en/uic-projecthrms-harmonisation-of-running-behaviour-and-noise-measurementsites/ [accessed 08/01/2016] 18 RAIB Report 02/2013 Freight train derailment at Reading West Junction, 28 January 2012 19 RAIB Report 20/2014 Freight train derailment near Gloucester 15 October 2013 ‘a’ denotes: available to XIFDWG members, including ORR. Other references are published. RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 19 6 Abbreviations Abbreviation 20 Definition ACCTRAF Actual Traffic Data HSE Health And Safety Executive IMO International Maritime Organisation IRR Institute of Rail Research, University Of Huddersfield ORR Office of Rail And Road RAIB Rail Accident Investigation Branch SOLAS International Convention for the Safety of Life at Sea, 1974 (IMO Convention) SRM Safety Risk Model (RSSB) XIFDWG Cross-industry Working Group On Freight Derailment RSSB | Cross‐Industry Freight Derailment Working Group: ORR Progress Report V3.4 Appendices Appendix A: List of group members George Bearfield, RSSB, Chair Neil Halliday, RSSB Bridget Eickhoff, RSSB Gareth Tucker, RSSB Lynne Collis, RSSB Alan Tordoff, RSSB Ben Gilmartin, RSSB Mike Laskowski, RSSB Janette Lissaman, RSSB Richard Thomas, ORR Mark Burstow, Network Rail Colin Newsome, Network Rail Ian Coleman, Network Rail Tim Gabb, Freightliner Andy Martlew, DRS David Barney, Private Wagon Owners Federation Simon Blake, Aggregate Industries Julian Stow, Institute of Rail Research Paul Molyneux-Berry, Institute of Rail Research Philip Rogers, Interfleet Stephen Tidmarsh, Interfleet Joss Apps, Ricardo Rail RSSB | Cross-Industry Freight Derailment Working Group: Interim Progress Report 21 Appendix B: Relevant RAIB recommendations Recommendations from RAIB report 21/2014 (Camden Road), [12] 2 & 3 are relevant to the XIFDWG. 2. The intent of this recommendation is for the key stakeholders in the railway industry to work together to assess the risk from asymmetric loading and to identify and adopt reasonably practicable control measures to mitigate that risk. Freightliner and Network Rail should jointly request that RSSB: a Researches the factors that may increase the probability of derailment when container wagons are asymmetrically loaded, and in particular: i sensitivity to combinations of longitudinal and lateral offsets in loads that can reasonably be encountered in service; ii the predicted performance of wagons with high torsional stiffness along their length (using the FEA type as an example); and iii the effect of multiple twist faults, track twist over distances other than 3 metres (as commonly specified and measured by Network Rail) and lateral track irregularities. b updates and amends as necessary the risk assessment contained within the RSSB and Transport Research Laboratory joint report (‘Potential risks to road and rail transport associated with asymmetric loading of containers’); this should take into account the results from the research referred to in a) and additional evidence presented in this investigation report; and c works with industry stakeholders to use the outputs of a) and b) to identify, evaluate and promote adoption of any additional reasonably practicable mitigations capable of reducing the risk from asymmetric loading of wagons (paragraphs 128c, 130a, 130b and 131b). 22 RSSB | Cross-Industry Freight Derailment Working Group: Interim Progress Report 3. The intent of this recommendation is to clarify the requirements for the design and acceptance of freight wagons, taking account of the possibility of asymmetric loading. RSSB should amend Railway Group Standard ‘Resistance of Railway Vehicles to Derailment and Roll-Over’, GM/RT2141 to refer specifically to asymmetric loading, including possible combinations of longitudinal and lateral load imbalance (paragraph 131a). Recommendations from RAIB report 11/2015 (Angerstein Junction) [13] 1, 2, 4, 5 & 6 are relevant to the XIFDWG. 1.The intention of this recommendation is to prevent wagons operating on the network with unacceptable uneven retained loads after unloading. Aggregate Industries, in consultation with relevant train operators, should review its processes for discharging aggregate hopper wagons, and for inspection of train loading and condition prior to despatch, to ensure that the risks arising from uneven residual loads are identified and effectively managed. Aggregate Industries should then implement appropriate control measures to mitigate this risk so far as is reasonably practicable (paragraphs 153(c), 153(e) and 154(a)). 2.The intention of this recommendation is to manage the contribution that diagonal wheel unloadings, due to twisted bogie frames or other defects, make to derailment risk. The RAIB notes that action taken in response to this recommendation could be informed by work undertaken as part of the railway industry’s response to the ORR’s letter of 5 December 2014 (paragraph 163). RSSB, in conjunction with freight wagon operators, freight operating companies and entities in charge of maintenance for freight wagons, should review the extent to which diagonal wheel unloadings are present within freight wagon bogies that are operating on Network Rail infrastructure, and the contribution that this makes to derailment risk. This review should consider: identifying the magnitude and prevalence of diagonal wheel unloadings caused by bogie frame twist (and other possible causes); proposing criteria for acceptable levels of diagonal wheel unloading, or for bogie frame twist; and proposing proportionate measures for identifying, and then managing, unacceptable diagonal wheel unloadings (paragraphs 153(d) and 155(b)). RSSB | Cross-Industry Freight Derailment Working Group: Interim Progress Report 23 4.The intention of this recommendation is to review whether the historic track twist measurement base (3 metres) is still a sufficient control for track twist risk applicable to current rolling stock. The RAIB notes that this recommendation could be informed by the joint industry action taken in response to ORR’s letter of 5 December 2014 (paragraph 163). Network Rail should liaise with RSSB to review whether the existing 3 metre measurement base used for identification of track twist is sufficient for managing the derailment risk applicable to rolling stock currently operating on Network Rail infrastructure. If found to be inadequate or insufficient, Network Rail should: update its process for assessing track twist by the inclusion of additional and/ or alternative measurement bases; and implement a time-bound plan to apply the new process to all of its infrastructure (paragraphs 153(b) and 155(a)). 5. The intention of this recommendation is to encourage use of available monitoring data from wheel impact load detection systems, such as Gotcha, to inform rolling stock maintenance. Network Rail should review the potential to use wheel impact load detection system data to provide information about possible defects, such as uneven wheel loading or uneven load distribution, relating to specific wagons. The review should include consideration of how this information could be used to improve control of overall derailment risk (such as identifying the need for entities in charge of maintenance to check the condition of suspect wagons and take appropriate remedial action). Network Rail should seek inputs from relevant entities in charge of maintenance as part of the review. If justified by the review, Network Rail should implement track side and reporting processes needed for collecting 6. The intention of this recommendation is to ensure that the distribution of loads in wagons, including partly loaded wagons, is controlled in a manner compatible with wagon and track characteristics. The RAIB notes that action taken in response to this recommendation could be informed by work undertaken as part of the railway industry’s response to the ORR’s letter of 5 December 2014 (paragraph 163). RSSB, in consultation with industry, should review the risks associated with the uneven loading of wagons, with particular reference to partial loads, and propose any necessary mitigation, so that the extent of permitted load 24 RSSB | Cross-Industry Freight Derailment Working Group: Interim Progress Report imbalance is effectively controlled (paragraphs 153(c), 154(a), 154(b) and 155(b). Recommendations from RAIB Report 02/2013 Freight train derailment at Reading West Junction [18] 3 is relevant to the XIFDWG. 3. The intention of this recommendation is for inter-modal freight terminal operators to develop requirements and investigate introducing a suitable monitoring system, for use during routine container and train handling, to prevent freight container wagons entering traffic with a side-to-side wheel load imbalance. The system could be based on the measurement of individual or side-to-side wheel loads prior to the train entering traffic or the identification of freight container load offsets during lifting. Freightliner should develop requirements for a system to monitor and prevent load offsets from containers resulting in wagons with a side-to-side wheel load imbalance entering traffic from its terminals. The system should be considered when terminal equipment is planned to be installed or upgraded, and where practicable the system should be implemented (paragraphs 108a, 108a.ii and 108a.iii). This recommendation may also be applicable to other operators of intermodal freight terminals. Recommendations from RAIB Report 20/2014 Freight train derailment near Gloucester [19] 2 . These are not relevant to the XIFDWG current work but 5 and 7 may be relevant to a later phase of work of the XIFDWG on cyclic top. 5. The intent of the recommendation is to ensure that when a vehicle’s dynamic behaviour is assessed to identify whether its ride performance is compatible with the railway infrastructure in Great Britain (this may include infrastructure that does not comply with Technical Specifications for Interoperability), the susceptibility of its ride performance to track geometry with cyclic top is included in this assessment. RSSB, in conjunction with Rolling Stock Standards Committee, should carry out a review to identify how a vehicle’s response to regular changes in vertical track geometry should be assessed (a cyclic top assessment). RSSB 2 Cyclic Top (Gloucester Recs 5, 6, 7) is recognised as an issue within scope of the XIFDWG but is a separate issue from that of offset loading. The XIFDWG agreed to start by concentrating on the track twist, vehicle faults and the loading issue. These recommendations are included with reference to vehicle testing. RSSB | Cross-Industry Freight Derailment Working Group: Interim Progress Report 25 should then propose changes to the standards which are used assess the compatibility of vehicle’s ride performance with the railway infrastructure in Great Britain (at present this is Railway Group Standard GM/RT2141), which will implement the cyclic top assessment identified by the review. The proposed changes to the standards, as agreed by Rolling Stock Standards Committee, should then be implemented by RSSB by means of a time bound programme (paragraphs 194b.i, 194b.ii and 195c). 7 .The intent of the recommendation is to highlight the risk that a wagon may be susceptible to riding problems if it is designed with a bogie centre spacing distance that is the same as a wavelength commonly associated with cyclic top track defects. RSSB, in conjunction with Rolling Stock Standards Committee, should propose that guidance on the design of freight wagons in document GM/GN2688 is amended, to explain that as well as two-axle wagons, if a wagon is designed with a bogie centre spacing that matches a wavelength commonly associated with cyclic top, it may be susceptible to poor ride on jointed track and cyclic top (paragraph 196c). 26 RSSB | Cross-Industry Freight Derailment Working Group: Interim Progress Report Appendix C: XIFDWG work streams and projects – December 2015 Tranche 1 Workstream 1 Update of the risk assessment Project 1.1 Bowtie Workshop 1 Project 1.2 Bowtie Workshop 2 Project 1.3 Review of TRL risk assessment in PPR691 Project 1.4 Investigation of the feasibility of quantified assessment of combinatory risk Workstream 2 Identification of changes to the railway over last 10 years and in the future that could change our understanding of the way in which these types of derailment can occur and the way they are modelled/assessed. Project 2.1 Improved knowledge of derailment frequency Workstream 3 Assess the potential benefits that could be gained from adding an additional longer wavelength track twist measurement/criteria. Project 3.1 Long Wavelength Track Twist Project 3.2 Follow up work by NR - Title TBC Workstream 4 Review of existing loading practice and the guidance provided for vehicle testing. Project 4.1 Existing practice review Project 4.2 R&D project (if required) - Title TBC Project 4.3 Standards change (GMT/RT2141) (if required) Workstream 5 Assess the need and feasibility of testing and / or computer simulations of existing wagons to establish limiting offset loading conditions and related wheel unloading limits. Project 5.1 Modelling work Project 5.2 R&D Project (if required following Project 4.1) - Title TBC Tranche 2 Tranche 3 RSSB | Cross‐Industry Freight Derailment Working Group: Interim Progress Report 27 Tranche 1 28 Workstream 6 Analysis of GOTCHA measurements to establish existing wagon uneven load profile distributions. Project 6.1 Confirm data is fit for purpose and/or source additional module Project 6.2 Analyse data Workstream 7 Examine the rules and regulations around the loading of verification of containers as a wider transport issue. Project 7.1 R673 Quantify the distribution of unevenly loaded containers carried by road and rail Project 7.2 ORR/HSE discussion re Road Risk data re poorly loaded containers Workstream 8 Recommendations Mapping Project 8.1 Map projects to RAIB recommendations / Identify gaps & key dates Workstream 9 Communication and Engagement Project 9.1 XIFDWG Communications Strategy Project 9.2 Engagement with Client Groups (such as FTC, NFSG, RSSC, and ISC) RSSB | Cross‐Industry Freight Derailment Working Group: Interim Progress Report Tranche 2 Tranche 3 RSSB Floor 4, The Helicon enquirydesk@rssb.co.uk 1 South Place London EC2M 2RB http://www.rssb.co.uk