RSSB INS & RST Delivery Unit

advertisement

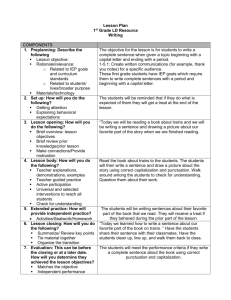

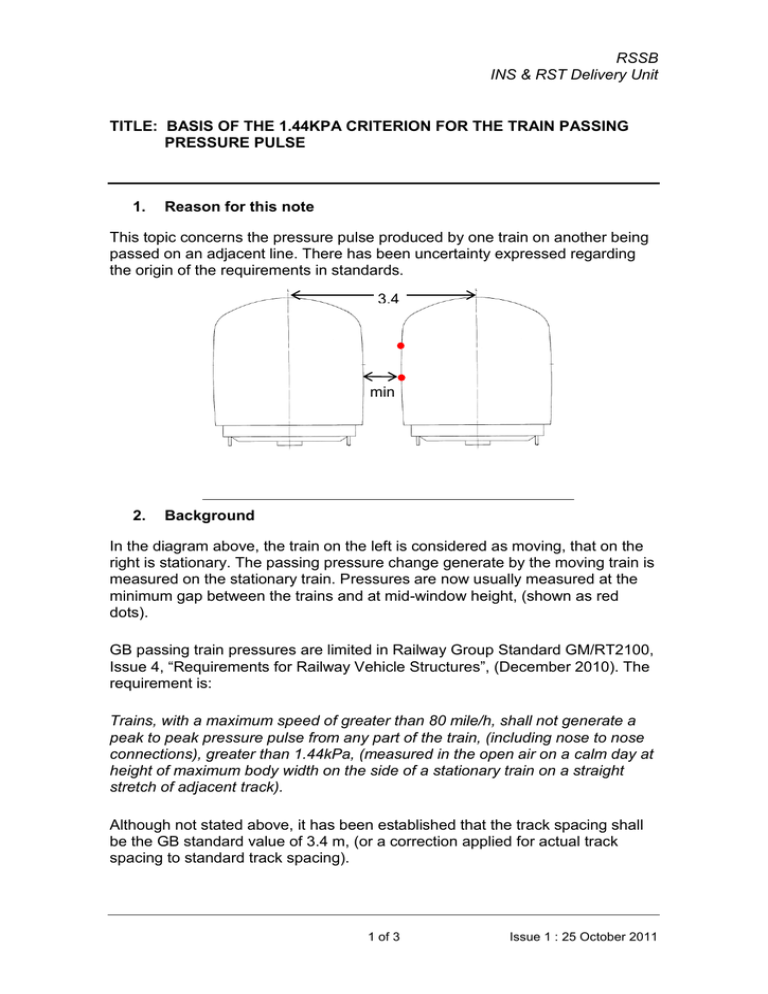

RSSB INS & RST Delivery Unit TITLE: BASIS OF THE 1.44KPA CRITERION FOR THE TRAIN PASSING PRESSURE PULSE 1. Reason for this note This topic concerns the pressure pulse produced by one train on another being passed on an adjacent line. There has been uncertainty expressed regarding the origin of the requirements in standards. 3.4 m X min X 2. Background In the diagram above, the train on the left is considered as moving, that on the right is stationary. The passing pressure change generate by the moving train is measured on the stationary train. Pressures are now usually measured at the minimum gap between the trains and at mid-window height, (shown as red dots). GB passing train pressures are limited in Railway Group Standard GM/RT2100, Issue 4, “Requirements for Railway Vehicle Structures”, (December 2010). The requirement is: Trains, with a maximum speed of greater than 80 mile/h, shall not generate a peak to peak pressure pulse from any part of the train, (including nose to nose connections), greater than 1.44kPa, (measured in the open air on a calm day at height of maximum body width on the side of a stationary train on a straight stretch of adjacent track). Although not stated above, it has been established that the track spacing shall be the GB standard value of 3.4 m, (or a correction applied for actual track spacing to standard track spacing). 1 of 3 Issue 1 : 25 October 2011 RSSB INS & RST Delivery Unit 3. Origin of the requirement Although studies of this phenomenon had been undertaken for research and development purposes during the 1970s, a need to quantify the magnitude of the effect for existing and future high speed service routes arose in the late 1980s due to adverse comments from train users. The comments were relatively rare, but mainly centred around passengers being startled by the banging of doors, (particularly of external sliding doors used on some types of multiple unit), and windows (particularly hopper windows), when passed by other trains at high speeds. In addition, coffee and other drinks resting on tables on the side adjacent to the Fast line, mainly in other HSTs, were regularly spilt by passing HSTs. This was caused by a rapid displacement of the coach wall against which the tables rested. Although the events could not be called serious, it was evident that a criterion was needed for the design of new trains for the: i) Door and window mounts and for the structural side-wall stiffness of vehicles likely to be operating on high speed routes ii) Future high speed train nose shapes, (as it was known that it was the aerodynamic shaping, as well as speed, of the source train that sized the pulse magnitude). Subsequently, tests were undertaken by the Research Division of BRB in 1988 to assess the magnitude of the largest pressure pulses produced by service trains at that time. Tests were undertaken on ECML with a test vehicle being passed, during both static and moving tests, by a number of service trains. Of particular interest was the HST, as it was often the offending train and was operating at speeds up to 125 mi/h on tracks at a nominal spacing of 3.4 m. In some places, track spacing was known to be less than this and, of course, considerably more than this in other places. In addition, the Class 91 loco was being produced and it was necessary to choose a criterion, bearing in mind future operation of the IC225 train (also on ECML). In that event, it was decided during discussions between the senior managements of the Research Division and the IC225 Project Team that IC225 operation at 225 km/h should form the limiting condition for defining the pulse limit. At that time, prior to tests being undertaken with Class 91, it had been assumed that the pressure pulse characteristics generated by the nose shape of the Class 91 would be similar to HST, and therefore that a criterion based on an HST result scaled up from 125 mi/h to 225 km/h should be adopted. Results from the tests produced a mean value, (taken over several passes at different track spacings and speeds of both trains), for the HST normalised to 3.4 m nominal track interval, which was given by the non-dimensional parameter, CP = 0.6. At 225 km/h, this equated to a 1.44 kPa peak-to-peak pressure amplitude. 2 of 3 Issue 1 : 25 October 2011 RSSB INS & RST Delivery Unit Subsequent tests with IC225 showed the Class 91 to have slightly better characteristics than HST, but the 1.44 kPa value was adopted for future project design purposes. Further, BR Research advised that, for practical purposes during track tests, compliance with the criterion was to be checked against a measurement taken at mid—window height on a stationary observing train on straight track on a windless day. The result then was to be corrected to nominal 3.4 m track spacing. 4. Observations In the same way as for the original tests and for the nominal service condition chosen by Research and DM&EE management, there will be circumstances now when 1.44 kPa is exceeded. For example, movement of the observing train, the presence of cross-winds, reduced track spacing and track curvature can all increase the pulse amplitude. Thus, it is important to adopt this specification of the reference set of conditions under which the criterion is to be met. Note that the above implies that rolling stock operating on high speed routes should be structurally designed to a criterion in excess of l.44 kPa for the train passing pressure pulse case. For the proof load case of unsealed trains, this will usually be covered by the +2.5 kPa specification for vehicle body structures (see GM/RT2100). Sealed trains will be covered by their own more stringent limits. However, fatigue load cases particularly for unsealed trains may need to incorporate higher values associated with regular exceedances of 1.44 kPa. Although the origin of the requirement appears rather trivial, as stated above the more important need for such a requirement is to limit pressures applied to other trains and structures passed by trains. As such there are requirements in EN14067-41 and in TSIs to limit train passing pressures. The primary concern of European railways is to ensure that trackside structures do not experience fatigue damage from the cumulative effects of cyclic pressure loads caused by passing trains. DB has reported such damage to wind and acoustic barriers placed at trackside. 5. Acknowledgement The above note is extensively based on a separate note prepared by Roger Gawthorpe and thanks are given to him for the information. Terry Johnson Aerodynamics Engineer 1 ‘Railway applications – Aerodynamics – Part 4: Requirements and test procedures for aerodynamics on open track’, EN14067-4. 3 of 3 Issue 1 : 25 October 2011