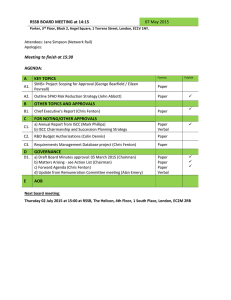

Questions and answers

advertisement

Questions and answers A Questions and answers discussed at the SMIS+ supplier day 16 July 2015 Item 1 Section 1.11 Specification The system shall have the ability to pull in reference data from the data repository automatically, to avoid users having to enter these details manually. Question from supplier Can the RSSB provide specific examples where reference data will be used to populate details automatically? 2 2.13 The system shall allow functions. Can the RSSB give a specific examples of the kinds of geographical areas that are implied in this requirement? 3 4.7 The system shall allow users to record 'other matters concerning safety'. These are not part of the event chain. Can the RSSB give a specific example of 'other matters concerning safety' that are not part of the event chain? Follow up: a) Would this be free-flow text? b) Will there be others that Answer from RSSB PS: This refers to fixed asset data that is mastered by other rail organisations. An example will be by the user selecting a signal id, the system will automatically display on the screen signal characteristics from the signal register. Appendix J provides a list of anticipated fixed asset types. PS: This will be defined during the design phase with the supplier, will be broken down, some as rail-specific and others more general. An example might be a train operator service route, or a county. PS: Other matters concerning safety – these are human errors or safety management failures which did not contribute to the safety event but are identified during the process of investigation. 1 2 Item Section Specification Question from supplier aren't categorised at all? c) If you find another safety issue not related to the event that you are investigating does that become a new safety event? Answer from RSSB Follow up: a) Would probably still be categorised but needs to be worked out with the successful supplier. b) The aim is to fit everything into one scheme of categorisation. c) We think so but need to work this during the design phase. 4 7.12 Incidents in SMIS+ will create safety events based on specified criteria automatically. What is the difference between an incident and a safety event? Can RSSB provide an example of an incident that is not a safety event? Follow up: a) Specific to CCIL? 5 10.17 The system shall allow admin users to maintain a list of 2nd and 3rd tier contractors. What is the list of 2nd and 3rd tier contractors needed for? Can the RSSB give a specific example of how this data will be used? Follow up: PS: An incident is a pre-SMIS+ safety event, and may form the basis of a safety event. Incidents will include wholly operational incidents that are not safety related, for example a report of a staff member being unavailable for work. Follow up: a) Yes, this is only related to CCIL, there will need to be a capability to create a safety events from an incident - this will be based on business rules that are yet to be defined. JB: They are external to the system and may need be referenced when close calls being are logged into SMIS+. Lower-tier contractors will work closely with principal contractors who are actually using the systems. We need to identify if an event Item Section Specification Question from supplier a) do we want TOCs and FOCs' principal contractors to use the new SMIS+ system? b) We don't have a vision for contractors getting BI data out of SMIS+ do we? Answer from RSSB came from a contractor in order to know who actually needs to take responsibility for resolving it. JB: There is a wide range of contractors currently reporting into the current close call system (and some also reporting in current SMIS). Follow up: a) we do intend for them to have the choice to use SMIS+ but we expect this to be phased. Key concern is getting all the relevant close call data rather than replacing contractors' own systems for safety management - this will be via the upload of close calls b) There will be more opportunities for contractors to use the SMIS+ system to get BI data but they won't be required to use this to replace their own systems. Some principal contractors will be RSSB members and will have access to the full system. Network Rail will require their contractors to report close calls using the system, via bulk upload from their existing systems. 3 Item 6 Section 10.23 Specification The system shall have a model of programme and project hierarchies for each organisation, where applicable. Question from supplier Can RSSB provide an example of how the programme and project hierarchies will be used within the system? 7 25.3 It shall be possible to transform data in any of the data sources (held within the repository) into database tables via the use of transformation tools. Can the RSSB provide a specific example of when data would need to be transformed and inserted into database tables? The data management layer shall need to have the capability of an interface to receive public feeds of TRUST train movement data that is distributed by Network Rail's data feed service. The interface will receive messages throughout the Can the RSSB provide a specific example of when TRUST data would be used by the system? Is the system only meant to store the TRUST data from the Network Rail data feed service? 8 4 25.12 Follow up: a) Are the new database tables external to the system data repository? Answer from RSSB PS: Please note the example provided in Appendix A is based on the current CCS organisation hierarchy. This will need to be reviewed for the definitive future structure that will be required in SMIS+ RK: An example would be incident data from British Transport Police which will be used for reporting purposes and may need to be transformed into a common language (e.g. changing of the Route information to be rail specific). However, this will be defined as part of the data management specification work that will be done with the successful supplier. Follow up: a) They will be within the data repository. RK: TRUST data could be used in a number of ways to provide supplementary information for the other processes. For example: To make a link between harm and train performance to provide details of where a train was at a particular moment Item 9 Section 25.13 Specification day and store them in the data repository. Question from supplier The data management layer shall need to have the capability of an interface to receive train consist data for both passenger and freight trains. Can the RSSB provide a specific example of when train consist data would be used by the system? Follow up: a) Are we expecting TOCs to enter data in a central system? b) How fast are we expecting this data to be pulled through? c) so we also need functions to configure how that data needs to consist. Answer from RSSB First step is to collect the data and later in a future phase of implementation we will look to make use of that data into the processes. RK: As with the answer to question 8, this will be used to provide supplementary information for the other processes. JB: Specific example, train going past a red signal, we need to record the train locomotive number, the date, the service details, all pulled automatically into the system rather than being entered manually. Follow up: a) RK: No - We will expect to build in SMIS+ interfaces from common data systems which collect current Train Consist data for all TOCs (Gemini) and FOCs (TOPS) b) It doesn't need to be available immediately, could be a day or so later because there will still be time while the incident is being investigated to bring this data through. PS: We will need to define a process of adding that missing data if it is not 5 Item Section 10 26.17 11 26.26 12 Reporting & BI Specification What are the Quality Assurance, Production Support environments intended to be used for? The system shall support What does 'possible to map calling external web services. the structure of incoming It shall be possible to map data to the destination the structure of incoming structure within the system' data to the destination mean. Can RSSB provide structure within the system. examples of when this would need to occur? One requirement of Can you explain the different developing the new system is groups of reporting and BI that it is to be completely users and how their skills flexible and expandable (in vary? The following environments shall be required: terms of reporting etc.). 6 Question from supplier Answer from RSSB available. c) RK: yes. RK: QA equivalent of integration testing. Production support is for testing changes to the live system and supporting any queries. PS: Web services is just the method of getting the data to the data repository. See item 7 above for details of the transformation. PS: data consumer - this group will quickly digest data from the system. They will be passive users and will not expect to have any reporting skills to access data. Users will have no access to the system, but either receive reports from it, or view dashboards displaying their kpis. Data analyst - someone who will access the system to carry out some analysis. These users will have the skill to create and edit reports within a predetermined framework. Item Section Specification Question from supplier Answer from RSSB Data scientist - these users will have high levels of reporting skills, building on the data analyst. In addition to creating and editing reports they will have the skills to build statistical models, and identify trends. They wouldn't be confined to data views and would be comfortable mixing data sources, and applying scripts and advanced analytical techniques. Data reporter - these users will produce a publication. A publication will be a series of charts, tables, commentary. in addition to the skills of a data analyst they will also have the skills to organise the layout, add commentary, manage version control, collect reviews, manage feedback and publish the publication. Report developer - is an admin role, where the user can create, edit, delete reports, views, calculations and models. They will have in-depth knowledge of the reporting and BI tools, and have the ability to write reports efficiently. 7 8 Item 13 Section Support 14 DQ process 15 Reporting & BI 16 Non functionals Specification Question from supplier Will RSSB be the legal entity who owns and is responsible for the maintenance and upkeep of the new SMIS+ system? Could you elaborate in a little more detail what the Data Quality checking process is? In regards to your analytics requirements and the need for Predictive Models, is this something you currently have in place? Are there any algorithms you currently adhere to in regards to your predictive model? You have provided the volumes of users expected for SMIS+ in the document are these volumes expected Answer from RSSB TD: In terms of configuration but any advanced configuration is consultancy service to be provided by the supplier in the SLA. PS: The data quality process is designed to allow users (who are not the event owner) to raise change requests when the see data that is incorrect in SMIS. This process should encourage the industry to treat events as industry owned rather than just belonging to a specific organisation. The process allows for disputed events to be escalated to RSSB for resolution. PS: This is a capability we are looking to develop and currently have no algorithms. JB: Ramp up over a period of time Item Section 17 Tender 18 Tender Specification Question from supplier Answer from RSSB from day 1 or do you envisage a gradual ramp-up of users as the system is adopted over a time period as this may have an impact on expected on-going annual support and hosting costs. TD: if this is the case, we would want a In the pricing schedule breakdown separately and then the average provided there are entries figure in the schedule. for annual costs such as support and hosting. However annual costs may change over the life of the contract due to service maturity / productivity and user volumes. Would you like a response as an average over the life of the service, the first year only or a breakdown of individual years as an addition? TD: Yes - 1st September section 7 of the main document - Demonstration and dialogue day for selected tenderers (1 day per 9 Item 19 Section Investigation process Specification Question from supplier tenderer during this period). Is the date 01/08 a typo should it be 01/09? On the RSSB1965 SMIS+ Invitation to Request to Participate in Competitive Dialogue v1.docx on page 56 the following users and functions have been provided. We have a number of questions on these roles: Are the 300 safety team and 300 DCP the same people or a completely different set of individuals? Are the Lead Investigator/Investigation Team, Actionee/Responsible Manager, Action Resolver the same people or are they completely different individuals? 10 Answer from RSSB RK: The roles are different, and depending on the organisation they could be the same person (typically smaller organisations will have the same individuals performing multiple roles) Item 20 Section Non functionals 21 Tender 22 Tender 23 Tender Specification Question from supplier Do you have a view / assumption on likely end user number concurrency Answer from RSSB JB: Current SMIS system is 50-80 concurrent users which will increase for SMIS+. Based on an initial estimate it is likely to be no more than 200 concurrent users for SMIS but could be many more for mobile users of the new system. TD: We are looking for commitment on the number of days consultancy and support that we can buy to assist RSSB with implementing future phases of functionality. In order to evaluate this fairly across all suppliers, we will evaluate the same number of days options for the different suppliers. Please could you explain in further detail about the post phase 5 pricing table / structure. What is the intent and what are you looking to achieve from this part of the response. TD: We expect to finalise T&Cs with the What is the expectation for successful tendered but do not envisage 10 August submission in there to be major amendments relation to the T&Cs documentation, including schedules and appendix D. If there are points requiring further discussion, how are these to be managed at this / future stages of the tender. TD: This has already been amended Section 7 of the main document - Demonstration and dialogue day for selected 11 Item Section 24 Tender 25 Tender 26 Event recording & management process 12 Specification Question from supplier Record and Manage a Safety Event tenderers (1 day per tenderer during this period). Is the date 01/08 a typo should it be 01/09? Is there a defined process and timeline for following up with references/referees or as per the qualitative section of the main document, do you intend to rely on email supporting evidence only? Part A of the Draft Combined T&Cs scheduled document includes a number of different pricing mechanisms. In relation to section 15 - pricing schedule for TCO, do you have any expectations / assumptions in relation to which pricing mechanism should apply to which cost? Would it be possible for you to conduct a use case walk Answer from RSSB TD: Initially E-Mail supporting evidence, though we may request reference site visits for information during the dialogue process TD: We plan to use firm pricing because of the nature of SMIS+ PS: Data Overview presentation section covered this. Item Section Specification 27 1.3 The system shall allow the user to create a safety event from a sub-event template. 28 1.11 The system shall flag a record if it satisfies European Common Safety Indicator reporting requirements based on business rules. Users shall be able to overwrite this. The business rules will be defined during the design phase. 29 1.15 Question from supplier through to address the following questions? Fields of a sub-event will prepopulate corresponding fields in the Safety Event. What is the purpose for this? Concerns over issues relating to data value duplication. Would a roll-up view be suitable? Answer from RSSB PS: The intention of this is to give the user a starting point that will be consistent every time that sub event type is chosen. It shouldn't result in any data duplication. For example, if a user chooses the event type 'SPAD' a safety event will be created using the 'SPAD' template, which will have one sub-event, a number of related items, and a number of the sub-event and item fields may be pre-populated. PS: It is envisaged that this flag will initially flag potential European reportable events, which will then require further investigation. This investigation may then reveal the event to not be reportable to the European agency. Why would users be able to override this flag if it is a required reporting requirement, especially as this is not requested for 1.8, 1.9 and 1.10? What type of rules are asked of the reporting requirements? Mandatory? The system shall allow In the example provided it is PS: Allowing different injuries to be split across different injuries to be sub-events allows the correct reporting difficult to understand the recorded for a person against reasons for this requirement, under RIDDOR. multiple sub-events. For In general, it is expected that information on can you explain further? example, a driver might each item will be recorded once and linked 13 Item Section 30 1.22 31 1.24 14 Specification suffer shock from a SPAD, and then a broken arm from a subsequent derailment. Question from supplier Answer from RSSB to each relevant sub-event. So if the same train driver was involved in three sub-events, information about the driver would be recorded once, but relationships would be shown to all three sub-events. The train driver would show whenever the relevant sub-event was being viewed. What is the importance of having injuries recorded against individual events? In general, is it expected that information related to Items (People, Assets, Animals & Other) are recorded in each "sub-event" and rolled up for view within the Safety Event? The system shall allow the Is this just the ability to order PS: Yes. addition, change of position the timeline of events and deletion of the event correctly, either as reported chain nodes via the visual or as identified during representation. investigation? The system shall allow PS: Because some safety events come only Can you further explain the individual organisations to through the interfaces via control logs. This reason for this restriction? define which sub-event types Had you considered that this is to prevent duplication if it comes through can be captured by mobile the control log and the mobile. approach is likely to only, by web/integration only introduce a barrier to or both. reporting? If forms are published to roles then users will be able to use what is immediately available to them at the point of need, Item Section 32 2.2 33 2.6 Specification The system shall have the ability to send notifications and tasks to other organisations. For example, some safety events involve more than one organisation, which means that in addition to the owner of the event other organisations need to contribute to managing the safety event/investigation. It shall be possible to send notifications and tasks to these organisations. The system shall allow users from any organisation the ability to raise a change request against a safety event flagging any information (e.g. assets, persons) that is incorrect or missing from the event. The change request shall include Question from supplier rather than having to find the correct technical reporting mechanism. Does the RSSB anticipate that these organisations will have a login to the system, or will they contribute through some other means out with the system? Regarding the context of 'any'. Would this only be for those individuals from the organisations that are involved with the safety event in question, or is it wider to any relevant or authorised organisation? As an alternative, would an Answer from RSSB PS: They would be users of the system. PS: It is any organisation that has access to the system. We only want the event owner to have the permission to change the safety event, but allow any other organisation to raise a change request if they think something is incorrect. We do not want all organisations to be able to change records that do not belong to them. 15 Item Section Specification the facility to add comments, select the fields/values they don’t agree with and record the value(s) they believe is correct. If the event owner doesn't respond it shall escalate. 34 2.16 The system shall have the ability to send regular feedback on the progress of the safety event to the recorder as a default. 35 3.5 The system shall help users to create a remit or structure to support the investigation. This shall be defined by the sub-event(s) of safety event, level of investigation, LSR breached, business area, and causation factors. 16 Question from supplier "open" system be acceptable if a fully transparent audit log facility were provided highlighting who had changed the record, what had changed and when? Follow up: a) What about data security to stop other organisations viewing the data? What sort of information and at what frequency would be required for such updates? Is there anything they shouldn't know, for example sensitive information relating to an investigation? Please could you provide an example of a remit or structure if this is not a workflow? Answer from RSSB Follow up: a) Personal data will be restricted to the event owner. JB: RSSB will arbitrate over disputes on data sharing or record changing. JB: This will be defined during the detailed design phase. It won't be constant, more likely when event is closed etc. PS: The remit is a template of what needs to be addressed as part of the investigation, please see appendix B. Item 36 Section 4.3 37 38 9.7 Specification The system shall allow users to apply the IFC process to events which are not recorded in SMIS, such as non-GB rail events and events that have not occurred in the GB rail industry e.g. overseas rail events, aviation events, etc. Integration The interface with Network Rail’s CCIL system shall be able to automatically pull incident files from a location on Network Rail’s IT infrastructure into the SMIS+ environment. Need an area of storage of these files. Question from supplier Answer from RSSB If the events are not recorded in SMIS+, then where do they exist for applying the IFC process? Our assumption is that this is a "placeholder" Safety Event without any "sub-events" and only Causation Factors? PS: These events will be recorded in SMIS+ and we may define a small number of subevent types that are only applicable to non-rail records so that they fit in the data model. Do any of the interface scenarios to 3rd party systems require users of SMIS+ to be able to interact with the 3rd party system from within the SMIS+ interface? Can you provide an indication of storage requirements based on data volumes, typical data size and how long these must be retained for? RK: No - all interfaces with 3rd party systems will provide data to SMIS+ only JB: CCIL data is only stored in SMIS for 3 months after which it is deleted as per the process for updating incident records which has a 90 day time limit. In SMIS+, however, we may want to keep it for longer therefore no decision has been made at this stage. 17 Item 39 Section Commercial requirements Specification Intellectual Property 40 Event recording & management process Appendix A - event recording and investigation process – PM1, PM1.4 18 Question from supplier With regards to IP, how does the RSSB envisage this working, given the foundation of SMIS+ is a commercial product (COTS solution)? Answer from RSSB TD: We are looking, as a minimum, to retain event data model and investigation management processes as IP and be able to benefit from further sales of the solution using this model and/or sales leads we generate. Please explain your suggestions for this as answers to these questions. Can you please clarify the PS: An incident is a pre-SMIS+ safety event, meaning of the term Incident and may form the basis of a safety event. as used in this process flow? Incidents will include wholly operational According to the glossary it is incidents that are not safety related, for a “record that originates example a report of a staff member being from an incident file…” but unavailable for work. See item 4 what is its equivalent entity Follow up: within the system? Suba) They can be zoomed in to read all of the event or Occurrence? details so this should not be a problem. Follow up: However if suppliers are still having a) Is it possible to view the problems they need to contact RSSB. process flows in their original Visio format? It is difficult to follow some overlapping links. Item 41 42 Section Event recording & management process General 43 General 44 Implementation 45 Implementation Specification Appendix I – sub-event template examples Question from supplier Answer from RSSB How many sub-event templates are likely to exist? PS: This will be defined during the design phase. Initial estimate is between 50 to 100. RK: No, the concept of SMIS+ is based on an off-the-shelf product enterprise management system that can be easily configured and maintained by RSSB without having to go through further development cycles. The tender seems to be set up with the methodology of purchasing and adapting an off the shelf system. Are the RSSB open to the idea of a bespoke greenfield development project aimed at meeting the requirements in their entirety? Is the plan for Network Rail to use this system entirely? Is there an opportunity to combine the design and build phases in some respects in order to move more efficiently? How will we deal with key sign-offs on design and what is the potential time lag? JB: Yes. RK: Potentially, yes, we are looking for proposal from the supplier with their implementation plan which may or may not be the same as RSSB's. Should the supplier go for their own implementation plan then justification would be needed as to why this is a better plan. RK and GB: We are consulting a lot with the industry already, and there is a Project Board with significant industry representation that will act as a central 19 Item Section Specification Question from supplier 46 Event recording & management process How is the event description created? 47 Future phases 48 Future phases 49 Future phases Any plans to require linking between modules and future phase functionality, e.g. linking risk assessment and audits with safety events CIRAS: Are the processes within CIRAS different for each member or sector? What's the commercial impact of those additional CIRAS users? 20 Answer from RSSB decision-making body to ensure this project sticks to the challenging timescales set by the industry. Time lags will be specified by the SMIS+ project team e.g. 5 days for a review JB and PS: Currently this is free text for the user, we might want to put some rules around it but this generally is selected from the major (or latest) sub-events in practice. JB and PS: We are looking to learn from safety events using as much related information as possible. However, we don't require this to be part of the event chain initially. PR: No, the processes are generic for all members PR and TD: There shouldn't be an impact as CIRAS users won't separately be using the system, so we don't expect a licensing / usage cost at the outset, just the days consultancy we can get for future phases of requirements. Item 50 51 Section Future phases Future phases Specification Question from supplier Answer from RSSB Is the plan with SMIS+ to interface with a mapping tool? Is this in the spec anywhere? RK: There are plans to interface with external mapping tools, however this is for future phases when the data management layer has matured and when risk modelling requirements have been implemented. This is not currently in the specification. In the meantime we are after, for phase 1 to 5, the ability to use electronic maps for identifying locations during the event recording and management processes. This will be built into the solution. The functionality may interface with external sources to bring in map data via a web services mechanism e.g. google maps TD: There is a separate cell in the cost breakdown table where we encourage tenderers to itemise any specific costs for the mapping solution such as the use of external map data (e.g. google maps) Do we want to have a future JB: Potentially, long term we would like facility for people to log NIR / these events to be logged once in one Rail notices and SMIS+ in real system but this is not the initial scope. time, at the same time? 21 Item 52 Section Investigation process 53 Functional requirements 54 Functional requirements 55 Tender 56 Training Who will be responsible for training on BI tools? 57 Support Do we envisage users being able to add additional fields 22 Specification Question from supplier Answer from RSSB How are you envisaging that you want the decisions in the investigation management process to happen? Have we decided on a hierarchical structure? Including matrix and traditional hierarchies? RK: These decisions will follow industry standards and processes. Do we have any idea of the types of mobile platforms that will be used for SMIS+? Is reducing overheads part of the business case? RK: We have some ideas, however, this will need to be worked out during the design phase. RK: Yes, including both, the system will need to be flexible. RK: Primarily Android, iOS, some organisations use Windows phones as part of their IT policy JB: It is not formally costed, we and our industry stakeholders have identified the opportunity. JB: As with training generally, we are looking for train the trainer training. This will be to RSSB who will support and develop the system. We would also welcome suggestions of other media and training methods to end users - this will be a specific question. JB: .We need the capability to create bespoke fields by organisation. Organisations will be able to make the Item Section Specification Question from supplier Answer from RSSB bespoke to their organisation? 58 Non functionals initial request for additional fields, however RSSB would do that on a user's behalf once the request has been reviewed and approved. Will other organisations have RK: Yes - all events are open to all the ability to see all events? organisations but as a read only. This will allow the feedback loop to work. However any personal information on the safety event will need to be restricted to other organisations. B Questions and answers submitted before 28 July 2015 23 Item 1 Section Tender Specification 2 In regards to question 4 previously submitted (requirement 7.12) Incidents in SMIS+ will create safety events based on specified criteria automatically. Event management The system shall have the ability to use different risk matrices for different subevents. 3 24 Question from supplier Would like to enquire as to whether or not there are word limits which apply to any of the responses requested in the SMIS+ tender document. In regards to question 4 can you please describe as to what functions are required under the term configuration. Answer from RSSB RK: There is no word limit to the responses. However, some will require more wordings to be provided than others. These should be self-explanatory Could you please explain how you envisage group reporting would work when there would be several different matrices being used for the difference sub events? PS: I’m not sure what is meant by the term ‘group reporting’. However we envisage one user would have to fill in the risk matrix. If a safety event had multiple sub events that each wanted a different risk matrix, then these would be managed separately via their own workflows, but only one person would take the lead in completing each risk matrix. Question 4- PS: Neither req 7.12 nor previous question 4 (or answer) mentions the term configuration. However, there will be the need to maintain business rules that will store the criteria on how safety events will be created from incidents. 4 Investigation Management Electronic Signoff The system shall allow multiple electronic sign-offs on an investigation report. 5 Integration with Incident files The system shall automatically flag cancelled incident records which have associated safety events that are still active. The user shall then be required to acknowledge the flag, in orders to confirm the cancellation. In regards to req 3.16 in reference to the ability to electronically sign off the event. Is this referring to an electronic signature? Or simply the ability to check something to indicate sign off has taken place? Could you please elaborate on req 7.17? PS: This refers to an electronic signature, which can then be shown on any electronic and published reports. There will also be a status indicator that will show the investigation report has been signed off. PS: This requirement is to deal with the scenario, where an event has been created in CCIL (incident record) from which a safety event has been created in SMIS+, and then later, the originating record in CCIL has been cancelled. In this scenario, we want SMIS+ to alert the user that the originating CCIL incident record has been cancelled. It will then be left up to the SMIS+ user to decide what to do with the safety event record. 25 6 7 26 Reporting and BI Reporting and BI The system shall have the ability to handle the following data sets to be used in reporting and BI: -safety event data - legacy data - reference data - organisation specific data - normalisers - admin data - statistical techniques - calculations - definitions - GIS data The system should give users the ability to link a scheduled transformation in the reporting and business intelligence module with a scheduled report, so that a report automatically runs on the completion of a transformation. In regards to req 9.6 could you please elaborate on what is meant by ‘admin data’ and ‘statistical techniques’? PS: Admin data – we would like any of the admin log data that the system is recording to be made available to the reporting and BI tools e.g. audit trail which would include tracking of who has changed what and when. This will be a key part of the data required in the data quality monitoring reports. Statistical techniques – we are looking to be able to apply statistical tests to the data when running the BI software tools on the SMIS+ data. These include, but are not limited to, significance and hypothesis testing, forecasting, time series analysis, classifications, clustering. In reference to req 9.31 what is meant by ‘transformation’? PS: An example might be one of our data models, which takes input data on a monthly basis from a number of external sources. This is then combined with internal data sources into a new single “common language” data set which is then passed into a model and the latest results reported. These activities need to automatically follow on from each other. 8 Reporting and BI The system shall have the ability to include, store and view meta data and criteria of individual charts and whole publications. Could you please elaborate on req 9.42? 9 Functional system service requests The system shall allow admin users to write, amend and delete definitions of terms used across the system. Req 10.5 mentions the ability to write, amend and delete 'definitions of terms' what is meant by this? PS: Whenever a report or chart is created we want to be able to capture the criteria that was used to generate it, the snapshot that was used and the details of the user who created it and when. Additionally, the user might want to add some of their own user generated meta-data, for example details of any assumptions they made while carrying out the analysis. This is particularly important when the analysis is revisited some time later. PS: As part of our data design work, we will be producing a set of definitions of fields and values. We would like these to be added and used across SMIS+. To ensure they stay up to date an admin user will need to be able to write, amend and delete them. 27 10 Safety event The calculations will be based either on the data entered for the risk matrix, other data previously recorded in the safety event or data stored in lookup tables. The calculations must include all standard mathematical functions such as addition, subtraction, multiplication, division, logs and powers. The calculations should be able to run as scripts as they could involve case statements, loops or nests (if statements) Please could the RSSB provide an example of this? PS: Appendix M in the high level requirements specification document, sets out the current SPAD Risk Ranking Tool (SSRT), which is the risk matrix for SPAD events. Currently the SSRT is being reviewed and some of the proposals include rewriting it to use more advanced scripts using case statements, loops and nests. 11 IFC The system shall allow association of the event with specific studies (e.g. ‘review of international rail events’; ‘detailed review of station stopping incidents’; ‘human factors high risk sample’). With regards to specific studies, are these external to SMIS+, or managed within SMIS+? PS: It is envisioned that the tagging of safety events to studies will take place in SMIS+, the data would then be extracted via the reporting and BI tools. The results of the study might then be loaded back into the data management layer and will be used for reporting purposes. 28 12 Recommendation, The system shall provide the task and action facility for users to view and tracking track tasks, actions and recommendations assigned to them. Do the RSSB expect that this would extend to the mobile applications in an offline capacity? PS: It is envisaged that there will be a major benefit of users being able to view and track tasks, actions via a mobile device. It is not a requirement for this to be offline. 13 Functional requirements Please could the RSSB provide an example output of this information? PS: This will be defined during the data design phase, but this will take the form of a number of events per ‘filter’ from which the user can drill into a list of safety events, and then into a specific safety event. E.g. Number of “open” safety events for Network Rail’s infrastructure team working on the Southern Route. The system shall provide the facility to view safety events by status and org hierarchy at all levels and units. 29 14 15 Functional system service requests Functional system service requests The system shall allow admin users to control access rights for each field. Access to fields will either apply to all users or to users of a specific organisation. The system shall allow admin users to implement and maintain business rules associated to the workflows. Please could the RSSB provide an example for this requirement, and specifically what is the purpose of a reporting field if users are restricted from using it? Please could the RSSB provide examples of the business rules, or likely examples if not yet known? PS: This means that SMIS+ might have fields that only one organisation can see and use, as the information being collected is specific to that organisation only. This will then be available for the organisation to report on. E.g. Internal information relating to their wider organisation or parent company All requests for new fields will be submitted to the central admin team. This will go through a review process where it will be decided whether or not the field should be added. In a number of cases the field may even become a system wide field rather than just an organisation specific one. PS: These will be defined during the data design phase. It is likely that safety events occurring in yards, depots and sidings, will require less information then a similar event on a running line. So those on a running line might trigger a further set fields that will need to be completed as part of data collection. We also envisage determining the RIDDOR reportability via a set of business rules. 30 16 System admin 17 Lessons learnt 18 Implementation plan The system shall have a model of programme and project hierarchies for each organisation, where applicable. The project structure will be mapped to organisation structures. The mapping will be part of the design phase. Please could the RSSB explain why they have project and programme as an extension of organisation hierarchy, rather than separate entities which are related? Are there not cases when a project or programme would cut across multiple organisations? The system shall present the finds of the investigation into the safety event(s) and the most effective way to prevent its reoccurrence What is the measure of 'most effective' as this implies that whatever was done to prevent re occurrence has been tested? We understand through time the SRM would be able to support this, but are there other measures we should be aware of? Structure of the implementation plan has been queried. Would a more iterative approach from Day 1 benefit the implementation? PS: We don’t see project and programmes as an extension of the organisation hierarchy. We see them as separate yet related entities. The line ‘project structure will be mapped to organisation structures’ was a recognition that there will be relationships between them, and that we want to capture those relationships. PS: How this information will be identified has yet to be determined as this is a future phase requirement. Only outcome based requirement have been captured for the future phases. There are no specific measures identified at this time. A possible way of achieving effectiveness could even be via a manual review of the recommendations with feedback being captured back into the system. RK: RSSB have recognised this and, after consultation with the rail industry and other stakeholders, have published an alternative plan that is based on an iterative design and build approach that will still be able to incorporate industry wide consultations. 31 C Questions and answers submitted after 28 July 2015 Item 1 32 Section Pricing schedule Specification Question from supplier We would like to propose a single cost along with a description of what that cost includes. This is for the following reasons: Our proposed solution already has much of the capability required, even for the post phase 5 requirements Our cost for the system includes multiple elements such as hosting, mobile and BI Our proposed agile approach to implementation of SMIS+ does not lend itself well to the line items detailed. Answer from RSSB TD: We ask suppliers to break down the costs in a common format in order that we can understand in granular detail the constituent elements of the cost, which we will discuss during the commercial session of the dialogue day with each selected tenderer in order to challenge unnecessary functionality and cost from tenderers’ solutions during the competitive dialogue. - Total cost of ownership is a significant evaluation criterion, weighted at 38% of the total score. Therefore, being able to break down, understand and remove cost benefits both RSSB and tenderers - as tenderers will achieve a higher score against this criterion in the evaluation because the total cost of their solution will be lower. - All costs must be contained within the schedule provided, though we encourage additional breakdowns and explanations of any assumptions. - If a tenderer’s solution does not incur additional cost (or cost is limited) for certain activities, please only specify the cost that is required or mark £0 if that activity does not incur cost. Appendix A: Organisation structure hierarchy The following example is an organisation hierarchy that is defined in the current CCS system. Contractor organisations have agreed to log all close call type of safety events arising during their work on Network Rail infrastructure projects. The larger contractor organisations are split into ‘divisions’, either geographically or by the type of work they do. For example Spence Refit is split into the following divisions: 1. Commercial Property 2. Greater Anglia 3. Kent Maintenance 4. London Midland 5. London Overground 6. Southern Railways 7. Spence Projects and Sussex Maintenance These divisions are then linked to the Network Rail projects that they are involved in (i.e. in this example the Network Rail projects become the third level – sub divisions - of the organisation hierarchy). See screen shot below: 33 At present all Network Rail projects are stored in a manually updated flat table. Each has a unique Network Rail project ID. This allows Network Rail to extract data against their projects, as well as allowing the contractors to extract data by their organisation divisions. Appendix B: - Example of a remit NR Formal Investigation Remit template.doc 34