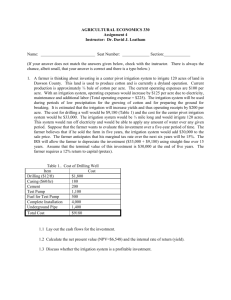

A I W C

advertisement