F

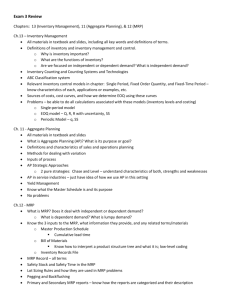

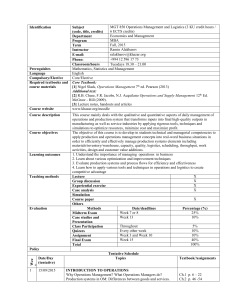

advertisement