Investigation of the Effect of a Circular Patch of Vegetation on Turbulence

Generation and Sediment Deposition Using Four Case Studies

By

Alejandra C.Ortiz

B.A., Wellesley College, 2010

Submitted in partial fulfillment of the requirements for the degree of

Master of Science

4ASSACHUSETTT T

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

and the

WOODS HOLE OCEANOGRAPHIC INSTITUTION

ARCHIVES

JUNE 2012

@ 2012 Alejandra C. Ortiz. All rights reserved.

The author hereby grants to MIT and WHOI permission to reproduce and to distribute

publicly paper and electronic copies of this thesis document in whole or in part in any

medium now known or hereafter created.

I '

Signature of Author.

.... .. ....

.. .. .. .. .. .. ..

....

......

Joint Program in Marine Geology & Geophysics

Massachusetts Institute of Technology

and Woods Hole Oceanographic Institution

A

May 11, 2012

Certified by....,

......................................................

Heidi M. Nepf

Professor of Civil and Environmental Engineering

Thesis Supervisor

Accepted by.............

Rob Evans

Chair, Joint Committee for Geology & Geophysics

Woods Hole Oceanographic Institution

Accepted by...

...........................................

Heidi M. Nepf

Chair,

epartmental Committee for Graduate Students

Massachusetts Institute of Technology

2

Investigation of the Effect of a Circular Patch of Vegetation on Turbulence

Generation and Sediment Deposition Using Four Case Studies

by

Alejandra C.Ortiz

Submitted to the Department of Civil and Environmental Engineering and Woods

Hole Oceanographic Institution on May 11, 2012 in partial fulfillment of the

requirements for the degree of Master of Science in Civil and Environmental

Engineering Jointly by the Massachusetts Institute of Technology and the

Woods Hole Oceanographic Institution.

Abstract

This study describes the spatial distribution of sediment deposition in the

wake of a circular patch of model vegetation and the effect of the patch on

turbulence and mean flow. Two different types of vegetation were used along with

two different stem densities totaling four different case studies. The spatial location

of enhanced deposition correlated with the steady wake zone, which has length, L1 .

The steady wake zone only occurred downstream of the rigid emergent patches of

vegetation and was not seen downstream of the flexible submerged patches of

vegetation. The enhanced deposition occurred when both turbulence and mean

velocity was below the upstream, initial values. The enhanced deposition occurred

when the mean velocity was less than or equal to half of the initial velocity. For the

four cases studied, these parameters of low velocity and low turbulence were

primarily met within the steady wake region immediately downstream of the two

rigid emergent patches of vegetation. In all four cases, large coherent structures are

created in the flow due to the patch. Lateral vortices are formed downstream of the

patch in a von-Karman vortex street that meets at the center of the flow a distance,

Lw, downstream of the patch. For the flexible submerged cases, streamlines reattach

to the bed of the flume a distance, L,, downstream of the patch. In addition, for the

flexible submerged cases, secondary circulation is generated with flow moving

laterally away from the patch at the surface and toward the centerline of the patch

at the bed.

Thesis Supervisor: Heidi M. Nepf

Title: Professor of Civil and Environmental Engineering

3

4

Acknowledgements

First, I offer my sincerest gratitude to my advisor, Heidi Nepf, for her advice

and help with my project. She has been invaluable with her patience and expertise

on this project. I would also like to thank my advisor, Andrew Ashton, for his help

and advice on this project. I would also like to thank him for his support for this

science master.

Several students have been very generous with their support and advice over

the last year. I would like to thank Elizabeth Follett, Natasha Maas, and Mara

Orescanin. I would also like to thank Lijun Zong for her instruction and time. Finally,

I would like to thank ZB Chen for his help in the lab and with the experiments.

Lastly, I give my most sincere thanks to my family and friends for all of their

love and support. I also thank my mother for her editing and my friends for their

unstinting encouragement.

This material is based upon work supported by the National Science

Foundation under Grant Nos. EAR 0738352 and OCE 0751358. Any opinions,

findings, and conclusions or recommendations expressed in this material are those

of the authors and do not necessarily reflect the views of the National Science

Foundation

5

6

Table of Contents

CHA PT ER 1

IN T R O D U CT IO N ....................................................................................................

1.1.

BACKGROUND..............................................................................................................................................15

1.2.

O UTLINE.......................................................................................................................................................17

CH A PT ER 2

M ET H O D O LO GY ....................................................................................................

2.1.

EXPERIM ENTAL M EASUREM ENTS......................................................................................................

2.2.

DATA PROCESSING.....................................................................................................................................23

2.3.

DATA A NALYSIS..........................................................................................................................................28

CHA PT ER 3

RESU LTS ................................................................................................................

3.1.

CONTROL EXPERIM ENTS...........................................................................................................................31

3.2.

RIGID EM ERGENT VEGETATION ..............................................................................................................

13

18

18

31

33

3.2.1.

Case 1 - Rigid D ense ........................................................................................................................

36

3.2.2.

Case 2 - Rigid Sparse.......................................................................................................................

41

FLEXIBLE SUBM ERGED VEGETATION ...............................................................................................

46

3.3.

3.3.1.

Case 3 - Flexible Dense ...................................................................................................................

50

3.3.2.

Case 4 - Flexible Sparse..................................................................................................................

5 7

CH A PT ER 4

D ISCUSSIO N ...........................................................................................................

64

CHAPTER 5

CONCLUSIONS & FUTURE WORK ....................................................................

74

7

List of Figures

Figure 1-1. Conceptual plan-view diagram of the flow around a porous rigid

em ergent vegetation patch ...................................................................................................

Figure 2-1. Plan-view experiment setup in the flume. .......................................................

17

21

Figure 2-2. Diagram of use of Acoustic Doppler Velocimeter (ADV) in flume for Rigid

Em ergent vegetation patch...................................................................................................

22

Figure 2-3. Diagram of ADV in the flume for flexible submerged sparse vegetation

p a tch ...................................................................................................................................................

23

Figure 3-1. Net deposition along centerline of flume for control experiment where H

= 13.5 cm with plotted mean and standard deviation of net deposition......... 32

Figure 3-2. Net deposition along centerline of flume for control experiment where H

= 21.5 cm with plotted mean and standard deviation of net deposition.......... 33

Figure 3-3. Mean velocity and turbulence along the centerline of the flume for Case

1............................................................................................................................................................

34

Figure 3-4. Mean velocity and turbulence along the centerline of the flume for Case

2 ............................................................................................................................................................

35

Figure 3-5. Quiver plot of the flume in plan view for Case 1. ..........................................

37

Figure 3-6. Deposition and velocity along centerline of the flume for Case 1.......... 39

Figure 3-7. Lateral transects of normalized A) velocity, B) urms, and C)TKE for Case

1............................................................................................................................................................

40

Figure 3-8. Spectral analysis of velocity data taken along centerline of flume at 7 cm

d ep th fo r Case 1 .............................................................................................................................

8

41

Figure 3-9. Quiver plot of the flume in plan view for Case 2 ...........................................

42

Figure 3-10. Deposition and velocity along centerline of the flume for Case 2........... 44

Figure 3-11. Lateral transects of normalized A) velocity, B) urms, and C) TKE for

Ca se 1 .................................................................................................................................................

45

Figure 3-12. Velocity Spectra measured along centerline of patch at 7 cm depth for

Ca se 2 .................................................................................................................................................

46

Figure 3-13. Conceptual diagram of plan view of the flow around porous flexible

submerged patch of vegetation. .........................................................................................

47

Figure 3-14. Conceptual diagram of side view of the flow over submerged flexible

v e g e tatio n .........................................................................................................................................

48

Figure 3-15. Conceptual diagram of normal view of flexible submerged patch of

v e g e tatio n .........................................................................................................................................

Figure 3-16. Quiver plot of the flume in plan view for Case 3.................

48

51

Figure 3-17. Vertical-lateral quiver slices taken in y and z throughout the flume from

x = -50, 50, 100, and 400 cm, respectively for Case 3 (x/D = -1.2, 1.2, 2.4, 4.8,

a n d 9 .5 )..............................................................................................................................................

52

Figure 3-18. Deposition and velocity along centerline of the flume for Case 3........... 54

Figure 3-19. Lateral transects of normalized A) velocity, B) urms, and C) TKE for

Ca se 1.................................................................................................................................................

55

Figure 3-20. Normalized intensities of turbulence fluctuations along centerline of

flume at three depths for Case 3........................................................................................

Figure 3-21. Quiver plot of the flume in plan view for Case 3.................

9

56

58

Figure 3-22. Vertical-lateral quiver slices taken in y and z for Case 4........................

59

Figure 3-23. Deposition and velocity along centerline of the flume for Case 3........... 60

Figure 3-24. Lateral transects of normalized A) velocity, B) urms, and C) TKE for

Ca se 1.................................................................................................................................................

62

Figure 3-25. Normalized intensities of turbulence fluctuations along centerline of

flume at three depths for Case 4........................................................................................

63

Figure 4-1. Predicted sediment deposition along the centerline of the flume for each

ca se ......................................................................................................................................................

70

Figure 4-2. Horizontal velocity versus turbulence kinetic energy colored and scaled

by th e n et d ep osition ...................................................................................................................

72

Figure 4-3. Locations in the flume where the deposition is measured ......................

73

10

List of Tables

Table 1. Summary of patch parameters for the four cases and two control

experim ents w ith standard deviations..........................................................................

19

Table 2. Summary of measured flow parameters with calculated standard deviation

for rigid emergent patch of vegetation (Case 1 & 2). ...............................................

35

Table 3. Summary of measured flow parameters with calculated standard deviation

for flexible submerged patches (Case 3 & 4) with standard deviation............. 49

Table 4. Summary of peak of intensities of turbulent fluctuations for each case along

centerline of flum e with standard deviation...............................................................

66

Table 5. Summary of estimated sediment concentrations for each experiment for

entire flume with calculated standard deviations based on 10% error.......... 67

11

Nomenclature

H

x,y,z

t

Uj

ui

Ut,rms

TKE

U

Uo

Ue

U2

Lo

Li

L2

Lw

Lv

n

d

h

a

D

height of water

streamwise, lateral, and normal

directions

time

time averaged velocity components

CD

CO

drag coefficient

initial sediment concentration

S-

final sediment concentration

probability of sediment

deposition

specific weight of sediment

non-dimensional fall velocity

r

sediment diameter

Ce

p

instantaneous velocity components

intensity of turbulence fluctuations

components

turbulence kinetic energy

S

total horizontal velocity

upstream velocity

exit velocity

steady wake velocity

upstream adjustment length

steady wake length

gravity

frequency

f

fall velocity

ws

hmeas depth of measurements

m

mass of sediment deposited

concentration of sediment

C(t)

over time

bed friction coefficient

Cf

Re

Reynolds number

Greek Letters

solid volume fraction

Shield's parameter

ipb

V

kinematic viscosity

density

p

9

wake recovery length

length to maximum turbulence

vertical reattachment length

dowels per bed area

dowel diameter

height of canopy

frontal area per volume

diameter of patch

12

Chapter 1 Introduction

Biogeo morphology is the study of how feedbacks between vegetation and

Earth surface processes affect the form and shape of landscapes. It analyzes the

complex feedbacks and readjustments that exist between landforms, and physical

and biotic processes (Corenblit et al., 2007). Fluvial systems have complex

interplays between the land, the flow, and biota. The linkages in fluvial systems

between vegetation and physical processes are conceptualized in the fluvial

biogeomorphic succession model (Corenblit et al., 2007; Schnauder and Moggridge,

2009). This research aims to understand the feedbacks between aquatic plants,

flow, and sediment deposition in fluvial systems, by investigating the relative

importance of turbulence and mean flow on sediment deposition. We examine how

porous patches of vegetation affect flow conditions, and consequently change

depositional patterns.

River types can be strongly influenced by the presence of riparian vegetation.

Vegetation consolidates and stabilizes riverbanks, allowing for meandering rivers to

develop instead of braided streams (Murray and Paola, 2003; Rominger et al., 2010;

Tal and Paola, 2007). Vegetation also grows within the channel as well as along the

banks. In fluvial systems, in-channel aquatic vegetation typically exists in noncontinuous patches (Corenblit et al., 2007; Naden et al., 2006). Aquatic vegetation

modifies flow hydraulics (Schnauder and Moggridge, 2009). Vegetation found in

rivers range from emergent reeds to submerged grasses. It affects water quality by

13

nutrient uptake, decreasing turbidity, and even heavy metal sequestration

(Christiansen et al., 2000; Hendriks et al., 2008; Naden et al., 2006).

Within fluvial systems, the flow entrains and transports sediment. Alluvial

rivers transport sediment in two different methods as bed load, sediment in contact

with the bed, and suspended load, sediment independent of the bed (Church, 2006;

Dade and Friend, 1998; Engelund and Fredsoe, 1976). Typically, transport as

suspended sediment comprises 50-90% of the total sediment load in the river

(Anderson and Anderson, 2011; Dade and Friend, 1998). Any sediment carried

within the flow as suspended sediment is strongly affected by changes in flow

characteristics. Sediment deposition patterns are spatially related to flow

characteristics within a river. Usually, sediment deposition is considered dependent

on the mean flow rather than turbulence (Bos et al., 2007; Christiansen et al., 2000;

Rodrigues et al., 2006). There is controversy over the role turbulence plays in

sedimentation. Some studies claim turbulence is important for sediment deposition

while others suggest mean velocity is more important for sediment deposition

(Boyer et al., 2006; Church, 2006; Nelson et al., 1995; Williams et al., 1989).

Previous work in our lab group has focused on the spatial distribution of sediment

deposition around a patch of vegetation where the primary transport is bedload

rather than suspended load (Follett and Nepf, 2012). We specifically investigate

suspended sediment transport and deposition.

14

1.1. Background

Aquatic vegetation is viewed as beneficial in fluvial restorations because it

decreases near-bed velocity and stabilizes the sediment at the bed (Pollen and

Simon, 2005). Vegetation also provides a heterogeneous habitat by creating

different flow regimes (Kemp et al., 2000). Research has focused on the

hydrodynamics of a continuous segment of vegetation (Bos et al., 2007; Ghisalberti

and Nepf, 2006; Luhar et al., 2008; Murphy et al., 2007; Murphy et al., 2006; Peralta

et al., 2008; Zong and Nepf, 2010). In fluvial systems, vegetation is commonly found

segmented in patches (Naden et al., 2006; Sand-Jensen and Madsen, 1992;

Schnauder and Moggridge, 2009). The presence of a patch of vegetation can divert

the flow around the finite size such that there is enhanced flow locally on the edges

of the vegetation patch, possibly inhibiting the expansion of the patch (Neumeier,

2007; Temmerman et al., 2005; Vandenbruwaene et al., 2011). This biogeomorphic

feedback may limit the expansion of vegetation patches.

Previous research has emphasized the importance of different stem densities

within the patch of vegetation on the flow and feedbacks with physical processes

(Bos et al., 2007; Bouma et al., 2007; Rominger and Nepf, 2011; Schnauder and

Moggridge, 2009). The individual plants in the patch of vegetation create a canopy,

whose geometry is based on the individual plants. Given a patch of vegetation with a

characteristic diameter of plants, d, and the number of stems per bed area, n, the

frontal area per volume is a = nd. The amount of flow through the patch is based on

the density of the patch described by the flow blockage value, CDaD, such that high

15

flow blockage occurs for CDaD > 4 and low flow blockage for CDaD < 4. Cases of high

flow blockage impose different behavior on the flow characteristics than low flow

blockage patches of vegetation (Chen et al., 2012 ).

Recent work has focused on the flow behind patches of rigid emergent

vegetation (Chen et al., 2012 ; Follett and Nepf, 2012; Zong and Nepf, 2011). The

flow patterns observed in these cases differ from those for a flow behind a solid

object because of the bleed flow, or flow through the patch. For a circular patch of

vegetation of diameter, D, the flow blockage parameter is defined CDaD. Given a rigid

patch of vegetation composed of wooden dowels, a steady wake velocity region is

observed behind the patch with a constant flow U1 over a region a steady wake

region, Li (Figure 1-1). The bleed flow and subsequent steady wake region delays

the onset of the von-Karman vortex street, as visualized by Zong and Nepf (2012).

When the von-Karman vortex street forms at the centerline of the flow, there is a

peak in the turbulence production. This peak in turbulence production is located a

distance Lw from the end of the patch. After the steady wake region, the velocity

recovers in the wake recovery region for a distance, L2. This study investigates the

different regions of flow that develop from an emergent rigid and a submerged

flexible patch of vegetation and the subsequent spatial effect on sediment

deposition.

16

Rigid

Emergent

7Vegetation

O

U

Figure 1-1. Conceptual plan-view diagram of the flow around a porous rigid emergent vegetation

patch.

1.2. Outline

We focused on the effect of a single patch of vegetation (of differing rigidity

and density) on flow characteristics and sediment deposition. The research

examined the spatial distribution of sediment deposition, linking it to the spatial

changes in mean flow and turbulence. Chapter 2 provides an in-depth summary of

the different methodologies used in the experiments and subsequent data analysis.

Chapter 3 details the results from each of the four case studies of varying vegetation

type and density. The cases were divided by the type of vegetation studied and by

the density of the vegetation patch. Chapter 4 discusses the linkages between the

four cases, and, based on the data, predicts when and where enhanced sediment

deposition will occur. Finally, Chapter 5 describes the conclusions of this research

and recommendations for future work.

17

Chapter 2 Methodology

All the experiments were conducted in a flume with a patch of model

vegetation. Two types of model vegetation were used to construct circular patches,

with varying stem density. The experiments were run with model sediment. Velocity

was measured with an Acoustic Doppler Velocimeter.

2.1. Experimental Measurements

The experiments were conducted in a 16-m long re-circulating flume; the test

section is 1.2-m wide and 13-m long. A 25 hp pump was used to pump water from

the tail box to the upstream head box where a large baffle dispersed flow across the

width of the flume. The horizontal bed of the flume was covered with PVC

baseboards, perforated with a staggered array of holes, 1 cm in depth for the length

of the test section. The patch of model vegetation was constructed as a circular

staggered array. Wooden dowels with a diameter d = 6.4 mm were used for the rigid

emergent vegetation. The flexible vegetation was created using a piece of wooden

dowel (d = 6.4 mm) 1 cm in height as a stem, with six thin blades of polyethylene

film as the leaves. The model blade had a thickness of 0.2 mm, a width of 3 mm, and

a length of 13 cm. The blades were attached to the wooden dowel piece with a piece

of duct tape. The patch of vegetation had a diameter D = 42 cm. The projected

frontal area, a, is calculated as a = n*d in cm-1 where n is the number of dowels per

bed area (cm- 2 ) and d is the dowel diameter (cm). The solid volume fraction is

18

calculated for each case using

# = nrd2 /4.

For each type of vegetation (flexible and

rigid), two different stem densities were considered totaling four different cases

studies. The two different patch densities with a solid volume fraction (SVF) were

= 0.03 and

# = 0.10 for the stem region

#

of each patch (Table 1). However, for the

flexible blades, the SVF calculations were based on the number of blades of each

plant that could be visible to the flow such that the range of SVF is

and

# = 0.01 -

# = 0.04 -

0.25

0.07 for the dense and sparse case respectively. For the rigid

vegetation, the density of the patch was constant in the vertical; however, for the

flexible vegetation, the density of the patch changed with the height above the bed.

Table 1. Summary of patch parameters for the four cases and two control experiments with standard

deviations.

M-2)

Rigid Control

Rigid Dense Case 1

Rigid SparseCase 2

Flexible

Control

0.34

0.02

0.09

0.004

Flexible

Dense - Case

3

0.34 2.01 ±

0.02-0.1

0.09 0.57 ±

0.004 0.03

Flexible

Sparse- Case

4

-

a (cm-1)

CDaD

(cm-1)

H (cm)

h (cm)

UO

(cm s)

SVF

_)

0.20

0.01

-

-

13.5±

0.2

-

9.4±

0.2

8.4 ± 0.4

9.6 ± 0.5

13.5 ±

0.2

14 ± 0.2

9.4 ±.2

0.057

0.03

2.5 ± 0.1

2.5 ± 0.1

13.5

0.2

14 ± 0.2

9.4±

0.2

-

-

21.5±

0.2

-

8.1±

0.2

0.134 0.80 ±

0.006 0.04

0.0381 0.23 ±

0.002 0.01

5.5 - 34

0.3-2

1.60 - 9.7

0.08 0.5

4.2 - 25

0.2 - 1

1.20 7.2 ±

0.05 0.3

21.5 ±

0.2

10

0.2

8.1

0.2

21.5 ±

0.2

8

0.2

8.1

0.2

The two values of SVF correspond to a high flow blockage and low flow

blockage configuration. These values of SVF are representative of densities found in

19

different aquatic vegetation (Nepf, 2012). In mangrove systems, the SVF can be

quite high, 0 = 0.45 (Mazda et al., 1997). Submerged grasses, on the other hand,

tends to have lower SVF where P = 0.01 - 0.1 (Ciraolo et al., 2006).

The upstream flow velocity, Uo, was defined as the velocity measured on the

centerline at x = -100 cm (x/D = -2.4) at the highest distance above the bed. The

velocity scale, U0, was used to normalize all the velocity data. A weir at the end of the

flume controlled water depth. Two different flow depths were used to ensure

velocity measurements could be taken above the top of the flexible vegetation

canopy. For the flexible vegetation, the flow depth was H = 21.5 t 0.2 cm; in the rigid

vegetation cases, the flow depth was H = 13.5 t 0.2 cm. For the flexible vegetation,

the sparse case had a canopy height of h =8.0 t 0.2 cm; for the dense vegetation

patch, the canopy height was higher due to the greater numbers of plant blades such

that h =10.0

0.2 cm.

The coordinate system was defined with x in the streamwise direction, y

cross-stream, and z vertical depth to the bed where x = 0 at the start of the patch; y =

0 at the center of the patch; and z = 0 at the bed (Figure 2-1). The flow

characteristics were assumed to be symmetrical about the y=0 line down the center

of flume. Measurements for both deposition and velocity were taken only on one

half of the flume.

20

Vegetationbo

o o

.4

000o

O

0nth

lm.Telrearo hw h ieto

0

~

~ 2-.Pa-iwdpstoneprmn0eu

~

Figure

0r niae yte ml etnlso h e

ofte en lw.Teaprxiat loain ofsie

of The

~ loato

~

~of ththe~oriaesse

flme

~ 0

ssonb hege ros hr

n

0Fatute cente Pan-idtepstam

edgre

n of th ircularpatch

21

.

Thlagaro

sowtedicin

Velocity measurements were taken using a Nortek Vectrino acoustic Doppler

velocimeter (ADV). The sampling volume of the ADV was 6 mm across and 3 mm

high, and was located 5 cm from bottom of the instrument prongs (Figure 2-2 &

Figure 2-3). The ADV was mounted on a movable platform above the flume, which

enabled manual positioning along and across the flume with an accuracy of t 0.5 cm

in they direction and ± 1 cm in the x direction and ± 1 cm in the z direction.

Longitudinal transects were taken through the centerline of the flume from 1 meter

upstream of the edge of the vegetation patch to 7 meters after the end of the patch

(x = -2.4 - 17D). Lateral transects were also taken: upstream of the vegetation

patch, in the vegetation patch, and downstream of the vegetation patch.

H 13.5 cm

Figure 2-2. Diagram of ADV in flume for rigid emergent vegetation patch (Case 1 & 2). The grey rods

represent the rigid patch. The ADV is measuring at a depth of 7 cm above the bed (hmeas) with a total

water depth of H = 13.5cm.

22

H = 21.5 cm

z

Figure 2-3. Diagram of ADV in the flume for flexible submerged sparse vegetation patch (Case 3 & 4).

The flexible patch is represented by the bent grey arrows with the top of the canopy at h = 8 cm for

the sparse canopy, for the dense canopy h = 10 cm. The ADV is measuring at a depth of 15, 10, and 6

cm above the bed (hmeas) with a total water depth of H = 21.5 cm.

2.2. Data Processing

The ADV collected instantaneous measurements of longitudinal (u(t)),

lateral (v(t)), and vertical (w(t)) velocity at each measurement location for 240 s at a

sampling rate of 25 Hz. The instantaneous velocity components were decomposed

into the time average ( ii,vandWi), where the over-bar indicates the time averaging,

and fluctuating components (u'(t), v'(t), w'(t)) using MATLAB & Simulink Student

Version, 2011b. The intensity of the turbulent fluctuations (Urms, Vrms, Wrms) was

estimated by the root-mean-square of the fluctuating components of velocity (

, and

V

). Finally, the turbulence kinetic energy (TKE), the kinetic energy

per unit mass associated with the turbulent eddies, was calculated as the mean of

the fluctuating components of velocity such that:

23

TKE =-( u'2+v2 +w'2

2(

Spectral analysis was used to analyze trends in the turbulence energy

cascade. For given locations, a spectrum for each component of the velocity time

series was produced utilizing MATLAB's inbuilt power spectral density with Welch's

method. Given the low patch-scale Reynolds number (Re =

= 39,000) and low

V

stem-scale Reynolds number (Restem

=

u=d = 60 -320), the Strouhal number is equal

V

to 0.2 (Norberg, 1994), allowing for the calculation of the expected frequency in the

velocity spectra for both stem turbulence production and patch-sized turbulence

production,

specifically: .2

fTtem d

.2 =

or

UV

paD

(2)

U,

where fstem was the frequency associated with the turbulence produced from the

stem; and fpatch was the frequency associated with the turbulence produced from the

patch itself in the form of a von Karman vortex street. In addition, d was the size of

the stems (wooden dowels, d= 6 mm) and D was the patch diameter (D = 42 cm).

However, for a Reynolds number close to 100 (i.e. Restem = 60 for Case 1), there is a

deviation of the Strouhal number and the alternating vortices are not formed.

The deposition experiments were conducted separately from the ADV

measurements. Numbered slides were placed along the bed of the flume, as shown

in Figure 2-1. Net deposition was estimated by weighing each slide before and after

24

a deposition experiment. The slides (7.5 x 2.5 cm) were cleaned, numbered, and

weighed prior to their use in the experiments. The flume was filled to the desired

water depth, dependent on the vegetation type, with the circular patch of vegetation

in the flume. The slides were placed perpendicular to the flow direction along the

bed of the flume every 10 cm on the centerline in a longitudinal transect starting 1

meter before the patch (x/D = -2.4) and ending 6-8 meters (x/D = 14.3 - 19.0) after

the patch (Figure 2-1). The flume was filled with water before the slides were placed

to prevent the slides from being moved out of position by the infilling water.

Lateral slide transects were also placed upstream and downstream of the

vegetation patch. Depending on the density of the vegetation patch, a different

configuration of slides was placed within the patch itself. For the sparse patch (<=

0.03), the regular-sized slides were placed every 2-3 cm along the centerline of the

patch without any removal of plants. For the dense patch (#= 0.10), five small slides

(2.5x2.5 cm) were placed within the patch by removing a single plant at each

location.

Once the slides were placed, the pump was started up slowly until the initial

upstream flow velocity was reached (Uo) so that the slides would not move out of

position. Spherical glass beads (made by Potters Industry with a diameter of 12 pm,

a density of 2.5 g/cm 3, and a settling velocity of 0.01 cm/s) were used as the

sediment in the deposition experiments. A total of 650 grams of the sediment was

vigorously mixed with water in small containers before being poured into the flume

upstream of the patch. Within a minute, the sediment was well mixed in width and

25

depth across the flume. The initial concentration in the flume was Co = 105 g/m

and 75 g/m

3

3

for the rigid and flexible vegetation cases respectively. Co was

calculated by estimating the total volume of water within the flume, given the

measured dimensions of the flume, the water height in each area of the flume, and

dividing by the amount of sediment released. The flume was left to run for four

hours. At the end of four hours, the flow was slowly decreased to prevent scour and

to decrease the possibility of backwash from a sudden drop in velocity moving the

slides. Once the flow was stopped fully, the flume was drained. This entire stopping

process took around 20 minutes compared to a four-hour experiment.

The slides were then left to dry in the flume for 2-3 days until the sediment

had formed a dry white coating on the slides and the rest of the flume was dry. The

slides were carefully removed from the flume and put into a drying oven at 500 C for

2-4 hours to remove all excess moisture. The slides were reweighed to determine

the amount of sediment deposited on each slide. The net deposition was calculated

for each location by the difference in weight for each slide before and after the

experiment divided by the area of the slide.

Each deposition study was run in triplicate for each plant case (i.e. rigid

dense - Case 1, rigid sparse - Case 2, flexible dense - Case 3, and flexible sparse Case 4). The variance among triplicates at each measurement position was used as

an estimate of uncertainty for that position. In addition, for each water depthvelocity combination, a control deposition experiment was run with the flume

empty of vegetation but otherwise with the same setup (i.e. PVC baseboards

26

covering the bed and slides used to determine net deposition). The control

experiment indicated the background deposition without vegetation for the given

initial flow Uo = 9.4 t 0.2 cm/s or Uo = 8.1

0.2 cm/s and water height H = 13.5 t 0.2

cm or H = 21.5 t 0.2 cm.

The deposition data showed high variability between the replicates in the

cases of the flexible vegetation within the patch. The large variance within and

around the flexible patch was due in part to the plant blades falling onto the slides

while drying and wiping off sediment. Attempts were made to decrease this

occurrence as the flume was drained, but these were limited by concerns of

disturbing the sediment off the slides while still wet. This issue only occurred with

the flexible blades; therefore, all values that were affected by the blades were

removed from the analyses.

Mean total deposition was estimated for each of the deposition cases and the

two control experiments. The net deposition was taken from the longitudinal

transect along the centerline of the flume for each slide measurement. The net

deposition measured for each slide was then used as the net deposition for a larger

area around the slide. The area covered half the distance streamwise until the next

slide and from the center to 21 centimeters laterally (x/D = 0.5) (- 210 cm 2 ). The

sum of the net deposition from the center to 21 centimeters laterally and from 1

meter upstream of the patch to 8 meters downstream of the patch was divided by

the bed area of the flume covered by the deposited sediment. This value was then

recorded as the net mean deposition for the given experiment.

27

2.3. Data Analysis

An advective-deposition model was used to analyze the spatial deposition

patterns for each of the four vegetation cases and the two control experiments. The

model (Zong and Nepf, 2010) was used to estimate the total sediment accumulation

per unit area on the bed of the flume as a function of x (longitudinal or streamwise

distance), such that

m(x)-pw

C(t)dt

(3)

Where ws is the calculated fall velocity for the spherical glass particles (ws = 0.01

cm/s) (Madsen). C(t) is the suspended sediment concentration in the flow over time

estimated from knowing the initial concentration, based on the amount of sediment

poured into the flume and volume of water, and extrapolating the final

concentration of sediment in the flow (Ce = C(4 hours)) by extrapolating the total

amount of sediment deposited on the bed of the entire flume. This is then integrated

over the total duration of the experiment. Finally, p is a probability function of

sediment depositing in the flow based on the Engelund-Fredsoe Equation (Engelund

and Fredsoe, 1976). This equation predicts whether or not sediment will be

deposited using the probability based on the critical shear stress: as flow

decelerates, the local friction velocity, u-, decreases and the probability that

sediment will deposit increases until $ equals $cr.

The non-dimensional shields parameter is estimated from:

28

u2

=U 2

(4)

(s -1)gr

where s is the specific weight of the sediment (ps/p, = 1.25); g is gravity 981 cm/s 2 ,

r is the sediment diameter (r = 0.0012 cm); and u* (x) is the friction velocity

estimated from u. = UCf . Cf is the bed friction coefficient previously measured for

flow over the PVC boards to be 0.006 (Zong and Nepf, 2010). Uwas calculated as the

total horizontal velocity measured at each location in x such that U = Vi +V2 .The

specific sediment weight is s = 2.5. Finally,

/cr

is calculated using the modified

Shield's diagram such that P,. = .1S- 2 /1 (Madsen and Grant, 1976). S* is the nondimensional value that is a function of the fluid and sediment properties such that

S,=-r(s -1)gr where v

4v

=

0.01 cm 2 /s is the kinematic viscosity for fresh water at a

temperature of 20*C. The estimated non-dimensional lpcr= 0.25. Though, the Shield's

value can be unrealistic at very low Re* values (where the sediment size is small),

given that the glass spheres were well mixed before and were perfectly spherical,

clumping and flocculating were assumed to be minimal (Madsen; Madsen and Grant,

1976). Thus, the use of the extended Shield's parameter at low values was valid. For

$< 4cr, the probability function is set to p = 1. For 0 > 0cr, the probability that

sediment will be deposited is less than unity due to initiation of motion because the

shear stress is above the critical shear stress.

The above deposition model did not take into account a change of bed

roughness and equivalent u values within the patch. It also assumed that C(t) was a

29

linear decrease over time, and well mixed over depth and width throughout the

experiment. Visually, this did seem to be a valid assumption. After the four hours of

the experiment, the sediment was still well mixed laterally and vertically. Previous

work with this model fit the resultant curves to the actual deposition data by

varying the estimated fall velocity ws; in this study, this was not done as the model

was used purely to estimate trends in the data set (Zong and Nepf, 2010).

30

Chapter 3 Results

3.1. Control Experiments

A control deposition experiment was run for both the h = 13.5 cm (equivalent

to the rigid emergent patch of vegetation Case 1 & 2) and the h = 21.5 cm

(equivalent to the flexible submerged patch of vegetation Case 3 & 4). These two

deposition experiments were run to estimate the variability in spatial deposition

along the flume. The control for the rigid emergent cases has a mean deposition of

0.0025 ± 0.0001 g/cm 2 where the error is estimated from the variability inherent in

both the longitudinal profile along the centerline and the variability along the lateral

transects that mirrored each other (Figure 3-1). The control for the flexible plant

cases has a mean deposition of 0.0026 ± 0.0002 g/cm 2 where the error is calculated

the same as for the other control experiment (Figure 3-2). The mean net deposition

for the rigid control experiment is 0.0025 ± 0.0003 g/cm 2. The mean net deposition

for the flexible control experiment is 0.0027 ± 0.0003 g/cm 2 .

31

Rigid Control Experiment

x 10-3

2. 6-

2.5

5-

E

*

*

0)

C:2.

0

Q.

z

2.4

1:-

e Control Data

-- Mean Deposition*

--- Standard Deviation

2. 4 -

.- -- Standard Deviation*

0

-

5

10

Distance Streamwise in Flume x/D

15

20

Figure 3-1. Net deposition along centerline of flume for control experiment where H = 13.5 cm with

plotted mean and standard deviation of net deposition.

32

Flexible Control Experiment

x 10-3

4

2.75

2.7

2.65-

*

c4- 2.6

E8

c 2.55 0

0

2.5 -...............

...

_._._.._._ _....______.....

..

..............

....................

2.45 8

Control Deposition

-Mean

2.4-

of Deposition

--- Standard Deviation of Deposition

---

Standard Deviation of Deposition

2.35 -8

-

2.30

5

10

20

15

Distance Streamwise in Flume x/D

Figure 3-2. Net deposition along centerline of flume for control experiment where H

plotted mean and standard deviation of net deposition.

=

21.5 cm with

3.2. Rigid Emergent Vegetation

Case 1 and Case 2 were specifically chosen such that they fell into the high

flow blockage (CDaD = 8.4) and low flow blockage (CDaD = 2.5) cases respectively

(Table 2). Upstream of the patch, flow is affected by the patch a distance, Lo, the

upstream adjustment length, which is proportional to the diameter of the patch, D

(Figure 3-3 & Figure 3-4). Different flow regimes develop based on the flow

blockage, where the high flow blockage experiences decreased flow through the

patch itself and has very low flow, U1

-=

0.05Uo, immediately downstream of the

patch and an area of recirculation (Table 2 & Figure 3-3). The low flow blockage

case has increased flow through the patch compared to the high flow blockage case

such that the flow immediately downstream of the patch, U2 = 0.5 U, with no area of

33

recirculation (Table 2 & Figure 3-4). The area of low flow, U2, lasts for the steady

wake region, Li. Within the steady wake region, there is both low velocity and low

turbulence. The shear layers converge on the centerline of the flume at the distance,

L2, creating the von-Karman vortices. The presence of the von-Karman vortices

increases turbulence and velocity, and the peak in TKE is at a distance, Lw. The

velocity increases in the wake recovery zone, L2 , till by the end of L2 the flow has

recovered back to initial upstream velocity.

Rigid Dense

1.5

-L

LT-++ -- L 2

-

1 Control U

*~

Ux/U

0a

TKE

*

7Control

0 075

TKE/U2

Ua

*

0-4

AS;

0

p

-2

0

2

4

6

8

10

12

14

16

Distance Streamwise in Flume x/D

Figure 3-3. Mean velocity and turbulence along the centerline of the flume for Case 1. Mean velocity

normalized to U0 on primary axis. TKE normalized on secondary axis. The x-axis is streamwise

distance normalized D. The control velocity with standard deviation is plotted as the solid black line.

The control turbulence with standard deviation is plotted as the solid grey line on the secondary axis.

The different flow regimes seen in the conceptual diagram, Figure 1-1, are labeled by the parameters

L,, L1, Lw, L2 (Table 2).

34

Rigid Sparse

1,5

10-08

Control U

Ux/U

0

*Control

U

-III

-L

01

TKEQ

TKE/U2

L2

U

a

Usa

0.5

a

-1004

Lj

U,

UU

gon aa aa

LW

"%-

-5

0

I

I

I

5

10

15

20

Distance Streamwise in Flume x/D

I

Figure 3-4. Mean velocity and turbulence along the centerline of the flume for Case 2. Mean velocity

normalized to U on primary axis. TKE normalized on secondary axis. The x-axis is streamwise

distance normalized D. The control velocity with standard deviation is plotted as the solid black line.

The control turbulence with standard deviation is plotted as the solid grey line on the secondary axis.

The different flow regimes seen in the conceptual diagram, Figure 1-1, are labeled by the parameters

Lo, L1 , Lw, L2 (Table 2).

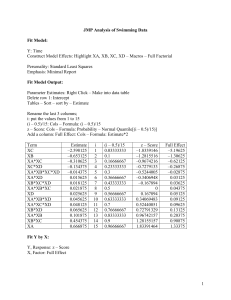

Table 2. Summary of measured flow parameters with calculated standard deviation for rigid

emergent patch of vegetation (Case 1 & 2).

Mean Total

Deposition

Rigid

Control

Rigid

Dense Case 1

Rigid

SparseCase 2

U1

L1

Lw

L2

-

UO

9.4±

0.2

-

-

4.2D

4.3D

13.5

0.2

14

0.2

9.4

0.2

0.05Uo

.06Uo

2.8D ±

0.5D

0.5D

13.5

14

0.2

9.4

0.2

0.53Uo

± .05Uo

6.6D

0.7D

8D

2D

0.5D

10.2

D±

0.7D

h

-

H

13.5

0.2

8.4

0.4

2.5

0.1

± 0.2

CDaD

35

(g/cm 2 )

0.0025 ±

0.0003

0.0022±

0.0004

0.0026±

0.0004

3.2.1. Case 1- Rigid Dense

Velocity measurements are taken at 7 cm above the bed of the flume. These

measurements are used to visualize the flow characteristics around the patch of

vegetation (Figure 3-5). The flow is strongly diverted around the patch laterally at x

= 0 - 1.5 D, and the velocity increases locally (ux = 1.6U0 ) by the diversion around

the patch. The flow is then directed back towards the center of flume where the flow

is back to initial flow (within 10% of Uo) by 4 meters from the patch (x = 9.5D, L2 =

4.3D) (Figure 3-3). In addition, measurements directly downstream of the patch

demonstrate the marked decrease in velocity. This effect of the patch on the flow

creates a zone of very low velocity known as the steady wake region, L, = 2.8D.

There is also a section of recirculation along the centerline starting at x = 3.1 - 3.8 D

from the start of the patch (Figure 3-6). The velocity measurements along the

centerline are not pointed purely in the streamwise direction due probably to

instrument position error, i.e. the ADV was not facing exactly perpendicular to flow.

36

Rigid Dense

15

1.6

1

1.4

1.2

E 0.5N

0.

0.2

-1.5

-4

-2

0

2

4

6

8

10

Distance Streamwise in Flume X/D

12

14

16

0

Figure 3-5. Quiver plot of the flume in plan view for Case 1, where the length of the arrows and the

color of the arrows indicate the horizontal velocity magnitude.. The colorbar on the right shows the

total horizontal velocity relative to the Uo. The location of the patch is shown by the black ellipsoid.

To visualize the change in velocity and deposition, data collected along the

centerline of the patch are graphed (Figure 3-6). The velocity measurements are

normalized by the upstream velocity, Uo, as calculated from the control experiments

(Table 2 & Table 3). In addition, the y-axis limits are set such that the dashed black

line is located at the measurement from the control experiments (i.e. in the rigid

control experiment, urms/Uo = 0.13 ± 0.3 cm/s). The secondary y-axis plots the mean

deposition values relative to the control mean deposition, by subtracting the mean

deposition from the local deposition. The dark gray shaded line is the measured

standard deviation from the three replicates, where the middle of the grey area

37

marks the mean value of the three replicates. The dashed black line also denotes the

zero deposition relative to the control (i.e. anything below that line is deposition

that is less relative to the control, while anything above the zero line indicates

enhanced deposition relative to the control experiment). The location of the

vegetation patch is shown by the thick black vertical lines located at x= OD & 1D.

Deposition upstream of the patch is highly variable between the three

replicates, as indicated by the high variance (Figure 3-6). Downstream of the patch,

the deposition increases relative to the control experiment for 1 meter behind the

patch (till x = 3D). From x > 3.5D, the deposition is lower than the control, and it

stays lower to the end of the measurement section (x = 21D). The decrease in

deposition, relative to the control, corresponds to the positions with an increase in

urms and TKE. The peak in TKE and urms at x = 5D corresponds to where the von-

Karman vortex street begins, Lw = 4.2D (Table 2).

38

Al.

X10

Velocity and Deposition Data Relative to Control forRigid Dense Vegetation Patch at y = 0 @ H =7cm

LStd Dev of Dense RIG Deposition Data with Control Subtracted 1.2

Rig Dense Velocity-1.

0.8 E

0.4

~

--------------

0--------

---------------

-0.4

a

-0.80

-.2 z

-3

2

7

Distance Streamwise X/D

B1.2

1

72

12

-

x 10

E

17

22

x 10

C)1.2

0 8

0.8 0-0.8gi

E

0

0.4 a

0.4"

-------------

-------

----------

~

-------

--

-0

-0.8 0705-0.8

-1.2

-3

2

12

7

Distance Streamwise XID

17

22

-1.2

0

10

15

5

Distance Streamwise X/D

20

Figure 3-6. Deposition and velocity along centerline of the flume for Case 1. The x-axis is normalized

by the patch diameter, D. The secondary y-axis is the net deposition relative to the control

experiment (g/cm 2). The location of the patch in the streamwise direction is indicated by the black

vertical lines on each graph. A) U/Uo on the primary y-axis and the mean deposition of the three

replicates with the standard deviation of the replicates indicated by the edges of the polygon fill on

the secondary y-axis. B) urms/Uo on the primary y-axis. C) TKE/u 0 2 on the primary y-axis.

The lateral velocity transects indicate the lateral extent of patch influence on

the flow(Figure 3-7). Directly downstream of the patch at x = 1.2D, flow is strongly

depressed to 0.05 U0, but a large increase in velocity to 1.5Uo is visible at the lateral

edge of the patch (x = 0.5D). At half a meter behind the patch (x = 2.4D), the lateral

transect is still similar in structure to that measured directly behind the patch. By

three meters from patch (x = 7.14D), the flow is laterally uniform. Directly

downstream of the patch, there is a peak in urms that increases strongly at 1 meter

from the patch (x = 2.4D). Even though the urms remained high along the centerline

39

of the flume after the peak at x = 6D (Figure 3-6), it is much less than the urms spikes

at x = 1.2D and 2AD.

Directly downstream of the patch, there is a spike in TKE at the lateral edge

of the patch (y = O.5D), and this elevated region of TKE moves laterally inwards

towards the center moving downstream (x = 2.4D). This is associated with the shear

layer forming at the edges of the wake and growing inward over distance (Figure

3-7). However, by three meters from the patch (x = 7.1D), the TKE is significantly

elevated over the entire lateral transect corresponding to the presence of the large

coherent turbulent structures of the von-Karman vortex street, Lw = 4.2D (Figure

1-1).

Rigid Dense

A)

2

0 Lateral Profile @ X = 50cm Z = 7 cm

0

D

D

*

* Lateral Profile @ X = 100cm Z = 7 cm

+ Lateral Profile @ X = 300cm Z = 7 cm

-- Control

1.5

*

*

*

*

+

+

+

+

*..

0

98

0.5

I

f rMau"m-

0.2

0.4

0.6

0.8

1

Distance Across Flume Laterally y/D

0.1

0.3

+

+ +

B)90.25

.- +.

-

+

+

C0.08

+

+

+

+

+

+

0.06

++

+++

D 010.

++

+

*

--

0.1

.--------4*

*

0.0

*

0.04

@6

*

*

0

*

0.02

*

*0*

0

* 0*

0.4

0.6

0.2

0.4

0.6

0.8

0

1

Distance Across Flume Laterally y/D

~.

------------------------------------------------------6

"p

0

0.2

0.8

1

Distance Across Flume Laterally y/D

Figure 3-7. Lateral transects of normalized A) velocity, B) urms, and C) TKE for Case 1. The

horizontal axis is the distance across the flume from the center of the flume (y = 0), normalized by

the patch diameter.

40

Spectral analyses of the velocity measurements taken along the centerline

indicate the varying production terms of turbulence (Figure 3-8). Upstream of the

patch of vegetation (x = -2.4D), the spectra have no distinctive peaks indicating a

lack of a specific length scale to turbulence production. Downstream of the patch (x

= 2.6D), the largest peak in Sv is observed to correspond with the turbulence

associated with the length scale of the entire patch of vegetationf= 0.05 Hz using

the upstream initial velocity. There is no peak observed in turbulence associated

with the length scale of the individual dowel stems because the stem Reynolds's

number is around 60, thus there is no vortex shedding (Norberg, 1994).

SpectralAnalysis@y= andox - -100z7

SpectralAnalysis@0

uand a

7 c

dsZ=7

SuuU

Snl()

000,00

10iS0ini

101

0

il

S

where x = -2.4D and 2.6D (A and B). The x-axes are the frequency (Hz) and the y-axes are the spectra

in cm 2/s. Each graph has two curves plotted; the black line is the spectra in the x-component (Suu)

and the grey line is the y-component (Svv). B), the vertical grey line marks the turbulence production

based on the size of the entire vegetation patch (see Methodology for calculation).

3.2.2. Case 2 - Rigid Sparse

The rigid emergent sparse vegetation patch affects the flow characteristics

for 7 meters (x = 16.8D). The flow is diverted laterally around the patch (x = 0

-

1 D),

accelerating around the outer edge (ux = 1.1UIo) (Figure 3-9). The flow is decreased

downstream of the patch; the decreased flow lasts for 6 meters from the start of the

41

patch (x = 14.2D). The magnitude of flow retardation and acceleration is less than

that for the rigid emergent dense patch of vegetation where U2 = 0.05 U0 and U =

0.5Uo in Cases 1 and 2, respectively (Table 2). However, the distance of the steady

wake zone is longer for Case 2 than Case 1 (i.e. L2 = 2.8D and L1 = 6.6D for Cases 1

and 2, respectively). In addition, the wake recovery is longer for Case 2 than Case 1

(Lz

=

4.3D and L2 = 10.2D for Cases 1 and 2, respectively). There is no recirculation

zone for Case 2 as it is a low flow blockage case (Chen et al., 2012 ; Rominger and

Nepf, 2011; Zong and Nepf, 2011).

Rigid Sparse

1.4

1.2

1

1

E 05k.V)

CA

0.8

0

-

N

0.6

Ai)

0

-0,.:

0.4

-1

-1.5'

-5

0,2

0

5

10

15

Distance Streamwise in Flume X/D

20

25

jo

Figure 3-9. Quiver plot of the flume in plan view for Case 2, where the length of the arrows and the

color of the arrows indicate the horizontal velocity magnitude. The colorbar on the right shows the

total horizontal velocity relative to the Uo. The location of the patch is shown by the black ellipsoid.

42

The deposition upstream of the patch is only slightly elevated above the

control deposition (Figure 3-10). Downstream of the patch, however, there is

enhanced deposition relative to the control deposition for 3 meters (x = 8D), which

corresponds to the steady wake region (Li = 6.6D). This trend follows the decreased

mean flow, us, and the depressed urms and TKE. After 4 meters (x = 9.5D), the

deposition is no longer elevated relative to the control, and both urms and TKE are

also elevated. The mean flow, u, does not increase back to the initial flow until

around 6-7 meters, L2 = 10.2D, (x = 14.2D). Within the patch, both the urms and TKE

are elevated. In addition, there is decreased deposition within the patch relative to

the control, and relative to the deposition immediately downstream of the patch.

The spike in urms and TKE is highest within the patch compared to the rest of the

flume (Figure 3-10 & Figure 3-11).

43

Velocity and Deposition Data Relative to Control ior Rigid Sparse Vegetation Patch at y = 0 @ H =7cm

Std Dev of Sparse RIG Deposition Data with Control

Rig Sparse Velocity

F]

A).

L

-3

12

7

Distance Streamwise X/D

2

7

12

17

12

17

22

-3

22

%1 a

Distance Strearnwise X/D

0

5

10

15

_3

20

Distance Streamwise X/D

Figure 3-10. Deposition and velocity along centerline of the flume for Case 2. The secondary y-axis is

the net deposition relative to the control experiment (g/cm 2 ). The location of the patch in the

streamwise direction is indicated by the black vertical lines on each graph. A) U/Uo on the primary yaxis and the mean deposition of the three replicates with the standard deviation of the replicates

indicated by the edges of the polygon fill on the secondary y-axis. B) urms/Uo on the primary y-axis. C)

TKE/uo2 on the primary y-axis.

Upstream of the patch, the mean flow is laterally uniform within uncertainty

of the measurements (Figure 3-11). Downstream of the patch, the flow is depressed

on the centerline (u, = O.5Uo); but elevated outside the patch wake (u, = 1.4Uo).

Moving downstream from the patch, the mean flow gradually becomes laterally

uniform until by x = 14.3D, (u, = 0.8 - 1.1 Uo). Upstream of the patch, both urms and

TKE are relatively low; it is 0.8 of the measured open channel flow from the control

experiment. Immediately downstream of the patch, there is a peak in Urms and TKE at

the lateral edge of the patch (y = 0.5D). Further downstream, Urms and TKE remain

elevated compared with both the upstream flow and the open channel flow from the

44

control experiment. In addition, while elevated overall, the TKE is not laterally

uniform; the urms is laterally uniform. Both of the values remain elevated above the

open channel flow due to initiation of the von-Karman vortex street at the center of

the flume, Lw.

Rigid Sparse

Control

* Lateral Profile @ X = -200 cm Z = 7 cm

* Lateral Profile @ X = 50 cm Z = 7 cm

2-

1.5

+ Lateral Profile @ X = 400 cm Z = 7 cm

A Lateral Profile @ X = 600 cm Z = 7 cm

0

A

A

A)

A-

+

01 *

A

A

+

*

+

4

+

*

. +

A

*

.

**

0

0.6...0.8

0.

0.2

0.4

0.6

0.25

0.03

0.2

0.025.

++

0.15

+

+

D) 0.

D

w 0.01.

~

+

+A'&

+&

A

I±+ +

+

41 A*4

A

A

S0.0

0.05

+

+

0.05

+. + +

A

DI

0.8

Distance Across Flume Laterally y/D

*~

@*

0.005

Un

0

0.2

0.4

0.6

0.8

0.2

1

Distance Across Flume Laterally y/D

0.4

0.6

0.8

1

Distance Across Flume Laterally y/D

Figure 3-11. Lateral transects of normalized A) velocity, B) urms, and C) TKE for Case 1. The x-axis is

the distance across the flume from the center of the flume (y = 0), normalized by the patch diameter.

Within the patch of vegetation and immediately downstream of the patch of

vegetation, there is a peak in the turbulence energy cascade linked to the individual

wooden dowel stem (Figure 3-12) the grey vertical line marks the predicted

frequency for the individual stems,ftem = 2.5 Hz (as calculated in Methodology). For

the sparse case, the Restem = 320, thus the predicted presence of vortices off of the

dowel is expected unlike in Case 1, where Restem

-

60. Further downstream where

there are peaks in urms and TKE, the largest peak in the power spectra is linked to the

45

von-Karman vortices created by the diameter of the patch of vegetation,fpatch = 0.04

Hz (where the vertical grey line marks the predicted frequency for the length scale

of the patch).

SpectralAnalysis@ y = and x = -1609z=8

SpectralAnalysis@ y =0 and x =23@z=8

100

-- Suu

Svv'1000

Svv1000

O

E

10

-

B).

10'.

A

iy

to-'

o2

10

Frequency (Hz,)

SpectralAnalysis@ y

1o

10

10,

Frequen

cy (Hz)

0 and x= 400@z8

t0

10,

-Pa

10

t0

10

10

to

is-

10

1

Frequency(Hz)

10

i0

Figure 3-12. Velocity Spectra measured along centerline of patch at 7 cm depth for Case 2, where x =

-4.3D, O.5D, and 9.SD (A, B, and B). The x-axes are the frequency (Hz) and the y-axes are the spectra

in cm 2/s. The black line is the spectra in the x-component (Suu) and the grey line is the y-component

(Svv); the light grey vertical line represents the predicted frequency for possible turbulence

contribution. B), the light grey vertical line marks the expected frequency for turbulence production

based on the size of a single wooden dowel. C), the vertical grey line marks the turbulence production

based on the size of the entire vegetation patch (see Methodology for calculation).

3.3. Flexible Submerged Vegetation

The flexible vegetation of a submerged patch produces a range of different

flow patterns and turbulent structures in all three dimensions. In the horizontal

46

plane, or "plan-view," the flow is diverted laterally around the patch similar to the

rigid cases, but there is no L1 or evidence for a von-Karman vortex street (Lw)

(Figure 1-1 & Figure 3-13). The wake recovery zone lasts a distance, L 2 , from the

downstream edge of the patch, after which the flow is uniform again. In the vertical

plane, or "side view," the flow is diverted over the top of the patch and reattaches to

the bed a distance Ly (Figure 3-14). In addition, there is small recirculation area

downstream of the patch. Finally, there is a secondary circulation pattern that

develops visible in the view normal to flow (Figure 3-15). Vertical vortex tubes

develop alongside the lateral patch caused by the lateral shear. The vortex tubes are

tipped forward by the mean flow shear. This creates a component of vorticity with

an axis in the streamwise direction. The resulting circulation is directed away from

the patch centerline at the free surface, and towards the patch centerline at the bed.

Flexible

Submerged:

Plan View

U+

L2

Figure 3-13. Conceptual diagram of plan view of the flow around porous flexible submerged patch of

vegetation.

47

Flexible

Submerged: Side

View

L

LF

Figure 3-14. Conceptual diagram of side view of the flow over submerged flexible vegetation.

Flexible

Submerged:

Normal View

hmeas= 15 crn..

h

hmeas

= 10 crrr-

H = 21.5 cm

~

cm

D--+

Figure 3-15. Conceptual diagram of normal view of flexible submerged patch of vegetation.

48

Fluvial systems contain both emergent vegetation and frequently submerged

vegetation. The submerged vegetation can be both flexible and rigid, however, in

this research only flexible vegetation was used for the submerged cases (Case 3 &

4). This type of model vegetation is a good mimic of grasses (Bos et al., 2007;

Folkard, 2005). Sometimes flow over flexible vegetation generates monami,

however, this was not seen in Case 3 or 4 (Nepf and Ghisalberti, 2008). There is no

generation of monami because the patch length, D, is too short for a shear layer to

develop and generate Kelvin-Helmholtz vortices (Nepf, 2012). The patch of flexible

vegetation is slightly deformed by the flow, and has a given canopy height that

differs for the two different densities (Figure 3-14 & Table 3). Previous work looked

at the hydrodynamic effect of a patch of vegetation on flow by investigating the flow

fields around the patch and the distribution of Reynolds stresses (Folkard, 2005).

However, this work had a patch that extended across the width of the entire flume.

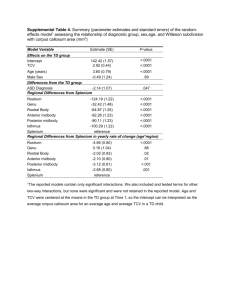

Table 3. Summary of measured flow parameters with calculated standard deviation for flexible

submerged patches (Case 3 & 4) with standard deviation.

Flexible

Control

Flexible

Dense Case 3

Flexible

SparseCase 4

h

UO

L2

L

-

H

21.5

0.2

Mean Total

Deposition

(g/cm2)

-

8.1 ± 0.2

-

-

0.0027

0.0003

1.3 - 8.0

0.4

21.5

0.2

10.0

0.2

8.1 ± 0.2

11.4

0.5D

1.4D

+

0.5D

0.0025

0.0005

0.3

21.5

0.2

8.1 ± 0.2

12.8 ±

0.5D

CDaD

CDah

5.533.6

± 0.4

1.69.7 ±

0.1

1.5D

1.8

0.1

-

8.0 ± 0.2

49

0.5D

0.0026

0.0005

3.3.1. Case 3 - Flexible Dense

Measurements taken near the surface show the diversion of flow laterally

around the patch (Figure 3-16). The velocity is accelerated both laterally around the

patch and vertically over the top of the patch. The velocity is then slowed to half the

initial velocity a meter and a half downstream of the patch (x/D = 5), an effect which

lasts for another 2 meters. Measurements taken at mid depth are exactly at the top

of the canopy of the patch of vegetation. The flow is diverted laterally away from the

center. The velocity is slowed to half of the initial flow half a meter behind the patch

for 3 meters (x/D = 2.2 - 5). Measurements taken near the bed are 4 cm below the

top of the canopy (almost mid canopy). The flow is slightly diverted laterally away

from the center of the flume at the upstream edge of the patch. Return flow is visible

in the half meter behind the patch (x/D = 2.4). Overall, the flow is strongly decreased

to almost zero flow downstream of the patch, and then recovers slowly staying

around half of the initial flow for four meters (x = 9.5D).

50

Flexile Dense@ Depth= 15m

B),

Flextie Dense

@ Depth = 10CM

D

1~

0

E

01 L

F-

E-05'

01

005

I.'

0

5

10

'5

Distance Streamwise in FlumeXD

.1

25

-5

0

5

10

15

DistanceStreamwisein FlumeX/D

I

20

25

Flexible Dense @ Depth = 6 cm

5.I

1.2

-i

-~

--- I

I'

r= 0.5

I'

2

0,8

H

0.6

-0.5

0.4

-~-.

-1

-1.ri

-5

0

5

10

15

Distance Streamwise in Flume X/D

20

25

Figure 3-16. Quiver plot of the flume in plan view for Case 3, where the length of the arrows and the

color of the arrows indicate the horizontal velocity magnitude. The x-axis is the position streamwise

in the flume relative to the location of the patch; the y-axis is the position laterally across the flume.

The colorbar on the right shows the total horizontal velocity relative to the uo. The location of the

patch is shown by the black ellipsoid. A) quiver at depth = 15 cm. B) quiver at depth = 10 cm. C),

quiver at depth = 6 cm.

Secondary circulation is visible throughout the measured sections of the

flume (Figure 3-17). Half a meter upstream of the patch, the flow is directed away

from the patch centerline at the surface, and then returns to the center of the flume

near the bed. While the secondary circulation does seem to diminish in magnitude

51

throughout the flume to three quarters of the initial value, the flow pattern remains

visible for at least 3.5 meters behind the patch (x = 10D).

In addition to the secondary helical flow that is created, the flow is diverted

over the top of the patch, and reattaches to the bed half a meter behind the patch

(Figure 3-14). This accounts for the return flow in the near bed measurements

behind the patch. It also accounts for the flow directed towards the bed in the center

of the flume at x = 100 cm. As seen in Figure 3-16 downstream of the patch, the flow

is slowed near the bed, and then directed back towards the patch.

0.

C

E

2

Sx

0

I

=100 cm, x/D=21 38

-1

n

0

-0.5

0.5

1

05

1

1

x = 200 cm, x/D =" 476

-0.5

-1

21-

0

0.5

1

2

0,06

0.04

0M

= 400 cm, x/D = 912

-1

-0.5

0

0.5

1

Distance Laterally Across Flume y/D

Figure 3-17. Vertical-lateral quiver slices taken in y and z throughout the flume from x = -50, 50,

100, and 400 cm, respectively for Case 3 (x/D = -1.2, 1.2, 2.4, 4.8, and 9.5). The length of the arrows

and the color of the arrows indicate the horizontal velocity magnitude. The x-axis is the position

laterally across the flume; the y-axis is the depth above the bed flume. The colorbar on the right

shows the total horizontal velocity relative to the Uo.

Velocity is accelerated over the top of the patch near the surface (Figure

3-18). Downstream of the patch, flow is decreased to at least half of the initial

52

velocity for all three depths. Within four meters (x = 9.5D), the flow recovers back to

the initial velocity. Mean flow measurements taken near the bed show highly

decreased flow (almost zero) that recovers quickly to half of the initial velocity

within one meter (2.4D). Both ums and TKE have peaks immediately downstream of

the patch, with a smaller peak above the patch. The deposition upstream of the

patch has a large standard deviation compared to the standard deviation for the rest

of the transect. The area of large standard deviation of net deposition corresponds

to the upstream flow adjustment length scale, Lo. Downstream of the patch, the

deposition is decreased relative to the control experiment. Within one meter from

the end of the patch, deposition increases slightly and stays relatively constant, but

below the control experiment.

53

A).

=1Std

Velocity and Deposition Data Relative to Control for Flexible Dense Vegetation Patch at y = 0

Dev of Dense RIG Depo Data with Control Suib

Flex Dense Velocity Depth = 15

Flex Dense Velocity Depth =10

Flex Dense Velocity Depth = 6

Disanc

Ftlrnie

XDeneVlct

-3

1

Distance Streamwise X/D

x 10

-1.2

-0.8

0,4

-0.48

et

9 5

z

13

-

17

-1.2

-1

0.4

-0A

-0.4

-04

Distance Streamnwise X/D

Distance Streamnwise XJD

Figure 3-18. Deposition and velocity along centerline of the flume for Case 3. The x-axis is the

streamwise position along the flume normalized by the patch diameter, D. The secondary y-axis is the

net deposition relative to the control experiment (g/cm 2). The location of the patch in the streamwise

direction is indicated by the black vertical lines on each graph. A) U/Uo on the primary y-axis at three

depths and the mean deposition of the three replicates with the standard deviation of the replicates

indicated by the edges of the polygon fill on the secondary y-axis. B) urms/Uo on the primary y-axis at

three depths. C) TKE/u 0 2 on the primary y-axis at three depths.

The lateral transect taken upstream of the patch indicates that the flow is

relatively uniform across the flume width (Figure 3-19). Immediately behind the

patch, the flow is depressed very strongly to almost zero, but increases to one and