TECHNOLOGICAL ADAPTATION AND IN by AEHYUNG

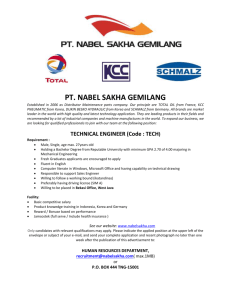

advertisement