JUN 3 0 LIBRARIES

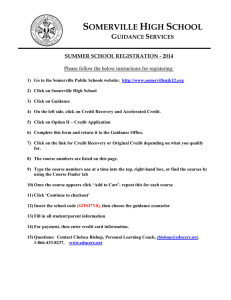

advertisement