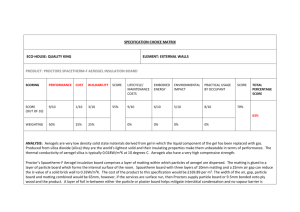

SEP 12 Thermal Properties of Advanced Aerogel Insulation ARCHIVES

advertisement