DRAFT - COMMENTS WELCOME PRODUCTIVITY: By

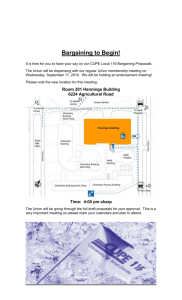

advertisement