TOTlIl SYNTHESIS OF IIUINOlINE-5,B-DIONE IINlIlOSS liND I-N-BUTYRYlDEMETHYlUlIIENDIIMYCIN BENlYl

advertisement

TOTlIl SYNTHESIS OF IIUINOlINE-5,B-DIONE

IINlIlOSS

liND

I-N-BUTYRYlDEMETHYlUlIIENDIIMYCIN BENlYl

ESTER

by

Mentor

Dr. Mohammad Behforouz

t .....de. I •• tlhllu.

May 1998

Expected Date of Graduation: May 9, 1998

I. Preface-Introduction for Non-Science

Honors Students

It seems that HONRS 499 is encapsulated by a foggy, thick, and not-well-understood

mystique that sends the shivers down the spines of even the hardiest of Honors students. There

are a thousand and one questions to ask, and acquiring the nerve to search out the answers may

seem impossible. Please let me assure you that it is not. A few possible places to begin inquiry

include the Honors College Dean, the Honors College Assistant Dean, the Honors College

Academic Advisor, Honors College Peer Advisors, past Honors College students, and even

present Honors College students. As of 1998, there was also a "Thesis Guide" published by the

Honors College that may prove helpful. From this point forward, I will try to be rather general

(as you may have already noticed) in hopes that the information in this introduction will not

become quickly outdated.

After becoming at least somewhat informed about the nature of this great adventure, it

may be advisable to begin searching for a mentor. Ideally, one should find a qualified person

who works well with students (with you in particular) and who has extensive knowledge about a

subject (or subjects) that interests you. It is usually helpful to begin searching very early.

Although it is by no means the standard across all disciplines, beginning work on an Honors

thesis in the summer after one's sophomore year is not uncommon for chemistry majors. Several

of us are still writing this last week of our senior year. Don't let this cause undue panic, though.

Chemistry research is generally very time-intensive.

This introduction has probably not told you anything you did not already know, but if

anything, perhaps it has reiterated the fact that one should start as early as possible, but within

11

reason, of course. For example, it would probably have been useless for me to ask Dr.

Behforouz, my kind mentor, to start research on the synthesis of anticancer drugs before I took

his organic chemistry class. Start as early as possible, but wait long enough to find something

you really enjoy and something you are capable of doing.

Please allow me to close with a few personal comments about myself. I am a Chemistry

and Premedical Preparation major, and I am a Biology minor. Overall, I have enjoyed my

chemistry research, but there were many trying and difficult times. I think it sort of comes with

the territory. I must confess, however, that a few of my peers seemed to fair much better than I

did in being able to obtain satisfactory results. Maybe that's just a sign that organic chemistry

doesn't like me as much as I like it. ©

This is just to say that I wish you the best in all of your endeavors, and especially in the

exciting area of research you choose. I am sorry I could not be more helpful, but maybe just

knowing that someone else cares enough about you to write a special introduction will make the

journey a little easier. I surely hope that is the case, and so long, friends.

-Darric

II. Table of Contents

I. Preface-Introduction for Non-Science Honors Students

II. Table of Contents

III. Acknowledgments

2

IV. Abstract

4

V. Background Information on Lavendamycin

5

VI. Quinoline-5,8-dione Importance

8

VII. Biological Activity

9

VIII. Total Synthesis of Quinolinediones 21 and 23 and Lavendamycin Ester 26

12

IX. Experimental Section

17

A. General Information

17

B. Solvent Purification

17

C. Procedures

8-Hydroxy-2-methyl-5,7-dinitroquinoline (16)

5,7-Dibutyramido-8-butyroxy-2-methylquinoline (18)

7 -Butyramido-2-methylquinoline-5,8-dione (19)

7-Butyramido-2-formylquinoline-5,8-dione (20)

7-Butyramidoquinoline-5,8-dione-2-carboxylic acid (21)

Pyrrolidine 7-Butyramidoquinoline-5,8-dione-2-carboxamide (23)

L-Tryptophan benzyl ester (25)

7-N-Butyryldemethyllavendamycin benzyl ester (26)

18

19

20

22

23

24

26

27

Appendix A

Spectra

29

Appendix B

Research Presentations

52

X. Works Cited

53

2

III. Acknowledgments

I would like to express my deepest sense of gratitude for Dr. Mohammad Behforouz. He

kindly allowed me to be a part of his prestigious research group when he already had a sufficient

number of students to fill the laboratory space provided to him by the university. After I joined

his group, Dr. Behforouz selflessly took time to explain the concepts that needed clarifying from

time to time. Dr. Behforouz also willingly shared his incredible knowledge of so many things

besides organic chemistry. And perhaps something I will never forget, Dr. Behforouz gave me

words of encouragement when he knew I was despondent about the progress of my project. He

has excelled in every aspect of being a mentor, teacher, and a friend to me. Thank you, Dr.

Behforouz.

As I already mentioned, Dr. Behforouz performs research that many organic chemists can

only dream of doing. His noble goal of finding antitumor compounds that may someday cure

you or me alludes to his great character. Dr. Behforouz has an insurmountable desire to aid the

advancement of science, and his fortitude and work-ethic have been the tools he has used to

reach his goals. Recently, I was honored enough to attend a recognition reception for Dr.

Behforouz-he is the first faculty member at Ball State University to earn a patent for his

research. This exemplifies Dr. Behforouz's exceptional quality as an individual and as a

scientist.

I also would like to thank Mrs. Wen Cai, who was instrumental in all the research

presented in this work, and especially in the synthesis of the lavendamycin analog when success

3

was so necessary and important for all of us. She was always willing to take time from her busy

schedule to help me, even when she was pressured by the work of her own projects. I am

grateful to her as a scientist and a friend.

I want to say a great big "Thank You" to all the past, present, and future fellow members

of Dr. Behforouz' s research team. The research of past students made my task much easier. The

kindness of the present fellow-workers made my experience enjoyable. The work of future

members may make my efforts more worthwhile, if my labor will ever become anything. I

would especially like to thank Michele Etling, who aided me immensely in the synthesis of all

new quinoline-5,8-dione compounds, and the Masters and Honors Thesis authors I cite in the

procedures. Also, the format and content for this thesis was patterned after Anthony Rose's

Honors Thesis. Discussion of some of the chemistry was taken from Ervin Walter's Honors

Thesis. Thanks to everyone of you.

The Ball State University Department of Chemistry deserves much credit. All of the rich

opportunities provided, all of the knowledge made accessible, and all the financial assistance

offered have been very beneficial to me. My temporary home in the Chemistry Department has

been quite wonderful.

The work that I have tried to do could not have been possible without the fiscal support of

the National Institute of Health, the American Cancer Society, and Eli Lilly. I am thankful to all

our financial providers.

Last, but far from least, I would like to thank my family and friends for all their moral

support and prayers. It is wonderful to have so many others to care for you.

4

IV. Abstract

The synthesis of 7-butyramidoquinoline-5,8-dione-2-carboxylic acid, pyrrolidine 7butyramidoquinoline-5,8-dione-2-carboxamide, and 7-N-butyryldemethyllavendamycin benzyl

ester are reported. The carboxylic acid was synthesized from the commercially available 8hydroxy-2-methylquinoline via nitration, reduction-butyrylation, oxidation to the dione and then

to an intermediate aldehyde, followed by final oxidation to the product. Reaction of the acid

with N-hydroxysuccinimide and then pyrrolidine afforded the ester. The lavendamycin analog

was synthesized by condensation of the intermediate aldehyde and a tryptophan derivative.

These three compounds can now be tested for biological activity. This will hopefully aid in the

current structure-activity relationship studies being performed on the related quinones and

lavendamycin analogs synthesized as chemotherapeutic agents.

5

V. Background Information on

Lavendamycin

In 1981, the researchers at Bristol Laboratories found lavendamycin (1) in the

fermentation broth of the aerobic, gram-positive bacterial microorganism Streptomyces

lavendulae. 1•2 Isolation of the structurally and chemotherapeutically similar compound

streptonigrin (2) from Streptomyces flocculus had been reported in 1959 by Rao, et al. 3•4 Both

lavendamycin and streptonigrin show potent anticancer and antimicrobial activity, but

unfortunately both compounds are also highly cytotoxic.

4

CHP

°

°

"'-'::

B

C0 2H

~

N

H2N

C0 2H

CH 3

°

2

CH 3

H2N

HO

CHP

OC~

In 1984, Kende and Ebetino, researchers at the University of Rochester, were the first to

publish the synthesis of lavendamycin methyl ester. 5.6 Their lavendamycin methyl ester was

produced by using a Bischler-Napierski cyclodehydration to obtain a pentacyclic product which

was converted to the final ester through a number of transformations. A ~-methyl tryptophan

6

was used as an intennediate in their condensation. In 1985, Hibino et al were the second to

report the synthesis of lavendamycin methyl ester? Their methodology made use of the PictetSpengler condensation reaction between a quinoline analog and

~-methyl

tryptophan to acquire a

pentacyc1ic intermediate. A several-step transfonnation was perfonned on the intennediate to

give the final product. The same year, Boger's research group published a third way to

synthesize lavendamycin methyl ester. 8 Their synthetic strategy involved twenty steps and gave

an overall yield of less than 1%.

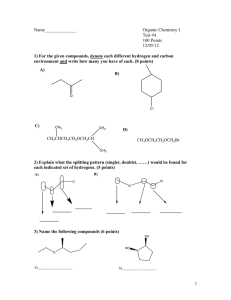

Dr. Behforouz reported the highly concise, five-step synthesis of lavendamycin methyl

ester (9) in 1993 (Scheme I ).9 The overall yield of the procedure was 33%, and the methodology

far superior since only a small number of stable intennediates are involved. A Diels-Alder

condensation of bromoquinone 3 and the novel I-azadiene 4 produces the AB ring system 5. The

methyl group of the quinolinedione 5 is oxidized to aldehyde 6 via selenium dioxide. A PictetSpengler condensation of aldehyde 6 and

~-methyl

tryptophan (7) gives 7-N-acetyllavendamycin

methyl ester (8). Sulfuric acid, water, and heat are used to hydrolyze 8 to the end product 9.

In 1996, Dr. Behforouz reported an even better synthesis of lavendamycin methyl ester. 10

The starting material for the production of the AB ring portion of lavendamycin is the

commercially available 8-hydroxy-2-methylquinoline (8-hydroxyquinaldine). The method has an

excellent overall yield of 40%. The synthesis of 7-N-butyryldemethyllavendamycin benzyl ester

utilizes this procedure (Scheme 2).

In addition, many of the lavendamycin analogs currently being synthesized by Dr.

Behforouz's group are made using this superb method. The analogs are then tested for biological

7

activity. The ongoing structure-activity relationship studies are focused on finding the

relationship between the compound's structure and its biological activity.

Scheme 1

°

~

_H~B' O-ri~

°

C6 H5 CI

+

°

heat

Se02

-...:::

•

h

N

AcNH

°

3

•

CH 3

5

°2CH 3

°

xylene

-...:::

h

AcNH

N

°

.

+

CHO

reflux

7

6

°

°

N

~

AcNH

C02CH 3

HP, H2SO4

•

°

H-

8

CH 3

C02CH 3

H2N

°

CH 3

9

8

VI. Quinoline-5,8-dione Importance

The 7-aminoquinolinedione segment of the more complex antitumor compounds

lavendamycin (1), streptonigrin (2), and streptonigrone is suspected to play the most critical role

in determining the anticancer activity of these compounds. IO ,11 The quinoline-5,8-dione

compounds (10) in general have a wide spectrum of biological activity as antifungal,

antibacterial, antitumor, antiasthmatic, and antiparasitic agents.

0

4

"'::::

~

N

8

1

0

10

Some new synthetic methodologies dealing with the quinoline-5,8-diones were recently

reported by Dr. Behforouz. 12 The new methods included the replacement of an amino group on a

quinone ring by alkoxy groups, and the 1,2-addition of the ethyl group (instead of the expected

I A-addition of the cyano group) of diethylaluminum cyanide to a quinolinedione.

The quinolinediones have been in the literature for decades, but the C-6- and/or C-7substituted quinolinediones have been the compounds of most intense study. These substituents

include functionalities such as amino, hydroxyl, thiol, and their derivatives, as well as alkyl,

halogen, and nitro groupS.12 Part of the synthesis described herein deals with modifying the C-2

position of the quinolinedione ring. It is hoped that such derivatives will lead to elucidation of

the smallest, most potent pharmacophore of the lavendamycin structure.

9

VII. Biological Activity

As mentioned previously, the quinoline-5,8-dione portion of several antitumor

compounds is critical, and perhaps essential, for biological activity. In fact, streptonigrin entirely

loses its antitumor activity if the aminoquinone moiety is blocked as in azastreptonigrin. 13 This

important part of the lavendamycin compound is of particular interest as more data is accrued on

the relationship of chemical structure to biological activity.

The cytotoxicity of the quinones, and of streptonigrin in particular, has been studied.

Several biological mechanisms of action have been proposed, but there is no complete consensus

within the scientific community on any given mechanism. The quinone reduction potential may

be important and correlated to the compound's demonstrated ability to cleave DNA.14 Some

research has shown that the quinones may exert their effect through the electron transport system

within the mitochondria. 4. 13•15,17 The hydroxyl radical is thought to be particularly important. A

commonly seen mechanism 15 is given below:

[1] QQ + NADH + H+ ~ QQH2 + NAD+

[2] QQH2 + O 2 ~ QQH' + H02'

[3] H02' H H+ + O 2'[4] 20 2'- + 2H+

~

H 202 + O 2

[5] O 2'- + H202

~

HO' +HO- + O 2

[6] 2H202

~

2H 20 + O 2 (in the presence of the enzyme catalase)

10

Since the biological activity may depend on the quinoline-5,8-dione portion of the

lavendamycin molecule, the synthesis of quinolinedione analogs with modifications at the C-2

and C-7 positions was performed. It is hoped that a better understanding of these groups'

importance will be achieved as more and more data become available. Ideally these studies will

lead to the synthesis of a small, soluble, potent, nontoxic chemotherapeutic drug.

Structure-activity relationship studies on the larger lavendamycin analogs have become

much more feasible because of Dr. Behforouz's concise synthetic methodologies with good

overall yields.

0

4

':::: 3

B

h

R'NH

Analogs showing excellent results against

N

8

0

oncogene-transformed cell lines

'0'

Analog Rl

H

11

12

CH3CO

13

CH 3CO

14

CH 3CO

".

R2

C02CH3

C0 2CH3

CO 2

C02C gH 17 - n

R3

CH3

CH 3

H

H

NRK

0.1

0.9

1.62

>33

Kll

1111.2

0.031

0.10

0.09

0.25

0.11

0.70

1.42

7.60

N/4.2

0.06

NT

1.50

9.00

3LL

0.25

>33

1.69

>33

These studies, along with similar studies on quinolinediones, have, in fact, been taking

place for several years with collaborators at the National Institute of Health, Eli Lilly, and others.

K

Certain lavendamycin analogs seem to be especially active against ras tumor cells. A few

examples are given above, where compounds 11, 12,13, and 14 have 3, 9, 18, and 130 fold

11

activity against ras K oncogene transformed cells. 18 To date, the structure-activity relationship

studies have shown that the amide and ester functional groups at the C-2' position endow the

compound with a great deal of biological activity. The various analogs synthesized by members

of Dr. Behforouz' s group should aid in the further identification of the particular groups and

positions that are most important.

12

VIII. Total Synthesis of Quinolinediones 21

and 23 and Lavendamycin Ester 26

Quinolinediones 21 and 23

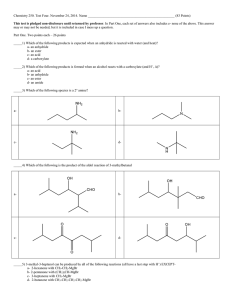

The compounds 21 and 23 were prepared according to Scheme 2.

Scheme 2

N02

~

HN03

~~CH3

OH

H:/Pd-C 5%

'"'"

•

'"'"

N

°2N

OH

15

•

conc HCI

CH 3

16

NHCOCH2CH 2CH 3

butyric anhydride

'"'"

N

OH

CH3

Na2S0:1'NaOAc

17

'"'"

CH 3CH2 CH2 CONH

N

18 OCOCH2CH2CH 3

o

Se02

•

glacial acetic acid

N'"'"

CH 3CH 2CH 2COHN

o

CH 3

•

CH 3

19

o

NaS03

N'"'"

CH 3CH 2CH 2COHN

o

20

•

CHO glacial acetic acid

N'"'"

CH 3CH 2CH 2COHN

o

21

COOH

13

DCC

pyrrolidine

'-':::

h

N-hydroxysuccinimide

N

CH sCH 2 CH 2 COHN

0

0

'-':::

N

0

23

0

0

fJ

h

CHsCH 2CH 2 COHN

22

0;:5

0

8-Hydroxy-2-methylquinoline (8-Hydroxyquinaldine) (15) is commercially available

from Aldrich Chemical Company. A nitration of this compound in concentrated nitric/sulfuric

acid solution gave dinitro 16. The hydroxyl of 15 is an ortho-para directing activator, so the nitro

groups perform an electrophilic attack on the ring via the nitronium cation. The pyridine ring is

not nitrated because of its low electron density and because of the nitrogen's electronegativity.

The reaction is quite exothermic and should be performed in an ice bath.

The ammonium chloride salt was made by the reduction of dinitro 2 in a Parr

hydrogenator with hydrogen gas, palladium charcoal, and HCl for at least 24 hours. The acid

was used to convert the free amino groups to ammonium chloride salts (dihydrochloride salts)

since the electron donating nature of the amino groups on the aromatic ring make them

susceptible to air oxidation. Sodium acetate (NaOAc) and sodium sulfite (Na2S03) were added

directly to the ammonium chloride salt solution. Sodium acetate's role is to act as a base to

liberate the basic amino groups from the salt. In other words, sodium acetate deprotonates the

ammonium ion to change the salt into the free amine. The sodium sulfite is both a base and an

antioxidant. The basic properties of Na2S03 allow it to convert the dihydrochloride salt to the

14

free amine. Sodium sulfite acts as an antioxidant because it is a source for the production of S02

in solution, which is rather susceptible to air oxidation; therefore, the S02 is oxidized before the

compound. The last reagent added to the salt solution is butyric anhydride. The nucleophilic

attack of the amino groups on the carbonyl carbons of butyric anhydride give product 18.

A solution of potassium dichromate in glacial acetic acid was used to oxidize 18 to

quinolinedione 19. The aqueous reaction mixture was extracted with dichloromethane and the

organic extracts were neutralized with a 3-10% sodium bicarbonate (NaHC0 3) solution. The

neutralized organic extracts were rotary evaporated to dryness.

Selenium dioxide in a wet dioxane solution was used to oxidize quinolinedione 19 to

aldehyde 20. An argon system must be used to protect the reaction mixture, and the complete

conversion to 20 may take a day or more. Only the methyl group of the dione is successfully

oxidized to the aldehyde. This is accomplished by the formation of an unstable oxide of

selenium when the selenium dioxide reacts with water.

Sodium perborate tetrahydrate (NaB0304H20) was added to a glacial acetic acid

suspension of aldehyde 20. The suspension was heated slightly, and the reaction typically took

no longer than a couple of hours to run to completion. The solid carboxylic acid 21 was isolated

by vacuum filtration.

The acid was dissolved in DMF and the solution was cooled in an ice bath. Then, DCC

(dicyclohexylcarbodiimide) and N-hydroxysuccinimide were added. After several hours in the

ice bath, the solution was vacuum filtered to remove the urea and other possible insoluble side

15

products. The resulting reactive intermediate 22 was not isolated, so the solution was taken to

the next step.

The addition of pyrrolidine to the solution containing the N-hydroxysuccinimide ester

resulted in an immediate change in color from yellow to red. The amide was then isolated by

vacuum pump distillation that took several hours. The red compound could be further purified

by column chromatography, but a quick work-up was necessary to avoid formation of other

products from the once-pure column fractions.

7-N-Butyryldemethyllavendamycin Benzyl Ester (26)

Pentacyclic lavendamycin derivatives may be synthesized by performing a PictetSpengler condensation of a quinolinedione aldehyde and a tryptophan, both fully functionalized

before the reaction. Care must be exercised to make certain of the purity of the reactants and the

solvents. A spiroindolenine intermediate is thought to occur in the reaction pathway of a PictetSpengler condensation. 19

Lavendamycin ester 26 was synthesized following Scheme 3.

Scheme 3

0

o~

NH 3 CI-

24

0

NHpH

•

EtOAc

NH2

N

I

H

25

o~

16

0

0

"'"

+

~

CH3CH 2CH2COHN

0

xylene

NH2

CHO

N

O~

25

20

0

"'"

~

N

CH 3CH2CH2COHN

0

0

N

~

O~

~

26

According to Scheme 3 above, aldehyde 20 was reacted with L-tryptophan benzyl ester

(25) through the Pictet -Spengler condensation to produce a lavendamycin analog. The

commercially available tryptophan hydrochloride salt (24) was suspended in ethyl acetate

(EtOAc). The free amine was liberated by careful addition of 14%

N~OH.

The organic layer

was washed with water until both it and the washings have a pH of 7. Rotary evaporation

initially yields an oil, but a solid, white compound eventually is obtained. This product is dried

and reacted with aldehyde 20 to produce 7-N-butyryldemethyllavendamycin benzyl ester (26).

17

IX. Experimental Section

A. General Information

Reagents: 8-Hydroxy-2-methylquinoline, 5% palladium on charcoal, butyric anhydride,

selenium dioxide, N-hydroxysuccinimide, L-tryptophan benzyl ester hydrochloride,

and N-dicyclohexylcarbodiimide were purchased from the Aldrich Chemical

Company.

Solvents: 1,4-Dioxane and xylene were dried and distilled before use. All other solvents were

reagent grade and were not distilled.

NMR Spectra: IH NMR were recorded on a Varian Gemini 200 spectrometer in deuterated

chloroform (CDCI 3) or dimethyl-~ sulfoxide (DMSO-~) with residual

chloroform (CHCh, Ii 7.24 ppm),

dimethyl-~

sulfoxide (DMSO-d6 , Ii 2.49

ppm), or tetramethylsilane (TMS, Ii 0.00 ppm) as the internal standards.

Thin-Layer Chromatography: Eastman silica gel thin-layer chromatography strips and sheets

with fluorescent indicator were used to monitor reactions and

to determine product purity.

B. Solvent Purification

1,4-Dioxane's tendency to polymerize and to contain free radical impurities made the

purification and drying of this solvent necessary. Two similar procedures were used for this

process. The older procedure required refluxing the solvent over potassium hydroxide (KOH),

filtering or decanting the solvent, and then refluxing it over sodium spheres until the spheres

18

I

,

appeared shiny and metallic. Benzophenone was then added, and if a blue color was achieved,

the solvent was simple-distilled. The newer procedure skipped the reflux over potassium

hydroxide and the subsequent filtration or decantation step. It is important to note, however, that

f

r

I

j

the solventshould be used the same day it is purified with either procedure for best results.

The solvent used for the condensation reaction, xylene, was dried and purified. First,

xylene was refluxed over sodium spheres in a medium-sized still. Then, benzophenone was

added. When the mixture turned blue the purified solvent was collected.

C. Procedures

Preparation of 8-Hydroxy-2-methyl-5,7-dinitroquinoline (16)

This procedure was similar to that reported by Mark G. Stocksdale. 2o

In a 500 ml ice bath-cooled Erlenmeyer flask, equipped with a magnetic stir bar, was

I

placed 210 ml of concentrated nitric acid. While stirring, 90 ml of concentrated sulfuric acid was

added slowly. (These steps are equivalent to adding 300 ml of 70% v/v concentrated nitric acid concentrated sulfuric acid solution to the 500 ml Erlenmeyer flask.) Stirring continued while the

solution remained in the ice bath. To this solution, 8-hydroxy-2-methylquinoline (8hydroxyquinaldine is the trade name for the same compound) (15; 30.00 g, 0.188 mol) was added

in small portions over a ten minute period. Upon addition of the 8-hydroxy-2-methylquinoline, a

brownish-red gas was evolved. The mixture was continually stirred in the ice bath for three

hours and fifteen minutes. The resulting black-red solution was then poured into a 2 L beaker

containing 800 ml water and 400 ml of ice and was stirred vigorously with a glass stirring rod. A

bright yellow precipitate in an orange solution was obtained after allowing the precipitate to

19

settle. The precipitate was filtered using a water aspirator and was left on the filter paper in the

Buchner funnel overnight. The precipitate was washed with 300 ml 95% ethanol and then was

washed with 300 ml diethyl ether two times (600 ml diethyl ether total). The resulting 8hydroxy-2-methyl-5,7-dinitroquinoline (16) was air-dried on the filter paper in the hood and

massed 26.94 g (57.4%): IH NMR (DMSO-dt;) Ii 9.65 (lH, d, J = 9.1 Hz, C-4H), 9.19 (lH, s, C60),8.13 (IH, d, J = 9.1 Hz, C-3H), 2.94 (3H,

S,

C-2CH3)'

Preparation of 5,7-Dibutyramido-S-butyroxy-2-methylquinoline (IS)

This procedure was similar to that reported by Mark G. Stocksdale,20 but was scaled up

two times.

In a 500 ml heavy-walled hydrogenation bottle, 8-hydroxy-2-methyl-5,7-dinitroquinoline

(16; 10.00 g, 0.04 mol) and 5% palladium on charcoal (3.00 g) were suspended in 200 ml of

water and 24 ml of concentrated hydrochloric acid. This mixture shook under 30 psi of hydrogen

for about 45 hours, with a decrease in pressure over time. The catalyst was filtered off using a

water aspirator, and the filter cake should be washed with some water. The dark red solution

(with a yellow tint, especially if it forms a thin film on the glassware) containing the

dihydrochloride salt of 5,7-diamino-8-hydroxy-2-methylquinoline (17) was placed in a 1000 ml

round-bottomed flask (rinsing the glassware to complete transfer increased the volume to the

point the solution would not fit in a 500 ml flask) with a magnetic stir bar. To this stirred

solution was added in sequence as quickly as possible, sodium sulfite (Na2S03: 24.00 g), sodium

acetate (NaOAc; 32.00 g), and butyric anhydride [(CH3CH3CH2CO)zO; 130 ml)]. The thick

20

whitish precipitate which continued to form over four hours and forty-five minutes was filtered

using a water aspirator and was washed with a total of 800 ml of water in the filtration apparatus.

The product was eventually dried between paper towels and left in tbe hood overnight. The

whitish compound (18) massed 14.24 g (88.8%) and had NMR peak values significantly different

from those reported by Stocksdale. An error in referencing to the DMSO peak, since the

spectrum (see Appendix A) is complex and crowded around 0 2.55 - 2.30, may be part of the

reason for the discrepancy (those reported here are for tbe spectrum in Appendix A). Another

contributor to the differences could be tbe impurity of the sample: IH NMR (DMSO-~) 09.75

(JR, s, C-7NH), 9.50 (lH, s, C-5NH), 8.15 (lH, s, C-6H), 8.09 (IH, d, J = 8. 1Hz, C-4H), 7.38

(JR, d, J = 85 Hz, C-3H), 2.71 (3H, s, C-3CH 3), 2.50 - 2.30 (4H, m, 2NHCOCHzCH2CH3), 2.20

(2R, t, J = 7.3 Hz, OCOCHzCH2CH3), 1.80 - 1.60 (4H, m, 2NHCOCH2CHzCH3), 1.60 - 1.40

(2R, m, OCOCH2CHzCH3), 1.03 - 0.94 (6H, m, 2NHCOCH2CH2CH3), 0.90 (3H, t, J = 7.3 Hz,

OCR2CH2CH3).

Preparation of 7-Butyramido-2-methylquinoline-S,8-dione (19)

This procedure was similar to that reported by Mark G. Stocksdale. 2o

In a 1000 ml Erlenmeyer flask, equipped witb a magnetic stir bar, 5,7-dibutyramido-8butyroxy-2-metbylquinoline (18; 3.29 g, 8.25 mmol) was suspended in 122 ml of glacial acetic

acid. Potassium dichromate (K2Cr207; 8.80 g, 0.03 mol) was added directly to the solution.

Both massing dishes were rinsed with water poured from a graduated cylinder that contained lIS

ml of water to aid in quantitative transfer of the reagents. The remainder of the lIS ml of water

I

I......

21

was added to the reaction solution. A watchglass was placed over the mouth of the Erlenmeyer

in order to prevent the solution from splashing out of the container since it was stirred as

vigorously as possible. After waiting two hours, 70 ml of CH2Ch was added to the solution.

The resulting two-phase solution was stirred for 22 hours, and then poured into a I L separatory

funnel. After the solution separated, the organic layer (bottom layer) was released into a 1000 ml

Erlenmeyer flask (which will contain all the organic layers eventually). The water layer was then

extracted with CH2Ch (12 x 50 ml). On extractions 7-12,50 ml of a saturated NaCI solution was

added after the CH2Ch each time (the order of addition is not important). The combined organic

extracts were washed with 3 x 200 ml 10% NaHC0 3 (add 100 g NaHC0 3 to 1000 ml of water to

make I L of 10% NaHC03) and both layers were saved. The water layers were extracted with 2

x 50 ml of CH2Ch and 50 ml saturated NaCI solution was added on the first extract only. The

two approximately 50 ml CH2Ch extracts were combined, neutralized with 200 ml 10%

NaHC0 3, and then added to the original CH2Ch extracts from the 12 original extractions. This

final CH2CI 2 solution was dried with MgS04 , and then filtered with a water aspirator and

sintered-glass filter. The filter cake was rinsed with CH2Ch two times. The resulting orangeyellow solution was rotary evaporated to yield a light yellow solid with an orange-red impurity.

After vacuum drying, the solid (19) massed 1.60 g (75.1 %): IH NMR (CDCh) Ii 8.37 (lH, br s,

C-7NH), 8.28 (lH, d, J =8.1 Hz, C-4H), 7.89 (lH, s, C-6H), 7.53 (lH, d, J =8.1 Hz, C-3H),

2.74 (3H, s, C-2CH3 ), 2.48 (2H, t, J = 7.4 Hz, C-7NHCOCHzCH2CH3), 1.84 - 1.66 (2H, m, C-

22

Preparation of 7 -Butyramido-2-formylquinoIine-5,8-dione (20)

This procedure was similar to that reported by Mark G. Stocksdale.

20

Yields up to 120%

were recorded, but this procedure is similar to the reference and gives a decent yield.

In a 25 ml round-bottomed flask, equipped with a magnetic stir bar, water-cooled reflux

condenser, and an argon filled balloon, recrystallized 7-butyrarnido-2-methylquinoline-5,8-dione

(19; 0.516 g, 2 mmol), selenium dioxide (Se02; 0.255 g, 2.3 mrnol), 12 ml of dried distilled 1,4dioxane, and 0.25 ml of water were stirred and slowly heated to reflux over one hour. The final

temperature should be close to 120-130 °C. The solution was refluxed for 65 hours and 45

minutes. The selenium metal was allowed to settle, and the supernatant solution was pipetted off

and filtered. Dried, distilled 1,4-dioxane (10 ml) was added to the selenium metal still in the 25

ml round-bottomed flask, and the solution was magnetically stirred and refluxed for ten minutes.

The entire mixture was filtered and the selenium on the filter paper was washed with about 10 ml

CH2Ch. All filtrates were put in a beaker along with the filter paper, and everything was heated

on a steam cone until boiling. The solution was then refiltered with a fresh filter paper, and the

selenium was washed with CH2Ch. (If the next reaction is to be the conversion of this aldehyde

to the corresponding acid, the solution can be rotary evaporated and dried under 40-50 °C heat on

the vacuum pump for several days.) This solution was diluted with 50 ml of CH 2Ch and

neutralized with 2 x 50 ml 3% NaHC0 3 . Organic and water layers were both saved. The water

layers were combined and extracted with 50 ml of CH 2Ch, The approximately 50 ml CH 2Ch

extract was neutralized with 30 ml of 3% NaHC03 , and then it was added to the original CH2Ch

extracts from the first neutralizations. This final CH2Ch solution was dried with MgS04 , and

23

then filtered with a water aspirator and a sintered-glass filter. The filter cake was rinsed with

CH2CIz. The resulting solution was rotary evaporated to yield a yellow-orange solid. After

vacuum drying overnight, the solid massed 0.422 g (77.6%): IH NMR (CDCh) 010.29 (lH, s,

C-2CHO), 8.62 (IH, d, J = 8.1 Hz, CAH), 8.39 (lH, br s, C-7NH), 8.31 (lH, d, J =8.0 Hz, C3H), 8.06 (lH, s, C-6H), 2.52 (2H, t, J = 7.4 Hz, C-7NHCOCH2CH 2CH3 ), 1.90 - 1.70 (2H, m, C7NHCOCH 2CH2 CH 3), 1.02 (3H, t, J = 7.4 Hz, C-7NHCOCH2CH2CH3).

Preparation of 7-Butyramidoquinoline-5,8-dione-2-carboxylic acid (21)

This procedure was similar to that performed in the reference cited below. 22 Yields up to

160.3% were recorded, but this procedure gives a more believable yield.

In a 5 ml round-bottomed flask equipped with a miniature magnetic stir bar, 7butyramido-2-formylquinoline-5,8-dione (20; 0.1064 g, 0.39 mmol) and 1.0 ml glacial acetic acid

(AcOH, unpurified) were placed while the silicon oil bath was warming up. When the

temperature reached 75-85 DC, addition of 0.3016 g sodium perborate tetrahydrate (NaB0 30 4H 20)

in four portions over 30 minutes was begun. Compound 20 dissolved partially (the solution

appears more like a suspension than a solution for the entire reaction) only after addition of the

first portion of NaB0 3. The solution turned from yellow-brown to orange-brown shortly after the

first portion was added, so the heat was removed but stirring was continued. Almost

immediately before the addition of the second NaB03 portion, 0.5 ml AcOH was added.

Approximately two minutes later, another 0.5 ml AcOH was added. After addition of the final

sodium perborate portion, the reaction was left stirring for another 1 hour and 30 minutes. At the

24

end of this time period, since a total of 2.0 ml AcOH was used for the reaction, 2.0 ml H20 was

added to the reaction mixture. After about five minutes of stirring, the solution was filtered using

the water aspirator. The filtrate was poured back into the reaction vessel, and a spatula was used

to scrape the sides of the round-bottomed flask. This suspension was filtered using the same

filtration apparatus as previously (including the same filter paper). Other attempts were made to

increase the yield, but seemingly the most significant amount of product is the filter cake. The

light, bright yellow compound (21) massed 0.0745 g (66.1 %): IR (KBr) 3384, 3315, 3221, 1680,

1654,1506, 1464, 1414, 1387, 1323, 1204,894,800,724 cm· l ; lH NMR (DMSO-dt;) /) 10.01

(lH, s, C-7NH), 8.47 (lH, d, J =8.1 Hz, C-4H), 8.36 (lH, d, J =8.1 Hz, C-3H), 7.80 (lH, s, C6H), 2.59 (2H, t, J = 7.3 Hz, C-7NHCOCH2CH2CH3), 1.70 - 1.50 (2H, m, C7NHCOCH2CH2CH3), 0.90 (3H, t, J = 7.3 Hz, C-7NHCOCH2CH2CH3).

Preparation of Pyrrolidine 7-Butyramidoquinoline-5,8-dione-2-carboxamide (23)

All glassware should be oven-dried. Reagents were dried as specified. N,N-Dimethyl

formamide (DMF) was dried over 4

A molecular sieves.

About 50 ml pyrrolidine was poured

into a 125 ml Erlenmeyer flask and 5.0 g magnesium sulfate (MgS04 ) was added. After shaking

and stoppering the flask, it was allowed to sit overnight. The pyrrolidine was decanted into a 100

ml round-bottomed flask with 2.0 g CaH2, then fractionally distilled (boiling point 87-88 cc).

The 100 ml receiving flask was stoppered with a rubber septum and placed under an argon (Ar)

system. To a 50 ml round-bottomed flask was added 0.1445 g 7-butyramidoquinoline-5,8-dione2-carboxylic acid (21; 0.5 mmol), 10 ml DMF, and a miniature stir bar. The reaction flask was

25

placed under an Ar system, and the solution was stirred and heated at 70°C until a clear solution

was obtained. The heat was then removed, and the flask was allowed to cool under Ar in an ice

bath. After more than an hour of cooling, N-hydroxysuccinimide (0.058 g, 0.5 mmol) and 1,3dicyclohexylcarbodiimide (DeC; 0.110 g) were added and the reaction solution was allowed to

stir overnight under Ar and on ice. The solution was then filtered, and the filtrate containing

product 22 was poured into a clean, dry 50 ml round-bottomed flask. The product was not

isolated. The solution containing 22 was stirred under Ar in an ice bath. Pyrrolidine (about 0.05

mI, l.l equivalents) was added, and the solution turned deep red immediately. The reaction was

allowed to stir, and then the 50 ml round-bottomed flask containing the red solution was placed

on a short-path distillation apparatus equipped for vacuum distillation. This room-temperature

distillation took 2-3 hours, after which the compound was placed directly on the vacuum pump to

dry. The compound was removed from the vacuum pump and 10 ml diethyl ether was added to

the reaction flask. The compound was then scraped against the sides of the flask and filtered

with additional ether rinsings. This afforded the dark purple compound 23, which was placed on

the vacuum pump to dry for a few days and massed 0.1187 g (69.4%). The dried compound was

suspended in a 5% methanol in ethyl acetate solution, and then filtered following concentration

with an argon stream. The filtrate was run through a column for further purification (it is

important to work up the desired fractions soon after collecting from the column so that

impurities do not interfere with purification); the yield after the suspension and column

chromatography dropped to 7.0%: IR (KBr) 3377, 3217, 2965, 2875, 2370, 1715, 1679, 1624,

1565,1543,1479,1432,1306,1197,1098,1023,802 cm'\ the IH NMR spectrum of this

26

compound located in Appendix A is difficult to interpret, but it appears as though 23 was

successfully synthesized; IH NMR (CDCh) /) 8.33 (lH, d, J = 8.1 Hz, CAH), 8.03 (lH, d, J =

8.1 Hz, C-3H), 7.67 (lH, s, C-6H), 3.80 - 3.50 (4H, m) may be due to CONCH2 of the

pyrrolidine ring, 2.44 (2H, t, J = 7.5 Hz, C-7NHCOCH2CH2CH3), 2.10 - 1.80 (4H, m) may be

due to CONCH2CHz of the pyrrolidine ring, 1.80 - 1.60 (2H, m, C-7NHCOCH2CHzCH3), 0.99

(3H, t, J = 7.3 Hz, C-7NHCOCH2CH2CH3).

Preparation of L-Tryptophan Benzyl Ester (25)

Prepared 14% NH40H by adding 5 ml concentrated N~OH (assay 28.7%) to a 25 ml

Erlenmeyer flask and then diluting with 5 ml water. Added the commercially available Ltryptophan benzyl ester hydrochloride salt (24; 0.9920 g, 3 mmol) to a 2-necked, 250 ml roundbottomed flask equipped with a stir bar. Next, 60 ml ethyl acetate (EtOAc) was added to the

flask and stirring was begun. Stirring was continued for a minute or two without successful

dissolution of the compound, and then 14% NH40H (1.7 ml) was slowly added to obtain a clear

solution. Upon termination of stirring, a white precipitate was noticed, so 0.5 - 2.0 ml water was

added with concomitant dissolution of the precipitate. Since this result was an indicator that the

precipitate was N~CI, the procedure was continued. Working quickly, the solution was poured

into a 125 ml separatory funnel and the bottom aqueous layer was removed. The organic layer

was washed with water (7 x 9 ml) until both the organic and aqueous layers had a pH of about 7.

The resulting organic layer was dried over MgS04 in the refrigerator. From this point forward,

all glassware was oven-dried before use. The cold MgS04 solution was filtered through cotton

27

into a 100 ml round-bottomed flask. A few ml of EtOAc was used to aid in quantitative transfer

of the compound. The solution was rotary evaporated-at first an oily substance appeared, but

the white, solid compound 25 eventually emerged. After drying on the vacuum pump, the white

to off-white 25 massed 0.9351 g (106.0%): 'H NMR (CDC h) /) 8.01 (lH, br s, N-IH), 7.54

(lH, d, J = 7.7 Hz, C-4H), 7.20 (lH, m, C-7H), 7.30 - 7.12 and 7.06 - 6.98 (5H, m, C6HS), 7.127.06 (2H, m, C-5H and C-6H), 6.86 (lH, d, C-2H), 5.04 (2H, s, C02CH2C6HS), 3.80 (lH, m, C3CH2CH(NH2)C02), 3.30 - 2.90 (2H, m, C-3CH2CH(NH2)C02).

Preparation of 7-N-Butyryldemethyllavendamycin Benzyl Ester (26)

All glassware was oven-dried prior to use. 7-Butyramido-2-formylquinoline-5,8-dione

(20; 0.0693 g, 0.25 mrnol), a magnetic stir bar, L-tryptophan benzyl ester (25; 0.0759 g, 0.26

mmol), and 100 ml dry xylene were added to a three-necked 250 ml round-bottomed flask under

an argon flow and equipped with a Dean-Stark collector connected to an oil bubbler. The

reaction was stirred and heated to 130 DC over an hour. The reaction was monitored by TLC (5

ml CH2Ch + 10 drops CH 30H). At about 16 hours, a precipitate started forming in the reaction

flask (it was cloudy before this), so the reaction was stopped and left under argon until the

solution was transferred to a 24/40-necked, 250 ml round-bottomed flask. The reaction mixture

was rotary evaporated to dryness, then about 10 ml acetone (CH3COCH3) was added, and the

flask was left open in the hood for approximately 5Yz hours. The solution was then filtered using

the water aspirator, and the 250 ml round-bottomed flask was rinsed with some acetone. The

filtrate and the 25 ml filtration flask were removed and placed open in the hood to dry overnight.

28

A clean 125 ml filtration flask was connected to the filter funnel containing the filter cake, and

the filter cake was rinsed with some acetone and then with hexanes. This filtrate was discarded,

but the filter cake was placed in a very small round-bottomed flask to dry on the vacuum pump

overnight. After drying, the orange-brown compound 26 massed 0.0306 g (22.0%). After drying

in the hood, the saved filtrate was suspended in acetone and refiltered. This filter cake and the

dried 26 were placed in separate small vials and stored: IR (KBr) 3377, 3332, 3308, 2964, 2875,

1731,1704,1648,1587,1500, \334, 1309, 1263, 1221, 1119,886,863,740,698 em"; the 'H

NMR spectrum of this compound located in Appendix A is difficult to interpret with respect to

the C02CH2C6H! hydrogens, but it appears as though they may be in the 7.80 - 7.20 region: due

to the complexity and crowding of this area in the spectrum, these five hydrogens are not

assigned; 'H NMR (CDCh) 811.80 (lH, br s, -NH), 9.17 (lH, d, J = 8.4 Hz, C-4H), 8.95 (lH, s,

C-3'H), 8.53 (lH, d, J = 8.4 Hz, C-3H), 8.40 (lH, br s, C-7NH), 8.21 (lH, d, J = 7.8 Hz, C12'H), 7.99 (lH, s, C-6H), 7.70 (IH, d, J = 4.4 Hz, C-9'H), 7.61 (lH, t, J = 8.4 Hz, C-10'H),

7.44 (lH, t, J =6.8 Hz, C-l1 'H), 5.54 (2H, s, C-2 'C0 2CH z), 2.53 (2H, t, J =7.3 Hz, C7NHCOCHzCH2CH3), 1.82 (2H, m, C-7NHCOCH2CHzCH3), 1.06 (3H, t, J =7.3 Hz, C7NHCOCH2CH2CH3).

29

Appendix A

Spectra

Index

Page Number

8-Hydroxy-2-methylquinoline (8-Hydroxyquinaldine) (15)

eH NMR-Full Spectrum with Integration)

31

8-Hydroxy-2-methyl-S,7-dinitroquinoline (16)

eH NMR-Full Spectrum with Integration)

32

5,7-Dibutyramido-8-butyroxy-2-methylquinoline (18)

eH NMR-Full Spectrum with Integration)

33

7-Butyramido-2-methylquinoline-S,8-dione (19)

(lH NMR-Full Spectrum with Integration)

34

7-Butyramido-2-formylquinoline-5,8-dione (20)

eH NMR-Full Spectrum with Integration)

35

7-Butyramidoquinoline-S,8-dione-2-carboxylic acid (21)

eH NMR-Full Spectrum with Integration)

36

7-Butyramidoquinoline-S,8-dione-2-carboxylic acid (21)

eH NMR-Full Spectrum with Integration and Labeled Peaks)

37

7-Butyramidoquinoline-S,8-dione-2-carboxylic acid (21)

(IR-Full Spectrum)

38

7-Butyramidoquinoline-S,8-dione-2-carboxylic acid (21)

(IR-Full Spectrum with Labeled Peaks)

39

Pyrrolidine 7-Butyramidoquinoline-S,8-dione-2-carboxamide (23)

eH NMR-Full Spectrum with Integration)

40

Pyrrolidine 7-Butyramidoquinoline-S,8-dione-2-carboxamide (23)

eH NMR-Close-up Spectrum of B8.47 -7.S1 with Integration and Labeled Peaks)

41

Pyrrolidine 7-Butyramidoquinoline-S,8-dione-2-carboxamide (23)

eH NMR-Close-up Spectrum of B4.20 - 2.33 with Integration and Labeled Peaks)

42

30

Pyrrolidine 7-Butyramidoquinoline-5,8-dione-2-carboxamide (23)

NMR-Close-up Spectrum of 15 2.20 - 0.60 with Integration and Labeled Peaks)

43

Pyrrolidine 7-Butyramidoquinoline-5,8-dione-2-carboxamide (23)

(IR-Full Spectrum)

44

Pyrrolidine 7-Butyramidoquinoline-5,8-dione-2-carboxamide (23)

(IR-Full Spectrum with Labeled Peaks)

45

L-Tryptophan benzyl ester (25)

NMR-Full Spectrum with Integration)

46

L-Tryptophan benzyl ester (25)

NMR-Close-up Spectrum of 15 8.20 - 6.60 with Integration and Labeled Peaks)

47

7-N-Butyryldemethyllavendamycin benzyl ester (26)

('H NMR-Full Spectrum with Integration)

48

7-N-Butyryldemethyllavendamycin benzyl ester (26)

('H NMR-Full Spectrum with Labeled Peaks)

49

7-N-Butyryldemethyllavendamycin benzyl ester (26)

(IR-Full Spectrum)

50

7-N-Butyryldemethyllavendamycin benzyl ester (26)

(IR-Full Spectrum with Labeled Peaks)

51

eH

eH

eH

o

31

....

CD

Q)

.!:

0

c:

::c'"

fj

Q

·s0-

~z

... -E,

>.

.s:::

II)

::c

0

$

Q)

,

C\J

~

CIt

~

"0

>.

::c,

00

CD

~

j,

t-.

r

rcN

.I

-3,

~

~

I="C

~

l-

t-.

r

'-c

Ih

IQ)

h

c:

0

c:

·S

J:'"

U

...

co

0

N

J:

Z

-

C"

e

0

""c:

'5,

r

......

U)

,

>.

.e:

1

-

l-

Q)

E,

Z

0 '"

C\I

,

S<'

e

'0

>J:,

<XI

-

t--en ..,

\

},.:

'J ~

,

t-

-

~o

I-

}~

NHCOCH 2 CH 2CH 3

~

..-::

N/' 'CH 3

CH 3CH 2CH 2CONH

18

OCOCH 2CH 2CH 3

5,7-Dibutyramido-8-butyroxy-2-methylquinoline

IT""

10

t..J

6.1

i

r

iii

'r'

1i.3

9

I i

I

8

L, 1

!2.!l

I

Iii

L.-J

6.5

ii'

7

i i i iii

I

6

i

I

Iii

I

5

Iii I

Iii

"

iii I

i

I

3

I Iii

Iii

i

I

I

{i,

I I 1~--'---r'"'J

2

~r'

11.9 .2-2.7

24.8

15.1

I...-J L.J '-.J

18.S

II

381

•. e

Q)

c:

'5,

I '"

(,)

0

CO

Ll'i

,

en

,..

Q)

.5:

"0

0

0

-,

z

Q)

E

I

0

(,)

I

.5:

::l

!Z"

>.r:

'"

(,)

'"

:c'"

I

C\l

,

0

"C

·E

!!!

(,)

~

(,)

ID,

::l

r-...

...

J-~

.....

...

~

;,...;

~

o

CH CH CH COHN' I f

3

2

2

~N'

~CHO

"

o

20

7 -Butyramido-2-formylquinoline-5,8-dione

..

...j

-1

fT'"

I • iii

11

I

10

I.,J

6.83

iii iii iii

Iii

".

•

'i

iii i • iii Ii' • Iii i I

9

8

L.,J

t.l-.J

'r'

7.3<18.01

5.58 6.10

Iii

7

--------

i I Iii iii iii iii iii

6·

---

I

--

iii iii iii

5·

II • I

4

I I iii I

J Iii

I I Iii i

3

1.

'"

.rv

I

I •• I

I •

2·

L.-J

1".21

~

i".85

I , i

I

;:;;

I I I -. I ""1 I

1 PPM

......

20.90

0

J

o

~

CH 3CH 2CH 2COHN

N-:;:::; 'COOH

o

21

7-Butyramidoquinoline-5,8-dione-2-carboxylic acid

i1~

'fA

iiii~lj

o.s'iu

o,.~

o.~

v:7i11

'J

'J

jiiii~pPMi

1.~1

1~

Ii

'r'1

2.3!11

t5<·O.

o

}~

}~...

-c

"util

I

0

"~

0

0

0

-etil

()

0,

~

a>

c

Sloe"L-

0

0

0

'6,

,

I

0

()

'"

()

I '"

()

I '"

I

()

...

~

..,

~

It)

z

J-~

a>

"~

0

c

"S

0-

0

-c

"E

til

~

Z.

::::J

a:l,

r--

J8OO"05-

on

..,

J-~

81.2

80

78

76

74

72

70

68

%T

66

64

62

o

60

58

CHaCH2CH2COHN

56

COOH

o

21

w

00

53.61

4000.0

7-Butyramidoquinoline-5,8-dione-2-carboxylic acid

i

3000

I

i

-2000

1500

em-I

1000

600.0

81.2

80

78

927.

76

2363.79

74

.22

;76.71

72

1721163

800.03

70

I

724.43

123513,

.4

.64

'72.60

1/147

68

1$11.97

%T

1119.80

66

64

1203.84

62

'0

60

1$53.78

58

1680.11

CH3 CH2 CH2COHN

56

3315.45

53.61

4000.0

COOH

o

15<)/;.87

1386.58

21

w

7 _Butxramidoquinoline-5,8-dio~e-2-carboXYlic acid

3000

2000

'D

"

1500

em-I

1000

600.0

o

o

CH 3CH 2CH 2COHN

o

o

23

pyrrolidine 7-Butyramidoquinoline-5,8-dione-2-carboxamide

I

,

L.,..r

2.9

I

I

I

iii i i i

B

7

L,.J

3.1

..,...

2.3

I

I

• I

6

5

i

I

Iii

i

•

iii

4

i." 8.2

i

I

I

I

iii

3

L.-I1. I " ' I '

19.7

3.3

,

I

I

I

I

I

I

I

I

2

L.J~

2.8

7.9

""",

11.2' 16.2

30.1

I

I

~

I

I

VI

1 PPM

I.......p.JLfl.'

13.1

16.

96.0

o

f)

CH 3CH 2CH 2COHN

o

o

23

Pyrrolidine 7-Bulyramidoquinoline-5,8-dione-2-carboxamide

-

~

-

0

~

CD

I

'"

CD

III

~ i

I

18

"!

~

CD

I

I

...

...

!§

~

/1

I

\

iii i i i

B.4

Iii

B.3

""'_._ . ___ .J

L~---2.92

iii

B.2

I

-r-r-r:--r.

iii

I

B.1

iii i i i

B.O

L--__ .. _ .

-'"t"'--'-

3.10

7.9

.;,

I

7.B

I

,

I

I

i

I

'-- ' _ _

I

I

I

I

,

I

I

TTf'

-

7.6 PPM .,..

7.7

~_~

_______ -1

2.31

if.,

... :

Co!

N ~~

,

...i

10

N

~L89'a -

1~

-====::::r

.",

J

co

N

o

...,

N

...,

Q)

:2

E

as

x

I

......, .....t:;

0

0

.0

.....

as

0

I

•

•

Q)

c

,2

~

C\I

0

-c

M

N

0

0

co•

U"J

•

Q)

,5

966!l'£W!9'£-

£Z99'£-

..1',

10

"'~.

...,

l

,

0

.5

J

:;j

0"

Z

I

0

:2

0

E

'"

U

I '"

~

al

U'"

,5

U

I

I

U

co

...,

l"'~

f"!

""

~

I

:;j

j

•

I"Q)

:2

0

• '1

"'1

•.l~

...•

0

.....

.....

a.>-

I

i

...

N

J

4

CD

o

~

I

t£08·0 ......

lIl'ilI!' 0--

MII'O

9068'0

8188'0

Ijl~

CD

o

~

"\...

I

6~'0~

9986'0(])

==00!i6~~·0~.r~.~5~

8QlO'J-

--====:?'

:2

E

~~

5J

as

x

~as

cr

Q

t}I

0

(])

I::

.Q

'tJ

,

1

C')

N

0

0

00

Lfi

,

(])

.5

.........

0

.5

::J

z

I

8I'"

(,)

I'"

(,)

I~

(,)

0'

0

:2

E

e

~

CD,

r-..

(])

.5

:2

e

~

~

CD

01;£9'1£J£9',6LOL'J- - - '

O9l'L·J'-. - - "

9JLL'J "\

()£8L'J-

t9OII'J 00ilII" .r:

E890'a-

C\I

N

73.3

70

65

60

.55

o

50

45

o

%T 40

23

Pyrrolidirje 7_Butyramidoquinoline-5.8-dione-2-c8rooxamide

35

30

2S

20

t

15

10.2/

4000.0

V

v

3000

,VV

ISOO

2000

em-I

,

1000

600.0

73.3

70

65

1812165

60

1781142

18.11

55

2369.86

o

CH3~H2CH2COHN

45

1.07

o

50

o

.63

867.

23

7.57

%T 40

Pyrrolidin!e 7_Butyramidoquinoline-5,8-dione-2-carboxamide

1209.

38

'48.04

35

30

1097.65

:74.98

801.89

I

1022.53

25

1714.

20

2984.93

3376·V

15

10.21

4000.0

3~17/47

•

3000

1196.55

1676.

~

U\

W

2000

cm-I

1500V\V

1000

600.0

- - _ j J Io

N

}::i

J-N

.,;

~

CD

I I)

~}~

}:

CD

>,

N

r:::

0

0

J:'"

Z

1l

r:::

It)

N

tIS

.J::.

a.

0

0..

~

I,

....J

CD

}::i

,....

UI

-

f

~

(])

,....

I II

(])

~

C

0

0

CD

(])

I

z

.0

'"

1

c

In

C\I

ell

..c

c.

0

c.

~

I-,

...J

0800'8-

~ ,~"!

,,

CD

..

4

}~

...

}~

....

t~

,}i

....

Q)

0

-

l'~

1::.

C/l

0

Q)

W...

~

c:

Q)

J-~

.0

c:

]I...

.~

E

<11

"0

0

CD

C'I

c:

CD

~

~

z

J:

-

0

CD

"0

U

J:'"

U

J:'"

U

J:'"

U

~

~

:::l

III

...

CD

E

~,

.....

...

N

J-I!

III

4

....

OJ

Vl

0

OJ

>.

N

c:

OJ

.0

~

z

I

E

::c

III

"0

CD

N

0

c:

.~

c:

!2III

>..c:

Z

::c

0

0",

::c

0",

::c

0",

::c

Qi

E

OJ

"0

~

~

::::J

ID

~

......•

BEL'" -'\

86.2

84

J

82

I

80

78

76

74

72

70

%T 68

66

:J

0

~

60J CH aCH 2CH 2COHN/

58

56

1

y

0\ \

'N.... ~ ';{

O~

0

26

54

52

V>

7 -N-Butyryldemethyllavendamycin benzyl ester

o

50.1 +I---------,--------,--------f.--------,-----'--___='.

600.0

1000

1500

2000

4000.0

3000

cm-I

86.2

84

82

791.

80

78

961.45

141411

5.23

76

.09 88~'rl

74

863.02

72

70

.72

U5 •.

,.".;9

3431

15014

%T 68

197.96

1

2963.75

337!WI

5·~79.

1

66

3331·66

3308.07

It04.

o

64

1731.88HI587.13

1$3188

1119.25

O~

62

60 J CH 3CH2CH 2COHN

o

58

1~9

26

56

739.79

1309.

I

1262.

1648.32

54

1221.28

15$0.37

52

50.1 I

4000.0

-

7-N-Butyryldemethyllavendamycin benzyl ester

u.

i

I

3000

2000

1500

em-I

1000

600.0

52

Appendix B

Research Presentations

Some of the material in this thesis has been presented to various audiences. A

presentation was made for the Ball State Chemistry Department in the Summer Research

Program for two consecutive years. The work was also presented at the Indiana Academy of

Science's 113th Annual Meeting held at Saint Joseph's College on October 30-31,1997.

53

x.

Works Cited

1.) Doyle, T. W.; Balitz, D. M.; Grulich, R. E.; Nettleton, D. E.; Gould, S. J.; Tann, c.; Moews,

A. E. "Structure Determination of Lavendamycin: A New Antibiotic From Streptomyces

lavendulae," Tetrahehron Lett. 1981, 22, 4595.

2.) Prescott, L. M.; Harley, J. P.; Klein, D. A. Microbiology. 2nd ed., Wm. C. Brown

Publishers, 1993, 507.

3.) Rao, K. V.; Cullen, W. P. Antibiot. Annu. 1050,950.

4.) Boger, D. L.; Yasuda, M.; Mitscher, L.; Drake, S. D.; Kitos, P. A. "Streptonigrin and

Lavendamycin Partial Structures. Probes for the Minimum, Potent Pharmacophore of

Streptonigrin, Lavendamycin and Synthetic Quinoline-5,8-diones," 1. Med. Chern. 1987,

30, 1918.

5.) Kende, A. S.; Ebetino, F. H. "The Regiospecific Total Synthesis of Lavendamycin Methyl

Ester," Tetrahedron Lett. 1984, 25, 923.

6.) Kende, A. S.; Ebetino, F. H.; Battista, R.; Lorah, D. P.; Lodge, E. "New Tactics in

Heterocyclic Synthesis," Heterocycles 1984,21,91.

7.) Hibino, S.; Okazaki, M.; Ichikawa, M.; Sato, K.; Ishizu, T. Heterocycles 1985,23,261.

S.) Boger, D. L.; Duff, S. R.; Panek, M.; Yasuda, M. "Inverse Electron Demand Diels-Alder

Reactions of Heterocyclic Azadienes. Studies on the Total Synthesis of Lavendamycin:

Investigative Studies on the Preparation of the DCE-~-Carboline Ring System and AB

Quinoline-5,S-quinone Ring System," 1. argo Chern. 1985,50, 57S2.

9.) Behforouz, M.; Gu, Z.; Cai, W.; Hom, M. A.; Ahmadian, M. "A Highly Concise Synthesis

of Lavendamycin Methyl Ester," 1. argo Chern. 1993, 58, 70S4.

10.) Behforouz, M.; Haddad, J.; Cai, W.; Arnold, M. A .. ; Mohammadi, F.; Sousa, A. c.; Hom,

M. A. "Highly Efficient and Practical Syntheses of Lavendamycin Methyl Ester and

Related Quinolinediones," 1. argo Chern. 1996,61,6552, and references cited therein.

11.) Rao, K. V. Cancer Chernother. Rep., Part 2 1974,4(2), 1.

12.) Behforouz, M.; Haddad, J.; Cai, W.; Gu, Z. "Chemistry of Quinoline-5,S-diones," 1. argo

Chern. 1998,63,343, and references cited therein.

54

13.) Cone, R.; Hasan, S. K.; Lown, J. W.; Morgan, A. R. "The mechanism of the degradation of

DNA by streptonigrin," Can. 1. Biochem. 1976,54,219.

14.) Shaikh, 1. A.; Johnson, F.; GroHman, A. P. "Streptonigrin. 1. Structure-Activity

Relationships Among Simple Bicyclic Analogues. Route Dependence of DNA

Degradation on Quinone Reduction Potential," 1. Med. Chem. 1986,29, 1329.

IS.) Lown, J. W.; Sim, S. "Studies Related to Antitumor Antibiotics. Part VIII. Cleavage of

DNA by Streptonigrin Analogues and Relationship to Antineoplastic Activity," Can. 1.

Biochem. 1976, 54, 446.

16.) Bachur, N. R.; Gordon, S. L.; Gee, M. V. "A General Mechanism for Microsomal

Activation of Quinone Anticancer Agents to Free Radicals," Cancer Res. 1978,38, 1745.

17.) Lown, J. W.; Sim, S.; Chen, H. "Hydroxyl Radical Production by Free and DNA-Bound

Aminoquinone Antibiotics and its Role in DNA Degradation. Electron Spin Resonance

Detection of Hydroxyl Radicals and by Spin Trapping," Can. 1. Biochem. 1978, 56,

1042.

18.) Behforouz, M. Grant Proposal to the NIH, 1997, unpublished.

19.) Ungemach, F.; Cook, J. M. "The Spiroindolenine Intermediate, A Review," Heterocycles

1978,9, 1089.

20.) Stocksdale, Mark G. Total Synthesis of Lavendamycin Analogs. Masters Thesis, July,

1992.

21.) Banerjee, A.; Hazra, B.; Bhattacharya, A.; Banerjee, S.; Banerjee, G. c.; Sengupta, S.

"Novel Applications of Sodium Perborate to the Oxidation of Aromatic Aldehydes, aHydroxycarboxylic Acids, 1,2-Diketones, a-Hydroxyketones, 1,2-Diols and Some

Unsaturated Compounds," Synthesis 1989, 765.