Buckeye Bulletin

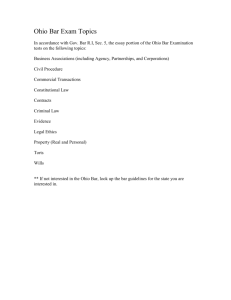

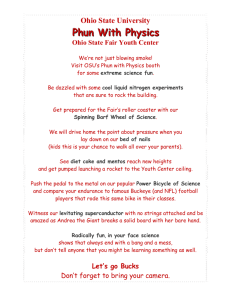

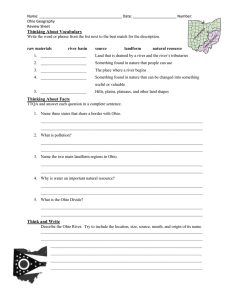

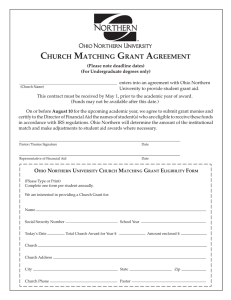

advertisement