Document 11182560

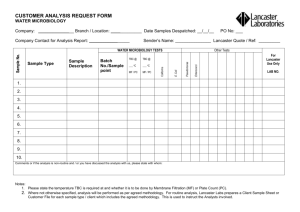

advertisement