MITLibraries

advertisement

MITLibraries

Document Services

Room 14-0551

77 Massachusetts Avenue

Cambridge, MA 02139

Ph: 617.253.5668 Fax: 617.253.1690

Email: docs@mit.edu

http://libraries. mit. edu/docs

DISCLAIMER OF QUALITY

Due to the condition of the original material, there are unavoidable

flaws in this reproduction. We have made every effort possible to

provide you with the best copy available. If you are dissatisfied with

this product and find it unusable, please contact Document Services as

soon as possible.

Thank you.

Some pages in the original document contain color

pictures or graphics that will not scan or reproducewell.

MATERIALS WITH SUPRAMOLECULAR CHIRALITY:

LIQUID CRYSTALS AND POLYMERS FOR CATALYSIS

'ARCIHIv

BY

MASSACHUSErS

IS

OF TECHNOLOGY

KAREN VILLAZOR MARTIN

MAR 2 5 2005

B.S., Chemistry, cum laude, 1999

Boston College, Chestnut Hill, MA

LIBRARIES

Submitted to the Department of Chemistry in Partial

Fulfillment of the Requirements for the Degree of

DOCTOR OF PHILOSOPHY

at the

MASSACHUSETTS

INSTITUTE OF TECHONOLOGY

February, 2005

© Massachusetts Institute of Technology, 2004. All Rights Reserved.

Signature of Author:

7)

Department of Chemistry

October 27, 2004

Certified by:

...

0

Timothy M. Swager

Thesis Supervisor

Accepted by:

Robert W. Field

Chairman, Departmental Committee on Graduate Studies

.

This doctoral thesis has been examined by a Committee of the Department of Chemistry

as follows:

Professor Timothy F. Jamison:

2'

Chairman

4-

Professor Daniel S. Kemp:

Department of Chemistry

'1

Professor Timothy M. Swager:

\

2

-J

Thesis Advisor

With much love and gratitude,

I dedicate this thesis to my family and friends,

who all came along for the ride.

3

MATERIALS WITH SUPRAMOLECULAR CHIRALITY:

LIQUID CRYSTALS AND POLYMERS FOR CATALYSIS

By

KAREN VILLAZOR MARTIN

Submitted to the Department of Chemistry, February, 2005

In partial fulfillment of the requirements for the degree of

Doctor of Philosophy in Chemistry

ABSTRACT

Mesomorphic organizations provide a powerful and efficient method for the

preorganization of molecules to create synthetic materials with controlled supramolecular

architectures. Incorporation of polymerizable groups within a liquid crystalline template

can set the stage for the synthesis of anisotropic molecular networks. This dissertation

details the synthesis and characterization of chiral liquid crystals and crosslinked polymer

networks, with an eye toward applications in asymmetric catalysis.

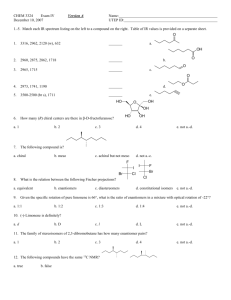

Chapter One gives an introduction to the study of liquid crystals and their phases.

Chapters Two and Three describe the incorporation of terminal olefins as polymerizable

groups within a columnar liquid crystalline template as an effective method for the

synthesis of robust, anisotropic polymeric materials. Upon in situ acyclic diene

metathesis (ADMET) polymerization, the original mesophase order is retained. Chapter

Two involves the room temperature polymerization of iron(III) tris(diketonate) liquid

crystals, resulting in densely crosslinked materials. The focus of Chapter Three is the

polymerization of dioxomolydenum-based liquid crystals, performed at high temperature,

and their potential to serve as catalysts for asymmetric epoxidation. In Chapter Four, a

different approach towards the synthesis of catalytically active anisotropic materials is

taken, incorporating well-established, transition metal catalysts within a liquid crystalline

framework. Progress towards the formation of liquid crystal phases containing C2symmetric bis(oxazoline) and pincer ligands is detailed. Finally, Chapter Five describes

the immobilization of chiral monodentate oxazoline ligands for use as catalysts in

asymmetric cyclopropanation. Preliminary results indicate that the heterogeneous system

gives higher enantioselectivities than the analogous homogeneous system.

Thesis Supervisor: Timothy M. Swager

Title: Professor of Chemistry

4

Table of Contents

Dedication.........

Abstract.........

.................................................................................

...................................................................................

Table of Contents.........

.......................................................................

3

4

5

Table of Figures ..........

7.............................

Chapter 1: An Introduction to Liquid Crystals .........................................................

10

11

1.1

The Liquid Crystal Phase...................................

..

... ................ 12

1.2

Classification of Liquid Crystals

1.3. Metallomesogens ........................................................................................... 17

18

1.4

Chirality in Liquid Crystals .........................................

21

1.5. Characterization of Liquid Crystals .........................................

22

Polarized Microscopy ............................................

1.5.1

....

22

1.5.2

Differential Scanning Calorimetry ........................................

23

1.5.3

X-Ray Diffraction ............................................

....

26

1.6. Outlook on Future Applications ........................................

References .........................................................

27

Chapter 2: In Situ Polymerization of Columnar Liquid Crystals using Acyclic Diene

Metathesis Polymerization: Iron(III) Diketonate Complexes ................................... 29

2.1.

Introduction ...................................................................................................

2.2.

Results and Discussion ..............................................

2.3.

Concluding Remarks ..............................................

Experimental Section.....................................................................................

2.4.

References ................................................................................................................

30

37

47

48

55

Chapter 3: In Situ Polymerization of Columnar Liquid Crystals using Acyclic Diene

Metathesis Polymerization: Dioxomolybdenum

Complexes .....................................

3.1.

Introduction .............................................

3.2.

Results and Discussion .............................................

3.3.

Concluding Remarks .....................................................................................

3.4.

Experimental Section .............................................

References .................................................. ..............................................................

5

59

60

62

68

69

77

Chapter 4: Liquid Crystals containing Catalytic Ligands.......................................... 78

4.1.

Introduction ..........................................

4.2.

Pyridine bis(oxazoline) Ligands..........................................

4.2.1.

Background ..........................................

4.2.2.

Results and Discussion..........................................

4.3.

Pincer Liquid Crystals ..........................................

4.3.1.

Background ..........................................

4.3.2.

Results and Discussion..........................................

4.4.

Concluding Remarks ..........................................

4.5.

Experimental Section..........................................

References ..............................................................................................................

79

80

80

83

89

89

92

93

94

105

Chapter 5: Immobilized Chiral Monodentate Oxazolines: Heterogeneous Catalysis

within an Organic Polymer Network ..........................................

107

5.1.

Introduction .................................................................................................

108

5.2.

Results and Discussion ................................................................................

111

4.3.

Concluding Remarks ........................................

4.4.

Experimental Section.................................

References ..............................................................................................................

119

121

127

Appendix 1: 1H and 13C NMR Spectra for Chapter 2 ......................................

129

Appendix 2: 1H and 13C NMR Spectra for Chapter 3 .....................................

138

Appendix 3: 1H and 13C NMR Spectra for Chapter 4............

Appendix 4: 1 H and

13C

....................... 151

NMR Spectra for Chapter 5 ......................................

167

CurriculumVitae........................................

172

Acknowledgements ..................................................................................

175

6

Table of Figures

Figures

Figure 1.1. Examples of lyotropic liquid crystals ...............................................

12

Figure 1.2. Micellar aggregates and phases formed by lyotropic liquid crystals..

.........

13

Figure 1.3. Examples of calamitic liquid crystals ...............................................

14

Figure 1.4. Some phases formed by calamitic liquid crystals.................................

15

Figure 1.5. Examples of discotic liquid crystals ...............................................

16

Figure 1.6. Phases formed by discotic liquid crystals ..........................................

17

Figure 1.7. Some chiral mesophases formed by calamitic mesogens ........................

19

Figure 1.8. Frustrated chiral phases ...............................................................

20

Figure 1.9. Examples of helical arrangements in columnar phases ...........................

21

Figure 1.10. Low (1)and wide (w) angle maxima for calamities and discotics ............. 23

Figure 1.11. Periodicities within the hexagonal lattice which give rise to low angle

peaks. The lattice constant a corresponds to the distance between neighboring columns,

while the distance d corresponds to planes of columns ........................................

24

Figure 1.12. Order (a) and disorder (b) within a column ......................................

26

Figure 2.1. Schematic representations of in situ crosslinking of an aligned smectic C*

phase and an inverted hexagonal phase ..........................................................

31

Figure 2.2. Acyclic diene metathesis polymerization of terminal olefins ...................

32

Figure 2.3. Grubbs' "first generation" catalyst (a) and "second generation" catalyst (b) for

olefin metathesis ...................................................................

34

Figure 2.4. Iron(III) octahedral complexes ......................................................

35

Figure 2.5. In situ polymerization of columnar hexagonal liquid crystals ..................

36

Figure 2.6. Microphotographs of the columnar hexagonal texture of 6a. Samples were

sandwiched between untreated glass slides and viewed through crossed polarizers ....... 39

7

Figure 2.7. Top: X-ray diffraction profiles of 6a on aluminum plates (a) before

polymerization and (b) after polymerization. Bottom: X-ray diffraction profiles of 6b on

aluminum plates (a) before polymerization and (b) after polymerization ................... 42

Figure 2.8. Circular dichroism of 6a on aluminum plates (a) before polymerization and

(b) after polymerization .................................................................

43

Figure 2.9. Circular dichroism of mixtures of 6b with chiral dopants, lb or lc............ 44

Figure 2.10. Left: X-ray diffraction profiles of 6b with 30% chiral dopant on aluminum

plates (a) before polymerization and (b) after polymerization Right: CD spectra of

crosslinked films of 6 on aluminum plates with (a) 30% chiral dopant and (b) 0% chiral

dopant..........

..............................................

46

Figure 2.11. Guest chromophores for porous networks........................................

47

Figure 3.1. Dioxomolybdenum liquid crystals ..................................

60

Figure 3.2. Tapered columnar phase formed by dioxomolydenum complexes............. 61

Figure 3.3. X-ray diffraction pattern of crosslinked film of 7a ...............................

66

Figure 3.4. Phase behavior of mixtures of 7a with 7b(S) as chiral dopant..................

67

Figure 4.1. C2-symmetric pyridine bis(oxazoline) ligand.........

.............................

80

Figure 4.2. Previously studied chiral oxazoline liquid crystals .........

................. 82

Figure 4.3. Microphotographs of the columnar hexagonal texture of CuDOS(7a).

Samples were sandwiched between untreated glass slides and viewed through crossed

polarizers.........

....................................................................................

Figure 4.4. a-Ketone solvents used as additives for CuDOS(7a) .........

85

................ 86

Figure 4.5. Microphotographs of the columnar hexagonal texture of CuDOS(7a).

Samples were sandwiched between untreated glass slides and viewed through crossed

polarizers ........................................................

87

Figure 4. 6. General structure of pincer ligands..................................................

89

Figure 4.7. Bimetallic pincer catalyst (a) and grafted onto silica support (b) where R =

phenyl,t-butyl........................................................

.........

Figure 4.8. Previously studied pincer liquid crystals ............................................

Figure 5.1. Swelling behavior of polymer films obtained by Route A .....................

8

90

91

115

Schemes

Scheme 2.1. ADMET mechanism ..........................................................

33

Scheme 2.2. Synthesis of iron(III) complexes ...................................................

37

Scheme 3.1. Peroxomolybdenum-catalyzed olefin epoxidation..............................

62

Scheme 3.2. Synthesis of dioxomolydenum complexes .......................................

63

Scheme 3.3. Attempted epoxidation of crotyl alcohol ..........................................

68

Scheme 4.1. Example of bimetallic catalysis observed in system using pybox ligands...81

Scheme 4.2. Synthesis of pyridine bis(oxazoline) ligand ......................................

83

Scheme 4.3. Synthesis of Cu(DOS)(7) ..........................................................

84

Scheme 4.4. Synthesis of Pincer Complexes..................

.................. 92

Scheme 4.5. Addition of 4'-Pentyl-4-biphenyl-carbonitrile to 12 ............................

93

Scheme 5.1. Copper-catalyzed cyclopropanation of styrene with ethyl diazoacetate....109

Scheme 5.2. Immobilization of bis(oxazoline)s ..............................................

110

Scheme 5.3. Synthesis of chiral oxazoline monomer.........................................

111

Scheme 5.4. Preparation of polymeric copper oxazoline catalysts .........................

112

Scheme 5.5. Polymerization of monomer 5 and the potential linkages present in the

resulting polymer network ........................................................................

114

Tables

Table 2.1. Phase Behavior of 6a and 6b.........................................................

38

Table 2.2. X-ray Diffraction Data for 6a and 6b Before and After Crosslinking ........... 41

Table 3.1. Phase Behavior of 7a-b..........................................................

64

Table 3.2. X-ray diffraction data for 7a-b .....................................................

65

Table 5.1. Results of cyclopropanation reactions ...................................

9

117

Chapter

1

An Introduction to Liquid Crystals

1.1

The Liquid Crystal Phase

The phases of matter can be characterized by the degree of molecular order

present within a given phase. Molecules in the solid phase are highly ordered, possessing

both positional order, wherein molecules occupy a specific site in a crystal lattice, and

orientational order, wherein the molecular axes are pointed in a specific direction. On the

other hand, molecules in the liquid phase possess neither positional nor orientational

order, resulting in a highly disordered, fluid phase.

A discrete phase exists in which the molecular order is intermediate between a

three-dimensionally ordered crystalline state and a disordered liquid state. Such phases

are often referred to as mesophases and can be separated into two broad categories:

plastic crystals and liquid crystals. Plastic crystals are formed when molecules in a

crystal phase lose orientational order while retaining positional order, allowing molecules

to freely rotate while remaining in their original position in the crystal lattice. Solid

methane is an example of a plastic crystal. When positional order is lost and orientational

order is retained, a liquid crystal phase is formed. Molecules in a liquid crystal phase

possess the orientational order of a crystal phase, as the molecular axes tend to point

along a preferred direction (called the director n), but also freely diffuse throughout the

sample, retaining the fluidity of a liquid phase.'

As a consequence of the orientational order present, liquid crystals exhibit

anisotropic behavior. That is, measurements having to do with elastic, electric, magnetic,

and optical properties of the material will give different results depending on the

direction along which it is measured.

Examples of such properties are index of

refraction, magnetic susceptibility, and dielectric constant. Contrastly, liquid phases

11

exhibit isotropic behavior, where the lack of molecular order allows such measurements

to be equivalent from any direction. The combined crystal-like anisotropy and liquid-like

fluidity of liquid crystals allows them to be oriented in the presence of electric and

magnetic fields, which is the basis of a large number of practical applications.2

The formation of a mesophase requires a delicate balance between attractive and

dispersive forces between neighboring molecules. While there is no way to definitively

predict whether or not a molecule will exhibit a liquid crystal phase, there are certain

structural and electronic guidelines often followed to ensure that there is sufficient

interaction between neighboring molecules. Such factors include the geometrical shape,

rigidity, polarity, and polarizability of a molecule. In general, a mesogen will possess

some rigid, structural core responsible for the stabilizing, attractive forces, as well as

aliphatic chains that are responsible for introducing dispersive forces.

1.2

Classification of Liquid Crystals

There are two broad classifications for liquid crystalline phases: lyotropics and

thermotropics. Lyotropic liquid crystals3 form anisotropic aggregates when combined

with a solvent, typically water, and the phase behavior is dependent on the concentration

Figure 1.1. Examples of lyotropic liquid crystals. Pictured are (a) sodium stearate or

soap and (b) a phospholipid.

O

C6r0

=

C15H31.o-

C 17H35

Na(D

(a Na®

(

O

0O

C17H35-o)

OO0O~ ,

(b)S~O'N0

(a)

(b)

12

I

and polarity of solvent and temperature. Molecules which form lyotropic phases are

usually amphiphilic, having non-polar, hydrophobic "tails" at one end with a polar,

hydrophilic "head" at the other end. Some examples are sodium stearate (soap) and

phospholipids. (Figure 1.1) The concentration of material in the solvent and the response

of the amphiphile to the solvent environment dictate the type of lyotropic phase formed.

For example, in a polar solvent like water, micelles are formed in which the hydrophobic

tails assemble together and the hydrophilic heads groups are presented to the solvent.

(Figure 1.2a) When combined with a non-polar solvent such as hexane, an inverse

micelle is formed where the hydrophobic tails shield the hydrophilic head groups from

the non-polar environment.

(Figure 1.2b) Under certain conditions, these micelles

Figure 1.2. Micellar aggregates and phases formed by Iyotropic liquid crystals.

jib

a.) micelle

b.) inverse micelle

c. ) lamellar

4?0

I

7'W"IF

4?_16

0""'weir

4?10

"I"saw

d.) hexagonal phase (Hi)

e.) inverse hexagonal phase (H2 )

13

further aggregate to form more complicated assemblies, such as lamellar and hexagonal

phases, which generate lyotropic liquid crystal phases. (Figure 1.2c-e) Lamellar phases

are particularly significant as they form the structural basis for biological membranes.

In thermotropic liquid crystals, the mesophase exists only within a certain

temperature range. When a thermotropic liquid crystal phase is observed upon both

heating and cooling processes, the phases are thermodynamically stable and the behavior

is referred to as enantiotropic. Thermodynamically unstable, kinetically formed phases

that only appear upon cooling and are referred to as monotropic. Molecules which form

thermotropic liquid crystals typically have large shape anisotropy (or high aspect ratio)

and consist of some rigid, aromatic core to provide dipolar attractive forces and pendant

aliphatic sidechains to provide highly dynamic motion and fluidity.

The most common thermotropic liquid crystals are formed by calamitic or rodshaped molecules. Calamitic mesogens4 typically consist of some rigid, elongated,

linearly-linked ring system that provides the shape anisotropy needed to produce

interactions that favor alignment. Usually, a number of alkyl or alkoxy sidechains are

Figure 1.3. Examples of calamitic liquid crystals.

C4H

XG/CN

C5H1

C

CH

C5H N_-CH1

NC

~-oC8H17

O

14

CN

-CN

placed at either or both ends of the mesogen to provide dispersive forces.

Some

examples of calamitic mesogens are shown in Figure 1.3. There are two types of phases

formed by calamities: nematic and smectic (or lamellar) mesophases. The nematic phase

is the simplest and least ordered thermotropic phase, as molecules freely diffuse

throughout the sample but, on average, align their long axes in the same direction.

(Figure 1.4a) Nematics are named for the "thread-like" features when viewed through a

polarizing microscope.

Smectic mesophases show a higher degree of order than

nematics, as the molecules are not only aligned in one direction, but are further organized

into layers. Smectic phases exhibit polymorphism, with each phase differing in the

degree of order present within and between layers. For example, in more fluid smectic

phases, the director n may lie perpendicular to the layer plane as in smectic A phases, or

it may be tilted with respect to the layer plane, as in smectic C phases. (Figure 4b-c)

Higher order smectic phases also exist, wherein molecules have more restricted mobility

and three-dimensional order is present.

Discotics5 are another type of thermotropic liquid crystal. Discotic mesogens

traditionally involve molecules with a flat, rigid, symmetrical, disc-shaped aromatic core

Figure 1.4. Some phases formed by calamitic liquid crystals.

a.) nematic

(N)

b.) smectic A (SA)

15

c .) smectic C (Sc)

surrounded by a periphery of aliphatic chains. Some examples of discotic mesogens are

show in Figure 1.5. Discotics can form either nematic or columnar mesophases. The

discotic nematic phase is analogous to the nematic phase formed by calamitics in that

molecules freely diffuse throughout the sample, yet the short axes of the molecules have

a preferred orientation along a single direction.

(Figure 1.6a) However, the most

commonly found discotic phases are columnar phases, wherein molecules aggregate in

columns that further organize to give different two-dimensional columnar assemblies. In

the nematic columnar phase (Figure 1.6b), columns mimic calamitic mesogens, aligning

the long axes of the columns along the same average direction. Some other examples of

columnar phases include rectangular, hexagonal, and tetragonal phases, based on the

symmetry of the two-dimensional lattice of columns. (Figure 1.6c-e)

In recent years, liquid crystal research has expanded beyond small, purely organic

molecules to include polymers,6 organometallic complexes (further discussed in section

1.5), and hydrogen-bonded supramolecular assemblies.7 Also, there has been an

increasing number of mesogens reported having molecular shapes that do not adhere to

Figure 1.5. Examples of discotic liquid crystals.

C7 H, 5

C 7H 1 5

H15

H1 5

16

Figure 1.6. Phases formed by discotic liquid crystals.

w

A

4EW- 4

4 40 4p4

A

n

4

1

a.) nematic

c.) rectangular

b.) nematic columnar

d.) hexagonal

e.) tetragonal

the classic calamitic or discotic model. Some of these structural motifs include cyclic

compounds and cyclophanes, swallow-tailed compounds, calamitic-discotic dimers,

epitaxygens, bowlic compounds, dendrimers, and bent-core liquid crystals.8 Many new

classes of liquid crystals have been created, each revealing new insights into ways in

which mesogens can interact and aggregate to support a liquid crystal phase.

1.3.

Metallomesogens

Metallomesogens, or metal-containing liquid crystals, combine the properties of

liquid crystals (fluidity, anisotropy) with those of metal atoms (magnetic, electrical,

optical, electro-optical properties).9 The metal centers can serve to induce, modify, or

enhance the liquid crystalline behavior of the free organic ligand. Metallomesogens that

17

mimic calamitics and discotics in shape anisotropy and phase behavior have been

described, as well as ones that largely deviate from the classic rod-shaped and diskshaped prototypes. The diverse array of coordination geometries and polydentate ligands

available has allowed researchers to study new types of molecular organization

previously inaccessible with purely organic mesogens. Additionally, metallomesogens

provide a reliable method for the ordered aggregation of metal centers coupled with the

long range orientation and ease of alignment in the mesophase, making them attractive

candidates for technologically useful materials.

1.4

Chirality in Liquid Crystals

When a liquid crystal phase contains molecules having one or more stereogenic

centers, the molecular chirality is translated to chirality of the macroscopic mesophase,

forming a helical, chiral assembly.

The pitch of the formed helix is temperature

dependent, and the handedness of the helical structure will depend on the stereogenic

center present, as one enantiomer generates a left-handed helix and the other enantiomer

generates a right-handed helix. Introduction of chirality into a mesophase results in a

reduction in the symmetry when compared to analogous achiral phases. In general, chiral

mesophases have reduced phase stability and lower clearing points (temperature at which

the transition from mesophase to isotropic phase occurs), often due to the steric effects

caused by the chiral center.

Chiral phases are most often formed by thermotropic liquid crystals. A chiral

mesophase can be formed in two ways. First, the phase can be composed of only chiral

molecules. That is, the mesogen itself has one or more stereogenic centers, found either

18

along the terminal chain of the mesogen or in the central core. Most often, the chiral

center is found in the terminal chain of the molecule due to relative ease of synthesis and

the number of commercially available, chiral alkyl chains. Second, a chiral dopant can

be added to an otherwise achiral phase. Although the chiral dopant need not be liquid

crystalline itself, ideally it will have a mesogenic-like structure, preferably similar to the

host phase in order to preserve the properties of the original mesophase.

Chiral mesophases formed by rod-shaped mesogens are analogous to their achiral,

calamitic counterparts. (Figure 1.7) The chiral nematic (or cholesteric) phase is much

like the achiral nematic phase, except that the presence of the chiral unit causes a gradual

rotation of the director n in the form of a helix along the long molecular axis. Helical

structures are also formed by several chiral smectic phases, but the most commonly found

phase is the chiral smectic C phase (Sc*).l° As in the achiral Sc phase, molecules within a

given layer are tilted with respect to the layer plane, yet, in the Sc* phase, there is a

gradual change in tilt direction from layer to layer in the form of a helix. The reduction

in phase symmetry causes a spontaneous polarization of molecules within each layer, but

Figure 1.7. Some chiral mesophases formed by calamitic mesogens.

)"""I\\

)

I,,,,

a.) chiral nematic (N*)

b.) smectic C* (Sc*)

19

due to the helical arrangement of the layers, the polarization direction is rotated from

layer to layer and the bulk polarization of the material is zero.

Frustrated chiral phases are formed when competition between different structural

features of the mesogens prevents a continuous phase from forming, giving rise to a

periodic array of defects. Blue phases form when molecules adopt double twist helices

which pack in a cubic manner. (Figure 1.8a) Twist grain boundary phases also exist,

where blocks of smectic phases (smectic A for TGBA*, smectic C for TGBC*) are

arranged in a helical fashion, broken by screw dislocations which abruptly twist the

director of the next block. (Figure 1.8b) Frustrated phases such as these exist only in

very narrow temperature ranges.

Discotic molecules also form chiral phases. Analogous to the structure of the

Figure 1.8. Frustrated chiral phases.

a.) blue phase

screw dislocation

where blocks of

smectic A meet

bloceks of smectic A

4

zI

zI

=1

b.) twist grain boundary phase

20

calamitic chiral nematic phase, the chiral discotic nematic phase has a gradual rotation of

the molecular director in the form of a helix. However, there are only a few examples of

the chiral discotic nematic, as chiral columnar phases are more commonly found. The

chirality of a columnar phase can be defined by the chirality within a given column and

within the lattice of columns. In either case, the loss of mirror symmetry can arise from a

helical twist in the molecular director (Figure 1.9a), a spiraling of molecular position

(Figure 1.9b), or the introduction of tilt and polarization in the molecules, analogous to

the smectic C* phase (Figure 1.9c).

Figure 1.9. Examples of chirality in columnar phases.

(a)

1.5.

(b)

(c)

Characterization of Liquid Crystals

Liquid crystal phases are typically characterized using three techniques: polarized

microscopy, differential scanning calorimetry, and X-ray diffraction. Other techniques

include miscibility studies with materials with known mesophases, neutron scattering

studies (usually of partially deuterated systems), and NMR studies (useful for studying

lyotropic systems), but will not be discussed here.

21

1.5.1

Polarized Microscopy

When an isotropic liquid is placed between polarizers crossed at 90° to each other,

the polarized light is unaffected by the sample and no light passes through the second

polarizer. However, when an anisotropic, birefringent medium such as a liquid crystal is

present, light interacts with the medium and a complex pattern or texture is observed.

Analysis of the defects and deformations in the texture can give information relating to

the molecular arrangement of the mesophase.1 ' 12 Typically, a thin sample of material is

sandwiched between a glass microscope slide and a glass cover slip and placed on a

temperature-controlled heating stage between two polarizers, and the mesophase behavior

is observed upon several cycles of heating and cooling.

Nematics normally give rise to schlieren textures, identified by black bands or

"brushes" that meet at point singularities or disclinations. Smectics can give a variety of

textures including focal conic fans, mosaic, schlieren, and homeotropic. Fan textures,

linear birefringent defects, and large areas of uniform extinction are common for

columnar hexagonal phases, while rectangular phases typically show wedge-shaped

domains.

1.5.2

Differential Scanning Calorimetry

Differential scanning calorimetry (DSC) detects the presence of a liquid crystal

phase by measuring the enthalpy change associated with a phase transition. A DSC

instrument measures the energy absorbed or released by a sample as it is heated or

cooled, indicating at which temperatures endothermic melting processes and exothermic

crystallization processes occur. The magnitude of the enthalpy change is proportional to

22

the change in structural ordering. As such, solid to liquid phase transitions are relatively

drastic in terms of structural change, as reflected by high enthalpy values. Liquid crystal

to liquid crystal and liquid crystal to liquid phase transitions are subtle, as evidenced by

the relatively small enthalpy changes. DSC alone cannot identify the exact nature of the

phase present, but can indicate the degree of molecular order within the phase 3 and

should be used in combination with other methods like optical microscopy and X-ray

diffraction.

1.5.3

X-Ray Diffraction

X-ray diffraction (XRD) is the technique most often used for unambiguous

characterization of liquid crystal phases. Reflected X-rays can be carried out on either a

"powder" sample, consisting of polydomains with random director orientation, or aligned

samples, usually obtained by application of an electric or magnetic field or mechanical

shearing of the viscous mesophase.

Only "powder" or unaligned samples will be

discussed in the following text.

Figure 1.10. Low (I) and wide (w) angle maxima for a.) calamities and b.) discotics.

ik

A

I

I

4

I

n

11111 III

I~lr

M

W

W

a.) calamities

b.) discotics

23

Low angle maxima correspond to long distances between molecules (tens of

Angstroms) while wide angle maxima correspond to short distances (between 3-6

Angstroms). Periodic distances d are calculated from these maxima using Bragg's law:

nX = 2dsin 0

For calamitics, low angle maxima are measured along the director, and d roughly

corresponds to molecular length (or interlayer spacing). (Figure 1.10a) Wide angle

maxima, on the other hand, are measured perpendicular to director, and correspond to

roughly the molecular width. For nematic phases, low angle maxima are diffuse since

there is no periodic structure and positional order is short range. Wide angle maxima are

also broad since the phase is liquid-like in the direction perpendicular to the director. In

smectics, sharp low angle peaks (Bragg peaks) are observed in the scattered intensity due

to periodic arrangement of layers. Wide angle maxima are diffuse for smectic A and C,

where molecular packing perpendicular to the director is liquid-like, whereas they are

Figure 1.11. Periodicities within the hexagonal lattice which give rise to low angle

peaks. The lattice constant a corresponds to the distance between neighboring

columns, while the distance d corresponds to planes of columns.

(1

(100)

24

sharp for smectics other than A and C, in which there is two-dimensional order within the

layer.

For discotics, low angle maxima are measured perpendicular to the director and d

roughly corresponds to the molecular diameter, while wide angle maxima are measured

along the director and correspond to molecular thickness. (Figure 1.10b) In columnar

phases, Bragg peaks are observed in the scattered intensity due to periodic arrangement

of columns. The spacing ratio of the low angle maxima reflects the type of columnar

packing present.

Hexagonal phases, for example, show spacing with ratios of 1: 3: N4 for the

(100): (110): (200) reflections. (Figure 1.11) Typically, a hexagonal phase has a strong,

sharp (100) peak and two weak peaks related to the (110) and (200) reflections, as well as

a broad peak around 4.5 angstroms due to the diffuse scattering from the flexible, alkyl

side changes. While the (100) peak is always observed, the (110) and (200) peaks may

not be present if the columnar lattice is sufficiently disordered. Rectangular phases

typically have two sharp, low angle peaks relating to the (100) and (200) reflections, and,

like the hexagonal phase, a broad halo at 4.5 angstroms. Additional mid-angle peaks are

needed to determine which type of rectangular symmetry is present.

The lattice constant a, which corresponds to the separation between nearest

neighboring columns, is calculated based on the symmetry of the two-dimensional lattice

of columns. The lattice constant for hexagonal phases, for example, can be calculated

from the distance d, which corresponds to the separation between planes of columns,

using the equation, a = d/cos30 ° = d213, where d is calculated from the (100) peak using

Bragg's law.

25

Finally, columnar phases can be ordered or disordered with respect to molecules

within a given column, depending on the length scale of molecular correlations within the

columns. (Figure 1.12) Ordered columnar phases will exhibit an additional broad peak at

3.3-3.6 A corresponding to the distance between neighboring cores within the individual

column caused by dense packing of molecules within the columns.

Figure 1.12. Order (a) and disorder (b) within a column.

b

4

(b)

(a)

1.6. Outlook on Future Applications

Until now, the hallmark application for liquid crystals has been restricted to the

field of displays, in large part since, historically, the majority of known liquid crystal

phases involved solely calamitic mesogens, which can be aligned in the presence of an

electric or magnetic field. It was in the 1970s that discotic mesogens and their phases

began to receive considerable attention, introducing more diverse modes of molecular

organization and providing new direction towards a wide range of potential technological

applications. In particular, columnar phases have been suggested to be useful as sensors,

charge transport materials, and other conducting materials. With an array of chiral

mesomorphic assemblies at our disposal, this thesis investigates the prospect of utilizing

chiral columnar liquid crystals and polymers as asymmetric heterogeneous catalysts,

26

exploring the influence that supramolecular chirality may have on the stereochemical

outcome of a chemical reaction. Such materials would have a tremendous impact on the

fields of liquid crystals, polymers, and catalysis.

References

1

Collings, P.J. and Hird, M.

Introduction to Liquid Crystals: Chemistry and Physics

Taylor and Francis: Philadelphia, 1997; pp 1-16.

2

Collings, P. J. Liquid Crystals: Nature's Delicate Phase of Matter; Princeton University

Press: Princeton, 1990; pp 35-55.

3

Collings, P.J. and Hird, M.

Introduction to Liquid Crystals: Chemistry and Physics

;

Taylor and Francis: Philadelphia, 1997; pp 133-146.

4

Collings, P.J. and Hird, M.

Introduction to Liquid Crystals: Chemistry and Physics

;

Taylor and Francis: Philadelphia, 1997; pp 43-77.

5 Collings, P.J. and Hird, M.

Introduction to Liquid Crystals: Chemistry and Physics

;

Taylor and Francis: Philadelphia, 1997; pp 79-110.

6

Collings, P.J. and Hird, M.

Introduction to Liquid Crystals: Chemistry and Physics

;

Taylor and Francis: Philadelphia, 1997; pp 93-110.

7

Some recent examples include: (a) Lee, K.-M.; Lee, Y.-T.; Lin, I. J. B.; J. Mater. Chem.

2003, 13(5), 1079. (b) Song, X.; Li, J.; Zhang, S.; Liq. Cryst. 2003, 30(3), 331. (c) Li, M.;

Guo, C.; Wu, Y.; Liq. Cryst. 2002, 29(8), 1031. (d) Chen, D.; Wan, L.; Fang, J.; Yu, X.;

Chem. Lett. 2001, 11, 1156. (d) Lee, H.-K.; Lee, K.; Ko, Y. H.; Chang, Y. J.; Oh, N.-K.;

Zin, W.-C.; Kim, K.; Angew. Chem., Int. Ed. 2001, 40, 2669.

27

8Demus, D. In Handbook of Liquid Crystals; Demus, D., Goodby, J., Gray, G.W., Spiess,

H.-W., Vill, V. Eds.; Wiley-VCH: Weinheim, 1998; Vol 1, pp 153-176.

9 For reviews of metallomesogens,

please see: (a)

Metallomesogens: Synthesis,

Properties, and Applications; Serrano, J. L., Ed.; VCH: New York, 1996. (b) Donnio, B.;

Bruce, D. W.; Liquid Crystals II, Vol. 95: Berlin, 1999; pp 193-247. (c) Hudson, S. A.;

Maitlis, P. M.; Chem. Rev. 1993, 93, 861. (d) Espinet, P.; Esteruelas, M. A.; Oro, L. A.;

Serrano, J. L.; Sola, E.; Coord. Chem. Rev. 1992, 117, 215. (e) Inorganic Materials, 2nd

ed.; Bruce, D. W., O'Hare, D., Ed.; John Wiley & Sons: New York, 1992. (f) GiroudGodquin, A. M.; Maitlis, P. M.; Angew. Chem., Int. Ed. Engl. 1991, 30, 375.

l0Gray, G.W. and Goodby, J.W.G.

Smectic Liquid Crystals: Textures and Structures

Leonard Hill: Glasgow and London, 1984; pp 61-64.

" Demus, D.; Richter, L. Textures of Liquid Crystals; Verlag Chemie, Weinheim, 1978.

12

Gray, G.W.; Goodby, J.W. Smectic Liquid Crystals: Textures and Structures ; Leonard

Hill, Glasgow, 1984.

13

Collings, P.J. and Hird, M. Introduction to Liquid Crystals: Chemistry and Physics

Taylor and Francis: Philadelphia, 1997; pp. 1 9 1 - 1 9 3 .

28

Chapter 2

In Situ Polymerization of Columnar Liquid Crystals using Acyclic

Diene Metathesis Polymerization: Iron(III) Diketonate Complexes

Adapted from:

Villazor, K. R.; Swager, T. M. Mol. Cryst. Liq. Cryst. 2004, 410, 775-781

2.1.

Introduction

Mesomorphic organizations represent the most powerful and efficient method for

the preorganization of molecules to create nanometer-scale ordered synthetic systems.' 2

The incorporation of polymerizable groups within liquid crystals is effective for the

synthesis of anisotropic molecular networks by in situ polymerization, wherein reactive

monomers are crosslinked in an ordered mesomorphic state with retention of molecular

order. The use of such polymerizable liquid crystals as self-assembling building blocks

provides a versatile method for processing anisotropic polymeric films with control over

both the order and symmetry of the material. Using the appropriate liquid crystal phase

as a template, "designer" organic materials can be tailored to suit a specific function. For

example, aligned smectic C* phases have been crosslinked in order to make

noncentrosymmetric polymer networks, either using a chiral polymerizable mesogen3 or

mixtures containing achiral polymerizable mesogens and chiral dopants.4 (Figure 2.la)

Such materials have been found to exhibit pyroelectric, piezoelectric, and nonlinear

optical properties.3 g' 4Also,

lyotropic liquid crystals exhibiting inverse hexagonal phases

have been crosslinked to produce nanoporous structures with hexagonally ordered,

hydrophilic pores.2 (Figure 2. lb) Gin and co-workers have applied such materials as

heterogeneous Lewis acid5 and Br0nsted acid6 catalysts, as well as molecular filters.2a

In the crosslinking of liquid crystal phases, the polymerizable group should

undergo rapid and efficient crosslinking with minimal perturbation of the liquid crystal

phase. Ideally, the reactive group should be synthetically accessible and stable to a wide

range of reaction conditions. Photopolymerization of acrylate-containing mesogens has

been the most common method of crosslinking with retention of the original mesophase.7

30

Figure 2.1. Schematic representations of in situ crosslinking of (a) an aligned

smectic C* phase where p = direction of polarization, and (b) an inverted

hexagonal phase.

a.)

%P

P

%%%%

cross-linked network with

bulk C2 symmetry

aligned smectic

phase

b.)

crosslink

C

>

cross-linked network with

hydrophilic pores

inverse hexagonal

phase

Typically, a photoinitiator and thermal inhibitor are added to decouple the polymerization

event from temperature, allowing for the ordering of the mesophase prior to irradiation.

While an efficient and reliable method for polymerization, the use of acrylate groups

presents certain drawbacks as well. A highly reactive functional group, acrylates are

typically introduced at the final step of a given synthesis, a limitation that can be

problematic for mesogens with more complex syntheses. Furthermore, introduction of

the polar and sterically bulky acrylate groups often precludes formation of the

mesophase.8 The addition of the branched functionality and intermolecular dipolar

interactions effectively destabilizes the mesophase, preventing the side chains from

31

efficiently filling space in the liquid crystal phase when compared to mesogens

containing only aliphatic side chains.

In order to circumvent this problem, Gin and co-workers have had success

employing 1,3-dienes, 9 and to a lesser degree, styrene 'Oand isoprene " groups, within the

sides chains of lyotropic monomers. Photopolymerization of the terminal dienes in an

inverted hexagonal phase proceeded with little perturbation to the liquid crystalline

order.9 However, while eliminating the steric bulk and polarity found in acrylate groups,

the syntheses of 1,3-diene-containing monomers still require several additional steps to

incorporate the polymerizable functional groups within the mesogen.

Acyclic Diene Metathesis Polymerization

Acyclic diene metathesis polymerization 1 2 (ADMET) is a step-growth

polycondensation reaction in which the production and expulsion of ethylene gas drives

the polymerization. An application of olefin metathesis, ADMET has proven to be a

powerful synthetic route to high molecular weight unsaturated polymers through the

polymerization of terminal olefins.'3 (Figure 2.2) The general mechanism involves two

metallocyclobutane intermediates in the reaction cycle, as show in Scheme 2.1, and the

Figure 2.2. Acyclic diene metathesis polymerization of terminal olefins.

ADMET

- C2H 4

32

Scheme 2.1. Mechanism of ADMET polymerization.

R'

VR

iIW===Nft=

\I

L,==

LnM=\

R'

L'M

R 1%_

0.

1

LnM=\

R

L-MRl

R

R 11

LM= A

R

active metal species is released from the polymer chain during each propagation step.

Similar to catalysts for ring-opening metathesis polymerization (ROMP), catalysts

for ADMET include ruthenium-based Grubbs-type carbenes, as well as tungsten-based

and molybdenum-based Schrock-type alkylidenes, pictured in Figure 2.3. Resembling

the general reaction conditions of other polycondensation reactions, ADMET is often

carried out in neat monomer to maximize monomer concentration and drive the reaction

towards polymer formation. Additionally, the reaction is carried out under reduced

pressure to remove the generated ethylene, again to shift the equilibrium irreversibly

towards polymer formation and to accelerate monomer conversion.

33

Figure 2.3. Grubbs' "first generation" catalyst (a), "second generation" catalyst (b),

and Shrock's molybdenum alkylidene (c) for olefin metathesis.

LDr

Er

Ci.

CI

r

0I

1-rI

II

PCy 3

I

H3 C(F3 C)2 C -O-Mo%

(CH3)2

:

I

Ph

PCy3

(a)

I

N

P

h

C(CF3)2CH3

(b)

(c)

To date, there have been no examples of the utilization of ADMET for the in situ

crosslinking of liquid crystal phases with retention of mesophase order. However, there

are limited examples of the use of ADMET in the polymerization of liquid crystals to

make main-chain liquid crystalline oligomers and polymers. 4 In ease case, terminal

olefins were easily incorporated into the side chains of the mesogen using commercially

available bromoalkenes. Herein we describe the incorporation of terminal olefins within

a metal-containing liquid crystalline monomer and the use of ADMET polymerization to

crosslink with retention of the original mesophase order. This approach is particularly

attractive since the olefin crosslinking groups more closely resemble typical alkyl side

chains of the mesogens in size, hydrophobicity, and thermal stability, yet are reactive

towards olefin metathesis. Another advantage of this method is that terminal olefins do

not require additional synthetic steps as bromoalkenes of various chain lengths are

commercially available.

Iron(III) Diketonate Complexes

Previous work in the Swager group focused on octahedral iron(III) diketonate

complex 1.15(Figure 2.4) In the liquid crystal phase, these low aspect ratio complexes

34

Figure 2.4. Iron(III) octahedral complexes.

la

R = (CH2)nH, n = 6, 12, 15, 18

lb R==

1c R=

I

align in columnar arrangements with hexagonal and rectangular packing of columns.

When the side chains are chiral (lb-c),'

6

the complexes resolve into single optical

isomers and segregate into microdomains of net chirality.' 7 This allows for

interdigitation of the aromatic rings of nearest neighbors within a column and the most

efficient packing arrangement.

In the isotropic phase, 1 is fluxional, rapidly

interconverting between optical isomers (A and A). However, in the case of lb-c,

examination of the circular dichroism (CD) spectra as a function of temperature shows

that the chiral sidechains provide enough perturbation in the mesophase to favor one

optical isomer and to effectively induce helicity within a given column. No CD signal

was observed for complexes with achiral sidechains.

Using polymerizable analogues of these iron(III) tris(diketonate) complexes, we

have developed a method to create robust, polymeric materials from columnar liquid

crystals. As demonstrated by Gin and co-workers, columnar phases can act as templates

for ordered, porous materials having a variety of potential functions such as ion transport,

35

molecular filtration, and catalysis. By employing ADMET as a means of crosslinking,

we have prepared anisotropic materials using polymerizable columnar hexagonal liquid

crystals with the retention of the original mesophase. (Figure 2.5)

We have also

employed chiral columnar hexagonal phases to synthesize materials having bulk chirality,

potentially for use in asymmetric catalysis and chiral separation technologies.

Figure 2.5. In situ polymerization of columnar hexagonal liquid crystals.

MEUU*

36

2.2. Results and Discussion

The liquid crystalline monomers were synthesized following similar procedures

as complex 1.14 (Scheme 2.2.)

Compound 2 was synthesized via a Williamson

etherification of ethyl 3,4-dihydroxybenzoate and the appropriate alkyl bromide.

Subsequent hydrolysis of the ethyl benzoate to carboxylic acid salt 3 followed by

treatment with >2.0 equivalents of CH3Li gave the methyl ketone 4. C-acylation of 4

with the appropriate ethyl benzoate using NaH in anhydrous THF gave the -diketone 5.

The iron tris([-diketonate) complexes were synthesized from reaction of the appropriate

ligand with Fe(acac)3.

Scheme 2.2. Synthesis of iron(III) complexes.

O

0

0

ii

j

OEt

·

OH

HO

RO

RO

OH

ii

%e%~

OEt

i,

-O

OR

OR

2a,b

3a,b

F,,e

O

O

OH

v

iv

RO

RO

[

OR

4a,b

OR'

OR

RO

OR'

R

5a,b

OR'

OR'

OR

6a,b

2a,3a,4a: R=

5a, 6a: R=m

2b,3b,4b: R = (CH )92

R' = (CH2)9

5b, 6b: R = R' = (CH 29) "

(i) RBr, K 2CO3, KI, 2-butanone, 90-100%; (ii) KOH, EtOH/H 20, 97-99%; (iii) CH 3 Li, THF, 0°C,

90%; (iv) 2a or 2b, NaH, THF, 68-72%; (v) Fe(acac) 3, benzene, 50-55%.

37

The phase behavior is summarized in Table 1. Complexes 6a and 6b exhibit

enantiotropic columnar hexagonal (Colh) mesophases as identified by polarized

microscopy and X-ray diffraction.

When viewed by polarized microscopy, these

compounds exhibited linear birefringent defects and large areas of uniform extinction,

characteristic of columnar phases. (Figure 2.6) The Colh phases were characterized by

the observation of sharp (100) peaks in the low angle region of X-ray diffraction patterns.

The wide-angle regions all display broad halos at approximately 4.5 A, which correspond

to the distance between liquid-like sidechains, confirming that the phases are indeed

liquid crystalline as opposed to crystal or plastic phases.

Table 2.1. Phase Behavior of 6a and 6b. The phase behavior for complexes lb-c

has been previously reported [ref 16] and is included here for clarity. The

transition temperatures and the enthalpies (in parentheses) are given in *C and

kcal/mol, respectively, and were determined by differential scanning calorimetry

(10 *C / min).

Phase Behavior

lb

Colh

81.0 (2.1)

_

I

-

73.8 (-2.1)

lc

Colh

83.8 (2.4)

I

_-

76.5 (-2.4)

6a

Colh

62.4(1.1)

I

54.0 (-1.1)

6b

Colh

_

68.8 (7.5)

I

-

61.0 (-7.6)

38

Figure 2.6. Microphotographs of the columnar hexagonal texture of 6a. Samples

were sandwiched between untreated glass slides and viewed through crossed

polarizers.

39

For the in situ crosslinking of polymerizable mesogens 6a and 6b, Grubbs'

"second-generation" catalyst (Figure 2.3b) was chosen for its stability over a wide range

of temperatures and high degree of tolerance for a wide variety of functional groups.12

Also, an induction period has been observed for the second-generation catalyst, making it

relatively slow at the initial stage of the reaction, attributed to the slower rate of

phosphine dissociation. g This induction period is particularly attractive for crosslinking

liquid crystals, as it allows the mesophase to form before polymerization occurs.

Crosslinking can be performed at any given temperature within range of the mesophase.

For this particular system, the mesophase is conveniently accessible at ambient

temperature.

Polymerization studies were carried out on thin films of the appropriate

mesogenic monomer and catalyst at room temperature. Film preparation was performed

in a glove box under nitrogen atmosphere. Hexane solutions of 6a or 6b containing 1.0

mol % catalyst were drop cast on aluminum plates for X-ray diffraction measurements

and spin cast onto a quartz plates for circular dichroism measurements.9 The films were

then annealed to 90 oC to order the mesophase and cooled to room temperature. The

annealed films were then placed under vacuum at room temperature for 24 hours to drive

the polymerization, resulting in heavily crosslinked free-standing films which were rinsed

with hexanes to remove any un-crosslinked material.

Table 2.2 lists the XRD lattice constants of the hexagonal phases for 6a and 6b,

before and after cross-linking, and the XRD patterns are pictured in Figure 2.7. The

XRD patterns of the polymerized films show slightly reduced peak intensities but closely

resemble the XRD patterns for the unpolymerized films, indicating that the columnar

hexagonal organization remains intact upon crosslinking. Also, circular dichroism (CD)

40

confirms that the post-polymerization film of 6a retains its chiral structure (Figure 2.8).

The achiral complex 6b showed no CD signal, verifying that the CD signal for 6a was

not a result of the chiral ruthenium catalyst, but from the bulk chirality of the mesophase.

Table 2.2. X-ray Diffraction Data for 6a and 6b Before and After Crosslinking.

Lattice

o

Constant (A)

6a (Before crosslinking)

26.9

Spacing

observed ()

23.3

13.5

4.49

6a (After crosslinking

and extraction)

6b (Before crosslinking)

6b (After crosslinking

26.1

13.4

4.45

28;3

2813

and extraction)

6b + chiral dopant (30 mol %)

29.4

(Before crosslinking)

6b + chiral dopant (30 mol %)

22.6

27.8

(After crosslinking and

extraction)

41

Miller

indices

(100)

(110)

halo

(100)

(110)

halo

24.5

4.18

(100)

24.5

4.29

(100)

25.5

4.44

(100)

24.1

4.39

(100)

halo

halo

halo

halo

Figure 2.7. Top: X-ray diffraction profiles of 6a on aluminum plates (a) before

polymerization and (b) after polymerization. Bottom: X-ray diffraction profiles of

6b on aluminum plates (a) before polymerization and (b) after polymerization.

, a nS5

L.

IV

5

2 10

1.5 105

1105

5 104

0

4

8

12

16

20

24

28

2 theta

o

0

n4

UIV

4

7 10

6 104

4

5 10

0

4 104

3 104

2 104

1 104

0

8

12

16

2 theta

42

20

24

28

In an attempt to introduce porosity into the materials, the achiral complex 6b was

combined with varying amounts of lb or lc as a chiral dopant. It is well known that

small chiral perturbations in liquid crystalline phases, often in the form of a chiral dopant,

can induce a strong, cooperative chiral response in the mesophase.20 Here we attempt to

synthesize chiral porous materials by using a chiral dopant to form a chiral hexagonal

phase with 6b, then extracting the dopant upon crosslinking.

Figure 2.8. Circular dichroism of 6a on aluminum plates (a) before polymerization and

(b) after polymerization.

10

i 5

0

-5

-10

300

350

400

450

500

550

Wavelength(nm)

43

600

650

700

Figure 2.9. Circular dichroism of mixtures of 6b with chiral dopants, (a) lb or (b)

Ic.

10

5

9

.3

0

'0

.R

.

-5

-10

350

400

450

500

550

600

650

700 350

400

450

500

550

600

650

700

Wavelength (nm)

12

E

10

0%

00

Cn

8

8

9

t

cu

~--

10% dopant

11

ae

0

.0

0%dopant

6

4

(,' Oclopatll

0

2

0

0

20

40

60

80

Mole % chiral dopant

44

-

50%dopant

----

70%dopant

100

90%dopant

Before crosslinking, the CD spectra of thin films of mixtures of 6b with chiral

dopant were measured and a non-linear dependence on the concentration of dopant was

observed, suggesting cooperative chiral induction in the mesophase.

(Figure 2.9)

Interestingly, addition of chiral (S)-3,7-dimethyloctyl bromide as a chiral dopant does not

induce chirality in the mesophase, indicating the importance of a covalent linkage

between the mesogenic core and the chiral alkyl chain.

The mixtures of achiral 6b and chiral dopant (lb or c) were crosslinked as

described above and rinsed with hexanes to wash away the chiral dopant. XRD profiles

show that the peak intensity is slightly diminished upon crosslinking, yet the hexagonal

phase is retained. Table 2.2 lists representative XRD spacing of the un-crosslinked and

crosslinked hexagonal phases of chirally-doped 6b, and the XRD patterns are pictured in

Figure 2.10. Circular dichroism confirmed the chirality of the doped polymerized

networks in contrast to the lack of chirality in the undoped network. (Figure 2.10)

Attempts were made to determine the extent to which the chiral dopants were

successfully extracted from the crosslinked films. UV measurements of crosslinked films

before and after hexane extraction of the chiral dopant were made, but the observed

decrease in optical density did not correspond to the amount of chiral dopant that was

presumed to be extracted. Also, attempts were made to incorporate a guest chromophore

within the crosslinked films following extraction of the chiral dopant. To maximize film

porosity, mixtures containing 70% chiral dopant or higher were crosslinked as previously

described and rinsed with hexanes to remove the dopant. The films were immersed in

solutions containing either chromophore 7 or 8 to allow the guest chromophore to diffuse

into the porous networks.

The chromophores are relatively small molecules with

potential ability to diffuse within the pores of the crosslinked film. The hope was that the

45

addition of these chromophores within the crosslinked films would be observable in the

UV spectrum and, ideally, would give rise to a new CD signal if the chromophores were

affected by the bulk chirality of the films. However, upon examination of the UV and

CD spectra, no change was observed to denote the inclusion of the chromophores within

the networks. These results were attributed to the densely crosslinked nature of the films,

wherein each monomer bears at least six polymerizable groups in three-dimensions,

making it difficult to extract any guest molecules trapped within the crosslinked network.

Figure 2.10. Left: X-ray diffraction profiles of 6b with 30% chiral dopant on

aluminum plates (a) before polymerization and (b) after polymerization Right: CD

spectra of crosslinked films of 6b on aluminum plates with (a) 30% chiral dopant

and (b) 0% chiral dopant.

610-

on

10

5 104

4

4 10

0

.

1 3104

-10

2 104

M-20

1 104

-30

-40

300

0

4

8

12

16

20

24

28

2 theta

350

400

450

500

550

Wavelength(m)

46

600

650

700

Figure 2.11. Guest chromophores for porous networks.

,N

7

/~NSO

2F

8

2.5. Concluding Remarks

In summary, we have demonstrated that the use of ADMET polymerization is a

viable and attractive route towards the synthesis of supramolecular polymeric materials.

Incorporation of terminal olefins within the side chains of mesogenic monomers is

synthetically straightforward using commercially available bromoalkenes. The addition

of the olefin groups within iron(III) tris(diketonate) complexes does not impede

mesophase formation, and the liquid crystalline monomers exhibit columnar hexagonal

phases over a wide temperature range.

Upon in situ crosslinking using ADMET

polymerization, retention of the original liquid crystal phase order is achieved. This

method has been used to synthesize both achiral and chiral polymer networks. Attempts

to synthesize porous networks were unsuccessful due to the densely crosslinked nature of

the films.

47

Experimental Section

General Methods. Tetrahydrofuran was dried by passing through activated alumina

columns. (S)-(+)-Citronellyl bromide and (R)-(+)-citronellyl bromide were purchased

from Aldrich (>99% purity) and hydrogenated to give (S)-3,7-dimethyloctyl bromide and

(R)-3,7-dimethyloctyl bromide, respectively, using literature procedure.21 All other

chemicals were of reagent grade and were used as received, unless otherwise specified.

The dialkoxy ethyl benzoate derivatives acetophenone derivatives,22 as well as complexes

lb and c, were synthesized using modified literature procedures. 'H and ' 3C NMR

spectra were obtained on Varian Inova-500 spectrometers.

All chemical shifts are

referenced to residual CHC13 (7.27 ppm for H, 77.23 ppm for 13C). Multiplicities are

indicated as s (singlet), d (doublet), t (triplet), and m (multiplet). DSC investigations were

carried out on a Perkin Elmer DSC-7. Optical microscopy was performed on a Leica

polarizing microscope in combination with a Mettler FP 80HT/FB 82HT hot stage. Spin

cast films were made on quartz plates using a Laurell Spin Processor WS-400-6NPPLITE at 500 rpm. X-ray diffraction studies were carried out on unoriented samples on

aluminum plates with an INEL diffractometer with a 2kW Cu K-a X-ray source fitted

with an INEL CPS-120 positive-sensitive detector. The detector was calibrated using a

silver behenate standard which was produced by Eastman Kodak and supplied by The

Gem Dugout.

3,4-Di-[(S)-3,7-dimethyloctyloxy]-benzoic acid ethyl ester (2a). (S)-3,7-dimethyloctyl

bromide (17.6 g, 95.7 mmol) and K2CO3 (19.7 g, 198 mmol) were added to a 2-butanone

solution (135 mL) of 3,4-dihydroxybenzoic acid ethyl ester (5.28 g, 38.1 mmol)

containing a catalytic amount of potassium iodide. The mixture was heated to reflux at

48

80°C under an argon atmosphere for three days. The excess salts were removed by

filtration, and the filtrate was washed successively with 0.5M NaOH (aq), water, and

brine, and extracted with dichloromethane. The organic fraction was dried over MgSO4

and the solvents were removed by rotary evaporation to give a yellow-tinted oil. Excess

alkyl bromide was removed by vacuum distillation, and the remaining residue was further

purified by filtering through a plug of silica gel (1% ethyl acetate/hexane) to afford the

product (13.4 g, 100%) as a clear oil. 1H NMR (CDC13, 500 MHz) 6: 0.87 (d, J = 6.5 Hz,

12H, CH 3), 0.96 (dd, J = 6.5, 3.0, 6H, CH3 ), 1.14-1.36 (m, 12H, CH2 ), 1.39 (t, J = 7.0 Hz,

3H, CH3 ), 1.49-1.57 (m, 2H, CH2 ), 1.60-1.73 (m, 4H, CH, CH2 ), 1.86-1.92 (m, 2H, CH),

4.04-4.12 (m, 4H, OCH 2 ), 4.35 (q, J = 14.0; 7.0, Hz, 2H, CH2 ), 6.87 (d, J = 8.0 Hz, 1H,

Ar-H), 7.55 (d, J = 2.0 Hz, 1H, Ar-H), 7.65 (dd, J = 8.5, 2.0 Hz, 1H). 13CNMR (CDC13,

500 MHz) 8: 14.60, 19.87, 19.91, 22.79, 22.89, 24.90, 24.92, 28.16, 30.09, 30.10, 36.16,

36.30, 37.49, 37.52, 39.41, 39.42, 60.87, 67.50, 67.72, 111.9, 114.2, 122.9, 123.6, 148.6,

153.2, 166.7. HRMS-ESI (m/z): [M+H]+ calcd for C29H50 04 463.3782, found 463.3767.

3,4-Di-(10-undecen-l-ol-oxy) benzoic acid ethyl ester (2b). The title compound was

prepared using the same procedure as above except that

-bromoundec-1-ene was used

instead of (S)-3,7-dimethyloctyl bromide (90%). 1H NMR (CDC13,500 MHz) 6: 1.331.40 (m, 20H, (CH 2 )5 ), 1.38 (dd, J = 7.0, 1.5Hz, CH 3 ), 1.45-1.49 (m, 4H, CH 2 ), 1.81-1.90

(m, 4H, CH2 ), 2.03-2.07 (m, 4H CH2 ), 4.05 (t, J = 6.5 Hz, 4H, OCH2 ), 4.35 (q, J = 14.0,

7.0, Hz, 2H, CH 2 ), 4.94 (dd, J = 10.0, 1.0 Hz, 2H, CHCH 2), 5.00 (dd, J = 17.0, 1.5 Hz,

2H, CHCH 2 ), 5.78-5.86 (m, 2H, CH), 6.87 (d, J = 8.5 Hz, 1H, Ar-H), 7.55 (s, 1H, Ar-H),

7.65 (dd, J = 8.5, 1.5 Hz, 1H).

13C

NMR (CDC1 3, 500 MHz)

49

: 14.61, 26.14, 26.18,

29.12, 29.13, 29.24, 29.33, 29.35, 29.36, 29.55, 29.57, 29.62, 29.63, 29.73, 29.75, 34.01,

60.89, 69.12, 69.39, 112.0, 114.31, 114.33, 122.9, 123.6, 139.4, 148.6, 153.2, 166.7.

HRMS-ESI (m/z): [M+H]+ calcd for C31H50 04 487.3782, found 487.3783.

3,4-Di-[(S)-3,7-dimethyloctyloxy]-benzoic acid (3a). A solution of 2a (2.01 g, 4.36

mmol) and potassium hydroxide (1.31 g, 23.4 mmol) in ethanol (15 mL) and deionized

water (15 mL) was heated to reflux at 80 °C for four hours. The solution was then poured

into 100 mL of 1N HC1to form a white precipitate, which was filtered and washed with

ethanol to afford the product (1.85 g, 97% yield) as a white solid.

H NMR (CDC13, 500

MHz) 8: 0.88 (dd, J = 6.5, 1.0 Hz, 12H, CH 3), 0.97 (dd, J = 6.5, 1.0 Hz, 6H, CH 3), 1.151.21 (m, 4H, CH 2), 1.25-1.36 (m, 8H, CH 2), 1.50-1.57 (m, 2H, CH 2), 1.62-1.71 (m, 4H,

CH, CH2), 1.87-1.93 (m, 2H, CH), 4.06-4.15 (m, 4H, OCH 2), 6.91 (d, J = 8.5 Hz, 1H, ArH), 7.61 (d, J = 2.0 Hz, 1H), Ar-H), 7.75 (dd, J = 8.5, 2.0 Hz, 1H, Ar-H).

(CDC13,500 MHz)

3C

NMR

: 19.91, 19.94, 22.83, 22.92, 22.93, 24.93, 24.95, 28.20, 28.21,

30.13, 36.12, 36.26, 37.51, 37.53, 39.43, 39.45, 67.59, 67.75, 111.9, 114.4, 121.5, 124.7,

148.7, 154.1, 172.5. HRMS-ESI (m/z): [M+Na]+ calcd for C27H460 4 457.3288, found

457.3291.

3,4-Di-(10-undecen-l-ol-oxy)

benzoic acid (3b). The title compound was prepared

using the same procedure as above except that 2b was used instead of 2a (99%). H NMR

(CDC13, 500 MHz) 6: 1.31-1.34 (m, 20H, (CH 2) 5) 1.46-1.50 (m, 4H, CH 2), 1.82-1.89 (m,

4H, CH2 ), 2.05 (q, J = 7.0 Hz, 4H, CH2 ), 4.07 (q, J = 7.0, 6.5 Hz, 4H, OCH 2 ), 4.94 (d, J=

1.0 Hz, 2H, CHCH 2 ), 5.00 (d, J = 17.0 Hz, 2H, CHCH 2), 5.78-5.86 (m, 2H, CH), 6.90 (d,

50

J = 8.5 Hz, 1H, Ar-H), 7.60 (d, J = 1.5 Hz, Ar-H), 7.74 (dd, J = 8.5, 2.0, 1H, Ar-H). 13C

NMR (CDC13, 500 MHz) 6: 26.15, 26.19, 29.14, 29.15, 29.21, 29.33, 29.35, 29.37, 29.56,

29.59, 29.64, 29.66, 29.74, 29.77, 34.03, 34.04, 69.19, 69.41, 112.0, 114.3, 114.6, 121.5,

124.7, 139.4, 148.7, 154.1, 172.2. HRMS-ESI (m/z): [M-H]- calcd for C 29H 460 4 457.3312,

found 457.3304.

3,4-Di-[(S)-3,7-dimethyloctyloxy]-acetophenone (4a). A solution of 3a (1.35 g, 3.11

mmol) and dry THF (30 mL) was cooled to 0°C under an argon atmosphere. A 1.4M

solution of methyllithium in ether (7.0 mL) was added dropwise via syringe, and the

solution was allowed to stir overnight, warming to room temperature. After being poured

into 100 mL of N HC1 and extracted with dichloromethane, the solution was dried over

MgSO4 and the solvents were removed by rotary evaporation. The remaining residue

was purified by column chromatography using 5% ethyl acetate/hexane as the eluant to

afford the product (1.22 g, 91%) as a clear oil. H NMR (CDC13, 500 MHz)

: 0.86 (d, J

= 6.5 Hz, 12H, CH 3), 0.95 (d, J = 6.5 Hz, 6H, CH 3), 1.13-1.17 (m, 4H, CH 2), 1.23-1.36

(m, 8H, CH2), 1.48-1.56 (m, 2H, CH2 ), 1.60-1.70 (m, 4H, CH, CH2 ), 1.85-1.92 (m, 2H,

CH), 2.55 (s, 3H, CH 3), 4.05-4.11 (m, 4H, OCH 2), 6.86 (d, J = 8.0 Hz, 1H, Ar-H), 7.52 (s,

1H, Ar-H), 7.53 (d, J = 8.5 Hz, 1H, Ar-H). 13C NMR (CDC13, 500 MHz) 6: 19.84, 19.87,

22.76, 22.85, 22.86, 24.86, 24.88, 26.36, 28.13, 30.05, 30.06, 36.08, 36.24, 37.45, 37.46,

39.36, 39.38, 67.49, 67.62, 111.5, 112.2, 123.3, 130.3, 149.0, 153.6, 197.0. HRMS-ESI

(mlz): [M+Na]+ calcd for C28H48 03 455.3496, found 455.3493.

51

3,4-Di-(10-undecen-l-ol-oxy)-acetophenone. (4b). The title compound was prepared

using the same procedure as above except that 3b was used instead of 3a (90%). 'H NMR

(CDC13, 500 MHz) 6: 1.30-1.38 (m, 20H, (CH2) 5) 1.45-1.50 (m, 4H, CH 2), 1.80-1.88 (m,

4H, CH 2), 1.80-1.88 (m, 4H, CH 2), 2.02-2.06 (m, 4H, CH 2), 2.55 (s, 3H, CH 3), 4.07 (q, J

= 6.5, 6.0 Hz, 4H, OCH 2), 4.93 (d, J = 10.0 Hz, 2H, CHCH 2), 5.00 (dd, J = 17.0, 1.5 Hz,

2H, CHCH2), 5.77-5.85 (m, 2H, CH), 6.86 (d, J = 8.5 Hz, 1H, Ar-H), 7.52 (d, J = 2.0 Hz,

Ar-H), 7.54 (dd, J = 8.5, 2.0, 1H, Ar-H).

13

C NMR (CDC13,500 MHz) 8: 26.11, 26.15,

26.40, 29.10, 29.11, 29.19, 29.32, 29.52, 29.55, 29.60, 29.61, 29.70, 29.73, 33.98, 33.99,

69.15, 69.33, 111.6, 112.4, 114.3, 123.4, 130.4, 139.3, 149.0, 153.6, 197.1. HRMS-ESI

(m/z): [M+H]+ calcd for C30H48 03 457.3676, found 457.3664.

1-[3',4'-((S)-3,7-Dimethyloctyloxy)phenyl]-3-[3",4"-(10-undecen-1-ol-oxy)phenyl]-

propan-1,3-dione (5a). A solution of 2b (1.67 g, 3.53 mmol) and 4a (1.02 g, 2.35

mmol) in anhydrous THF (10 mL) was added via cannula to a 3-neck flask containing

sodium hydride (0.624 g, 26.0 mmol) and 20 mL dry THF at 0°C under an argon

atmosphere and was stirred for two hours, warming to room temperature, then heated to

reflux at 80C for four hours. The resulting dark orange solution was cooled to room

temperature, and water was added to quench excess NaH. The diketone was neutralized

using N HC1 and was extracted with dichloromethane and dried over MgSO4 . The

solvents were removed by rotary evaporation to give a dark orange oil, which was

purified by column chromatography using 5% ethyl acetate as the eluant to afford the

product (2.68 g, 74.0%) as a bright yellow oil. H NMR (CDC13500 MHz) 6: 0.97 (dd, J

= 6.5, 2.0 Hz, 12H, CH3 ), 1.06 (dd, J = 6.5, 2.0 Hz, 6H, CH 3), 1.25-2.02 (m, XH, CH 2),

52

2.12-2.16 (m, 4H CH2), 4.09-4.24 (m, 8H, OCH2), 5.03 (dd, J = 10.0, 1.0 Hz, 2H,

CHCH2), 5.07-5.11 (m, 2H, CHCH2), 5.87-5.95 (m, 2H, CH), 6.78 (s, 1H, CH), 7.02 (d, J

= 8.0 Hz, 2H, Ar-H), 7.36 (s, 2H, Ar-H), 7.66 (dd, J = 7.5, 2.0 Hz, 2H, Ar-H). 3C NMR

(CDC13 500 MHz) 8: 19.91, 19.96, 22.83, 22.93, 24.94, 24.96, 26.27, 26.30, 28.20, 20.16,

29.19, 29.37, 29.41, 29.60, 29.68, 29.76, 29.77, 29.80, 29.88, 30.14, 30.16, 30.55, 34.04,

34.06, 36.19, 36.32, 36.36, 37.53, 37.56, 39.44, 39.46, 67.65, 67.99, 69.62, 73.80, 112.2,

114.3, 121.4, 128.4, 130.7, 139.4, 142.3, 149.2, 153.1, 184.4, 184.8. HRMS-ESI (m/z):

[M-H]-calcd for C57H920 6 871.6810, found 871.6816.

1,3-Bis[3',4'-(10-undecen-1-ol-oxy)phenyl]-propan-1,3-dione (5b). The

title

compound was prepared using the same procedure as above except that 4b was used

instead of 4a (68%). 'H NMR (CDC13 500 MHz) 8: 1.31-1.39 (m, 40H, (CH2 )5), 1.50 (m,

8H, CH2), 1.83-1.89 (m, 8H, CH2), 2.03-2.07 (m, 8H CH2), 4.06-4.10 (m, 8H, OCH2),

4.94 (dd, J= 10.0, 1.0 Hz, 4H, CHCH2), 5.00 (d, J= 17.0 Hz, 4H, CHCH2), 5.78-5.86 (m,

4H, CH), 6.73 (s, 1H, CH), 6.92 (d, J = 8.5 Hz, 2H, Ar-H), 7.55 (s, 2H, Ar-H), 7.57 (d, J

= 8.5 Hz, 2H, Ar-H). ' 3C NMR (CDC13,500 MHz) : 26.18, 26.21, 29.15, 29.28, 29.35,

29.37, 29.43, 29.58, 29.61, 29.64, 29.66, 29.75, 29.78, 34.03, 69.23, 69.58, 91.86, 112.3,

114.3, 121.2, 128.4, 139.4, 149.1, 153.1, 184.8. HRMS-ESI (m/z): [M-H]- calcd for

C59H92 06 895.6810, found 895.6816.

Tris[1-[3',4'-((S)-3,7-dimethyloctyloxy)phenyl]-3-[3",4"-(1-undecen-1-ol-oxy)phenyl]-propanedionato]iron(III). (6a) A suspension of 5a (1.05g, 1.20 mmol), iron