Microfluidics: Cost Effective Approach and Comparison

advertisement

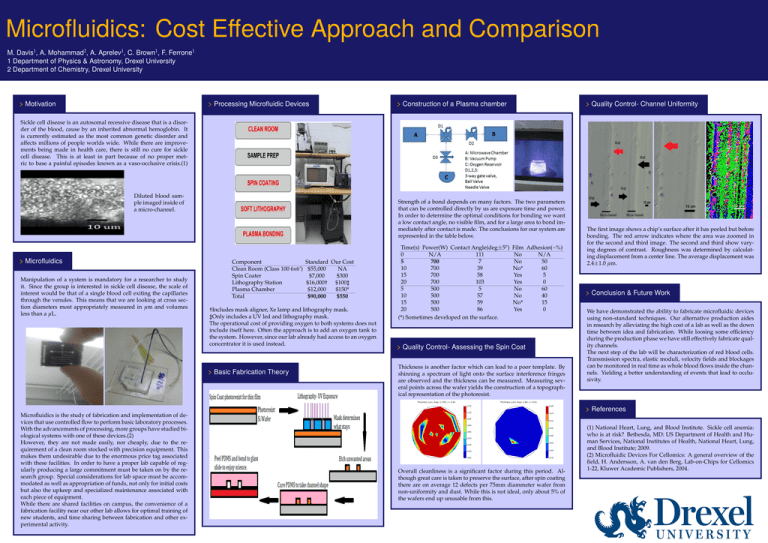

Microfluidics: Cost Effective Approach and Comparison M. Davis1, A. Mohammad2, A. Aprelev1, C. Brown1, F. Ferrone1 1 Department of Physics & Astronomy, Drexel University 2 Department of Chemistry, Drexel University > Motivation > Processing Microfluidic Devices > Construction of a Plasma chamber > Quality Control- Channel Uniformity Sickle cell disease is an autosomal recessive disease that is a disorder of the blood, cause by an inherited abnormal hemoglobin. It is currently estimated as the most common genetic disorder and affects millions of people worlds wide. While there are improvements being made in health care, there is still no cure for sickle cell disease. This is at least in part because of no proper metric to base a painful episodes known as a vaso-occlusive crisis.(1) Diluted blood sample imaged inside of a micro-channel. > Microfluidics Manipulation of a system is mandatory for a researcher to study it. Since the group is interested in sickle cell disease, the scale of interest would be that of a single blood cell exiting the capillaries through the venules. This means that we are looking at cross section diameters most appropriately measured in µm and volumes less than a µL. Strength of a bond depends on many factors. The two parameters that can be controlled directly by us are exposure time and power. In order to determine the optimal conditions for bonding we want a low contact angle, no visible film, and for a large area to bond immediately after contact is made. The conclusions for our system are represented in the table below. Component Clean Room (Class 100 6x6’) Spin Coater Lithography Station Plasma Chamber Total Standard Our Cost $55,000 NA $7,000 $300 $16,000† $100‡ $12,000 $150* $90,000 $550 †Includes mask aligner, Xe lamp and lithography mask. ‡Only includes a UV led and lithography mask. The operational cost of providing oxygen to both systems does not include itself here. Often the approach is to add an oxygen tank to the system. However, since our lab already had access to an oxygen concentrator it is used instead. > Basic Fabrication Theory Time(s) Power(W) Contact Angle(deg±5o ) 0 N/A 111 5 700 7 10 700 39 15 700 58 20 700 103 5 500 5 10 500 57 15 500 59 20 500 86 (*) Sometimes developed on the surface. Film Adhesion(~%) No N/A No 50 No* 60 Yes 5 Yes 0 No 60 No 40 No* 15 Yes 0 > Quality Control- Assessing the Spin Coat Thickness is another factor which can lead to a poor template. By shinning a spectrum of light onto the surface interference fringes are observed and the thickness can be measured. Measuring several points across the wafer yields the construction of a topographical representation of the photoresist. The first image shows a chip’s surface after it has peeled but before bonding. The red arrow indicates where the area was zoomed in for the second and third image. The second and third show varying degrees of contrast. Roughness was determined by calculating displacement from a center line. The average displacement was 2.4±1.0 µm. > Conclusion & Future Work We have demonstrated the ability to fabricate microfluidic devices using non-standard techniques. Our alternative production aides in research by alleviating the high cost of a lab as well as the down time between idea and fabrication. While loosing some efficiency during the production phase we have still effectively fabricate quality channels. The next step of the lab will be characterization of red blood cells. Transmission spectra, elastic moduli, velocity fields and blockages can be monitored in real time as whole blood flows inside the channels. Yielding a better understanding of events that lead to occlusivity. > References Microfluidics is the study of fabrication and implementation of devices that use controlled flow to perform basic laboratory processes. With the advancements of processing, more groups have studied biological systems with one of these devices.(2) However, they are not made easily, nor cheaply, due to the requirement of a clean room stocked with precision equipment. This makes them undesirable due to the enormous price tag associated with these facilities. In order to have a proper lab capable of regularly producing a large commitment must be taken on by the research group. Special considerations for lab space must be accommodated as well as appropriation of funds, not only for initial costs but also the upkeep and specialized maintenance associated with each piece of equipment. While there are shared facilities on campus, the convenience of a fabrication facility near our other lab allows for optimal training of new students, and time sharing between fabrication and other experimental activity. Overall cleanliness is a significant factor during this period. Although great care is taken to preserve the surface, after spin coating there are on average 12 defects per 75mm diammeter wafer from non-uniformity and dust. While this is not ideal, only about 5% of the wafers end up unusable from this. (1) National Heart, Lung, and Blood Institute. Sickle cell anemia: who is at risk? Bethesda, MD: US Department of Health and Human Services, National Institutes of Health, National Heart, Lung, and Blood Institute; 2009. (2) Microfluidic Devices For Cellomics: A general overview of the field, H. Andersson, A. van den Berg, Lab-on-Chips for Cellomics 1-22, Kluwer Academic Publishers, 2004.