1947 OXIDATION STUDIES METAL-CARBON

advertisement

OXIDATION STUDIES

IN

METAL-CARBON SYSTEMS

by

Watt Wetmore Webb

S.B. Massachusetts

Institute of Technology 1947

Submitted in Partial Fulfillment

Requirements

of the

for the Degree of

Doctor of Science

from the

Massachusetts

Institute of Technology

1955

Signature of Author

Department of Metallurgy

May 16, 1955

Professors

in Charge of Research

.~

Chairman, Departmental

on Graduate Students

--

-

.. -~

....

"1 .. v

r -

Committee

- ii

-

OXIDATION STUDIES IN METAL-CARBON SYSTEMS

By

Watt Wetmore Webb

Submitted to the Department

in Partial Fulfillment

of Metallurgy

of the Requirements

on May 16, 1955

for the Degree of

Doctor of Science

ABSTRACT

..

,-

~,~~;

A theoretical analysis of the behavior of carbon during

the high temperature oxidation of metal-carbon alloys indicates that in some systems carbon oxides may be evolved at

the alloy-oxide interface preventing the formation of a protective metal oxide while in other systems carbon may diffuse

away from the interface permitting retention of a protective

metal oxide layer. Criteria for predicting behavior in limiting cases have been established.

Oxidation experiments in the systems manganese-carbon,

nickel-carbon, tungsten-carbon and titanium-carbon confirmed

the theoretical analysis and contributed to the understanding

of oxidation of these systems.

An auxilliary investigation into the oxidation kinetics

of tungsten between 700 and 100000 revealed the presence of

two conjugated oxide layers only one of which is protective.

A mathematical formulation of the oxidation kinetics was

worked out and found to agree with the experimental data.

Initially the oxidation rate is proportional to the inverse

square root of the reaction time but as the reaotion progresse

the rate approaches a constant value and the protective oxide

layer approaches a constant thickness.

Thesis Supervisors:

Carl Wagner

John T. Norton

Professors of Metallurgy

- 111 -

TABLE OF CONTENTS

Page

Number

Abstract

.... .

Table of Contents

.

•••••

List of Illustrations

. . . . . . . . . •••

.........

..

...

..

Acknowledgements

• . . .

Introduction . . .

I

...

List of Tables •

A.

III

IV

..

Program

Oxidation

.......

...........

.........

A•

Theoretical

Analysis

Systems

.........

v

viii

1

1

.....

Theory for Metal-Carbon

l1i

vli"

.........

Experimental Procedures •• . .

...

A. Introduction

. . . . . . . . . ...

B. Preparation of Materials

. . . .....

C • Measurement of Oxidation Kinetlcs • . . .

....

D • Examination of Reaction Products

Oxidation of Tungsten • . • . • . • • • . . •

Introduotlon

A•

• . • • • • .

.• ..•

B • Experimental Details • • • • •

• • .

c. Rate Measurements

• • • • . • • . . . .

D . structure of the Oxides • • • • • • • . •

E.

• • • . .

Summary of the Data • • . •

F. Mechanism

.• • .• ..• .• .• • .•

General Discussion

• • • • • . • . . . •

G.

B.

II

Problem

...

1i

2

5

5

5

7

12

16

16

18

18

20

24

27

3:3

47

••

.

47

- lv Page

Number

B.

v

Calculation

Experimental

of Carbon Oxide Pressures

Studies of Metal-Carbon

•

...

•

•

Nickel-Carbon

D•

Manganese-Carbon

E•

Titanium-Carbon

F.

Titanium Carbide Based Commercial

System

•••

System ••

System

•

• •

. . ..

•

• • • • • •

.......

.........

Recapitulation

...............

A.

Conclusions

• • • •

B•

Status of the Problem

Bibliography

•

•

•

•

•

• • •

Appendix

I

Superheating

Appendix

II

Crystallography

Tungsten

Appendix

III

IV

•

• •

......

.........

. . . . • • ••

•

• •

•

of Oxidation Samples ••

62

65

71

78

87

96

107

107

108

110

116

of the Oxides of

............

Diffusion

••

• •

120

Note

..........

121

of Carbon During Oxidation

of Nickel-Carbon

Biographical

..

62

Thermal Data for the Oxides of

Tungsten

Appendix

••

•

.....

c.

Hard Metals

VI

System

60

...

.......

A • Method of Data Presentation

B • Tungsten Carbide

••

Alloys

••••••

128

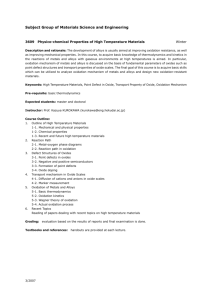

- v LIST OF FIGURES

Page

Figure

Number

Number

14

1

Schematic Diagram of Oxidation Apparatus

2

Oxidation Furnace

3

Da ta on the Oxidation

4

Linear Plot of Rate Data on the Oxida.tion

of Tungsten •

5

•

•

..

......

of Tungsten

• • •

• •

.... ...• .• ....

.• .

.• .

•

6

Photographs

of Oxidized Tungsten

7

Photomicrographs

8

Arrhenius Plot of Limiting Parabolic Rate

10

of Oxidized

• •

38

•

39

.

40

Plot of Linear Limiting Rate

Constants

for the Oxidation

Expression

of the Equation

b

b2

In (1 -

Comparison

a

Y)

=-

a t

•

.• ..

Tungsten • . .

Arrhenius

y +

•

•

for the Oxidation

Oxidation

12

• •

Constants

ab

11

1.5

Linear Plot of Rate Data on the Oxidation

of Tungsten

9

.

of Tungsten

•

•

42

••

44

of.Tungsten

•••

41

• • •

4.5

• •

46

of Theory with Data on the

of Tungsten Carbide ••

Rationalized

Data on the Oxidation

Tungsten Carbide

13

Photographs

14

Photomicrographs

• •

of

.............

69

of Oxidized Tungsten Carbide ••

of Nickel-Carbon

•

Alloys .•

70

76

- vi FigureNumber

15

Page

Number

Oxidation of Nickel-Carbon Alloys

at 10000C

16

Photomicrographs

Alloys

17

. . . . . ......

of l~nganese-Carbon

85

Oxidation of Manganese and a Manganese-

.............

86

Rationalized Data on the Oxidation of

Titanium-Carbon Alloys

19

77

................

Carbon Alloy

18

. ...

Photomicrographs

Carbide ••

93

••••••••

of Oxidized Titanium

. . . . . . .......

.

20

Photographs of OYidized Titanium Carbides

21

Rationalized Data on the Oxidation of

TiC Based Hard Metals and Alloys

22

•••

94

95

104

Rationalized Data on the Oxidation of

(Ta,Nb) Modified TiC Based Hard Metals

and Alloys

23.

..............

Photomicrographs

Bonded TiC

105

of Oxides on Nickel

..............

106

- vii -

LIST OF TABLES

Table

Page

Number

Number

I

Limiting Rate Constants for the

Oxidation of Tungsten •••

II

X-Ray Diffraction

Oxides

III

Data on the Tungsten

...............

37

Theory of Oxidation Kinetics of

Metal-Carbon

IV

.......

Systems

Decarburitation

Nickel-Carbon

........

During Oxidation

Alloy •••••••••

.59

of a

• •

128

- viii -

ACKNOWLEDG~mNTS

Profound

thanks are due to Professors

J. T. Norton for their supervision

many stimulating

discussions

Carl Wagner and

of this research, and for

whioh have been the most eluoi-

dative factor of the author's graduate training.

most of the theoretical

foundations

1n July 1953 by Professor

cussions witll him.

Professors

Wagner,

In partioular,

of this work were laid out

or were evolved from dis-

The problem was suggested

jointly by

Norton and Wagner.

The Amerioan Electro Metal Company supplied

specimens and hot pressed

the Kennametal

Company

some of the

others, and Mr. J. C. Redmond ot

supplied some of the oommercia1

hard

metals.

Mr. Peter Koros and Mr. Ernest Abrahamson

vided equipment and assisted

Mr. Charles

S. Fletcher

of the specimens

Guernsey

kindly pro-

in the melting of alloys.

of Harvard University

for metallographlc

polished

examination,

some

and Mr. Don

carried out the chemical analyses.

This work was supported

grant from the Allegheny

Gratitude

for two years by a fellowship

Ludlum Steel Company

is also due to Page Chapman Webb and Watt Webb III

for their patience,

sympathy and encouragement

oourse of this research.

dur1ng the

Ie

A.

INTRODUCTION

Problem

Although

the oxidation of pure metals and alloys has

been studied for many years, little has been done to understand the oxidation behavior of the extensive and important

group of alloys and metallic

Many investigators

a~ned

compounds containing

carbon.

have measured rates or oxidation and ex-

the oxide structures for carbon containing alloys

such as steels and metal-carbide-based

sideration

hard metals but con-

ot the behavior ot contained carbon during the

oxidation process has been largely speculative

lacking.

or entirely

Since the oxidation rate of metals often depends

on the action of the oxide as a protective

the possibility

o~ formation

might intuitively

barrier layer,

ot the gaseous carbon oxides

be expected to have a disturbing

on this layer and hence possibly

influence

affect the overall reaction

rate under some circumstances.

It is the object ot this investigation

temperature

to survey the high

oxidation kinetics in metal-carbon

establish a theoretical

basis for predicting

systems and to

and understand-

ing in a general way the oxidation behavior of carbon in such

systems.

It is not intended to supply an exhaustive report

or diffusion

mechanisms,

tor particular

understand

oXides structures,

or rate constants

systems in any more detail than is required to

the behavior

of carbon in these systems.

-

B.

2 -

Program

!he experimental

measurements

of the kinetics

of oxida-

tion of solid metals have usually been found to comply with

one of several simple rate equations.

been discussed

These have recently

in great detail in the book "OXidation ot

Metals and Alloys,. by Kubaschewski

and Hopkins(28)

and are

readily available there.

If diffusion

through the oxide formed is the rate limit-

ing step of the reaction, then usually the rate of oxidation

is inversely proportional

and the progress

parabolic

to the thickness ot the oxide formed

of the reaction may be expressed by the

oxidation law of Pilling and Bedworth(4l),

lAA,m)2.

where

:;

k2t

6m - weight change of the specimen

A

=

area of sample

k2 = parabolic

t

=

oxidation rate of constant

reaction time

Wagner(S3)

has discussed

oxidation as a diffusion

in detail the theory of parabolic

limited process and has related the

rate constant to other measureable

layer.

!he theory holds wherever

properties

of the oxide

either ionic or electronic

diffusion

through the oxide is the rate limiting

important

to note that the general principles

step.

It is

of Wagner's

theory may also apply to cases where the parabolio

rate law

- :3

1s not observed

reactions

due to the simultaneous

of other

which obscure the nature of the rate limiting

If some surface reaction

limiting

occurrence

step, the progress

rather than diffusion

A

is the rate

of the reaction may often be repre-

sented by the "linear oxidation

Am

step.

law ••

=

where kl is the linear oxidation rate constant.

A1though the linear rate law 1s algebraiely simpler than the

parabolio

law, less is understood

generally

about the meohan-

isms involved.

other oxidation

the "logarithmic

and1a:

1

"laws" have been observed,

law" is quite common in the thin f11m range

cubic lay 1s occasionally

to various

reported

it was suspected

be encountered

that deviations

laws mentioned

ot this researoh

Based on a preliminary

lem by Professor

sitions

reactions

with cases where

from the simple theory would

not ordinarily

above.

It is the immediate

theoretioal

analysis

a theoretical

of the prob-

analysis

of carbon during the oxidation

in metal carbon systems has been worked

metal-carbon

types ot behavior

considered

to study some of these deviations.

C. Wagner(S2)

to seleet particular

various

primarily

due to complications

in the oxidation

possible

to be applicable

cases.

The present work is concerned

objective

in particular,

expected.

of the

of compo-

out and used

systems representing

the

Only systems in which

-4the pure metal is characterized

have been considered

differences

by a protective

oxide layer

since only in these eases would significant

between the oxidation kinetics

of the metal-carbon

alloys and the pure metal be expected.

The experimental

program consists primarily

of direct

measurement

of oxidation rates as a function of reaction

by weighing

specimens as they hang in a hot oxygen tilled re-

action tube and by measuring

In order to understand

lographic

structures

the evolution

time

of carbon dioxide.

the results the mechanical

and crystal-

of the oxides were determined

in some

detail.

Although

a variety

the experimental

program was intended to survey

of systems it developed

carbon, the oxidation kinetics

in doubt so considerable

~n addition

for the unalloyed

detail was developed

the performance

carbides was studied.

that in one system, tungsten-

of some commercial

metal were

tor this material.

bonded metal

- 5II.

A.

EXPERIMENTAL PROCEDURES

Introduction

The experiments

conducted center around the measurement

of oxidation kinetics described in subsection C below.

ever, to understand

the results obtained from these experi-

ments, supplementary

information

about the nature of the

oxides formed and their behavior under controlled

is required.

The experimental

ing this information

B.

Preparation

procedures

are discussed

conditions

involved in obtain-

in subsection D.

of Materials

Surface preparation:

Since the preparation

of specimen

surfaces may influence the course of surface reactions,

ploratory

tests were made to determine

for the present work.

77, give a discussion

Kubaschewski

methods

pages

72-

It was anticipated

Thus only abraded surfaces

experiments were concerned with the

degree of smoothness required and the efficiency

Comparisons

ex-

should not be too critical since only

thick films were to be studied.

were used and preliminary

satisfactory

and Hopkins(28),

of this problem.

that surface preparation

methods.

How-

of cleaning

of samples of tungsten, titanium and

zirconium which had been abraded and oleaned in various ways

showed no important differenoes

after normal oxidation times.

It was decided to prepare all specimens for measurement

oxidation

of

rates by merely abrading on 120 mesh alumina paper

followed by washirg 1n reagent grade acetone.

Sinoe it was

-6observed

in some eases that oxidation

occurred preferentially

at the edges, the length of edge per unit area of specimen

was in those cases maintained

Preparation

of Pure Metal Carbide Specimens:

carbides ot ~gh

purity were commercially

powder, powder metallurgy

tion of metal carbide

reduce porosity

roughly constant.

Since metal

available

only as

techniques were used in the prepara-

samples.

Hot pressing was required

to

below a level at which internal oxidation

Pressing was carried out by the American Electro

occurred.

Metals Corp. at appropriate

temperatures

in grap~te

molds

for roughly 10 seconds, that is, until a limiting value or

sample density was reached.

consistently

exceeded

Preparation

Induction

alloys.

97 per cent.

of Nickel-Carbon

melting

atmosphere

The resultant apparent densities

and Man~anese-Carbon

in alumina cruoibles under a purified

was used to melt nickel-carbon

Tank. argon was purified

Test specimens were

the alloy to freeze in the tubing.

were approximately

sampling by optical pyrometer.

obtained

determined

at the time of

Smooth, clean surfaces were

on the samples but they were abraded on 120

mesh alumina paper before oxidation testing as ~th

samp1es.

before

the molten alloy into .Vieorn glass tubing

by suction and allowing

usually

and manganese-carbon

and hot magnesium

being passed through the furnace tube.

made by withdrawing

argon

by passing over "AscariteU,

ftAnhydronel (magnesium perchlorate)

Temperatures

Alloys:

other

- 7 Preparation

of Titanium Alloys:

Arc melting using a water

cooled copper mold, tungsten electrode and purified argon atmosphere was used to form titanium alloy ingots weighing about

100 grams.

Argon was purified as above except that titanium

sponge was substituted

train.

The ~naoe

for magnesium

chips in the purification

was flushed and evacuated repeatedly be-

fore melting and a flow of argon maintained while melting.

Contamination

of the alloy by tungsten was avoided by striking

the arc on a tungsten block and operating with an arc length

ot at least one-halt inoh.

The ingots were inverted and re-

melted several times to insure uniformity.

surfaces charaoterized

Shiny, clean

all of the ingots and samples tor oxi-

dation testing were prepared by cutting slices trom these

ingots which were abraded as usual.

C.

Measurement

Method:

of Oxidation Kinetics

Kubasohewski

and HOPkins(28)

discuss methods of measuring

tail.

in their Ohapter 2

oxidation kinetics

in great de-

The method adopted here follows the standard practice

of weighing

the sample periodioally

trom an analytical

funotion

balance.

This yields the weight gain as a

of reaotion time w~le

stant temperature.

as it hangs in the furnace

If allot

the specimen remains at a conthe oxidation product adheres.

to the specimen the weight gain is just the amount ot oxygen

reaoted

so the amounts

be determined

of metal consumed and oxide formed may

by stoichiometry

provided the composition

of the

- 8oxide is known.

However, if the oxide 1s not adherent or if

one of the oxidation products

not unambiguously

action.

is gaseous the weight gain does

give a measure of the progress

of the re-

For example, in the case of oxidation of tungsten

carbide the following

overall reaction might apply:

To verify this unambiguously

thE} carbon oxides formed must be

measured as well as the specimen weight gain.

accomplish

In order to

this the exhaust gases from the oxidation furnace

may be passed over tfascarite" (sodium hydroxide

on asbestos)

where CO2 is selectively absorbed.

If weighing bottles containing the absorbent are changed at intervals, a plot of the

amount of CO2 evolved vs. time may be made.

This procedure

was followed in the present work and a block diagram of the

apparatus

oonstructed

for this purpose is shown in Figure 1.

It should be noted that gas evolution and weight gain are determined

independently

on duplicate

specimens, the top of the

furnaoe tube being closed up during gas measurement.

details are worth noting too.

A few

It was found that at 70000

much of the carbon oxidized was not converted to C02 but appeared rather as CO.

in the exit gas train.

Hence the need for the catalyst furnace

The design of the oxidation furnace

tube (shown in Figure 2) includes a sight glass at the bottom

through which the specimen can be observed and on which any

oxide which might spall from the sample may be seen immediately.

- 9 Sinoe the top o~ the furnace tube is very narrow, to avoid

convection

currents it was necessary to hang the specimen

from ~ine straight quartz wires.

It was possible

to measure

weight changes with an accuracy of about :t: 0.5 mg provided

they occurred slowly.

Temperature

Control:

Temperatures were uniform to within

% 1°C in a hot zone of 2 inches length with normal gas flow

and were maintained

~ sOe

at the desired temperature well within

by a sensitive temperature

controller.

short periods was easily maintained within

Control over

~l.O

o

and drift

of the control point caused nearly all of the variations

long periods

of time.

over

The use of a heavy stainless steel block

around the reaction tube increased the thermal inertia of the

furnace and greatly facilitated

temperature

Another thermal faotor involved

idation kinetics

evolved.

in the measurement

of OX-

is disposal of the heat of reaction as it is

This problem

is usually rightly ignored.

during the early stages of oxidation

the parabolic

control.

However,

of a material following

rate law the rate of heat evolution

is likely

to be quite high and the heat of formation of the oxide may

not be radiated away with sufficient rapidity to permit temperature control.

problem

A straight fo~~ard approximate

analysis of this

is derived in Appendix I and presented with a typical

calculation.

This analysis

sive temperature

showed that in some cases exces-

rises could occur over a short period of time.

- 10 -

To insure that overheating

initial oxidation,

did not lead to greatly accelerated

in the present studies the speeimen is hung

in a cold zone or the furnace containing pure 02 and then it

is raised into the hot reaction zone of the furnace.

with this technique

intended.

the reaction begins below the temperature

Measurements

on typical specimens into which had

been inserted a tine pt - pt

+ 10

per cent Rh thermocouple

showed that the specimens reached temperature

to 120 seoonds and that no overheating

lag introduces

measurement

Actually

a fixed uncertainty

within from 30

occurred.

This thermal

of this order into the

of reaotion time.

Discussion

of Errors:

Calculations

of the oxidation kinetios

data was oarried out in a straight forward manner.

there is one factor which should be considered

However

carefully for

oxidation

in the thiok film range.

effective

sample area as the oxidation process progresses

the metal is consumed.

interfaee-area-change

the follo~ng

oxidation

That is the change of the

For example, calculations

and

of metal oxide

for the tungsten samples studied gave

interface area changes for various amounts ot

of tungsten to W0

3

~

A

m

Ao

Ao

0.001 gram/cm2

0.01

II

II

0.1

"

II

Sample size assumed

=

A

0.05 x 1 x 4 em.

.05 per cent

.5

per cent

4.7 per cent

- 11 -

Ao

AA

Am

= initial

=

=

area of sample

area change'

total weight change

Kinetios measurements

were stopped before

5 per cent area

change occurred(except

in special cases specifically

noted) to

avoid area corrections

since they are difficult to apply un-

ambiguously.

Analysis

of weig~ng

errors can be based on the assumption

that the error is determined primarily by the reprodueibility

of individual ba1anoe readings which is essentially

of A m but 1s dependent

independent

on the rate of weight gain which governs

the time available to take a reading of the balance.

Calcu-

lation shows that the maximum error is due to sample area

change (discussed above) for only a few data.

error turns out to be the principal

error and is essentially

tion of weighing

The weighing

source of measurement

a constant for all data.

error is based on a weighing preoision vary-

ing from .:I:. 0.0002 gram to :t. O. 001 gram depending

of oxidation.

Calcula-

Weighing

on the rate

of speoimens on an accurate analytical

balance before and after each run provided a check on possible

cumulative

error of the weight change.

invariably

negligible •.

In weig~ngs

The discrepancy

of gas absorption bottles the weight ohanges

were read to .:l: 0.0005 gram and were reproducible

oonsistent1y.

was

to :i:. 0 •001 gram

- 12 -

Analysis

identical

of results

speoimens

trom dup1ioate

indioated

runs on apparently

that usually

the overall repro-

ducibi1i ty of data was wi thin the .error.'ofm'easurement41 However in some cases, partioularly

tion was involved,

where relatively

somewhat higher

Figure 5 data from duplicate

order of reproducibility

deviations

occurred.

runs on tungsten

obtained

rapid oxida-

indicate

In

the

in this rather unfavorable

case.

The problem

of reproduoibility

'fully where data on gas evolution

for metal-oarbon

alloys

must be oonsidered

and specimen weight gain

are taken on separate

ly a good check is possible

the specimen used for gas evolution

weight

measurements

to equal reaction

change curve of' the comparison

materials

runs.

since the total weight

with the point corresponding

speclmen.

discussed

ohange ot

time on the

For the

of these values

wi thin the error of measurement.

oases whioh are specifically

Fortunate-

may be compared

tested in the present work, agreement

was invariably

care-

Only 1n a few

was the reproducibility

of data outside

of the range of the error of measurement.

D.

of Reaction

Examination

Determination

Products

of OXide Crystal

fraction

powder patterns

tion'and

a General Eleotrio

with intensities

radiation

peaks.

recorded

was passed

structures:

X-ray dif-

were made using CuKd or arK~ radiaproportional

counter

on a logarithmio

soale.

through a suitable f11ter

Results were analyZed

by comparison

to

spectrometer

Diffraoted

remove K~

with ASTM Standard

- 13 patterns

and with published

culation from reported

data and 1n some oases by cal-

structures using the usual prinoip1es.

See,tor example. Barrett (1) or Klug and A1exander(27).

Determination

ot the Mechanioal

Form ot Oxide Layers:

Polished

cross sections through metal and oxide layers were

prepared

for microsoopio

examination

with some difficulties.

Samples having sott friable oxides adjacent to bard metal

layers were prepared

University

by Mr. Charles S. Fletcher at Harvard

by mounting

in thermosetting

sure, and polished by petrographio

lead laps.

techniques

inary polishing

techniques.

oxide polishing

paper; finish polishing

covered diamond

In order to determine

whether

was carried

wheels.

observed porosity

of some of

or merely pitting due to

density measurements

were made using g1yeerene

using

charged po11shing

these oxides was a bu1k phenomenon

p1nenometrie

at M.I.T.

Grinding and prelim-

ot these seotions were acoomplished

out on broado1oth

polishing,

on eastiron and

Those having harder oxides were prepared

by standard meta110graphic

aluminum

plastic without pres-

on the oxides

or water as the dense fluid.

It was

noted that water was slowly absorbed by the porous oxides 'and

this was taken into account by making the measurements

as rapidly as possible

and weighing

before and after submerged weighing

had been absorbed

in water

the specimen in air both

to determine

in the specimen pores.

how much water

- 14 -

ANALYTICAL

BALANCE

o.

0'0.0'00.0

CuO:C~T~LY~T:~OO.C

l ....

TYGON

,

J

CONNECTORS

ANHYDRON~

TUBE

~

GROUND

TAPERED

JOINTS

FLEXIBI

D~YING

~

FOR

LITY

o •

o' •

o •.

o ..

0 ••

•

0

o

o

o. -

RADI ATION

AND

CONVECTION

SHIELDS

OF

ALUMINUM

FOl L

See Fi 9 2 for

Fur n ace Det a iIs

ABSORPTION

BOTTLES

ASCARITE

AND

ANHYDRONE

BUBBLE

TUBES

IIASCARITE

SODIUM

HYDRATE

II

"ANHYDRONE"

MQClO.

SAFETY

TRAP

COMMERCIAL

U.S. P.

OXYGEN

FIG.

I

-

SCHEMATIC

APPARATUS

DIAGRAM

OF OXIDATION

,- 15 Tygon tubing and clamp

to seal tu be for gas

evolution measurements

t

Distance from top of

fu rnace to bottom of

balance box = 40 cm

..

"To absorption

train

Thermocouple

Radiation

aluminum

wells

shields of

foil

Frame and nicrome

strap to support

stai n less steel block

. ....

,

\

,.

..

"

.

SPECIMEN hanging

from quartz or

platinum wire

25cm

Type 309

sta i n Iess steel

block

. : ... ~

••

#

•

22 mm I. D.

quartz

tubing

30cm

Sight glass sealed in place

with DeKhotinsky cement

FI G. 2 - OXI DATION

FURNACE

- 16 III.

A.

OXIDATION OF TUNGSTEN

Introduction

As a preliminary

metal-carbon

phase of the studies of oxidation in

systems, the oxidation

of tungsten was consid-

ered in some detail since this case appeared interesting

previous

published

and

work was in ~isagreement.

The oxidation kinetios for tungsten'at

700°0 have been measured by Dunn(lO),

and Kieffer and Kolbl(26).

temperatures

Scheil(4;),

Dunn found a parabolic

ship to hold in the range 700 tOlOOOoO.

above

N~chtigal(39)

relation-

On the other hand,

Scheil and Kieffer and Kolbl found linear relationships

be-

tween ;00 and 900°0.

Nachtigal

law applies initially

but that later the linear law applied.

Gulbransen

and Wysong{l;)

havior of tungsten

have studied extensively

in oxygen at pressures

and below in the temperature

parabolic

found that the parabolic

rate dependenoe

where a linear weight

range

rate

the'be-

of 0.1 atmosphere

25 to ;50°0. They obtained

except at .01 atmosphere

gain was observed.

and 500°0

Appreciable

vola-

tility of the oxide was noted only under good vaouum at temperatures above 800°0.

The work at temperatures

disagreement

so present

these discrepanoies.

above .500°0 thus shows apparent

experiments

were designed

to resolve

It should be noted that while very thick

films were formed on the specimens used by Scheil and by Kieffer

- 17 and Kolbl during the periods of several days of their tests,

the tests of Gulbransen

and Wysong and Dunn did not exceed

several hours so consequently

they formed only relatively thin

fi1ms.

Millner and Neugebauer(38)

that tungsten tri-oxide

in a short article, reported

is not volatile at lOO~oO in 02 or a

vacuum of 1 mioron Hg or in argon.

tungsten oxides volatilized

However, large amounts of

in the presenoe

of water vapor in

excess of 30 volume per cent.

Hickman and Gulbransen(l9)

have studied the orystal struc-

tures of the oxides formed on tungsten up to 700°0.

temperatures

below 70000 they found only W0

At all

0

3 but at 700 0 both

were reported, although examination of the diffracJ

tion data given suggests that the additional structure observed

W02 and WO

at 70000 is not neoessarily

The structures

determined

W02•

of the various tungsten oxides have been

by Bigg and co-workers and others and the thermo-

dynamic data on the tungsten oxides has been summarized recently by Coughlin(7).

referenoes

pendix III.

The crystal struoture data are given with

in AppendiX

II and the thermodynamic

Recently W0

3

has been investigated

data in Apat high tempera-

tures due to interest in its reported ferroeleotric

There appears to be a phase transition

second order transformation

at about 740°0 and a

at about 900°0 according

Hay and Wa.hJ.(24)and the investigators

propertle~.

to Kehl,

quoted by them.

- 18 B.

Experimental

Details-

Experimental

prooedures

were desoribed

in Section II, and

.it lsneoessary

to add here only a description

used.

sheet obtained from A. D. McKay Company,

Tungsten

of the material

(labeled 99.9 per cent pure) 0.5 mm thick was cut into strips

ov 5 to 10 em2 total area to form the oxidation test speoimens.

Surfaoe preparation

described.

following

followed the standard method previously

Chemical analysis

of this material

impurities:

Element

Per cent Impurity

Fe

0.002

Si

<. 0.005

AI

0.01

.L-

C~

c.

showed only the

0.01

0.03

C

0.033

s

0.004

Rate Measurements

All of the rate data obtained on the oxidation

are presented

grap~oally

in Figure 3 on logarithmio

of tungsten

coordinates

with the weight gain per unit area in grams per square centimeter plotted

against the reaction

time in seoonds.

anoe is made for the time required for specimens

reaotion

temperature.

No allow-

to reach the

Since this 1s less than 30 seconds in

every. case, a good idea of the reproducibility

of the data may

be gained by noting that the systematio deviations

between

- 19

duplicate

runs are about the same magnitude as the error. ot

measurement.

In logarithmic

ooordinates,

data following a parabolic

rate law should'plot as a straight line with a slope of

0.5

and data following a linear rate law should plot as a straight

line with a slop of unity.

None of the data observed quite

fit a straight line and all of the slopes lie between about

0.5 and 1.0 so that neither a parabolic nor a linear rate

law 1s adequate to represent these results.

Replotting

the same data in simple linear coordinates

is done in Figures

as

4 and 5 shows the trend of the time rate

change of oxidation more clearly.

tion times are omitted for clarity.

o't

Data points at small oxidaThe oxidation curves start

out with a steep slope which gradually deoreases until a limiting value is reached beyond which the rate is rough1y constant.

This suggests that a parabolic

time at the beginning

rate law may apply for a short

of the experiments and that transition

to a linear law occurs.

Two experiments under non-standard

test conditions were

made to determine

the effect of certain variations

mental conditions

that appeared critical.

of experi-

In order to determine whether the reported volatility

ot

W03 in the presence of water vapor would affeot oxidation rates

at pressure

conditions

of water vapor near that of ambient atmospheric

a run was made in oxygen saturated with H20 at 20°0.

-

The only signifioant differenoe

20 -

observed was a slight increase

in the constant oxidation rate approached after long reaction

times.

No noticeable

Since preferred

noticed,

deposit of oxide appeared in the furnace.

oxidation at sample edges and eorners was

specimens with an exceptionally

per unit of area were oxidized.

large length of edge

They showed some irregulari-

ties during the early stages of oxidation but only small differences in rate.

Rate constants were obtained from the oxida~ion data and

tabulated

in Table I by assuming that initia11y a parabolic

rate law holds and that eventua11y the linear rate law applies.

Rate constants were measured by estimating the limiting values

of the slopes of the oXidation curves when sultab1y p1otted.

The linear constants are the terminal slopes of data plotted

in Figures 4 and 5 and the parabolic

constants are the initial

slopes of plots of the square of the weight gain per unit area

against oxidation

time.

these app~oximations

The range of app11cability~r

is also tabulated in Table I.

terion for applicability

each of

The cri-

is the absence of systematic devia-

tions from the rate law larger than the maximum error of .

measurement.

D.

struoture

of the Oxides

In addition to the measurements

dation other observations

oxide were made.

of weight gain during oxi-

on the mechanica1

The most prominent

form of the surface

oxide layer' observed had

-nthe chartreuse

color typical of WO) and was very porous at

lea~t after cooling to room temperature.

During cooling, about

60 seconds to room temperature, in oxygen the oxide changed

from a bright orange to chartreuse.

,~eported previously

This phenomenon

by most investigators

of WO).

of the yellow oxide was readily ascertained

has been

The porosity

by touching the tip

of a fountain pen to the surface which resulted in ink being

rapidly absorbed by the oxide.

Density measurements

that about )0 per cent porosity

existed.

oxidized

indioated

Photographs

of typical

specimens appear 1n Figure 6 where it can be seen that

the extra t~ck

prominent

oxide at the edges of the specimens 1s especially

on the heavily oxidized specimen oxidized at 1000°0.

A photomicrograph

of a cross-section

oxides is presented

showing the form of the

in Figure 7a.

It was observed that the heavy oxide at the edges did not

become evident imm~diately

but that it became prominent

1n the final portion of the oxidation period.

only

It appeared

that oxidation took place more rapidly at the edges so that

eventual11

the metal core of the specimen took on an elliptial

rather than rectangular

cross-section.

However as previously

noted, specimens cut to a long narrow shape to provide a larger

ratio ot edge length to area were observed to approach

larger final oxidation

slightly

rat than others oxidized at the same

temperature.

On scraping the yellow oxide from the specimens a hard

dark blue layer appeared beneath.

This layer adhered tightly

- 22 -

to the metal surface and would not absorb ink placed on its

surface.

This layer is shown in a photomicrograph

taken with

objective at 2000X in Figure ?b.

The thick-

an 011 immersion

ness of the blue oxide on this sample is about 4 microns.

diffraction

patterns were obtained and its structure and thick-

ness are discussed below.

occurrence,

atmosphere

X-ray

tungsten

In order to get some idea of its

specimens were exposed to the oxidizing

for just a few minutes at various temperatures.

"blue oxide" invariably

order of magnitude

The

appeared and was found to have the same

of thickness

oxide at longer oxidation

as those formed under the yellow

times.

These specimens

also showed

an inoomplete'~ thin, powdery layer of yellow oxide over the

blue oxide after short exposure times.

Invariably

on removal of an oxidized specimen from the

furnace the platinum wire which had been tied around it to

support it was found outside of the oxide and often fraotured

by the expansion

of the sample during formation

This is clear in Figure 6.

of the oxide.

Outward growth of the yellow oxide

from the metal oxide interfaoe was also suggested by the presenoe

on the surfaoe of the oxide of defeets present

on the original

metal surfaoe.

X-ray diffraction

patterns

of the oxides formed on various

speoimens were made and some of the data are presented

II.

Comparison

with results

with the ASTM diffraotion

of Gulbransen

and Wysong(lS)

pattern

in Table

cards and

showed numerous

- 23 ambiguities

due to the large numbers of lines and the complex

and rather similar structures

involved.

of the various tungsten oxides

However, using the lattice parameters

given by

Breakken(:3) for ctW0:3 a set of "dU values was calculated.

of the lines of all of the patterns

All

obtained from the chartreuse

oxide could be fitted quite closely to these "d" values.

By scraping off the chartreuse

oxide the blue oxide pre-

viously mentioned

was exposed on the surface of the metal cores.

X-ray diffraction

patterns

of this oxide on the metal showed

strongly the lines of ~ tungsten and a set of five additional

sharp lines which appeared at "dn values which coincided with

some of those of W03 and of "W40ll" whioh is known to have a

blue color.

However,

only the five lines appeared.

The d values

were consistent with a cubic lattice parameter

equal to a multi-

ple of :3.77 Angstroms

were not too

reproducible

explained

but relative

intensities

and the laok of some of the lines could not be

from the data obtained.

It was possible

to chem-

ically remove the blue oxide trom the tungsten using concentrated nitric acid and hydrofluoric

acid and to obtain a feeble

powder pattern from this material by suspending

it in thick col-

lodion which was stirred while drying to reduce preferred

orientation

of the flakes of oxide.

No additional

peared in this case but the intensities

That the thickness

10 microns

lines ap-

changed significantly.

of the blue oxide was less than about

in every case was shown by a simple calculation

ot

- 24 the maximum X-ray absorption

in this layer that would be conot the ~ tungsten dirfraction

.siatent with the large intensities

peaks observed from samples having the blue oxide in place on

the tungsten

substrate.

It should be noted that it was observed that the tungsten

sheet used had a rolling texture suoh that cube poles were

roughly perpendicular

to the faces of the sheet and that pos-

sibly a texture in the blue oxide was indicated by the nature

of the lines observed.

However an epitaxial relation has not

been proven and further work is needed on both the structure

and epitaxy of the blue oxide.

E.

Summary of the Data

Rates:

Although

examination

shows that neither a parabolic

to express the results

ly short oxidation

oally represented

of the results for tungsten

or linear law alone is adequate

obtained, it is clear that for relative-

times the amount of oxidation may be emperlby a parabolic

equation of the form

[f'omj2 = k2t

Where the constant

(1)

k2 is given by an Arrhenius

-Q,2

RT

equation

(2)

in which the constants were found to have the values:

Figure 8)

(See

- 25 log

Q,2

=

k02

=

,

1.5

~

1.1 (g2 em ~4 sec -1)

:I: 6, 000 . calories,

4.5,000

These values check reasonably

calculation

Dunn(lO)

well with those obtained by

from the data of _Gulbransen and Wysong(15)

at temperatures

Figure 23.

and Wysong's

=

in Gulbransen

Their data yield:

= 3.6 (g2 em -4

log k02

Q

up to 85000 as plotted

and

see -1)

52,500 calories

Dunn's data show a substantial

deviation

from an Arrhenius

plot in the range 850 to 900°0 which was not considered

tail in the present

of irregularity

investigation

at 900°0.

in de-

but there is some evidence

His results are 'in general agree-

ment with the present work as can be seen from Figure 8.

The data of both Dunn and Gulbransen

over sufficiently

short oxidation

times that the parabolic

approximation

would be expected to hold.

the parabolic

approximation

correspond

to a constant

time period

for which

as the temperature

The range over which

holds may be seen from Table I to

amount of oxide formation.

the parabolio

(and the oxidation

rate) increases.

times it appears that the

may be represented

by a linear equation

of the form:

--AoLlm = kIt

+

Hence the

la~ may be applied decreases

In the limit of long oxidation

amount of oxidation

and Wysong were taken

0

(3)

- 26 where the constant kl 1s given by an Arrhenius

equation

(4)

in which the constants were found to have the values:

(See

Figure 9)

log

Q,l

=

kol = 0.5 .i: 0.5 (g cm-2 see -1)

30,500 calories ;I: 2,500 oalories

The constant c is added to account for the initial period

during which the linear equation cannot be applied.

at long oxidation times are of limited praotical

the pronounced

These data

value due to

effect of test conditions on the rates observed.

However where conditions were ac~urately duplicated

the data

were easily reproducible.

Oxides:

The principal

oxide found on tungsten was - - W03

in a porous powdery form with a measured apparent density

roughly

70 per oent of the X-ray density regardless of the

temperature

at which oxidation was carried out.

had a yellow or chartreuse

This oxide

color and appeared from its form to

have grown outward from its inner surface rather than having

been formed by combination

outer surface.

of metal and oxygen atoms at its

At room temperature,

at least, this oxide was

porous.

Another

oxide of uncertain

structure and ohemical composi-

tion called here the "blue oxide" was found tightly adhering

to the tungsten.

acteristic

It did not have a diffraction

pattern

char-

of any of the known tungsten oxides but is a distorted

- 27 torm ot one of the higher oxides, probably

positive

max~m

identification

thickness

beginning

F.

nW401l".

is not at present possible.

However

It had a

ot(lO microns and was formed rapidly at the

ot the oxidation.

Mechanism

The rate dependence

Transitions

trom a parabolic

noted in the literature

other rate law.

observations

observed in this ease is not uncommon.

to a linear rate law are usually

as small deviations

from one or the

However in the present case supplementary

of the details ot occurrence

a basis tor a more quantitative

of the oxides suggest

analysis.

It was observed that two oxide layers appeared on tungsten,

one, the blue oxide, formed quickly and then did not increase

greatly in thickness,

and the other, the yellow oxide,

appears as an outer porous layer which continues

ly during the entire oxidation period.

ficient-',that it probably

passage

d

W03,

to grow rapid-

Its porosity

is suf-

is not much ot a barrier tor the

of oxygen molecules.

Noting that the rate of oxidation during the first stages

ot oxidation approximates

a parabolic

rate equation and that

this rate is observed before the yellow oxide has tormed a

complete

surface layer, we assume that diffusion

blue oxide controls its own formation rate.

the porous

assume,

through the

Then noting that

yellow oxide forms outside of the blue oxide we

on the basis of the discussion

of the previous

section,

-

28 -

that the yellow oxide torms from the blue oxide process without further oxygen absorption

in weighable

assume that the rate of transformation

yellow oxide is constant.

amounts.

We ne,xt

of the blue oxide into

This is enough to establish the

basis of a general model for a mathematical

analysis to which

we next prooeed.

Mathematical

Analysis:

of two successive

Consider the case of the formation

oxide layers on a metal during oxidation

where the inner layer is protective

so that diffusion through

it oontrols its rate of formation.

Then if the outer oxide

layer is not protective

formation

due to (say) porosity

by transformation

constant.

its rate of

from the inner layer may be assumed

These rates may be expressed in terms of the weight

of oxygen per unit area in each layer as follows.

y

= amount

Let:

of oxygen in the barrier layer per unit area

at time t

z

= amount

of oxygen in the outer (porous) layer per unit

are~ at time t.

Then

g~

=~

dz

= bf

dt

(1)

- b

where f is the ratio of the oxygen content per gram atom metal

in the outer layer to that in the inner layer and a and bare

appropriate

constants.

previously

by Lorier(31)

These equations have been proposed

tor the oxidation

of Cerium.

29 The units of a are g2 cm-4 sec -1 and bare

Integration

(1) and ( 2) yield

of equations

1[

n

1

1-:

g cm-2 sec-1•

j

b

- a

Y

l'

::

b2

a

t

(3)

and

=

z

A particular

(4)

bft

characteristic

of this model is that the inner

oxide layer reaches a maximum thickness in the limit t -..

eX)

The limiting value of the weight of oxygen in the inner layer

turns out to be

= ~

y (maximum)

(5)

The over all weight gain per unit area which is often

measured in studies of oxydation kinetics may be expressed for

this ease as:

Am

A

=

Y'

+

Z

(6)

where y and z are functions of t determined by equations

(3)

and (4).

In order to test the validity of equation (6) it is necessary to obtain a plot of ( A m/A) against t for comparison

with experimental data.

(3),

(4)

and (6).

This may be done by using equations

First we note that in equation:..(3) the

constants a and b are so arranged that they appear as dimensionless groups with the variables; therefore, equation (3) may be

represented

graphically

in a plot independent of particular

- 30 values of a and b.

Equation

(3) establishes a relation be-

groups byja and b2tja.

tween the dimensionless

Thus we may plot

-In (1 - b y) versus b

a

which is a particularly

2

a

t

convenient form as will become appar-

ent.

This has been computed and appears as Figure 10.

It

should be pointed out that on a logarithmic

scale this 18

very nearly but not quite a straight line.

Combining equa-

tions (~, (3) and (4) leads to the useful form for the weight

gain per unit area,

Ii:

= - ~

In (1 - ~ y)

+

b (f - 1) t

(7)

the term In(l - b y) can be obtained as a function of t

a

directly from Figure 10 if the values of a and b are known.

The significance

of the oonstants a and fb is seen by observ-

ing the limits approached

by equations

(1) and (2):

(8)

The constants a and fb are associated with the parabolic

linear oxidation rate constants by the relations

and

- 31 (10)

(11)

as may be seen by comparison with equations

(1) and (2) of

Section I.

The relations

(10) and (11) may be utilized

values of a and bf from experimental

oxidation

times if a sufficiently

sidered.

However,

data at snort and long

large time range is con-

other independent

chemical compositions

information

such as the

of the two oxide layers must be known

to obtain a value tor t independent

Utilizing

to obtain the

of b.

(3) the thiokness of the inner oxide

equation

layer may be computed as follows:

d

=

tJ -t-

where d is the thickness

y(t)

(12)

in centimeters,

K .is the formula

weight ot the inner oxide, X is the number of oxygen atoms

per formula and

e

is the inner oxide density in g cm-3•

the lim1 t as t.....

OO a maximum thickness

seen from equation

d(maximum)

is approached

In

as is

(5); namely

:: !. ~

b

lOA

l

~

Comparison with Experiment:

:'k2

H

(13)

2kl l6X ~

The oxidation

of tungsten

in the range 700 - 1000°0 appears to be rather well described

by this model.

If the observed values tor kl and k2 are used

- 32 and f is approximated

by unity (see below), a set of calou-

lated curves of weight gain versus time may be calculated.

The results have been plotted along with the measured oxidation curves in Figure 11 where it is seen that the agreement

is good even for very small oxidation time where plotting

logarithmic

coordinates

amplifies

about equal to the experimental

on

the deviations which are-

error.

However,

tions suggest that either there are deviations

the devia-

trom this

model in the thin film range just as is often observed tor

cases where the parabolic

k2 are not quite right.

an additional

rate law applies or the values of

At 900°0 it appears that there is

complication

the nature of which is not clear.

The caloulated maximum thickness according

about 5 microns,

layer according

by micrography

to equation

and rapid initial growth of the inner oxide

to equation

(13) agree with the observations

and X-ray absorption.

The value of t chosen is not entirely arbitrary

the microscopic

observations

and X-ray diftraction

a hint that the inner oxide is probably

nW40111.

(12),

since

data give

similar to WO) or

The maximum possible range ot t in this case is

trom 1.0 to 1.09.

The shape of the calculated

curves is rather insensitive

to variation

range, so it remains tor an independent

the composition

oxidation

ot t within this

determination

ot

of the blue oxide to deoide the proper value

of t to use tor tungsten.

- 33 G.

General Discussion

It has often been observed during studies of the oxida-

tion of a pure metal that for a portion of the reaction

period one of the simple rate laws is followed

that eventually

there is a transition

This observation

has been discussed

to a different behavior.

in the literature

many specific cases have been olarified.

and

In particular

has been observed that quite otten a.parabolic

plies initially but eventually

closely but

rate law ap-

there are deviations

beoomes evident that there has been a transition

until it

to a eon-

stant oxidation rate, that is, to a linear rate law.

been shown above that tungsten

from a parabolic

formation

during oxidation,

any irregular

inoluding the transition

to a linear rate law may be explained b7

of blisters,

ing to acoelerated

suggestion

It has

shows this behavior.

Evans (l2) has suggested that practically

rate dependence

it

flakes, or fissures in the oxide lead-

and irregular

oxidation.

Following Evans'

one assumes a suitable rate of formation

of mechan-

ical defects in the oxide, notes that in real cases measurements of oxidation kinetics yield only an average rate over

all parts of the specimen and thus transition behavior

any form is explained.

the results

Undoubtedly

this approach

of

explains

observed in some cases in the literature.

On the other hand there are data in the literature

cases where the transition

for

of rate law occurs where more than

- 34 one oxide is ~ormed.

One oxide may be a dense protective

oxide and the other may tend to ~orm in a porous powdery layer.

In particular,

temperatures

Loriers(31)

has reported this ~or oerium at

around 60°0 and his results have been con~irmed

by Cubicciotti(8)

up to 125°0.

Here the two oxides occurring

are Oe203 whioh is dense and Oe02 which 1s porous. Loriers(32)

has also ~ound this transition behavior and two oxide layers,

one porous and one non-porous

tween 140 and 240°C.

on uranium at temperatures

be-

Similar transition ~rom a parabolio

to a linear rate law have been reported for a number of othsr

metals but in most cases the nature of the oxides occurring

is not certain and other complications

appear.

In the present research a detailed mathematical

description

has been worked out for transition behavior due to formation

o~ two oxides one o~ which is porous, and the results have

been compared with the observations

able that this mathematical

cases too.

Loriers(39)

o~ this mathematical

on tungsten.

description

has previously

It is prob-

applies to these other

suggested the essentials

analysis in discussing

the'data on cerium.

He has also suggested that the reason the outer oxide becomes

porous is that its specific volume

(per mole of metal) is

less than that of the underlying porosity-free

oxide.

Whether

this is true tor tungsten is not clear due to the difficulty

o~ identifying

the underlying

oxide with real certainty.

-35 The oxidation o~ tungsten seems to be rather more complex

than either Scheil or Dunn anticipated

although the data ob-

tained in the present work is in good agreement with theirs.

In the limit o~ long oxidation times Soheil's conclusion that

a constant rate is reaohed is oorrect and in the limit of

short oxidation times Dunn's conclusions

rate law holds is correct.

that the parabolic

However, it appears that diffu-

sion through the inner blue oxide 1s the rate limiting step

in the reaotion and the transformation

ot this oxide into

the yellow oxide leads to the special rate law derived here.

- 36 -

~

~

G>

.p

CXl

~

~

CH

0

m

a

eM

H

0

~

<3:

0

r-I

M

M

H

H

M

0

0

l.t"\

0

0

0

0

en

.,;

s::

oM

0

:l

eM

H

0

G>

.s:::

.::r

1

0

r-I

H

H

H

H

\I)

0

0

0

0

0

0

\I)

\1"\

('f"\

N

..::t

r-I

0

r-I

H

H

H

H

H

\I)

U\

.:t

0

r-I

0

0

rl

l.t"\

0

N

0

0

rl

l.t"\

r-I

Q)

..:l

ID

CD

I

I

0

Q)

0

r-I

M

H

H

0

0

0

0

N

r-I

oM

.p

oM

H

ai

r-I

::sbD

..:t-

.::t

.::t

I

I

r-l

.0

-

0

r-I

.::t

I

I

0

0

~

..:)-

I

r-I

r-I

0

~

::t:

.:t

..::t

I

r-I

oM

V'\

...:;t

t

<0

I

0

0

~

.::t

~

H

oM

-=l"

I

I

0

0

H

r-I

~

0

0

r-I

l.t"\

~

.:::t

0

co

..::t

I

I

r-I

0

r-I

H

H

0

0

0

l.t"\

U'\

(t"&

r-I

0

H

s::

.p

H

oM

.p

~

~

.::rI

.:t

I

I

r-I

~<Co

s::

0

.::t

I

r-

~;

~

c-

~

E"'-

I

I

'"I

I

~

\t)

I

I

r-I

M

r-I

'-0

1

I

N

r-I

r-I

r-I

M

r-i

r-I

0

r-I

H

H

H

H

H

H

H

H

H

H

~

~

•

'-0

('t\

,(\I

0

\1"\

C'-

\1"\

CO

«)

(t"&

\1\

f'-

r-I

r-I

0

r-I

t-

I

I

0

C""\

\l)

0

•

(f"\

0

•

0

0

•

•

..::t

0

(t"&

•

(t"&

•

U'\

0

•

0

•

0

+:'

•

E-t

J.t

.::r

0

CH

-;

I

..::t

I

.::t

..::t

I

0

r-I

0

r-I

r-I

0

r-I

s::

H

H

H

H

.p

0

0

0

U)

.p

as

s::

0

N

N

CXl

V'\

0

V'\

'.;2-

..t:

1

0

I

0

~

.::r

.::t

I

I

rd

CD

.,;

r-I

.p

.p

~

:::s

~

as

CD

J..e

0

r-I

r-I

0

r-I

H

X

H

H

0

0

0

.p

'"

r-I

0

V'\

r-I

N

m

N

C\l

N

0

0

cd

N

0

G>

.p

~

as

IX:

~

I

0

r-I

s::

H

.p

V)

a

oM

C\1

oM

•

.,...

H

N

::r:

.p

oM

.p

f:iI

H

~

cd

0

cd

r-i

::sbD

Q)

~

~

H

0\

CO

Q)

r-i

r-I

M

•M

H

be

H

I

0

U\

•

C\l

~

QS

::s

I

0

0

t-

I:'I

0

I:'I

1

0

0

s::

oM

0

r-I

r-I

r-I

r-i

H

H

H

H

H

0

0

0

(""\

('t\

~

(""\

(t"&

r-i

r-l

t'-

t'-

Q)

~

H

H

I:'I

•

•

•

•

•

•

•

s:::

&!

'D

t'-

0

0

0

t .:::t**r-I

~

r-I

r-I

**N

r-I

0

0

0

0

\0

0

0

•

~

Q)

E-t

I:'-

0

t'-

0

0

t'-

0

0

C'-

0

0

co

0

co

0

~

0

0'\

Q)

N

.....

rd

oM

~

as

as

cd

I

0

.p

I

Q)

bO

rd

Q)

Q)

~

J..e

as

..:l

* •*

0

z

rd

0

r-I

C""\

r-I

M

0

0

0

0

0

0

r-I

M

H

H

~

8

~

al

CD

rd

oM

~

J"

0

\-t

CD CD

rd'dll

::s

.p S

QS

r-ita

£'-

I:'-

•

C"'\

0

as

C)

~

~UJO

VClS..-t

r-f

CIS

0

CD

to

CD

0

rd

reS

s::

**rd

~ .-ICD

rd

""

H

o r-IP

O~rd

Q)~O

::S~

r-f

~

.-fO

~

CDm

~.a

CD

at

..... 0)

Q)

=

CD

s::

rdrd

CO

~

~

,q

Q)

.p

CD

s::

0

I'd

eMtd

><CD

O~

~

IX)

rd

Cl)

CD

oM

::s.

r-I

ClS~C)

.pO

"""

0

>I

CD

.-f,c

.-fO

:s:~

om

as

p

as

A

s::

a

oM

p

as

()

H

CH

CH

ori

A

ai

Sot

I

><

rd

s:::

H

~

~

CD

m

()

~~

cd

r-I

0

m

s::

G>reS

.p

~

~~

C'-I:'-

•

~

0

r-f

-~

~

~

ex>

eX)

'-0

r-I

r-I

31

~I

~r-ir-f

0

0

N

•

C"'\

'-0

N

C\i

•

.::T

..::T

N

'-0

r-t

•

N

V'\

N

.

N

'.()

r-i

-

•

N

-

•

N

rtJ

-

.

N

• H

M,o

~~

r-i

r-f

r-f

0

r-I

r-i

-

~C\lN

-

.

C"'\

'-0

N

........

• • •

o 0 (f"\

.-; 1:'-'-0

(W"\~(\J

COCO~(\J~~gCO(f'\N~t'-nr-lNr-f~"'n"'r-I~~"'~M~~'U"\~

.::TC\lNCOt'-~

n~No~"''''\t'\V'\~..::l"~~C''''\HOOOOO~~eX)co

n

.. . ..... ......... ... ... ... . .. ..

C'--C'--\t'\~C"'\C""\C"'\~(W"\C""\C""\NNNNNNNNNNNNNNNNMM.-fr-l

OOOr-iOOr-fr-lOOr-l.-fr-fO.-fNr-IOOOOr-ir-iOr-iOMMONN

r-IOr-fONOr-fONr-fr-iNONNr-Ir-IC"'\O(",,\r-INn~ON~~~r-IO

Or-fOOONOr-ir-lNr-IONNr-fNNo(",,\r-IC""\NoNC""\~M~OOr-f

C""\

a:>

•

C\i

r-I

.

N

o

r-I

r-I

N r-f 0

~

co

nC\i

@

00

NC"'\

No

NV\cr\CO'-OO

\t'\..::l" (f'\ N ~ ~

r-i

- - --

• •

C"'\

'U"\

r-Ir-I

r-f'D

~

r-f

•

r-f

--

•

0

-@

.....,

V'\Ot't'-

~

~

c::

1!

.p

~

CD

.s:t

H

.p

CIS

~

IS

eM

~

•

CIS

CD

CD

m

C)

..-f

~

.p

s::

eM

C)

CD

s::

H

CD

Q)

'\-t

\-t

- 37 -

•

a:a

s::

CD

r-I

eM

.p

CD

m

0

eM

r-f

.p

co

b

m

s:::

H

S

Q)

s::

.....

~

CI)

.t::

~

.p

~

,c

co

H

EJ

0

~

~

s:::

'E::s

Q)

H

H

In

CD

H

reS

CIS

0

~

r-I

rd

as

:>

r-f

::s

CD

..

s::

bO

CD

..-t

td

eM

r-I

H

H

CD

co

.-I

CIS

rd

•

M

.p

....eM

::s

01"")

to

eM

()

..-f

~

:>

ClS

~

.p

rd

as

~

fx1

E-t

0

Z

••

CD

0

..-t

::t:

E-t

tIl

r-I

•

*

<

.p

.p

CIS

~

r-I

I:."-

Q)

rd

~

.0

CD

.p

ai

IS

.p

..-t

H

0

A

~

~

~

M

0

..

CH

CD

::s

r-f

~

•

to

M

eM

G>

rd

~

QS

0)

0)

0

~

0

.Q

.p

~

0

~

~

C)

.-f

O!!~~~M~

~I

~o~

.

~...i...i.-i.-i...i....lr-i,..i.-i

-

co

•

r-i

'\0

•

~

0

0"\

r-I

('l

t'C""\

0

0

a:>

0

.

(f"\

0

~NO'.

Nr-I~

• •

r-Ir-IO

.p

.-f

r-f

•

.-f

'U"\V'\ V'\

~a:>.:::T

..•

r-i

r-l'U"\

t'-o",

• .p

r-f

0

a:> co co t'- ~ t'- '"

• • • • • •

.-f.-fr-ir-l.-fr-l.-fr-l.-fr-f

Or-f~NONC\1r-1C\1N

OC""\

r-IC'"\C\lo(",,\C\J(""\

.:tN(""\r-I(f"\ONC""\NO

co

\l\

•

r-I

o

o

N

><

o

o

><

o

'\13~n1 liNn

~3d NI'\1~ IH~13M

- 39 o

o

0..

N

Z

tzl

E-i

N

(J

0

0

0

f'-

(J

0

W

a::

::>

t-

«

a::

w

a..

~

0

tW

~

~

a

Z

a

(X)

H

8

~

c:4

(f)

lOf'-oo~mlO

0

~~~~~~

0

z

(J

W

.....J

(f)

0

~

~

>-7

;:J

8

0

0

0

Z

(])

~

f'-I'-I'-I'-OOOO

0

a::

((.)

000000

000000

t-

::>

c.,

z

w

z

0

0

0..

0

x.e+(1)O

(f)

0

0

0

w

~

lO

t-

z

~

a

~

~

8

z

a

~

~

E-t

A

0

P:l

«

~

~

t0

0 x

0 0

0

~

H

0

E-i

0

~

At

(J

~

0

z

0

0

H

~

(X)

0

0

0

N

~

.

0

H

~

o

o

(X)

(0

o

LO

o

N

o

o

o

- 40 100 x 10-3

90

.IOOO°C

80

./

I

i

70

N

I

E

u

C'

60

/

0:

<X

<X

I.&.J

t-

-+

/i

50

z

:::>

-t+

0:

-'-

I.&.J

CL

40

/

z

-

.+

,~

I