TITLE: INSTITUTION:

advertisement

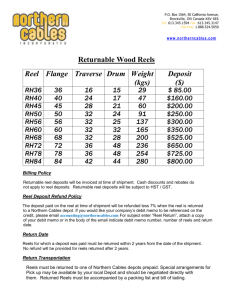

TITLE: Proposal for the Improvement of MTS Reels for Cost Efficiency INSTITUTION: AWTA Ltd., 70 Robertson St, Kensington VIC 3031 SUPERVISOR: Laura Walker RESEARCH FOCUS Agricultural, Horticultural & Materials Testing RESEARCH BACKGROUND Currently, MTS tuft reels for staple length and strength testing are shipped from Launceston and Fremantle to Melbourne on a per kilogram basis. There are some problems with the current MTS reel design: it weighs more than is desirable and the disc material and flywire are prone to breakages. Therefore, AWTA would like to explore ways in which the weight of MTS reels might be decreased while simultaneously increasing the strength of the reel’s components. This could either be by replacing the current materials with more lightweight alternatives, or by a novel approach to the transportation of wool tufts. An empty reel with wire currently weighs approximately 3kg. Alone, an empty reel weighs approximately 625g, meaning that the flywire accounts for most of the weight of each reel at circa 2.4kg. As detailed in Table 1, approximately 1300 reels are shipped to Melbourne on a per kilo basis each year. Each of these reels must be returned empty to their origin. Full reels are shipped overnight, while empty reels are shipped using regular post, hence the large difference in cost. Table 1: Costs of Shipping MTS Reels (excluding wool) Cost of Shipping to Melbourne ($/kg) Cost of Return Shipping ($/kg) Number of Reels Shipped Annually Cost of Shipping per Annum Launceston Fremantle $2.08 $0.72 600 $5,040 $4.58 $1.53 700 $12,831 Total $17,871 Reels from other areas such as Queensland and New South Wales are shipped by volume, rather than weight. In addition to the considerations of weight, the new materials used must be either durable or cheap enough to dispose of after use. Currently, the wire using on the MTS reels is prone to tearing and the plastic end discs of the reels are easily broken (see Table 2). Table 2: Cost of Reel Replacement Cost of Replacement (each) Frequency of Replacement (per annum) Cost of Replacement (per annum) Wire Mesh $39.09 263 $10,281 Plastic End Discs $5.95 595 $3,540 Spindles $4.50 262 $1,179 Clips $1.07 350 $375 Total $15,374 1 Version date: 2 October 2013 It is therefore important that the most cost effective materials be chosen, as each decision will have to be financially justifiable in terms of savings. Table 3 shows a projection of possible savings to be made in changing the reel design. Table 3: Potential per annum savings if costs can be reduced by x% Shipping (to Launceston and Fremantle) Reel Component Replacement Total potential savings Current Costs (per annum) $17,871 $15,374 20% $3,574 $3,075 $5,094 40% $7,148 $6,150 $10,188 60% $10,723 $9,224 $15,283 80% $14,297 $12,299 $20,377 RESEARCH PROJECT PROPOSAL The purpose of this project is to find a more lightweight and durable (or disposable) alternative to the current MTS reels AWTA uses. This may have a two-fold benefit, in reducing the costs of shipping and reducing the costs of replacing broken reels. The student will research and select a suitable and cost-effective replacement for the current MTS reel. The student will then write a report detailing the reasons why they have selected the materials, including a detailed cost/benefit analysis and a timeline of when tangible financial benefits would be received by replacing current MTS reels with the new design. Additionally, they should locate possible sources for any new materials. This project will allow a student to test their ingenuity as well as give them real life research and business experience, including report writing and cost/benefit analysis. Possible Directions While ultimately it will be the student’s responsibility to determine what direction would best suit this project, AWTA have come up with a couple of possible directions. Basically, either the existing reel will need to be modified to fit the requirements of this project, or the reel will need to be substituted with an alternative tuft container. For the first of these alternatives, a new bobbin material and, more importantly, a replacement for the fly wire might be sourced. Perhaps the circular ends of the reel might be discarded and replaced with more durable, metal alternatives which are fixtures of the MTS machines themselves, and are not shipped with the reels, instead being used simply to ensure the winding of the reel happens evenly. The second direction leaves the student with a lot more scope for change, but requires that some consideration be given to how the tufts will be conveyed from the MTS to the new reel substitute. Some suggestions for a suitable reel replacement are: • Disposable plastic bags (saving on return postage costs) which might be created by laminating the edges of two plastic sheets together with the tufts enclosed, • Shipping the tufts in plastic boxes (which has the disadvantage of making it difficult for staple prep workers to extract single tufts) or • Using stackable trays for tufts, thus tufts might be boxed and packaged in a similar way to eggs, on layered trays. 2 Version date: 2 October 2013 Trials Once a decision is made, the next phase is trialling the new reel substitute. This is optional and depends on the availability of the student. Between the two trials, the reel substitute will need to be either created or purchased. The student will have already demonstrated that the reel substitute results in considerable savings, and now the substitute needs to be trialled in the laboratory. MTS operators and staple prep workers will trial the replacement and give their comments on its practicality and functionality, perhaps offering suggestions for improvements also. The handling time will be monitored and compared to the time expended using the traditional reel. The student will write a report, recommending the implementation of the new reel substitute if applicable or suggesting further modifications to the design. NUMBER OF STUDENTS: Two PLACEMENT The ideal student will studying in the areas of physics and/or materials science. This placement will based in the AWTA building in Kensington. There is flexibility for attendance time; placements can be undertaken either full-time or part-time (total placement time of 80 hours) but full-time placement is preferred. Placement start time will be during the upcoming mid-semester break (preferably July 2014), and an allowance of $25 per hour (payable by AWTA Ltd.) will be available. Applications will be accepted up to June 27th, 2014. Successful completion of the placement confers eligibility for the Monash INV1000 Passport unit. 3 Version date: 2 October 2013 Science Industry Placement Program Application Form For more information visit http://monash.edu/science/current/undergraduate/getting-the-most/sipp/sipp-main.html All applications to be lodged in electronic form only, emailed to sci-sipp@monash.edu Personal details - Please type or write legibly Student ID number Surname Given Names Date of Birth / / Postal Address for correspondence Student email address @student.monash.edu Home Phone number Mobile number Course details Course Name Course Code Major Course Start Date Expected completion date Minor Current Year of Study Project details Industry partner name AWTA Ltd., 70 Robertson St, Kensington VIC 3031 Project title Proposal for the Improvement of MTS Reels for Cost Efficiency Dates available Working hours available e.g. 6 January – 6 March 2014 e.g. 9 am – 5 pm daily Meeting placement requirements What units have you completed that will make you a suitable candidate for the project? What attributes do you have that will make you a suitable candidate for the project? 4 Version date: 2 October 2013 Supporting documentation (please attach following documents with your application and tick box below) 0 Curriculum Vitae of no more than 3 pages. 0 Statement of results (download from WES--official versions are not necessary). Eligibility Eligibility Criteria To be selected for the Science Industry Placement Program, you need to meet the following criteria: Be currently enrolled in a Faculty of Science course, must have completed at least 48 credit points and have no more than 48 credit points remaining in the course; and Demonstrate a preparedness and capacity to complete a minimum of 30 hours or a maximum of 80 hours placement at an industry partner organisation without compromising their other science studies; Demonstrate work readiness (i.e. we are looking for evidence of personal qualities which equip you to function appropriately and autonomously in a professional work environment). Selection Criteria The selection criteria are the ‘best fit’ match between your enrolled course, units you have completed, interest and experience with the particular project requirements. The industry partner has the final decision. Applicants who are closer to completing their course will be given priority if they meet the 'best fit' match. Please visit the projects section to view the projects available. The webpage will be updated as project proposals are submitted by the industry partners. Privacy The information on this form is collected for the primary purpose of applying for the Science Industry Placement Program which includes deciding whether the application will be granted and sending related correspondence. If the form is incomplete, it may not be possible for the Faculty to process the application. The information provided by the applicant in this form, curriculum vitae and academic may be provided to the industry partner of the project in the event that the student is provisionally matched with that industry partner in order for the industry partner to assess the application. All information for the application of the Science Industry Placement Program is managed in accordance to the University’s Privacy Policy. If you wish to access or inquire about the handling of your personal information contact the University Privacy Officer: Privacyofficer@adm.monash.edu.au 5 Version date: 2 October 2013 Applicant’s Declaration I am enrolled in a course belonging to the Faculty of Science and have completed at least 48 credit points and will have no more than 48 credit points remaining to complete YES / NO I can commit to completion of a minimum of 30 hours or a maximum of 80 hours as required by the industry partner without compromising my studies YES / NO I have addressed the selection criteria including my suitability and match to the agency/ies and the project/s offered by those agencies in my cover letter YES / NO I understand that no salary will be paid for the industry placement and Monash University holds no responsibility for any allowance agreement between the industry partner and the student. YES / NO On signing the Science Industry Placement Program application form I agree: 1) That I meet all of the eligibility criteria for the Science Industry Placement Program. 2) To represent Monash University in a manner that does not compromise the integrity, reputation or relationship of the University and Faculty with the participating industry partners in any way. 3) That information provided by me in this form, my curriculum vitae and academic transcript may be provided to the industry partner in the event that I am provisionally matched with that industry partner in order for the industry partner to assess my application. Student Declaration I declare that the information provided on this form and the information given to support my application is correct and complete. I acknowledge that Monash University, Faculty of Science reserves the right to vary or reverse any decision on the basis of incorrect or incomplete information. Student signature Date Received by (print) Date 6 Version date: 2 October 2013