Document 11076993

advertisement

W.I.T LJSH

DEWEY

HD28

.M414

The

Economic Lot Scheduling

Problem:

Heavy Traffic Analysis of

Dynamic Cyclic Policies

Stochastic

David M. Markowitz. Martin I. Reiman and

Lawrence M. Wein

#3863-95-MSA

October,

/

1995

MASSACHUSETTS INSTITUTE

JAN 23

1995

THE STOCHASTIC ECONOMIC LOT SCHEDULING PROBLEM:

HEAVY TRAFFIC ANALYSIS OF DYNAMIC CYCLIC POLICIES

David M. Markowitz

Operations Research Center, M.I.T.

Martin

AT&T

I.

Reiman

Bell Laboratories,

Murray

Hill

Lawrence M. Wein

Sloan School of Management, M.I.T.

We

nomic

consider two queueing control problems that are stochastic versions of the eco-

lot

scheduling problem: a single server processes A^ customer classes, and com-

pleted units enter a finished goods inventory that services exogenous customer demand.

Unsatisfied

demand

is

backordered, and each class has

demand

tribution, renewal

problem, a setup cost

is

its

own

general service time dis-

process, and holding and backordering cost rates. In the

incurred

when

the server switches class, and the objective

first

is

to

minimize the long run e.xpected average costs of holding and backordering inventory and

incurring setups.

the objective

is

to

The setup

cost

is

replaced by a setup time in the second problem, where

minimize average holding and backordering

restrict ourselves to a class of

dynamic

cyclic policies,

where

costs. In

both problems we

idle periods

and

lot sizes

are

state-dependent, but the

N

heavy

these scheduling problems are approximated by diffusion con-

trol

traffic conditions,

in

problems. The approximating setup cost ])roblem

dynamic

lot sizing

policy

procedure are derived

to

must be served

classes

is

found

in

for the setup

a fixed sequence. Under standard

is

solved exactly, and the optimal

closed form. Structural results and an algorithmic

time problem.

compare the proposed policy and several straw

A computational study

is

undertaken

policies to the numerically

optimal policy.

October 1995

computed

We

consider a queueing system scheduling problem that

commonly found

and multiple customer

product has

its

own

we assume

is

that an

Each product has

available.

the inventory, and unsatisfied

We

which

classes,

will

be referred to as products. Each

general service time distribution, and completed units are placed into

a finished goods inventory;

is

motivated by a situation

make-to-stock manufacturing. The system consists of a single server,

in

or machine,

inventory

is

demand

is

ample amount of

(costless)

own renewal demand

its

raw material

process that depletes

backordered.

analyze two variants of the scheduling problem. In the setup cost problem, a cost

incurred

when

machine switches production from one product

the

setup time problem, a random setup time

incurred

is

when

We restrict ourselves to the class of dynamic cyclic policies,

to another; in the

the server switches product.

where each product

is

serviced

once per cycle and the order of production does not change. Thus, the server has three

scheduling options at each point in time: Produce a unit of the product that

set up.

change over

to the next

problem), or remain

backordering a unit

idle.

product

in the

Each product has

in inventory.

The

These problems are prevalent

make-to-stock

mode

setup time problem

is

also less

is

its

own

in

costs per unit time for holding

objective in the setup time problem

to

currently

cycle (and initiate service in the setup cost

the long run expected average inventory costs (that

objective in the setup cost problem

is

is,

is

to

minimize

holding and backorder costs); the

minimize the average inventory and setup

many

costs.

industries because facilities that operate in a

typically produce standardized products that require setups.

is

amenable

more

realistic

to analysis.

than the setup cost problem

The setup

and

in

cost problem, however,

most

is

The

situations, l)ut

relevant for

manu-

facturing systems that have embraced just-in-time (JIT) manufacturing and internalized

their setup times; that

is,

they incur significant material, labor and/or capital costs to

achieve essentially instantaneous switchovers.

This dynamic scheduling, or

economic

lot

lot-sizing.,

problem

scheduling problem (ELSP), which

is

is

a stochastic version of the classic

NP-hard (Hsu 1983) and has not been

solved in general. Despite the vast literature devoted to the

by Elmaghraby 1978, and Zipkin 1991

inistic

for a list of

viewpoint has probably prevented

its

ELSP

more recent

(see the survey

references),

its

paper

determ-

widespread industrial use: The solution to

a deterministic problem in a make-to-stock setting will not hedge against uncertainty

in

future service times (e.g., machine failures) and

backorders (see the numerical results

Not

in

When

the state space

ELSP

many

costly

appears to be analytically

taken to be discrete, the stochastic

is

in

Federgruen and Katalan 1993).

surprisingly, the stochastic version of the

tractable.

demand, resulting

ELSP

(or

in-

SELSP)

can be viewed as a make-to-stock version of the dynamic scheduling problem for a polling

system, which

is

a traditional

(i.e.,

make-to-order) multiclass queue with setups. In fact,

our paper can be viewed as a companion to Reiman and Wein (1994).

namic scheduling problem

for a two-class polling system.

who analyze

The SELSP

is

the dy-

more challenging

than the polling scheduling problem, which also appears to defy exact analysis, because of

the nonlinear cost structure and the lack of an

its difficulty, this

imposed boundary

problem has been the subject of a recent

at the origin.

flurry of activity.

develops a Markov decision model for a one-product problem, and uses

heuristic for the

lego (1990)

ELSP

the

SELSP

in a

periodic review setting.

with stochastic demands that are rooted

first

Sharifnia,

it

to develop a

(1988), Gal-

lot-sizing algorithms for the

in the solution to the

of these papers considers a discrete time

Graves (1980)

Leachman and Gascon

and Bourland and Yano (1995) develop heuristic

Despite

deterministic

ELSP;

problem with nonstationary demand.

Caramanis and Gershwin (1991) employ a hierarchical approach

heuristic policies for a stochastic fluid version of the problem.

to develop

Federgruen and Katalan

(1993, 1994) develop accurate distributional approximations for polling systems, and use

these to analyze the performance of a class of periodic base stock policies for the

SELSP.

Anupindi and Tayur (1994) also consider a

and use

class of periodic base stock policies,

a simulation based approach (infinitesimal perturbation analysis and gradient search) to

obtain good base stock policies for a variety of performance measures. Sox and Muckstadt

(1995) formulate the

SELSP

tion algorithm to solve

it.

as a stochastic

Qiu and Loulou

decision process, and numerically

this

is

to the

As

(

compute

program and propose a heuristic decomposi-

1995) formulate the problem as a semi-Markov

the optimal solution in the two-product case;

the only paper to date to gain any insight into the nature of the optimal solution

SELSP.

in

Reiman and Wein, we employ heavy

traffic

approximations

in

an attempt to

make

further progress with this problem. This approach assumes that the server

busy the great majority of time

draw upon

order to meet average

in

We

the long term.

and Reiman (1995a, 1995b)

the results of Coffman, Puhalskii

the setup cost

demand over

must be

approximate

to

Their results

and setup time problems by diffusion control problems.

On

allow the analysis of the problems to separate onto two different time scales.

the

time scale over which the total workload content of the inventory varies, we solve a onedimensional diffusion control problem to determine the machine idling policy; this time

heavy

scale corresponds to the standard

compressed by the factors n and

expand time by a factor of

time

scale, the total

normalization, where time and space are

y/n, respectively. Starting with this normalization,

y/n, so that both time

and space are compressed by

workload content of the inventory

levels vary according to a fluid

the state-dependent lot sizes

in

traffic

model. Here, deterministic optimization

when

the server

is

busy.

lot sizes

is

we develop some

is

used to derive

In the setup time

derived.

derived under the fluid scaling impact the drift of the one-

dimensional diffusion process that arises under the standard heavy

In this case,

this

These two controls are decoupled

the setup cost problem, and a closed form solution

problem, however, the

on

and the individual inventory

fixed

is

\/n;

we

traffic

normalization.

structural results about the optimal solution

and provide an

algorithmic procedure to solve the one-dimensional diffusion control problem. Although

no weak convergence

no doubt that our

results are provided to rigorously justify our analysis,

we have

we conjecture

that our

results are essentially correct; consequently,

proposed policies are asymptotically

(in

the heavy traffic limit) optimal for the two-

product problems, where the optimal policies are dynamic cyclic policies.

In an attempt to both assess the effectiveness of

ize

some

of the existing literature on the

two straw

some simpler

policies

SELSP, we perform a heavy

policies that are closely related to those considered

(1993) and by Sharifnia, Caramanis and Gershwin.

and synthes-

traffic analysis of

by Federgruen and Katalan

Then a computational study

is

under-

taken that compares our proposed policies and these two straw policies to the numerically

derived optimal policy for a variety of two-product problems; several five-product prob-

lems are also examined.

The

explicitness of our results reveals a

number

of

new and unexpected

insights into

SELSP. Readers who are not curious about the

the nature of the optimal solution to the

SELSP may

mathematical details but who wish to obtain a deeper understanding of the

find

useful to bypass the heavy traffic analysis

it

and focus on

§1.8, §2.5

and

where

§3.4,

the key insights and observations are collected.

The remainder

of the paper

is

divided into four sections. §1 and §2 are devoted to

The computational

the analysis of the setup cost and setup time problems, respectively.

study

described in §3 and concluding remarks are

is

made

in §4.

THE SETUP COST PROBLEM

1.

A

Problem Description.

1.1.

products. Each product

z

=

1.2

.

.

.

,

N

single server, or machine, produces

has

its

own

general service time distribution with

service rate n, and coefficient of variation (standard deviation divided by the

The demand

for

easily generalize to correlated

pt

—

^i/Pi

Let

I,(t)

time

we say

t

at

time

depletes It(t) by one.

that this unit of

cj,,

processes; see

c^,.

respectively.

Reiman

increases

t

If

demand

a

is

is

p

Our

results

(1984) for details.

=

Yl',=i{^i/^'t) a'ld

i.

denote the number of units of product

i

and

long run average server utilization,

the utilization for product

completion of product

at

compound renewal

traffic intensity, or

is

mean)

each product follows a renewal process, where the mean and coefficient

of variation of the interdemand times are given by A~^

Hence, the

types of

A'^

[,{t)

demand

for

i

in inventory at

time

by one, and a unit of product

a unit of product

i

A

t.

i

service

demanded

occurs when

/,(/)

<

0.

backordered.

Since the scheduler follows a dynamic cyclic policy, only three options are available

at

each point

initiate

in time:

Produce the product that

production of the next product

is

currently set up, switch over and

in the cycle, or sit idle.

Because a setup

and instantaneous, the option of switching to another product and then idling

suboptimal and

will

not be considered.

The

server

resume manner, although the subsequent heavy

between

A

cost

this

cost h,

b, is

and the non-preemptive

is

is

traffic

assumed

analysis

to

is

work

in

costly

is

is

clearly

a preemptive-

too crude to distinguish

discipline.

incurred per unit time for holding a unit of product

incurred per unit time for backordering a unit of product

i.

i

in inventory,

and a

Let us also define the

cost indices

/?,

=

unit of expected

^,7^,

and

work

Without

=

which represent holding and backorder cost rates per

6,/^f,,

These indices play a key

in inventory.

the analog to the classic

1961).

b,

index

"c/^i"

in stochastic

loss of generality, the

role in

scheduling theory

our analysis, and are

(e.g.,

products are numbered so that

For notational convenience, we assume that

6/v

=

hj\!

Cox and Smith

=

we show

from that of the more general

that this restriction does not change the analysis

will often

h,.

mini<,<Arft!, so that the product with

the smallest holding cost index also has the smallest backorder cost index;

Consequently, product A^

mini<,<,v

later

case.

be referred to as the least cost product.

Because products are produced once per cycle

in

a fixed sequence, the performance

of the system depends on the setup costs only through the total setup cost per cycle,

a quantity we denote by

Of

A'.

course, the optimal sequence of products can be found

by solving a travelling salesman problem, where the "distance" between

is

given by the setup cost incurred

when switching from product

K/N

convenience, we simply assume that a setup cost

is

i

"cities"

i

and

j

For notational

to j.

imposed whenever the server

switches from one product to another.

The scheduling

policy determines the inventory process

/,

and the counting process

J,

where J{t) denotes the cumulative number of setups incurred by the server up

t.

Although the scheduling

policy,

and hence the stochastic processes

/,

to time

and J, can be

rigorously defined in terms of a sequence of starting and stopping times for each product,

we omit

this detailed specification

Our problem

because

to find a scheduling policy,

is

it

is

not required in our subsequent analysis.

which

is

nonanticipating with respect to

/;,

to

minimize

\imsup

^E\

"r J2ChJ+(t)

+ bj-it))dt

+ ^J{T)i

EC

'^

(1)

1=1

where

x'^

1.2.

described

in

heavy

=

max(.r,0) and

The Heavy

in §1.3 allows us to

traffic.

Since

and

it

=

min(.r,0).

Traffic Normalizations.

we

to precisely formulate the

traffic,

,r~

will

The heavy

compactly characterize the

traffic

class of

averaging principle

dynamic

cyclic policies

be optimizing over this class of policies, there

(more general) control problem that approximates

will suffice to describe the

heavy

traffic

is

no need

(1) in

heavy

conditions and normalizations.

The standard heavy

condition states that the server must be busy the majority

traffic

meet average demand. To prove a heavy

of time to

defines a sequence of control problems indexed by

??,

system approaches unity. Because a limit theorem

traffic limit

where the

theorem, one typically

traffic intensity of the n'

not be proved here,

will

we ease

notational burden by assuming the existence of a large integer n satisfying \/n\l

where

c is positive

and 0(1). Our recommended policy

of the heavy traffic scaling parameter

embedded

sum

the

in the finished

goods inventory

amount

/,.

If /,(/)

standard heavy

and

c,

turn out to be independent

W] denote

is

— p) =

the workload content

positive then W,{t) represents

if /,(/)

is

negative then W,(t)

of time that a continuously busy server requires to clear product

Vs backlog. The process W^

—

Let the process

of the service times for units in inventory,

represents the

I,(t)

/).

will

the

will

be referred to as the workload process

traffic scalings will

for

product

The

i.

be employed to define the normalized inventory process

I,{ni)/y/n and the normalized workload process W,{t)

=

W^int)/ \/ri (throughout

the remainder of the paper, a "tilde" denotes the unsealed version of the normalized

process).

Although the workload process

inventory

is

H',

known

is

employed

The

to hold for a

is

expressed

in

1^.

heavy

is

traffic control

in

heavy

problem

terms of the unsealed inventory process

(/i,

ial

magnitude

heavy

in the

traffic analysis,

we need

I,

=

for

i^iiW,,

traffic, will

be

into a scheduling

.

.

.

,

objective function (1) consists of inventory costs and setup costs.

a nontri\

when

more convenient

However, the linear identity

wide variety of queueing systems

for translating the solution of the

policy that

not observable by the scheduler

backordered, the normalized workload process W^

analysis than the normalized inventory process

which

is

these two costs to be of the

/,v)-

To perform

same order

of

approximating control problem. Since the inventory contents and time

are normalized in the heavy traffic control problem, the relative magnitude of the inventory

costs

and setup costs also need

to

The appropriate normalization

cost

A

is. if

traffic,

(see

in order to

achieve the aforementioned balance.

Reiman and Wein

for details) is to

reduce the setup

by a factor of n relative to the inventory costs, and consequently we leave the

inventory costs h, and

That

be scaled

6,

the setup cost

and

if

unsealed at 0(1), and define the normalized setup cost k

is

=

h'/n.

smaller than 0{n), then setup costs will be negligible in heavy

they are larger than 0(»), then they will dominate the inventory costs in

6

heavy

to be

Thus, heavy

traffic.

traffic

conditions for the setup cost problem require the server

busy most of the time, and require the setup cost to be very

A

1.3.

Preliminary Heavy Traffic Result. A

recent heavy traffic result obtained

by Coffman, Puhalskii and Reiman (1995a) provides the basis

result,

result

which

be referred to as the

will

=

only proved for the A^

is

CPR

2 case,

large.

our analysis.

for

This

result, considers a traditional multiclass (the

and

is

conjectured for

A'^

>

2), single

server

queueing system with renewal arrival processes, general service time distributions and

A

no setup times.

cyclic exhaustive polling

mechanism

each class to exhaustion and then switches to the next

notation

and

/u,

characterize the arrival process to this queueing system.

workload

Reiman

for class

/'

in the

traffic

and

A,

If

we

in the

Cd,

SELSP

to also

denote the normalized

let Vj

queue, then limit theorems in Iglehart and Whitt (1970) and

(1988) imply that the total workload process

under heavy

Let us reuse the service time

class.

and allow the demand parameters

Cj,,

employed: The server serves

is

V =

Ylv=i

K

is

well

approximated

conditions by a reflected Brownian motion on [0,oo) with drift

—

and variance

-^

See Harrison (1985)

The

process.

CPR

It

=

£^(4 + 4)-

for a definition of this process,

result allows us to obtain information

(2)

which we denote by

RBM

moves

infinitely quickly (in the

for the total

workload, the

linear path connecting points

case, the path

is

N— dimensional

On

the time scale giving

workload (V'i,...,Vyv) process

asymptotic limit) along a constant workload, piecewise-

where the server exhausts a product.

In the

two-product

the line segment from (O.V) to (V, 0); in the case of three identical

products (with the same service and

connecting the points

We make

{—c,a^).

about the multidimensional workload

provides a time scale decomposition for this system:

rise to

RBM

(0, V'/S,

demand

rates), the path consists of the line

2V/3), (V73,2V73,0) and (2V73,

0,

segments

V/S).

the crucial assumption that the time scale decomposition holds not just for

the cyclic exhaustive policy (which corresponds to a cyclic base stock policy in the

problem), but

for

more general

cyclic policies;

objections because the time scale decomposition

this

is

SELSP

assumption should not raise any

inherent in the heavy

traffic scaling.

The time

scale decomposition gives rise to an averaging principle that facilitates our

analysis in the following way:

expand the time scale

stays constant

(i.e.,

If

slow

we consider

and then

the heavy traffic normalization

down time) by

workload

a factor of x/n, then the total

and the A^-dimensional workload behaves

as a fluid

(i.e.,

moves

at a finite

rate in a deterministic fashion).

1.4.

An Overview

as consisting of

of the Analysis.

two interrelated decisions:

policy that specifies

The

CPR

useful to view the control policy

busy/idle policy and a dynamic lot-sizing

We

of the heavy traffic control problem

which measures the

total

begin by characterizing

and the well known relationship between queueing

result

systems and production/inventory systems

inventory.

is

what the server should do while working.

the busy/idle policy.

Xli=i 11'm

A

It

is

Morse 1958) imply

(e.g.,

that the system state

machine time embodied

in the

current finished goods

Furthermore, since setup times are zero, the total workload process

affected by the server's busy/idle policy, not by

how

often the server switches

products. Hence, the only reasonable form of the optimal busy/idle policy

to stay

u'o.

busy

if

< wq and

\V(t)

The quantity Wq

to idle

will often

if

W{t) >

uiq, for

The

CPR

result

Although the

only

among

for the server

the unspecified control parameter

and the one-to-one relationship between

queueing systems and production/inventory systems

W

is

is

be referred to as the idling threshold, and can be viewed

as an aggregate base stocA' level.

the total workload process

W=

the one-dimensional total workload process

is

a

RBM

(c, cr^)

(i.e.,

W{t) = wq —

on (—00. Wq] under

lot-sizing policy does not influence the total

the rate at which inventory costs and setup costs are incurred

V'(/))

imply that

this busy/idle policy.

workload

W

when W(t) =

.

it

does affect

w. Therefore,

a two-step procedure, with each step being performed at a different time scale, can be

used to find the optimal dynamic cyclic policy. In the

is

first

step,

CPR's averaging

principle

used to find the lot-sizing policy that minimizes the average (inventory plus setup)

cost incurred as the individual inventory levels oscillate deterministically while the total

workload remains constant

at w. let us call the resulting

minimum

cost c{w).

a family of deterministic optimization problems indexed by the total workload

able to construct a

dynamic

(i.e.,

workload-dependent) lot-sizing policy.

By

iv,

solving

we

are

In the second

step,

we

find the aggregate base stock level ivq that

c(ti.)

/- oo

where we have used the

minimizes the long run average cost

4e-''< ""'-"'>/''

f/u),

(3)

(7^

fact (e.g., Harrison) that

RBM

{—c,a^) on [0,oo) has an expo-

nential stationary distribution with parameter '2\c\/a^.

In §1.5,

when

§1.6.

we

dynamic

calculate the average cost incurred by a generic

The optimal heavy

the total workload equals w.

Finally, the

heavy

traffic

cyclic policy

traffic cyclic policy is

found

in

normalizations are reversed in §1.7 to obtain the proposed

scheduling policy as a function of the unsealed inventory levels and the server location.

1.5.

is

Construction of Dynamic Cyclic Policies.

to find the cost associated with

\'V(t)

=

traffic

normalization Wi{t)

w.

The

CPR

fluid scaling, W,{t)

is

=

=

N—

and the

A

is

Because idleness

stock level,

cyclic policy

we assume

is

=

\V(nt)/y/n

at a finite rate in

occur before the diffusion process

W

one cycle.

essentially characterized by the lot size for each product (or ecjui-

valently, since the analysis

cycle).

fluid cycles

suffices to analyze the deterministic behavior of

cyclic policy

factor of y/n to obtain a

dimensional workload W, moves

many

workload

Starting with the heavy

we slow down time by a

Wt{nt)/s/n,.

a deterministic manner. Because

it

this calculation tractable:

total

Wi{y/nt)/ ,/n. At this time scaling, the process W{t)

fixed at the value u\

changes value,

goal of this subsection

any dynamic cyclic policy when the

makes

result

The

is

deterministic, the length of time each product

only incurred

is

that no idleness

when

is

is

served in a

the total workload reaches a certain base

When W{t) =

incurred during a cycle.

il\

a

best viewed as a closed A^ — dimensional deterministic path in the constant

workload hyperplane J2i=i

'^'-'i

=

^'-''^

that

is,

the process traverses the

same path repeatedly,

once per cycle.

Although a cyclic policy can be specified

acterization that

is

convenient for analysis.

in

A

many

cyclic policy (or, equivalently, the closed

loop generated by the policy) will be defined by A^

and the cycle center x^

=

(

jj,

.

.

of the total workload w, but this

.

,

ways, we choose a particular char-

-|-

1

quantities:

The

cycle length t

x%). These control parameters are actually functions

dependence

will

be suppressed

for

improved

readability.

time

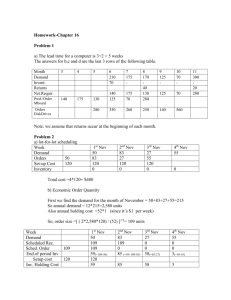

Figure

The

cycle length r

is

1:

Workload fluctuation over a

cycle.

the length of time recjuired to perform a cycle, and

is

.r^

product

Vs "center of fluctuation", or equivalently. the average amount of this product's inventory over the course of a cycle. Because the transient effects associated with initiating or

temporarily moving a cycle vanish

can be placed anywhere

We

levels

heavy

traffic

cyclic policy

when

\\'{i)

of each product produced per cycle

throughout this

=

w. For the system to remain balanced, the

must equal the amount demanded, and hence

of the time;

p,

fluid analysis, so that the server is

an arbitrary instantaneous

total

workload

w and

the work content in this product's inventory

at rate one,

and W, increases

the remaining

(1

—

at the fixed rate

p,)t time units in the cycle

the workload inventory

is

decreasing at rate

the

machine

depleted at rate

—

p, for

p,

i

is

level, as the reference point.

10

must be

servicing product

and

is

replenished

not being produced,

To uniquely determine

a cyclic policy, a reference starting point also needs to be specified.

average inventory

is

i

for

p,T units of time per cycle. For

when product

p,.

that p equals one

busy throughout the cycle. Thus,

when

is

1

we assume

cycle time r, each product

serviced for p,T units of time per cycle. Therefore,

?'s

.r'"

constant workload hyperplane.

in the

each product must be produced a fraction

i,

time scaling, the cycle center

begin by examining the deterministic behavior of the individual product workload

W, under a

amount

in the

We

the behavior of

use

.r^,

product

Readers are referred to Figure

1

for a

reinforcement of these notions.

The

center

cost of a cycHc policy can be expressed in terms of the cycle length r, the cycle

(an A^— dimensional vector) and the total workload w.

.r*^

inventory cost for product

i

per unit time, c,(r,

The average

over the cycle and divide by the cycle length.

regions depending on whether the product

and backordered or

is

is

we

if),

j-j',

=

,r^, ty)

find the average

integrate the inventory cost

cost breaks

down

into three

entirely held throughout the cycle,

entirely backordered. Figure

is

held

allows us to deduce that

1

h,x'^

c,(r,

To

if .r^

iMiz^il

>

<

-M^

if

J^< - '^'^'-'^'^

(4)

The

total

1.6.

controls:

average cost, c{t,x'',w), which includes inventory and setup costs,

The Optimal Dynamic Cyclic

The aggregate base

arbitrary

(iii)

w

is

derived

and

r, (ii)

in

cyclic policy consists of three

stock level wo and, for each total workload level

length T and the jV — dimensional cycle center

cyclic policy

Our

Policy.

three stages:

(i)

In this subsection, the

x"'.

in

u',

the cycle

optimal dynamic

find the optimal cycle center

optimize over the cycle time r

is

x"^

in

terms of

terms of an arbitrary

u',

and

substitute the derived cost function c{ui) into equation (3) and find the optimal idling

threshold wq.

The Optimal Cycle Center. We

cycle center

.r^

tion c(t,x^,w)

for

is

begin by showing the existence of a cost-minimizing

a given total workload

w and

differentiable with respect to

x"^

is

x"^

and

its

derivative

is

continuous.

If

one

=

iv,

for fixed r the cost function in

piecewise-quadratic with linear edges;

its

second derivative

ignores the constant workload constraint X]!I,

terms of

cycle length r. Note that the cost func-

ive step function.

Thus c{t,x'^,w)

is

^'i

is

a nonnegat-

convex and the restriction of the cost function to

the constant workload hyperplane determined by

w

is

also convex. This fact implies the

existence of a solution to the constrained minimization problem: Choose

c(t,x'^,w) subject to Yli=i

Now we

—

^"l

x'''

minimize

to

w-

use the cost function

in

The

to find the optimal cycle center.

(4)

total

workload constraint can be used to eliminate one variable and express the cost function

as a piecewise

polynomial function of

N—

N—

Any

variables.

1

1

components of x'^ can be

used. Over the constant workload hyperplane, the polynomial order of the

between one and two depending on whether

fluctuates

respectively.

For the gradient to be equal to zero, each of the iV

quadratic. Consequently, at the optimal

.r*-",

at least

.'V

—

1

two, with the remaining component possibly being linear.

of Ci(r,

u')'s

.rj',

-Pi(i-p,)

— or

>

|x^'|

—

1

of the Ci{t,

To

N —I

<

x*:'

variables

.rj",

u')'s

variables

Tp,{i-p,

must be

are of order

see this, suppose that

are not of order two, and let j denote the index of such a term.

some

If

we

eliminate Xj, the gradient equation can then be written as

N

=

1

1

The

have a solution only

1

ff there

are only

function at the optitiial x"

Proof: This

Cj

if

is

h,(x1)^

/

the remaining A^

linear

fact

is

and

+ b,{xX +

—

\

theu^ the linear

,

most

c,\ is

ikx

N

+

easily seen by

By

quadratic.

quadratic Cj(r,

term must

x'i

—

1

c,{t^x'j, u')'s are

(4), the

- Pn)

rp,v(l

h Nl

tradeoff between x^ and

+ xl; =

w' (with

iv'

.r^v

.r^,u')

quadratic.

+

sum

bN

,

ter'ms in the total cost

be C!\]{t,x']^,w).

examining the function

8

The

.

1

following proposition greatly simplifies our analysis.

Proposition

where

=

V

<*1

will

Y.x%w

W

T,

1

This equation

\

(

V,c

Ct{T,

+ hN

2tpn(1 -

u''

^2,^'V-6N„.

+

'N-

H

1

^;^

2

Tp^{l

-

12

p?

.ry^,

w]

— x^

for

rX\,

'N

if

(6)

pj^

.r^'

N

X^=^r

sum

along the line

into equation (6)

the derivative with respect to x%- yields

-h,

a')+c.v(T,

is

can be examined by looking at this

arbitrary). Substituting

.r,",

> w\

and taking

Since the quadratic region of

j^

that the c}uantity in (7)

than or equal to

than or equal to

for

>

x'i^j

w' or

6,

—

is

Hence, neither

bj^.

equals

b,

less

.r^

+ x% ^

of these solutions

lie in

when

solutions occurs

<

6/v for j/y

then the optimal .r^ satisfies \x%\

along the line

restricted to the region

is

=

>

If

I

'^^'^^"^^'

it

.r*^,

be

will

c/v(t,

t*-^, u»).

product

product

<

;

A^

A^'s cycle

that product A^.

from

equals

hj^j

if

>

lM|z£il.

\x1\

and

A^ are linear,

Although many

one of the optimal

components are quadratic

there

is

(or

on the

a linear cost component at the

center, or average

—

amount

of inventory per cycle,

p,)/2,Tp,(l

—

p,)/'2].

whereas

which

is

the least cost product by our indexing convention,

amounts

of

work when the

is

w

workload

total

the product

fluctuates

zero.

We now

erality, the

.T^'

greater

center can be arbitrarily far from zero. Intuitively, this fact suggests

that will hold the excess or deficit

far

is

multiple optimal solutions

in

and

restricted to the region [— rp,(l

is

/?,

follows

|

As a consequence, the optimal cycle

for

i

of the cost

border between quadratic and linear). Hence,

optimal

in (8)

jj

the holding or backorder costs are equal,

the region where products

—

LpkL^ipnI^

and the quantity

LPml^Lmi^ resulting

w' with |x^|

at least A^

/?,,

<

nor (8) can equal zero unless

(7)

w'.

—

/?Ar

|.r5v|

= w —

use Proposition

1

to find the optimal cycle center

workload constraint

Y^tJl^

x'i.

To

is

.r"-".

Without

loss of gen-

used to eliminate .r^ from the cost function, so that

find the optimal center,

we take

the gradient of (5) and set

it

equal to zero:

N-l

N-l

V,c[X;Q(r,x^u;) + c^(r,a>- ;^

At

this point,

the (A^

—

c,(r,

u;)'s

J-"',

we do not know whether

7

.r^ u.)

+

-]

=

0.

c/v(t, .r^, ly) is linear or quadratic.

l)-dimensional vector that solves (9) under the assumption that

x^ satisfies

are quadratic in

{w and r multiply

jj^.

Taking the

their vectors

-^^"^

T

-

(9)

71

(A^

—

x"^

be

A^ of the

l)-dimensional gradient, we find that

component-wise

- -72 =

T

all

Let

0,

in the analysis

below)

(10)

where

b,+h,

A

+

/?A'(1

7i

;i2)

2

2

^N+^N

=

72

(11)

- Pn)

131

pn{^-pn)

Th us.

= tA

.r^

w here

the matrix elements of

Pi(l-P.

h,

w—

Z!!^i

^

-J"?!

the optimal center:

we must

With

^

x'i

=

)

Pj(l-Pj)

hj+h,

for

«

7!^

^^^''

x'j

Y^iV

h.

^1=1

^^^ then C/vIt,

for

;

<

A'

and

x^, w)

x'^

=

Pi(i-Pi)

hi+hi

is

indeed quadratic and

»'— Xl,-/

If

-'"i-

|ft'~I2,=/

solve the multivariate gradient equation with the linear

this substitution,

2

h,

2

'15)

and

J,

;i6)

+

6,

I

+ h,

Pi(i-P()

Y^.v

^^'=1

b,+h,

Oin

If

14)

72,

are

.4

On

+ wA

7i

.rj'

-^'i^l

form of

determines

>

~rpN(l-PN)

c.\'(r, ,r^

N

lU]

equation (9) decomposes into univariate expressions of the form

- p,)

6, + h^

+

Tp,{\ - p,

(17)

T/9,(l

6,

,

x:

+ bN

if

w-

E

1

'

!

^

2

(18)

Putting the results from (14) and (17)-(18) together, we obtain a complete expression for

14

the optimal cycle center. For

i

N

<

Tp,(l-p.)

h,+h,

(

we have

+ N

if »'

ll

-

E!IT'

^^

''^^2"'''^

>

(19)

rp.jl-p,)

b,

where a,

is

The

the ith row of .4"'.

The Optimal Cycle Time.

calculus.

if "'

}N

+ h,

The optimal

Substituting the optimal cycle center

it;.

'"^^2"''''

equal to

10

—

J2i=i^

7i

+

shorthand for the region

I^^d^fMl, and case

cost function

w-

III is

E,=7'

wa,

cycle time r can be derived by simple

into (4) yields the average inventory

.r^

For

N

<

i

this cost

is

given by

(20)

72]

^P<i^-P')

2{b.+h,)

Ih J- fit)

h \L£A1:zpA -t

_u

\iJ,-t

g

is

•^?-

11

^!h_Li^T(y,

I

and

is

< -

=

Ct{T,w)

where case

a^?

component, i^,

last

cost for each product as a function of r

- e!It'

4^-6 N th^-b N

— E!Ii'

»'

^1

>

""^^^2

>

< - ''^^[-"^l

4

''^^

^^^^

III

^^ '^

l^i'~E,Ii^

Similarly, product

N\

-^i^l

^

inventory

is

f

cn{t,w)

=

Mu'-rEf=T'13^[^ + /^N

PN{i-PN

<

II

(21)

.

2/

2TPfv(l-Pw)

i'

1

(1

hfj-b^

_

+ ^li^(u,(l

•r^N-l „

- E,=l «

E;17' a,

.

72)

•72

-

J

N-l

r E:IT' «.

71)

-M--rEr=7'^fe^N"-6

'/v

The optimal value

of r

is

determined by taking the derivative of the

III

total cost function

Y^iLi Cifr,

w)

+ k/r and

solving against zero.

2[b,

we

If

(22)

+ h,)\

b,

+

2

h,

•lp.[\-p.

+2/)Af(l

y^' (k

6

-

+

TI4

9

8

N-l

bi

+

hi

^,2p,{l-Pr)

=

1

—

Y^^-i^ o,

•

72

2

>'

and

72)'

•

=

7^

7-y

O'

(23)

li

(24)

_ p^il-p^) f b, 2

2{b, + h,)\

h,)p,(l-p,)

+

74,

?;

pat)

—-6,

—

/?,

2

,

o, -71)

e2

where 73

define the constants

,

+

— +-hN

^'V

Ylf=i'

<^i

•

_ ^^

(25)

2

T

2p^(l

h,

(26)

r73,

pn)

then the optimal cycle length

7i,

is

given

by

I

T

=

<

7«ligd±

11

III

Considerable insight can be gleaned from (27). However, a discussion of the insights from

our analysis

is

deferred until §1.8.

The Optimal

Idling Threshold. With an expression

ecjuation (3), which determines the idling threshold Wq.

lengths at the borders of region

expressed

levels

w >

in

II

and

its

terms of the total workload

u'l.

region

II

by

u'2

<

ic

<

By

for r in

hand, we can refine

using (27) to ec|uate the cycle

two adjacent regions, the three regions can be

level.

Region

Wi and region

III

I

by

is

characterized by workload

w <

W2, where the workload

level cutoffs are

Wi

6-ei

(28)

A-,

Ui

6Us

/

102

16

e.-

k.

(29)

By

and

(3)

(5), the total

for r in

is

given by

Y^c,(t.x%w) + -] -e-^^'^'°-U:w.

^/ '^'

/:

Having solved

average cost

(30)

u=l

terms of the system parameters and w, we can substitute (27) into

the inventory cost (20)-(21) and into the setup cost term k/r in (30) to express the total

average cost solely

in

terms of the total workload w; we

expression because

it

adds

Depending on the

terms based on the

little to

split of the total

closed form solution. Therefore,

we

not explicitly write out this

our understanding of the problem.

can be broken into three or fewer

idling threshold wq. the integral

Because of the irregular form of r

will

workload into three regions as defined

for

w G

[»'2,u'i],

in (28)-(29).

the integral over region

resort to numerical

methods

to

has no

II

determine the optimal

value of Wo-

Our

derivation of the optimal

Recall that

when

dynamic

cyclic policy in

the problem was initially defined,

the smallest holding and backorder cost indices.

heavy

we assumed

The

traffic is

now complete.

that product

—

1) to

A"

—

1

in

heavy

This

in

place of product

traffic policy

is

(for

example,

designate the product with the lowest backorder cost index, and use product

The Proposed

1.7.

had both

analysis would remain unchanged,

however, without this restriction. One only needs to introduce new notation

A'

N

done

in

two

N

when

Policy.

derived

stages:

the total workload level

The

in §1.6 to

We

final

is

less

step in our analysis

is

than zero.

to

employ the optimal

develop a proposed policy for the original SELSP.

reverse the heavy traffic scalings to express the solution

terms of the original problem parameters, and then interpret the resulting solution.

If

we

replace the normalized quantities

w,k and

r

spectively (r undergoes this normalization because time

by w/\/n,h'/n and i/y/n,

is

compressed by

\/n. in

re-

the fluid

model), then the optimal cycle length formula

=

r

<

becomes

in (27)

JiAEI+K

31)

ii

III

=

Motivated by (14), we define x

W(t) =

Then

lb.

fp,(i-p.)

TO,

.

ijy

c,{T,y, w).

is

7i

"^m^

equal to

is

^')i

+ibA

the unsealed cycle center

(

and

f.4

tt'

equal to

—

b,-h,

+

^72 for fixed total

for

x'^ is,

unnormalized workload

< N,

t

+ hN

U'Q,

[^ -

^n]

if

- - Ef=T^

-n

< -

2

Hence, the unnormalized average inventory cost,

Z]'=i'.r^.

r,(f,.r'', lu).

(32)

72

•

Upon

u'l

=

U'2

=

reversal of scaling, ecjuations (28)-(29)

\l-^—.

— A,

become

(33)

U^

/6-6,^.

(34)

^46

Therefore,

if

wq minimizes equation

(30), then

wq

=

\/nwo

minimize the unnormalized

will

long run average cost expression

A'\ 2(1

-

Notice that the heavy

§3,

we use Maple

V

traffic

p)

-e

U'

_m^,a.o-w

(u.o-u-)^/

"'

parameter n does not appear

W.

in (31)-(35).

(35)

To compute Wq

in

to numerically solve the first-order optimality conditions associated

with (35).

Our proposed dynamic

original

hit)

{N +

cyclic policy for the

SELSP must

l)-dimensional system state, which

/a'(0 and the server location. There are

18

is

be expressed

in

terms of the

given by the current inventory levels

many ways

in

which the unnormalized

policy in (31)-(32) and (35) can be interpreted for purposes of implementation. Perhaps

the most natural

maximum

By Figure

workload

way

to express a

inventory (or "produce-up-to"

when

1,

level for

lot-sizing policy

level for the

)

product

traffic identity

i

is

when

=

/,

+

.i'j

p,{l

—

IZ,=iMr'/i(0 ^

II is

W{t) equals w. the maximum

i

is

[^^'-i.ii'i]

in (33)- (34):

and region

product with the smallest holding cost index

for

product

i

The server should

b^.

<

N

f

^/^

achieved at the

Making use of the

finished.

Region

III is J2,=i 1^-7^

proposed policy can be described as follows: IfY2t=i l^~^h{t) >

the smallest value of

is

us define the three unnormalized workload regions in

terms of the inventory process and the thresholds

Wi, region

to specify a state-dependent

p,)t/2; of course, this level

the production of product

/ijM^j, let

is

product currently being produced.

the unnormalized total workload level

instant within a cycle

heavy

dynamic

h^;

otherwise, let

idle ifJ2^=i lJ-T^h[t)

h{i)

then

N

>

ZlUi /'r'^i(0 >

I is

<

let

W2-

N

Then our

refer to the

denote the product with

Wo\ otherwise, if set up

then produce this product as long as

\a: 6,+/i y

.

/'r'A(o<

I

+

{o,-'n

\IpAI

-

K

p,

«3

^^^) +

h

{a,-j2)Zl,^^7'kt)

b,-b

^-''^'

b,+h,

III

(36)

Once

p^ '/,(0

reaches or exceeds this

product N, then produce

p,^^lN{t)

<

this

switch to the next product.

up

If set

for

product while

S^N

,,-lf//\

2^,=i

A',

''I'^

I

+

$2

<

level,

ff^i P;v('-P.v)

V^i^

>>

2

Y^N-1

^t=i

1^1=1

2

p,(1-p,)

b,+h,

"i

\

b,-h,

[~2

,

i

^ "'^

I

II

III

+(E!Ii/ir'^.(0)(i-E;=7'".-72)

n^l PnI^-Pn)

E^t=i Piii~^fli\-L

^'y-i'^y^^y

2

v^iV-1 P,(l-PpA

2^1=1

b,+h,

b.~h,

'iV

)

III

(37)

and then switch to the next product when

1.8.

Insights.

optimal policy

in

Our

heavy

p]^^ij^(t) reaches or

analysis reveals

traffic.

numerous

exceeds this

level.

insights into the behavior of the

Before reading this subsection, readers

may want

to

digest the graphs

marked "proposed"

policies in both the

in

Figures 3 and 4 in §3.2, which depict the proposed

symmetric (each product has the same parameters) and asymmetric

two-product settings.

An

Three Workload Regions.

essential feature of the

heavy

traffic

policy

characterization via three workload regions, as described in (28)-(29). There

workload

in region

I,

significant backorders in region III,

intermediate case where the total workload

State- Dependent Lot Sizes.

cycle

in

is

an interval containing zero.

SELSP).

lot sizes for the

when

that the optimal lot sizes are state-dependent

contrast, the lot sizes are constant in regions

I

and

thereby generating constant

remains constant

lot

/

within a

I

and

points in the intermediate area of region

the deterministic

ELSP

literature

can observe from (27)

III; in

is in

region

II.

In

these regions, surplus or deficit

lot sizes

and setup costs

stabilize,

This observation and (19) imply that the cycle

sizes.

in regions

We

the total workload

unavoidable, and the trade-off between

is

.r'^

sufficient

represents the

Because the time spent producing product

(and determines the optimal expected

center

II

its

the optimal cycle length r determines the optimal lot sizes in heavy traffic

is /9,r,

inventory

and region

is

is

III,

It is

II.

(Dobson 1987

and gradually

shifts

between these two

worth pointing out that

is

in nearly all of

a notable exception), the analysis

is

restricted to policies with constant lot sizes.

Relationship to the

the lot size

region

As

in the

in

is

Focused

in the

Least Cost Products.

the product with the smallest

h,,

hold (small h,) and lengthy to process (small

inventory

6,;

In

this

economic order quantity (EOQ) model,

I

and

III.

In

the setup cost again appears in the numerator of the square root term.

II,

up

Model.

proportional to the scjuare root of the setup cost in regions

is

Inventory

built

EOQ

(i.e.,

backorders)

product

is

is

which

f/,).

In region

is

excess inventory

is

inexpensive to

III,

excess negative

a product that

Similarly, in Region

is

held in the product with the smallest backorder cost index

inexpensive to backorder and has a long expected processing time.

both regions, inventory

is

held in the least cost product so as to reduce the absolute

value of the inventory of the higher (holding in region

I

and backorder

products. In this regard, the dynamic lot-sizing policy derived here

traffic policy

I,

is

derived for the corresponding problem without setups

20

in region III) cost

similar to the heavy

in

Wein

(1992).

In

that paper, instantaneous switching causes the inventories of

heavy

to vanish in the

added

is

When

normalization.

traffic

normalized cycle length and,

to the

setup costs are introduced, breadth

r

=

=

then region

0,

and

.r^

Lot Sizes

optimal

=

In fact,

w >

(region III) corresponds to

I

workload, a "corridor" of

for a fixed total

possible inventory states replaces the least cost axes.

case A'

the higher cost products

all

if

we consider

0(w <

in

0);

the special

both regions,

w, and the solution reverts to that of Wein.

Grow

lot size is

By

with Absolute Value of Total Workload.

smallest

when

absolute value of the workload.

(27),

we

see that the

the total workload equals zero, and grows with the

When

the total workload

near zero, costly backorders

is

can be avoided by switching frequently between products. In contrast, when the absolute

value of the workload

large,

is

it

is

possible to

employ large

without adversely

lot sizes

affecting the inventory costs (because inventory tends to be held in the

product

regions

in

produce products

and

I

III); in this case,

it

i

product

for

< N, product

product

/'

and

i

is

i

advantageous to avoid setup costs and

is

In

heavy

under our proposed policy

inventory

positive

cost

batches.

in large

Inventory Levels at Switching Epochs.

workload

minimum

negative

is

when

(i.e.,

is .r^

the

traffic,

maximum

+ /9i(l — p,)t/'2.

It

normalized

follows that for

backordered) when the server switches into

the server switches out of product

i.

For product

N

the

sign of the inventory level during the switching epochs depends on the region: In region

II

product

positive

N

when

inventory

is

backordered when the server switches into product

N.

the server switches out of product

always positive

in region

I

Cost-Symmetric Case.

=

and

is

Our

=

always negative

and

is

In contrast, product A^ inventory

is

in region III.

results simplify considerably

=

A'^

under the cost-symmetric

example,

case,

where

if all

products are relatively indistinguishable, except for their color. Then each product

h,

h and

would be expected

demand

h^

h for all

to have the

rates, since

some

same

colors

;'

1,...,A'^.

This case

service rate and inventory cost rates, but different

may

be more popular than others.

and, by (28)-(29), the workload always resides in region

workload resides

we

in

only one region (region

define the constant p

=

Xlfli Pi(^

will arise, for

~

Pt)-

II) if

then

II.

and only

when

In fact,

if

Then

^i

=

ifs

=

one can show that the

the costs are symmetric.

the server

is

busy and

is

set

up

If

for

product

I,

this

product

is

produced as long as

(E^, ^-'i,(t)y ^

It is

T:l,^i7'h{t)

(38)

evident from this expression that the cost structure effects the

K/{b +

the ratio

h)\

not surprisingly, the

lot size is

lot sizes

only through

an increasing function of

this quantity.

THE SETUP TIME PROBLEM

2.

Problem Description.

2.1.

(rather than a setup cost)

is

In the setup

when

incurred

another.

In all other respects, the setup cost

identical,

and

we

^

f>{b+K

P"

\

-IK

all

time problem, a random setup time

the server switches

dynamic

As

cyclic policies. Let 5 denote the

Coffman, Puhalskii and Reiman (1995b) show that the heavy

system depends upon the setup time distributions only via

parameters are unaffected by a permutation

the desired permutation

given by the

is

mean setup

deterministic service times,

Under general

Fuhrmann

mean setup time

traffic

per cycle:

performance of

this quantity,

Thus

this

and other key

in

heavy

traffic

traffic conditions,

Poisson arrivals and

(1992) and Cooper, Niu, and Srinivasan (1992)

time over the cycle. Also, numerical calculations

performance of a cyclic policy

setup cost problem,

where the intercity distances are

show that the mean waiting time depends on setup times

that the

in the

in the cycle order.

the travelling salesman tour,

times.

to

problem and the setup time problem are

relevant notation from §1 will be retained.

shall only consider

from one product

is

in

through the

onl\'

total setup

Federgruen and Katalan (1993) show-

quite insensitive to the chosen permutation.

The

server has three scheduling options at each point in time: Produce a unit of the product

that

is

currently set up, initiate a setup for the next product in the cycle or

control problem

is

to find a nonanticipating scheduling policy to

\\msupl;E\rY.ih.!^{t) +

T_>co

Once

again,

i

'Jo

^

^

we avoid unnecessary notation by omitting

inventory vector

/ in

terms of an arbitrary cyclic policy.

99

The

minimize

b,i-{t))dt].

^

sit idle.

(.39)

J

the equations that express the

The

2.2.

same

as in §2,

The form

Diffusion Control Problem.

and the setup times are not rescaled

of the proposed policy

and works otherwise, where

the server

busy and the

is

The heavy

is

also the

same

in

heavy

traffic

traffic; that is,

The

as before.

server idles

workload equals w, the cycle time

of average inventory workloads

is

they are 0(1).

if

is

t{iu)

x'^(w).

and Coffman, Puhalskii and Reiman (1995b) show

is

\'V{t)

equals

traffic limit,

that the time scale decomposition

described in §1.3 also carries over to the setup time problem.

normalized workload

When

and the vector

Since the setup times are 0(1), they occur instantaneously in the heavy

total

W{t) > wq

an unknown normalized threshold parameter.

ioq is

total

normalizations are the

More

specifically,

the ./V-dimensional fluid process {Wi,

u',

when

.

,

.

.

the

Wj^j)

identical to the A'^-dimensional fluid process in the setup cost problem; hence, the

optimal placement of cycle center

c,(.r",r, u') is

We now

x'^ is

given by equation (19) and the inventory cost rate

defined in equations (20)-(21).

characterize the normalized total workload process

problem under the

class of

dynamic

workload process follows from existing heavy

and Reiman (1995b)

position holds for

all

after

Our

cyclic policies.

for the setup

time

characterization of the total

theorems

traffic limit

W

making the innocuous assumption

in

Coffman, Puhalskii

that the time scale

decom-

multi product cyclic policies, not just for two-product cyclic base

stock policies. For make-to-order systems, readers are referred to Coffman, Puhalskii and

Reiman 1995b)

(

and

case,

to

for a derivation of this characterization in the

Reiman and Wein

the approximation.

process.

The

Its

drift of

W

is

for a discussion of the controllable case; here

The normalized

variance a^

is

the

same

no longer v^(l

workload process

total

—

W

is

the total workload equals w.

is

assumed

as in the setup cost problem,

but x/'^(/(«')

p).

—

p),

of time during a cycle that the server serves customers, as

when

two-product uncontrollable

When

and

state

to be a diffusion

is

where f{u')

opposed

we only

defined in (2).

is

the fraction

to incurring setups,

the normalized workload equals

lo,

this fraction

given by

'nri w)

where t{w)

is

the cycle length, which

is

+

s

both deterministic and controllable.

Hence,

\/n{f{iv)

—

p) -^ c

— s/t{w)

as n -^ oo,

W has the state-dependent

and we assume that

drift

;^(uO

= c--i-.

(41)

t(w)

Notice that this drift approaches the drift in the setup cost problem as the setup times

vanish or the cycle length becomes arbitrarily large.

=

Define the cost function c(t, w)

are defined in (20)-(21).

J2',=i c,(r.

The approximating

>

state-dependent cycle length t{w)

w), where the individual cost components

problem

diffusion control

and the threshold wq

is

to choose the

minimize

to

1

Imis up ^E[j\{Ti\V(t)),Wit))dt],

T

W

where

a (i^i{w),a^) reflected diffusion process on

is

(

(42)

— ocwq]-

Hence, the controllable

cycle length t(w) affects both the drift i.i(w) and the cost c{t, w) in a nonlinear fashion.

The Optimality Conditions.

2.3.

and a singular control via the

as

t{w] -^

0,

we proceed

as

if

Problem

reflecting barrier wq.

(42) involves a drift control t{w)

Although the

drift is

unbounded

standard arguments apply (Mandl 1968) and state the

Hamilton-Jacobi-Bellman optimality conditions:

min

{

'(u')>o

c{t(w). w)

-g+

[

[c-

-—

\

t{w)J

<r\..,

\"(w)

+ —V"(w)

2

}

=0

for

w < wo

(43)

J

and

V'{w)

where g

the gain and

is

V'(.r)

is

{g.V{w),T{w). Wq) can be found

to (42),

is

g

is

=

for

that V

(44)

to (43)-(44).

then (r(«'),a'o)

is

If

a solution

the optimal solution

the optimal long run average cost (independent of initial state), and

when

the initial state

G C^, and define p{w)

jjrinciple of

Wo,

the potential (relative value) function.

the cost incurred under the optimal policy

incurred

w >

smooth

fit

when

the initial state

which we take

is

some reference

=

V'{w); this assumption, which

state,

is

(Benes, Shepp and Witsenhausen 1980),

solving diffusion control problems.

24

is

to

w

is

minus the cost

be Wq.

known

often

V{w)

We assume

as the heuristic

imposed when

Using the workload cutoff

unknown

{wi and W2 are

and

levels ivi

u'2

to distinguish

among

regions

I,

II

and

III

and are not given by (28)-(29)), we substitute the

at this point

three forms of cost function c{t,iu) into (43) to obtain

min

<

+ h^w -

<fir(u')

r{w)>0

min

<^

+

g

^-Tiw)

ic

\

^2Tiiv)

+ ^sw +

w

^4—~ -9+

t{w)

t(i())>0

+

p{iv)

[c

——

\

t(w)J

-—p'{iu)

2

p{w)

-

\

=

for

lui

+ —-p (w)) =0

2

< w <

wq,

for

< w <

it;2

(45)

uh,

J

(46)

min

r(w)>0

(3t{w)

<

-

bjwiv

-

g

+

^

c

(

where the new constant

N-l

b,

+

-7,

p{iu)

)

+

Tiw) J

\^

[

-—p'(iv) >

2

J

=

for

w <

(47

1V2,

^5 is

h,

-

h,

z{Olz

7l

•

".

)

72

+ h^

:7473 +

p.v(l - Pn)

b^

b,

+

,

CVi

72

•

/?/v

-

^Af

::;

73-

(48)

Solving the first-order optimality conditions for t{w) yields

sp(w}

for 10

=

r [w]

1

for u;2

<

< w

<

It'

<

(49)

ifi

«2

sp{v

for

w < W2

43

we obtain

Substituting t'{iv) into (45)-(47),

the nonlinear ordinary differential equations

(ODE's)

\/~^isp(w)

'2y/^2U^^

-

+

^2Sp(w)

hiMiv

—

+ ^5W +

g

+

cp{io)

Cp[w)

+

+

—p'(io)

—p'{lo)

-

^

=

for

Wi

< w <

Wq,

(50)

=

for

W2

< w <

Wi,

(51)

2

-y-^sspiw) - bNW - g + cp{w) + —p'{iv) =

2.4 Structural Properties.

for iv

<

W2.

(52

Before pursuing a solution to the diffusion control

problem, we derive several useful structural properties.

Property

— —00

If 102

1.

=

p(w)

if u'2

/ — oc

then

w+

o(W)

w—

as

>

—00;

(5o)

f/jen

p(it')

=

w+

o(w)

as

IV

-^

— cxo.

(54)

c

The

derivation of this property, which assumes an asymptotic monotonicity property,

nearly identical to that in the Appendix of

is

Reiman and Wein

(1994); see

Markowitz

(1995) for details.

Property

if

and only

if

wq

>

u'l

2.

The idhng threshold wq

if h,

=

hj for all

i

and

At the

j.

and t'(wo) = y'6/G»'o

>

it'i

and

r*(ft'o)

=

\/^4/^2Wo

=

'Tft'o

and equality holds

=

"'i-

and equation (49) imply that t'(wo)

<

if u'o

it'i,

idling threshold, the cycle length r"(u'o)

—

Proof: The boundary condition p(wo)

Wq

greater than or equal to

is

In order for iuq

u'l-

<

u'l,

must

r'(»'o)

=

if

satisfy

the cycle placement conditions originally specified in the conditioning of equation (19).

We

can rewrite the centering condition as

\wo

- l^T

!

Rearranging terms,

=

(u'o)a,

•

-/I

+

tt'oQ,

•

72I

<

^

this inequality

.

is

pn{1--pn)

[ii,

73<\/— (^4 +

,

i^f..

)

(5")

7,

^

V V2

Algebraic manipulations (see Markowitz) show that this inecjuality

holding costs are not identical and holds at equality only

cost-symmetric case, the placement conditions

by the idling threshold

that

is,

»'o

Property

=

3.

U'l.

u'2

(55)

•

1

u'o,

and hence wq

is

in

if h,

if

and only

if b,

—

false

hj for all

i

the boundary between regions

bj

26

if

and

inventory

j.

In the

equation (55) are satisfied at equality

I

= — oc

—

is

for all

i

and

j.

(I)

and

(II);

Derivation: The constant

imply that

T'(tu)

Hence,

= —00

as

u'2

w — —00

(II),

unbounded

for

in the

w <

u'2.

cost-symmetric case.

1,

This fact and (49)

which would violate the placement conditions.

cost-symmetric case.

in the

by Property

>•

region

is

equals

^3

-J 7^

and t''{w)/w ->

= — cxd

W2

If

w —> -00 by

as

**

then p(w)/w -^

(49).

^^.

—

To remain

-

in

42

the placement condition

AT-l

IV

-

V

T'{iu)a,

7i

-I-

a»Q,

•

72I

t'{w)Pn{1

<

- pn

r

(57)

1=1

must be

For

satisfied.

approaching —00, we can substitute the limit of t'[w) and by

10

algebraic manipulation reduce equation (57) to

73

1^,Pn{1 - Pn)

^

< \/^(

T

V

As

in

Property