Document 11057615

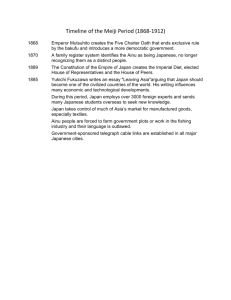

advertisement