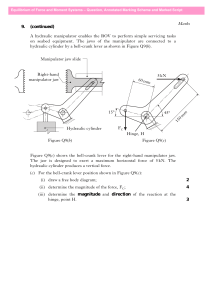

Delicate Manipulation of Irregularly-Shaped Rigid Objects

advertisement