s. \.:~'

advertisement

\ c.

?J\J~

{\

'\}

..

,

..~

jl,'\~J.l

/V"

()

/)

\ OJ-'

\.:~'

C/'

')-/

·

THE EFFECT OF REFLUX IN THE CONTINUOUS SEPARATION OF

.HYDROCARBON MIXTURES B~CTIFICATION

by

L. P. Elliott

B. S. University of California

1922

and

Emil H. M. Lehnhardt

B.

s.

University of California

1923

Submitted in Partial Fulfillment of the Requirement

for the Degree of

MASTER OF SCIENCE

from the

Massachusetts

Institute

of TeChnology

A C K NOW LED

G II

----------------

E N T.

The authors wish to express their appreciation

for the kindly criticism and invaluable suggestions

afforded by Prof. W. K. Lewis under whose direction this

thesis was prepared, and to extend their gratitude to

Mr. Welling of the Research Laboratory

of Applied Chem-

istry whose helpful advice was of assistance in the man-!

ipulation of the apuaratus.

QF

I..Introduction.

Page

(1) Purpose of investigation.

- - - - - - - - -

(2)

Theory of rectification.

- - - - - - - - -

(3)

state of the art of rectification

in the petroleum industry - - - - -

(4)

Previous investigation -

II. Summary - - ~ - - - - - ~ ~ - - - ~ - - - - - ~

III. Experimental work

(1) Propos~d method of attack - - - - - - - (2) Description of apparatus - - - - - - - - still, using reflux -

[b) The continuous

still, using no reflux -

(c) The anaJ.ytical still (3)

-

(a) The continuous

--------

Procedure

(a) The continuous still, using reflux (b) The continuous

-

still, using no reflux -

--------Resul ts - - - - - - - - - - - - - .. - - - - - - (c) The analytical still

IV.

v.

Recommendations

- - - -' - - - - -

VI. Calculations VII, Sample calculations

VIII. Original data - - - - - - - - - - - - - - - - -

.

IX. Bibliography - - - - - - - - - - - - - - - - - -

(1) purpose of investigation

Due to the very large and increasing demand

for the lighter fractions obtained in the distillation

of petroleum it is essential,from

the point of view of

the refiner,that all of the light components which are

salable as gasoline be removed from the higher fractions,

insofar as this is economically

feasible.

It is well known that these light components

can be practically completely separated by the use of

a rectifying column but,unfortunately,the

heat require-

ments for complete separation are so large that it is

not economically advisable to carry the rectification

to this point. The question the refiner must solve is

hoW' far he can carry the se:oaration before its cost

becomes greater .t\jhan

the value of the prodnc'(jwhich he

obtains.

In Order to determine the oDtimum conditions

i

for the operation of a rectifying still it is neaossary'

to lcnow the relationship between the heat requirements

and the separation obtainable. This relationship has

been quite accurately determined for certain binary

mixtures but practically no data are available for

petroleum mixtures.

Therefore,the primary object of this

e:z::perimental

investigation

is to study the heat

requirements for distillation,insofar

as they influence'

the degreOs of separation

the heavy components.

of the light

components

from

(2) Theory of reotifioation

The se~aration of liquid mixtures by

distillation

heatedtthe

is based on the faot that when they are

I

vapor given off is rioher in the more VOlatilr

oomponent than is the liquid from whioh it oomes. The

ideal distillation

prooesstat

oonstant prescuretoonsiets

of allowing vapor and liquid to oome into intimate

oontaot in a oolumn. The va~or rising from the still

passes upward and meets the decending

ideal columntcomes

differenoes

into equilibrium

in relative volatility

liquid and,in the

with it.Due to

the asoending vapor

beoomes richer in the more volatile

constituent

whereas

the decending liquid becomes poorer in this constituent.

I

A oonoentration

gradient is thereby set up in the oolumn

and if the column is suffiomently

high the vapor leaving

the top will oonsist of only the more volatile

component.

The liquid flowing down thru the tower is oalled refl~.

It is formed by condensing part of the vapor. The larger,

the amount of reflux returned to the still,per

•

producttthe

greater will be the ooncentration

unit of

gradient

thru the column and hence the better will be the degree

of separation.

In any actual oolumn it is impossible to

bring the vapor and liquid into oomplete equilibrium

due to imperfect

equilibrium

contacting.

may be approached

The extent to whioh a true

depends largely upon the

material with which the column is packed.

I

I

I

I

I

Reflux may be obtained either by partial

conaensation

I

Ii

of the vapors at the tmp of the column or

by allowing the column to be cooled by radiation.

If the

latter method is employed it is easily seem that there wili

I

be more reflux at the bottom of the column than at the top~.

I

This is undesirable

since' maximux separation,for

I

a given

I

amolUlt of heat used in producing

reflax,will

I

occur when

I

the reflux is a maximum thruout the column.

Furthermore_partial

condensation

increase the degree of separation,due

I

I,

serves to

I

to the tendency for

the less VOlatile material to be condensed

in preference

to the more volatile.

The laws governing

the separation

mixtures have been worked out matha~atically

I

of simple

.1

and are qUit~

t

well understood.

mixtures

However_in

suoh as petroleum

mathamatical

the case of complicated

/

I

it is obvious that a rigid

treatment would become hopelessly

I

involved.

!

For a qualitative

.

examinatimn

to consider the complicated

of this problem

it is possi~le

I

i

mixture as if it were a two

I

component system.

In the distillation

continuous

of such a mixture ,in a

I

still,there are five variablest

(1) Height of column and type of paoking,or

of theoretioal

I

!

number

I

plates.

I

I

(2) point of introduction

I

of feed.

I

I

(3) Heat supplied to still and temperature

of feed,--+

equivalent to reflux.

I

I

I

(4) Relative volatility

(5) completeness

of distillate and bottoms.

of separation

of distillate and bottoms.

I

1

I

!

I

II

I

In order to investigate the ralationship

between these variables it is of course necessary to

maintain all but two of them constant. The first two;

!

I

I

I

I

namely,the height of column and the point of introductionl

of the feed are.for a given apparatus,fixed.

The relative I

volatility of distillate and bottoms will be constant

I

providing that the ratio of distillate

I

to bottoms is

constant,and that the composition of the feed is constant~

This leaves only the completeness

of separation and the

heat required for the separation as variables. As

previously stated,this is the relationship

investigation.

I

I

desired in this

II

I

i

I

I

I

I

(3); state of the art of rectification in ihe petroleum

industry.

In many industries in which distillation

is

an important plant p.roceedure J oolumn apparatus .has been

developed almost to the exclusion of other types of

equipment for separation of liquid mixtures. curiously,

the petroleum industry has,until quite recently,taken

but slight advantage of the many desirable points of

column distillation. It has developed and used dephlegmating equipment almost exclusively_

Dephlegmating

app~ratus produces separation

by fractional condensation. This condensation must be

distinguished from the partial condensation

produce ~flux

used to

in the rectifying column. The prima~y

purpose of th9 reflux condenser is to return

8

definite

amoun-t of liquid to the column in order that sepafation

may take place in the column. But fraotionating

oondense~s

are intended to produce a vapor richer in the more

j

volatile component thah the vapor entering the apparatus

It appears that in some refineries the first

I

principles of the operatio~ of a rectifying column are

not understood. This is shown by the fact that expensive

.columns are known to have been erected,carefully

lagged

to prevent heat loss by radiation,an d then operated

without reflux. This method would of course give maximum

an'ount of distillate per unit of heat but the separationl

is equivalent only to that obtainable with a simple stili.

I

I

However,during

the past few years the number

of rectifying columns used in oil refineries has

I

increased

I

rapidly.

Compared \'lith 1he previous

methods

of separation they have constituted a tremendous advance

I

in the art ,but so little is known aD out their correct

operation that it is doub-tful ihat many of them are

being operated in the most economical manne:r.

I

I

I

I

I

j

I

!

I

I

I

I

I

I

I

I

I

I

(4) previous

investigation.

The available

of

I

I

I

hydrocarbon

mixtures

data

re8arding

by rectification

the

separation

are

!

!

\

extremely

chiefly

meager.

The v;ork which h~s been done Y/as

fo r ~he purpose

method for

point

curve.

batch

still

the

of developing

determination

of the

In practically

an a.nalytical

true

all of this

was Llsed rather

boiling

work a

a co ntinuol1s

than

still

such as wollld be most advantageo usl~T nsed in

refinery

practice.

Hovlsver ,Reeder

on a continLl0nStplaJ(jG type ,still

1922)made two runs

us ing

11

end Gordon (11. I. T. Thesis

so conytrgasoline

fe d di rectly

to the

I

I

still.

I

I

i

Their

data

for

two runs have been recalcnlatea!

these

I

I

and will

be discussed

later.

iI

I

vr.T.Davis

(I.T.l.T.Research

I1ab.of Applied

I

i

I

coo mist ry 1923) has

]Ie

rfe ct ed a rnetho d 0 f deJlie rmining.

!

the true

boiling

point

This method is based

distillation

of the

reflux

rectifying

. ratio

liqUid

is

ratio

condensed

column, to the

that

ratio

110 int

of

i

I

i

I

!

amount of

condensed

I

I

the

and allmwed to flow back into

amount of liquid

I

height~-Ref1ux

of the

I

i

I

the

a sufficiently

and that

of sufficient

as the

mixturesJ

v,~;,rious fractions

is maintained

column is

defined

that

a:Dproximate the bo i1ing

Dure components providing

large

of hydrocarbon

on the principle

tempero.ture

vr.i.ll vE:ry closely

the

curve

I

I

the

as product.

I

I

!

I

I

I

Davis found that in order to, :>btain satisfac&o~y

!

separation

of normal gasoline blends with a column

packed with 28"

of carbon nipples of cylindrical

shape, 7/32" outside

with a 1/16" concentric

maintain

I

diamete r>by 7/32" long and

I

hole, it. was neceffiary to

I

a reflux ratio of 12:1. With a shorter

column it would be necessary to increase

this

I

ratio.

He also found that the boiling point difference

I

between the fractions

I

the reflux necessary

being separa"tedinfluenced

for the separation.

gasmline blend containing

oonsiderable

I

I

For a

benzol it

!

j

VIas necewary

to increase the ra..lliio

to abont 20:1

during the period at which this component was being

II

distilled.

,

I

IIIcFarlandan,a.l1cGrath (I','I.I.T.Thesis

1924)

began the investigation

Lack of time prevented

quantitative

considered

I

in this thesis.

them from obtaining

I

i

any

results.

I

I

I

I

I

I

I

I

II

I

I

I

SUM:~

.......

I

I

_--Y.

MAR

.....

\

I

I

The effect of reflux on the degree of separation

l'

of hydrocarbon mixtures when they are subjected to bCOene-n

tinuous distillation

in a fractionating

column has

studied for the case where there is no rectification

abov

I

the feed plate. The relationship

between reflux and sepa- I

ration was found to be hyperbolic

in nature, with a. ltmit

ing value for the separation obtainable

J

I

in'the given COluJn.

(

The degree of separation obtained in the continuou~

distillation

of a hydrocarbon mixture without reflux was

also studied. The degree of separation in this case is

surprisingly

small.

I

I

II

The degree of separation was found to be a functionl

of the size of the cut.

I

I

\

III EXI'ERI1.1ENTAL

(1) Eroposed

WORK

method of attack.

In order to investigate

ship between degree of separation

requirements

for the separation

mixtures in a oontinuous

the relation-

and the heat

of petroleum

rectifying _column it was

proposed that a column be operated'with

ordinary

"soconyn gasoline as feed. In general,the

ships for this mixture should be similar

relation-

m those

of other mixtures of hydrocarbons •

.Thetlbottomsn ~from the still were to be

analysed by determining

their t~ue boiling point

curves. From a comparison of these curves with

of the feed the amount of nlighta"left

in the

"bottoms" ,i.e. the degree of separation,could

be

determined.

The reflux was to be obtained by~

partial oondensation

by means

of the vapor in the still-head

I

I

of oil passing thru a cooling coil. The

oil oiroula.ting apparatus was to be so.oonstruoted

that the volume. of oil passing thru the system per

unit of ~ime,as well as its temperature

rise in

pass ing thru the coil co u1d be determined.

prom

this data the heat required for the productimn

of

the reflux was to be calou1ated.

I

The degree of separation

zero reflux

obtainable

,i.e.by straight distillation,was

witTh

to bel I

I

~

I

I

\

,

\

determined in a simple continuous

a column.

still without

I

II

I

!

!

!

I

I

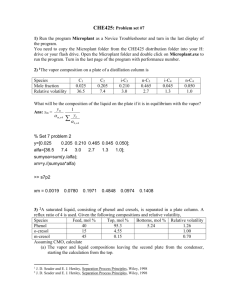

(2) Description

of apparatus.

(a) The continuous

stiIl.using

The continuous

inves~igation'

reflux.

still used in this

was designed and built by McFarland

and MCGrath(M.I.T.Thesis

1924)and

is described

in great detail by them. A diagram of the a~paratus

will be foun~ in this report.

still

The still itself consisted of a section

of eight inch standard iron pipe.approximately

foot in length,onto

one

each end' o~ which caps had been

screwed and welded to prevent leakage. Into the side

of the lower cap a half inch standard iron pipe was

scwewed and welded. This pipe was for the purpose of

drawing off the bottoms from the still and had a

slight upward slope in order that the stiililwould

not be completely

drained by it. The end of this

overflow pipe was connected to a twenty inch, waterjacketed condenser •.A the rmometer well extended

from the top to near the batt am of ghe still.

Column

A four foot section of standard two-inch

iron pipe was connected to the top cap of the still

by means of a union,a six inch piece of similar

two inch pipe ,and a 3nx2" standard bushing. A wire

screen was forced into the column slightly above the

Mion

for the purpose of sup-.vortingthe c"olumn

packing which was placed in the four £00 t section of";

pipe.

column packing

The column was packed for a distance of

three feet with sa ctions of 6-8mm glaas tubing,the

length of which were BIll roximately

equal to the

diameter.

partialBcondenser

The column head consisted of a two inch

standard lateral in Which a condensing

comected

thru compression

joints to three-eights

inch pipe in which were thermometer

-

coil was

wen s to enable

,

the operator to determine the rise in temperature

of the oil circulated thru the condenser.

Oil circulating

system

This system oonsisted simply of a

olosed cirouit. The oil was pumped from the bottom

of a pail,thru

a half-inch

pipe ,to the partial

condenser by means of a small rotary pump and was

then returned to the pail. A by-pass was construct)

ed around the pump in order that the oil rate

thru the condenser might be controlled.

sometimes necessary

As it was

to heat the cooling oil a

circular gas burner was placed under the pail.

Head temperature

The temperature

at the top of the column

was determined by introducing

a thermometer

the column head thru a compress ion bushing.

into

TO

prevent radiation to the cooling coils this

thermometer

was shielded by a small lead cone as

recommended by W.T.Davis.

Total condenser

The top of the column head was connected to

a thirty inch,water-jaoketed

conoonser to condense

.the product from the column.

Feed reservoir

The fee d reservo ir was a five gall.0 n

galvanized

oil can with a sight glass on its side.

TO its bottom was soldered a short piece of copper

tubing whioh was connected to an eighth-inch

needle

I

valve. This reservoir fed into the constant head tank.

\

constant head device

The constan~ head device vms constructed

I

froml

I

a three inch iron pipe one foot high, with a sight

.!

glass on the sidi. A swivel joint w8.s\-placedat the

bottom and connected to an overflow pipe in such a

manner that the hight of liqUid in the tank could be

i

maintained

I

at any desired point by raising or

lowering the overflow pipe. In order to maintain

oonstant rate of feed

made by drilling

a

to the still an orifice was

I

a hole O.04l"in diameter in a piece!I

t

I

I

I

!

I

I

of galvanized

iron. This was soldered onto the top

!

of a half inch pipe and the pipe was screwed into the

I

bottom o.f the constant head tank.

I

still .and column insulation

I

The still was sun-otl!ldedwith brickwork

prevent

I

to

coaling by air currents. The column was insuI-1

ated from heat loss by means of a flue gas jacket

consisting

of a piece of six inch galvanized

II

iron pipe~

I

This pipe was open at the bottom and so situated that

I

the hot flue gas from the burner

under the still

I

passed thru it. When this source of heat was in-

I

sufficient burner gas from a Btl!lsenburner was admitte~

I

thru a short piece of 2" stove pipe which was riveted

I

to the side of the larger pipe.

I

Receivers

The distillate

coming from the total

oondenser was caught and measured

so arranged

in two 500c burets

that they could be filled alternately.

The bottoms were allom d to overflow

a graduate.

dnto

DIAGRAM

of

~

RESERVOIR

ELLIOTT

cxnd

LEHNHARDT

M. I.T.

THERMOMETER

....-

CONSTANT

EAD

STILL

CONTINUOUS

,.EED

19;t4

IN

VAPOR

TANK

COOLING0' L

-----~

~--.:::Ir---T"

THERMOMETER

IN JACKET

SHEET

METAL

JACKET

- --- - -

-

-

- --

-- - -- -------- -

(OVER;L~W

FEEO~

-.

-- ---

RECTIFYING

COLUMN

_0

HOT

GASES

BUNSEN

FROM

BURNER

BURETS

STILL

WATER

..........

c:=~~~OIL

CIRCULATING ~Y5TEM

C'RCULAR

BURNER

Description

of apparatus

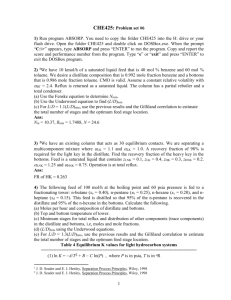

(b) The continuous

still uSing.~

reflux

This still ~onsisted of a two 'liter pyrex

short necked round bottomed

the flasktincluding

flask. The upper half of

the neck,was

covered with half an

inch of -magnesia and the entire flask vias surrounded

with insulating boards in such a manner that the hot

flue gas from the burner jacketed the flask and

maintained

it at a temperature

slightly higher. than

that of tlE liquid in the flask.

The fee d

ViaS

introduced

into a separatory

fu.ri.nel,froma graduate •and allowed to flo w into the

the flask thru a glass tube reaching nearly to the

surface of t he liquid in the flas k.

The bott:.orns

were drawn oft continuously,

at a constant rate ,by means of a siphon extending

from the bottom of the flask. AS shown in the

accompanying

diagram the bottoms were cooled in a

condenser before they were drawn from the apparatus.

The vapor leaving the .still was led into a

30" condenser and the resultant

j

I

distillate vias

I

measured in a graduate.

A

flask.

thermometer was inserted

at tbe top of thel

This th ermometer was not shieldeel and it

v~J;y..::probable that the temperatures

somewhat erroneous due

react

is

from it are

m radiation from the flame of

the gas burner beneath the flask,and

from the insuaat~

I

II

I

I

I

DIAGRAM

of

CONTINUOUS

STILL

with

NO

ELLIOTT

RErLUX

~nd

M.I.T.

1924

~THERMOMETER

--t+--MAGNES'A

ASBESTOS

WATER

CIRCULAR

~

VVATER-COOLED

WATER

.

~

t-----;~

BOTTOMS

SYPHON

BURNER

LEHNHAROT

/

-ing

boards

which wefe at a temperature

that

of the still.

higher

than

j

(c) The analytical

The still

true

boiling

point

(M.I.T.Thesis

that

I

still

I

u.sed for

curves

1924)and was very

is

shown in this

This apparatu.s

1.5 gallon

packing,a

.a

I

of the

by Mackey I

in design

I

to

I

diagram af the

I

I

repe rt.

head with

partial

amount of reflux,and

partial

similar

oonsisted

still,40"still

carbon nipple

proper

defer mination

w as constructed

recommended by W.T.Davis •

apparatus

ess.entially

28 inches

condehser

a final

I

I

of a

of

I

to secure

condenser.

I

I

The

!

I

cond.enser consista:1 'of about four fee t of-i-"

copper tubing

was fixed

in the form of a c oil.

below the

temperature

thermometer

A

vnich

100 tal

it

from radiation

Radiation

from the

with a flue

to the

cooling

colmnn was prevented

gas jacketing

I

cone

Ii

gave the

of the \B..por go ing to th e final

to shield

it

the

condenser~

coil.

I

by surroundinh

!

chimney.

I

I

I

I

i

I

I

I

I

I

I

I

I

THERMOMETER

IN

---.

VAPOR

.

DIAGRAM

of

ANALYTICAL.

ELU OTT

Cl.nd

M.I.T.

l--i~

........

STILL

LEHNI-4ARDT

1924

-THERMOMETER

IN JACKET

"~

~~~===~

THERMOMETERS

tI

FINAL

tONOENSER

--.

GLASS

SHEET

METAL

COLUMN

JACKET

HOT £TASES FROM

BUNSEN BURNER

STILL

~=====;JI~-CIRCULAR

BURNER

DETA\L5

of

ANALYTICAL

ELLIOTT

and

STILL

LEHNHAROT

M.I.T. ----192.4

NI PPLE

1/

COUPLI NG

COMPRES510N

MERCURY

4'- !l4'1 COPPER

TUBING

I!I-L'THARGE

J

NECK

CEMENT

OF" BOTTLE

+-STRINC:t - WOUND

AND

5H£LLACEO

~46

Mm.

TUBING-

o

AERIAL

THERMOMETER

42.0°,:-'

2.Y.z

"

SHORT

NIPPLE

FLANGE

"

II

Y4 X Y8

COMPRESSION

COUPLING

5TilL

L.EAD

CONE

WIRED

TO

THERMOMETER

AS

SHOWN

(3) prooedure

continuous

still, using refl~~

Before a run was started the feed

reservoir was filled with gasoline. This oould be

done either by pourOing the gasoline di rectly inyo

the tank thru a funnel oroby means of compressed air

age that it oontains an element of danger. Glass

bottles will withstand

only small pressures,and

if

disoretion as serious accidents have resulted from

its use.

to flow into the constant head devioe. Any desired

level of liquid was maintained

in the head box by

raising ~r lowering the overflow pipe. The valve

mentdoned

from

above Vias so adjustedo~that the overflow

the head box amounted to a steady drip. As

,

the liquor level in the feed reservoir deoreased it

i

was necess.ary to open_ the va~ve somewhat more.

I

I

.The gasoline flowed thru the orifice beneatl1 -'

the head box and_then entered the column. After a

small amount had reaohed the still the gas burner

beneath the still was lighted and fully turned on' in

order that the still and oolmnn might be brought up

I

to heat as soo~ as po.ssible. When the temperatnre

at the top of the oolumn had reaohed approximately

150 F. the oil ciroulating

desired_refl~

I

pump was started if the

I

I

I

was greater than that furnished by

the oold feed. If a large reflux was desired the oil

was not heated,but

in order to obtain a somewhat

I-

I'

I

I

smaller reflux it was neoessary to heat the oil. The

I

amount of heating was controlled by adjusting the gas'

burner beneath the oil:-reservoir.

It was very difrioult to bring the still tal

I

oonstant operating conditiqns. This was_particularilY!

--

I

true if it was desired to operate at predetermined

I

condit~ons.

I

In general

method was to adjust

it was. found that

the best

the burner beneath the still

and allow it to remain unchanged. The oil rate was

then adjusted in such a manner that the product of

its rate by the temperature

difference at the inlet

and outlet of the cooling coil was constant. The

temperature at the tOl> of the column would then

either rise or fall until it would eventually become

constant. The distillate rate would then be constant

also.

I

I

I

I

I

After the column had been operating

uniformly for approximately

I

an hour a run was

started. During the run the distillation

watched continually.

I

rate was

I

I

If it very s.uddenly decreased

the cause was usually plugging

of the orifice in

the feeding device. In such a case the pipe

containing the orifice was struck a sharp blow

with a hammer. This usually ~emoved the obstruction

~d

allowed the rate to almost immediately

normal. If the distillation

return tO

fate showed a tendency

to either decrease or increase,the

I

I

I

!

reflux remaining.1

unchanged,it was usuallydue to a change in the

I

I

amount of heat under the still resulting from a

fluctuation

of gas pressure.

slight adjustment

In this case a very

of the burner was made.

I

I

I

In case it was desired to operate under

predetermined

conditions

it was neoessary

to adjust

the heat under the still and the temperature

and

!

rate of the cooling oil until the desired

con~itionsi

were obtained. It was almost impossible to do. this

with the apparatus

used in this investigation.

In order to prevent radiation and

. consequent

condensation

in the column it was

necessary to maintain the jacket surrounding

column at very nearly the same temperature

column itself. This was accomplished

by adjusting

the

as the

quite easily

the amount of hot fiue gas entering

I

i

I

i

I

I

I

from the space surrounding I

the batt am of thejaokei;

the still. In oase the heat supply from this source

I

I

I

was insuffioient

it was augmented by inserting a!,

Bunsen burner in the sidearm provided for that

I

purpose.

The distillate

was caught and measured in

II

I

two burettes oonnected by a y in such a manner

that one could be emptied while the other was bei~g

filled.With

the use of a watch the distillation

rate could be determined

qUite aoourately.

rates were very valuable as an indication

uniformity of operation.

temperature

These

of the

The total, volume and the

of the distillate

collected during a

run was recorded. Its specific graVity was

measured at 60 F.with a hydrometer.

The bottoms were allowed to overflow from

the still thru the overflow pipe provided for that

purpose. ordinarily this worked quite smoothly

but on a few occasions pressure

fluctuations

still caused it to operate very erratically.

exact cause of these fluctuations

in the

The

was not discovere~.

When they oocured the bottoms were forced from the

still. at.a very rapid rate and the continuity

of

the still operation was disrupted. During the run

ocoasional

rates of flow were taken on the bottoms

to see that it was at least reasonably

There were minor fluctuations

constant.

but over a period of

!

i

I

I

I

a few minutes t'he ~a.te was ordinarily

MoFarland,and

still determined

MOGrath

qUite oonstanl'~

in operating

this

I

the r!J,teof fee'd when the still

i

,

I

was oOI.d and assumed .that this rate would be the

\

.

I

They measured I

same when the. s till was in OJ? eration.

the distill~te

oolleoted

eaSh minutetsuptraoted

I

it

J

from the volume of feed fO~ t,he same length of t'ime

and then drew 6ff-:the diff'eranoe as bott-oms. This

method of determining

the rate 6f feed was ohecked

up and found to be erroneotts due to the fact that

the pressure

in the oolumn is not the same during

the run as when the still is not in operation.

The total volume. and the temperature

bottoms from a run were measured

of the

and recorded.

s:pecific gravity at 60 F. was determined

The

with a

~ydrometer.

The length of a run was determined

the bottoms

rate since it was necessary

by

to have at

least tv/o Iitars of bott,'omsfor the de.termination of

the true boiling

I

point ourve.

At intervals

of five minutes

the column temperature;

I

during a run

the temperature

I

of the

inlet and outlet oil; and the oil rate twere recorde~.

The oil rate was determined

in a graduate,the

,

oil returned from the cooling cOill

during a :period of one minute.

enoountered

by measuring

in maintaining

Some difficulty

was

this ra.te constant')on

accoun.t of the fact that the l)um:pwas belJG driven.

\

I

I

Oil on yhe belt caused it to slip a great deal,

especially

Ylhen a high oil rD.'bewas

Considerable

1)8

ing used.

technique which can be

obtained only by actual operation

of the still

must be acquired before the column can be operated

altogether

successfully_

certain structural

before this apparatus

These are disoussed

changes should be made

is used for further work.

under tfRecommendationsn•

I

II

I,

I

(3)

Froc.edl1.re

continuous' still, tising no reflux.'

i

I

The' op~ration of th i'8 still was quite simple-I

I

Before ,a run 'was started the size of the Ctlt to be mad.e

was deoiAed. About 400cc of feed was then run into thel

still and the burner Ullder the still was lighted. b..

I

\

I

I

d~finiteamoUn~

of feed was then measured

in a graduat~

and added to the s0Daratory funnel each minute>the

stopcook on the funnel being so adjusted

that

a

I

minute was required to empty it.This gave a practicall~

\iniform rate .of'faed. Thebott oms were d.r~wn off thru I

the siphon at a xaye suffioient

to maintain

a cons.tant I

I

level in the flask. The heat under the still

carefully adjusted

\vas

until the rate of distillation

cOlTes:Pondi~g to the de~ired cut was obtained.After

oonstant conditions had been established. for approximately half an hour the run was started. During the

run the rate of distillation

was watched continually

and any tendency toward a ohange Vias oompensated by a

very slight adjustment

at the top of

the flask;and the density of feed,distillate,and

at 60 F.were recorded.

The length of a rWl was determined by the

time required to collect somewhat more than two liters

of bottoms.

I.

of the burner. The total time;

total feed;totsl distillate;temperature

bo~oms

I

I

I

I

1

(3) pro oe.dure

The analytical

I

I

still

!

This still was a very unwieldly thing to

charge. The top of the jacket had first to be

removed,using

I

great care not to break the thermornetet

which protruded thru it. The condenser was then

disconnected

I

from the stillhead. Thestillhead,

\

I

containing the partial condenser, yiCts .then lifted

I

I

straight up until the cooling coil had been

removed from the. column. The col~1n could then be

removed from the jacke.t by lifting it until it was

disconnected

!

I

I

;

from the mercury seal at the top of the

still, and then talcing it out thru the door in the

jacket. When this had been done the jacket was

lifted high enough to clear the mercury seal at the

top of the still,and the still was lifted from its

position

under the jacket. The mercury was removed

from the seal and the still was turned up side daVin

to remove any residue from it. since all of the

liquid remaining

by this method

in the still could not be removed

it was necessary

to insert a glass

tube into the still and draw out the remaining

residue.

A two liter charge of the gasoline,or

bottoms,which

measured

it was desired to analyze was

in a liter graduate and poured into the

still.The reverse of the operations described

in the

preVious paragraph was then carried out to restore

,J

I

I

I

I

!.

i

j

I

!

!

the ~pparatus to operating

conditions.

The gas burnerl

I

beneath the s.till was then lighte'd and'the still bJ:'oug~t

up to heat.The

jacket tem~rature

was then adjusted

the temperature

at which the first

to approximately

I

fraction was expected to come over. The oil

circulating

pump was started and so adjusted that

When the column was operating a ref~~

ratio of

I

I

15:1 to 25:1 was maintained.As

the column temDeratur~

increased.'.itwas neeesBary

to heat the oil to

I

pr~vent total condensation

by the reflux condenser.

I

.

'.

-

1

The heat under the still was oarefully adjusted

it was as high as could be maintained

without

until

I

cauSine

i

the oolumn to ,prime. ,In general,tha

rate was maintained

i

distillation

I

I

at from loc to 3.'50c per

minute.

The volume of distillate

5000 graduate. Readings

temperature

was measured

of total distillate'Joverj

at the top of the oolumn;jaoket

eratureitemperature

temp-

of the inlet and outlet oil;

and the oil rate,eA~ressed

v~re taken at frequent

simultaneously

in a .

as seoonds per 200cc,

intervals: and as nearly

as poeaible.

The distillation

of the bo~oms

oontinued until the column temperature

was

reaohed a

point somewhat higher than the tempera-ture on the

true distilla~ion

curve of the feed oorresponding

with the same percent

cut as that taken off in the

continuous still.

The reflux ratio was obtained from charts drawYn

by Welling, (M.I.T.Research Lab. of Appd. Chern.). With

their aid, the reflux could be calculated in a very few

minutes.

Copies of these charts are contained in this re-

port.

The method of using can best be explained by an

example:

Consider a case where the time read for 200c.c.

of oil to flow thru the cooling coil is 20 sec. and where

i

the temperature of the inlet oil is 130 F and that of the

i

exit oil is 150 F.; the rate of distillation being 12 c.c.

i

in five minutes, and the column temperature 200 F.

!

From

chart A, the number of c.c. of oil per minute corresponding

I

i

!

to 200c.c. per 20 sec. is 600.

I

The number of pounds of oil!

per minute is read from the line corresponding

I

to the aver-i

I

age temperature, and in this case is 1.05# Imin.

For a tenl-

I

perature difference of 20 F., this gives 11.7 B.T.U. per min.

I

carried away by the cooling oil.

i

Turning now to chart B, the

•

I

I

number of pounds of distillate per minute for a rate of 12c!.c.

I

in five minutes, with a column temperature of 200 F. is •

i

!

I

The corresponding number of B.T.U.'s, required to i

;

vaporize the distillate, is 0.46. The reflux ratiois then i

.00323.

I

I

I

11.7 divided by 0.46 or 25.4.

The data for the construction

I

of these curves wasl

obtained from tiThe Physical Properties of the Paraffin

Hydrocarbons"

(R.E.V/ilson, W.R.Bahlke.

I

!

Journal of Ind. and I

!

Eng. Chem. Feb. 1924).

I

The specific heat of the oil and ofi

i

the disti11a.te' ..was taken as 0.5.

I

!

.' _.j.

...

_._~

<)

I'()

....

._-

-

I

.

.- -_._-;_

..----.,-m,.

-_..

Ii.

--,-: +-_ ..... ~

.1

.

/

....

-/

,./'.

o

N

~

~

~

~

~

U-'.

~

-_.._._. '~inl.c!

Q

~

~

I

AO,:

I

I

I

~

OO~

-'~~cr-;sP~ nOd

.::>.~

J

I

SpUOJ~

()

~

N

~

i

i

I

__ .. _ ....L. ..

bW!.1

~

...J

o

c

- -

~

I

)

j::::

0

~

..Q

0

18

I

I

,

J

I

I

1

I

.j

I

l

!,

I

j

t'--

Cl

tt

<:::l

~

E

U

U

Cl.

~

),..

cr:l .-

~~

~

~ s::

<J)

~

()

OJ

-.0

0

0

Q

O"l

~

<:)

q,

lJ)

C>

....I ~

I ~

I

.. -.

I

I

IQ

I'()

I'D

0

N

'0

0

W

l<)

~

,l'\()

;n

,CJ

J(J)

i

I

I

I

I

._----

i----

\

j

i

1

!

1

-:._-

!

I

'j'

.•

-----

!

I

• __

0

Q

ti

N

c)

c)

\()

I

;

r

,

'

a.

_

.

a)

',J'

j

i

<:)

...:

('(

""'~g

....:.

.,.

~2'd

t-

'uJ -

~

I

Z

_

-.I

~-~

'2=

'-~~

0::lJ.JO

r-

WZ_

"-0-

-!.L.. .....

.-

--

....:

~

j'

'

.

...:

I .

I

ern

Q

.1/

\!J

~ £z

UJ

~4:3

-i

:

'j

:

....

3

ro

....J

--::;

W

._

"i

~

~

ci

I

J!

I '~

I

.; -, I

J

'-']

. ---

I

II

0/' 4

,tll,

, ,

8/, D/ /

~

0/.

~

".

.....

",

-/

,'/1.'

'"

I,'

- I

I'

,.

~I

:..

.-

, " ,

_...

-

.c-!

I

'

I

-:

!

••

:

~

'1

I

0

~

a

.

:

Q

~

j

l""

_.J ~

.!

i

i- ~._( ~

._: ..jI ~

:':]1 ~

'"" ~

~

l'I-7-~ "",'-- ~-..~g .i~

I

V.' . I.

/--/

I:"~'i

I

I

~

'rot'

<I: .

..'-u- W

: 0 ...,...

:~W

. U <t:

.-I

!_~

-.-:r

.!

1.-;-r-

-- a: z

-----~

o

..J-_

I-

~~nur~

i

"t

-- .. - ------,..I

I

I

\

1-

I

I

I

--I

I

I

-.

+._.--. _..

L. -:

:

!

!

1__

1

"

\~""

•._. 'I'-_.-

I

I

j_

I

\~"\?&0

,

i

; 'r

!_:

,

I.

-'. X~. '

i':

;' ,

L!_

..~..---{-:-~-.1--~-'\'\\

'~,.;--

~. __

0\

~

.~,o

•

-

I

,

I

,

,--.- ._-- ;.-1 '0"

,

I

I

I

..

,

,

",'0..._

.

'

"',

0

__"~

!.

;~:

'.-.........

-._---

-

'. ..-....

1#' '---~"--"---~~-'\-'~

/.0"

,- I

i"L.LI__

Tj

;

--

..

"

'.

~

~

,

i

'!to.

~~

00

.--.

U,";)':J:

"

ci)'.

IV

,0

"

0

-.-:.___

L._

~

.

I

''\

'..

__

_

__

I

I,

i

1

'"

0

-t-'~

___,

:~.

~

,

"!...

o!

--'7. '

'.

_L

1,

fI)

i

._

.

.!

. 0.0:'

'.

~

<i

~

fjO

!l'

g

I ...

i

'j./I

..

----'-------1 ,

1_-

r- ' _ ,.jl g

0

I .;

I

..__

~_ 0

i - ..!

L~.--l-----t-~-: ",

~

-- '-~'l" .J" __

I

i .. _..~

!'--'lr-~~-;1)11'; '. -. ".~~-~~-~:-----':-~_J~-~~~-~.--~

g

;

.

~~-.,.i-.

-_.-

0Ch

."

; ,"~

"\

I

'"

... _ ...

-C

---

~ __

1,

'

I

.I.!Y-------,

'.'

'.

.. ' ,-.

--. S2'~nU!~1

~

('C')

t_

~-.' '(/ ( ~--..::--=-=~.'-::. -= -'.-= .: ~,~.: -.: =-~.:- ~;...,

1/./'

j j 1./

~

0

..

I

. -- ',..

V.

/1/,

11j_'____

'ItY

I,

,

~---1t

~

i:

'}Jf--: .---

..

,- ~

-.--L - .7~,-

~"~""o

----_._-;-

--_ ~~~..

L - j_

~

-->

--~.-.-~.-. ..-i .

~--

~-

i

I

--'--,-

----:~-_.-

~--..

..

as to the best method of calculating the results.

reached had the same cut been made under conditions com-

I

plete ~ectification.

I

Then, from the distillation curve

of the bottoms, the per cent of material distilling below this temperature could be determined.

This per. cent of bottoms distilling below the

temperature mentioned above was plotted against B.T.U.

per pounds of bottoms, required to give the reflux used

in the run on the continuous still.

Plot I shows the

curve obtained by plotting Runs 5,10,11,12, and 13 in

the above manner.

These particular Runs were used be-

cause it is essential that, in order to be comparable,

the cuts be very ?early equal.

The initial point on

this curve was interpolated from Plot V which will be

disuussed later.

It will be noted that one point appears to be

.much too low.

This is undoubtedly due to insufficient

reflux during the determination of the distillation curve

I

of the bottoms, since this curve for Run 13 is much Clost

er to the Engler curve than it is in the case of the other

t

runs.

.

separation

Altha this method of determining the degree of

does undoubtedly give an indication of the

effect of reflux on separation, it is impossible to say

that it is an exact measure of the separation.

The dif-

ficulty encountered is in the definition of what is

meant by degree of separation.

In the case of a binary

mixture, it is perfectly possible to determine this quan-"

tity since, if the bottoms contained, for example, 20%

"of th~ lower boiling constituent it would be obvious that,

I

the degree of separation was 80%.

However, in dealing

•

I

II

with a mixture such as herein encountered, it ~s necessarr

to arbitrarily define what is meant by degree of separ~on.

I

If the lights left in the bottoms are defined as the amount

I

therein which distills-below the temperature which would II

have been attained had the same cut been made under conditions of complete rectification,

of calculation is permissible.

then the above method

It is obvious that, on

the basis of feed, the per cent lights in the bottoms

must equal the per cent of heavy ends in the overhead or

distillate.

It must be realized that it is impossible tol

obtain complete separation in a tower in which the feed

is introduced at the top of the column, since in such a

column there 1s no section provided for the purpose of

stripping the heavy ends from the distillate.

{,c

It was found to~impossible to obtain points on

the left hand portion of this curve.

The lowest "value

of heat was obtained using only feed as a means of producing reflux.

It was suggested that a still lower re-

flux could be obtained by preheating the feed.

However,

had this been done, some of the more volatile portions

of fhe feed would have been vaporized, thus changing the

composition of the gasoline actually introduced as feed,

and thereby making the results incomparable.

(See also

McCready M.I.T.The~is 1924)

Plot II shows the effect of the per cent cut

vs. lights left in the bottoms.

The straight line is for

continuous distillation with zero reflux whereas the

curve shows the relationship when operating with reflux.

that, within the limits used, the degree of separation,

as determined by the method previously discussed, did not

I

I

vary greatly with change in reflux.

I

curve are therefore comparable.

in nature.

The points on this

The curve is hyperbolic

Its equation may be derived as follows:

EQUATION FOR THE RELATIONSHIP

BETVffiENVffiIGHTPER CENT OF

BOTTOMS vs. PER CENT CUT FOR A HIGH REFLUX.

I

I

I

Plot II

Call:

x

I

Per cent cut.

Weight per cent of bottoms distilling below the I

temperature

at which the given per cent cut ,is

I

0

over with complete rectification.

'A Plot of"x vs. x 'has been made and is found to be a

y

straight line. (Plot IIa). This line was drawn using

the method of least squares, omitting the ,two points

which are apparently in error, judging from a comparison of the true b. pt. curve of the bottoms with the

'1

;

Engler for these runs.

/

X

Run

x

Y

y .: Y,

1

28.2

7.8

3.62

The equation of this

2

23.7

7.2

3.29

straight line is

3

12.7

5.2

2.44

y. = 1.22 T 0.085 x

4

19.3

4.2

4.6

from which we get

5

39.0

8.8

4.44

6

52.6

9.0

7

59.8

9.4

6.36

10

35.5

8.0

4.44

11

34.5

8.5

4.06

12

35.0

9.0

3.89

13

34.6

6.0

5.76

x::

58.5

1.22

0.085

1. Y

I

PLOT

I/)

2.. 6

~

o

t-

....o

z4

en

-::-:1

--...

u.

----_._---

!

o

)-

-,.

--

;Zo

[

.

I

..-..- ... - ..

.1

Z

--- .-

I

!

-

W

\J

/8

cr:

w

a..

/6

/111-

I

II

10

--'--,

.

B

o

..

'._ ...- ..,

80

8TU

12.0

PER

POUND

OF"

BOTTOM:5

~4

tf)

~

0

t-

.-

40

f-:-+----:-- -:----

345

~~--!-c--.

:_-- +~-~ -!-

0

--t-

1._ _ : _ ~

0)

LL. 32.

0

z

w

\J

I.

w

a.. £..0

3

,

1

4

-

---~:

I

_

1

.!

..

.

.1

J-

: --- -!--~I

--~

.1

- -,

.

_::1

I

. I

rn----~:--I

.

of

.:

r- -

!

<-::-

.

j

:

j

t

I

.

,

.

-....-1---.._._---:

-----,

i

.-r-----.-;---

: :i

:-rI

i

_" ~_ .... 1

16

_

i

.\.

f-

Ill.

.I

_.... _.__~_._.._._---J-- ---

1

t-,.

r

w

~

-'~-.

;_:

r

)-

;.

-

~.

C1:

~ i_I

!

,- -: -:: 1-\.

i.4

_!

L-.-' __L : .L .L

I

t- ~B

i-

_

:

_:_~j

I

I

'-1

REFLUX

..\

-'

I

..

e

1

I

o

- --~

ELLIOTT

t

o

---.-

_. ----

----

40

10

PER

Ii

, .

- - .--- . __ .- --:

o

---l

CENT

50

.----

f,O

CUT

--- j

and

L£HNHARDT'

~.

..----

70

eo

90

_.

_--.J-

i

..

100

II a

PLOT

.j

..

!'_._----_-..~

J

---

I

'v:

.J A

.... 'Y=

Y

belowth~

give!1.

p~r.

~'cctlflcatlon.

:

.

,

'j.--.-:-~-:~~.!

;.:.!', :

--_.

~-

;

__

l._~:.~_~

::.

__ . ~ ..

I

. , .- .' f

.

W,eightl_-peJ"

I

-:-.-t~-.-.

P..er .. cent __cut. : __

~"".

X

;

:

:

•

I .

t ..

;_.~

..-...1

'j

_____

'jx.::

.~

I

- -.

_+_~-:.~_.:-,

. . '1.:":::-\

_ ,.

• ~. -- ' .. i

','_cent' of J2Dtt()m~;"

disdUi.n,.~"::"

temptrYatLlt"~

at whi<.n; the::'

cint cut is ~V~y

""'riih

,

.

'brri~~~r

.:

.-.. _--1.-- -- -..• -, i,-_.. - - .,. I(.....

I

_

.!

i

••.

_

I.

,f

'1

I

I

l - .., -

--1----- ..L..--

:

-

:

!

,"'r

----

I

"--1

..

0

'0

I.

i .

;

!

:.1

,-_._~ ....:_-~

!

- ---t.-

5---' -----.----.:..-------..-"'---

!

.:

. ~

t.

. :1

I

I

t.-_:__

I

,

_._-i

.--4-. -

.~ __

-- ".

I

i

I

;

.-----;----5---.

i

.

.j

.\

,

':1

---"-1

":~-'--:-:-1i

_.-

._~ -'-'.-''';-1

....

, : -: ~1

! -

.... ---1

1

-

-~----:-1

j

x

o

I

L_~__~

Ie

30_

so

60

ELLIOTl:

~

.l~

L EHN.H.~__

R~!

and

J

~_~

Perhaps a better method of calculation is that

used in the determ~nation of Plot III.

In this case the

initial boiling point of the bottoms was considered as

the determining factor in calculati~

lights in the bottoms.

the per cent of

From the true boiling point curve

of the feed the per cent which should distill below the

initial boiling point of the bottoms was determined.

Thi~

volume per cent was then calculated to weieht per cent,

and subtracted from the per cent cut.

method is as follows.

The basis of this

The per cent lights in the feed

is arbitrarily defined as being equal to the per cent

cut.

If when the bottoms are subjected to complete rec-

tification it is found that the initial boiling point

has been raised, it follows that the amount of feed dis-

j

tilling between the initial boiling point of the feed and

I

the initial boiling point of the bottoms has been removedJ

Then, since the per cent lights in the feed was defined

as equal to the per cent cut, the per cent of lights in

the bottoms must be equal to the difference between the

cut and the amount distilling between the temperatures

mentioned above.

I

I

I

It is obvious, from a material balance, \

that regardless of the degree of separation obtained, the I

pounds of lights in the bottoms per pound of feed, must

be equal to the pounds of heavy in the overhead per pound

of feed.

The initial point on this curve was interpolate

from Plot

v.

The curve obtained by this method of calculatio~

is hyperbolic in nature. Its equation may be derived as

follows:

I

I

EQUATION FOR THE RELATIONSHIP

BETVffiENLIGHTS IN BOTTOMS

AND HEAT REQUIRED.

Plot III

Call:

x

Btu. per lb. of bottoms

y

I

Pounds of lights in bottoms per 100 lbs. of feid.

Assuming

a hyperbolic

relationship

between

x and y, the

equation may be set up.

following

- c

(xta) (y-b)

From the experimental

where a, b, and c are constants.

.

I

data it is knovm that when x ~ 0,

y ::- 33.5

Now,

And

Y

= --£

+

x-a

33.5::.JL

a

b

t b

subtracting,

33.5 - Y

x

33.5-y

=

= ~a

--2xta

a

)

'6

(xta

I

Which shows the left hand member of the equation to be

I

a ,linear function of x.

I

vs. x gives a straight

assumption

The accompanying

33.5-y

line (Plot IlIa) showing the

of a hyperbolic

to be justified.

plot of ~

relationship

between

x and y.

I

Run

x

Y

x

y,

33.5-y =

10

19.2

209.4

14.65

11

19.1

272.7

18.94

12

22.3

75.9

6.78

13

20.6

140.8

10.91

33.5

0

------

From the straight1in~

=

when x • 280, Y,

plot, when x

=

0, Y, =2.3

19.2.

The slope of the line, a , is then 19.2-2.3

c

280

When x

=

.

0, 8

c

c

=

~

=

Then a

2.3

And

630

Y

and

= x+38

630

=

2.3

0.0604

=

0.0604

=

I.

38

b - 16.9

.. 16.9

T

I

I

PLOT

C

LIJ

lAJ

LI-

L&-

0

36

V>

0

z

:>

0

34-

0

0

32-

0:

30

(l,

LoW

a..

C1)

~

Z8

....

0

~

~

0

I

___ ....

l.

2.6

Z

.__.!..

i

CO

:

.!

24

-

.._--~-

.L

'j

I

---~-1

.

I

~ .., :. ::-:j'

1

t..

:

•

c.!>

I::

'"__..•.:i

_1

.... J

t.

_.

I

. : . :,:

-

I

LI..

.20

---t_~

I

2

a

0..

~

16

I~

.

L--- - L __1.-•

.----.-

j

..

t:.. ...

...

_~~

...

.

-.

.--

.•

_---

.----.-

._-

._.

---

••.•

-

.+--

-i---' -_.. , -.~-~.'_: '-" _._~

--.

80

IloO

8TU

/60

PER

POUND

.

i

ELUOTT

.

~nd

,

LE ~ ~.~RbT

._._._~

200

;

."j,'::

:: I

:-:I

.;._.__.. . :-_:L_: __~ I

_._.

-- .

_.. _._ .-.

----40

-

._\

. .. :--1

I'

I

~

~_ _~~---~-----_

1

:j

-f

.

,

~-'_!

- .• -,

.

i

1 ...

::>

---.

I

I.

/8

.. ~

I.

0

~

•

-: -- -.. ---'+--,1 -.-:-7-,1

2'-

-J

i

L

...

I

V)

~

::t

: _.. "j

\

I

.,

:l80

OF'

320

eOTTOM~

360

...

.\

i

.~__..J

+00

ma

PLOT

,

. ---._---- --y-

:----~.

J

-.- -+-- _.._--_._-

- 16--

--OJ

//

I

i

I

[~--~~-t--'-/4 --- --- ---- ..---

--t

[

-,

t

/;(.

t

I

!-_.--

,

.j

!

i

-J-'-IO-1

-

I

8

,

6

.j

j

::1

.~.-!

i

~.Xr~.';

_

I

:

Xl

0

40

80

11.0

160

.R-OO

;?40

280

I

ELl.I01T

I

I.

:

I

,

VI

. Qnd

LEHN HA'~DT

II

I

I

I

i

J

I

A comparison of PlotatV and V~'.shows ve-ry clear-j

I

ly the effect of rectification.

I

In these plots the per

!

cent cut is plotted against the temperature at which a

I

given per cent is over in the distillation of the bottoms.

I

In general these points, for different reflux ratios,

I

would not fallon

I

the curves as they do.

But due to the

I

fact that most of the runs were made under conditions

I

where a change in reflux ratio made only a slight difference in the degree of separation the points fall reasonably close to the curves.

I

I

It is interesting to note the, !I

very low initial points obtained when no reflux was used. I

Plot VI was constructed by reading the initial

points for various cuts from Plots IV and V and from them

I

I

l

determining the amount of lights in the bottoms, by means II

'

of the "initial point method" previously discussed.

The

similarity between this plot and Plot II should be noted.

,I

I

I

Plot VII shows the effect of rectification.

Hadl I

I

complete rectification

taken place, the center curve WOUldl

have been identical with the upper curve.

These curves

I

show that in the case of Run 12 no bottoms boiling above

290 were taken over in the overhead.

The lower curve shows

I

that when no reflux was used a large amount of high boillnk

material was carried over in the overhead.

I

Plot VIII was determined directly from Plot VII_I

It shows the ratio of the per cent over on the true boil- I

I

ing point curve of the bottoms from a continuous still using

I

no

reflux, to the per cent over at the same temperature oh

,

I

the true boiling point curve of the bottoms from a contin-I

!

I

300

i

~80

'>------

_ ....

_-.~_. __ ._~._--_.-.--._--

;

- 1

_.

.

1.1

~60

r-~:

:

A.40

I

.J

L

.

I

.

.,

I

~~:.__

.

I

I

'"

i"

t--- ---,---- - ~ .~--

Z20

: ----

---j

;?OO

:

IBO

-'

_.-

:'j

to

_"-

I

1

_

160

i

i

I

I .

140

-

,

:'--'\

I/?, 0

100

60

60

ELL10n

(;and

LEHNHARbT

o

10

20

~lO

PEA

60

CENT

60

CUT

TO

80

90

PLOT

h~:'~:l4J-q::

f

dl---l

i

~SINGi'-~O

~.~.

;

t_;_c::';~:Yh~~1

-----I::

:FROMf"-A~foN~5~iE;;;~

:::'PERtENT{UT

f'

V

REFLUX

. v~.

- TRVE .-8~ll-I.NCt ..

i-' .. t>r'el5TIOM5-7ir-A-:{;lVE~

l'~':'.;-.~..~.,

;.:--;.;- _.. _.

~--.J.

... _.

OFt

:.!'

.'

.;. -:. .:

: .~:. .. ~ -1.:'::'

r .,

.'

2.~O

240

"

:

.. i

,:

.. :---

,;.

i'::.

:

-!

.

•

--.--'

,

\.

;.

I

;.;

- _ ..

I

.•

..

'

~.__ "_ .' __

•

~

I : -:.

":,'::

~.:: .: ~

t. peR .CENT: , ovSFr:DH:':'

-

I

:~-

..

f:

. --

14:.

..1

~

-. .

I.:.,.:'

.\.,..::

I

;

.:

TTCU,E::b.tiY:

:--i-----;- ..-.-:~:-.- --:-r:I~u-'-:-fD"~~

• .

..

:.

t

.

j

.;

;~~~f

PElirccmr;:mfER,~~

;~":l ::~J~.:~FI~~

-. -~-f-.--+------f

~~2:-'j::'~;--J-J-...L ....:. ;~-i'~o

~, -.. ,--'r~.--t--7--:-:~-.

~-

;?20

.1

!

'P01:N!

~_.:

~

__

:~

: ~ .. _ .

."'~'I

,1.'.:

:J.~t~

..

..

:-~

_

i

i . .;:

:

I

;'

_. ~.

.' ~:

.. _.~

:~>: :: ..

. .......

;200

/8 o

:

160

r---'--:-:- .. - .-!-: .. ~L-

:--. .

'.

.

,."0

'.'

,

---'--j--'-

'..

"T::

.

j'

:.

I

,

.

,+

r: . ..

+.:....

/40

:i.

-.\.

-.

~:-r..:~ ~

-':!'-..-f~.' ..

-'-~i"

;

,

I:l.O

:.~:

:~~

L ..:, I

r

...

b.::.- .. \.:~~:-:c~.

:~--;P:-J]

-- 'j. ,-" ..

j: ~-::::-

.. _---~._-----_._

..--- -~.. -_:.~-j---~ .. " : :~:-:

100

.

. I

I'!

,

. I

. ~. ::--

~li_'L.._~_.:~--~C.••j •••~t:'-~~f~--j--:.:~-J::

80

r- .••

60

L,.I ....:, "6

!

_ .•

40

."::::

I."

;Z.5

I-i~--'-'l-.-,

!

l

L.--

.. ,

-----+- ---.

l'

'

.'

I'

30

PER

_:-

i. ".

:-.1

EWOTT G1~.; d: .:~

; '-... : : :__.L.~.~N..H~R~L:::.'

~

/0

I.:.~i::::

,.:i..

-1----- .---:

_....

--~ ....- .~.

;--_._.

-- ,-.-'-.

j-. "1:,:,:.:

.

40

50

CENT

60

CUT

70

80

.,

gO

PLOT

0

CUT' ......." ...-

""'L:T'PER'C.ENII

w

w

u.

La..

0

V)

55

0

z

:>

0

Cl.

0

0

ex:

llJ

n.

50

1.1.

. ..',;,,_,

.. c. ,.N:rREE~x':'I-+-l-L.

4.5

40

V)

~

35

...

0

I0

CO

z

-

30

~5

(r,

....

:z:

\:>

zo

[118;:..'

•.•....••.• ,I ..•.••

:~.::~+

'I,~.

-oJ

LA.

/5

0

V')

Q

10

Z

~

'0

0..

5

::: .::L~..:I

.

-I

0

- " ... (. -,

o

10

:zo

30

PER

so

CENT

60

CUT

70

80

90

~.:.£

100

;z60

<:::: i-~ I

2. 00

r:

I - :.- -;

I-

IBO

. :1

I"T~t=

/GO

I --1

/40

~

1

I

f;lO

I

f~-~~-+-.-.

tf----

30

:

-40

PER

50

CENT

60

OVER

70

80

0

CY)

u...

f

>---

'"

:z: 0

.Q ..,

w

If~".,'~. __.. ~>

...... c::

0 u

I.:..

.'

~,:J

f,

~

0

....

~

<:)

t!I

C't)

0

t""

~

<:>

~

~

<:)

m

C'l')

<;)

<T)

L..

0

I

w

0

ex:

C't(

~

~

g

::>

<:

ex:

w

~

(l.

0

w

~

~

<;)

(t")

N

0

~

(;)

O'l

<:)

r--..

~

.-.

uous still using reflux,

I

vs. temperature.

I

The next four c~rves show the relationship

I

be-

tween the true boiling point of the bottoms from the con-

I

tinuous

I

still and the per cent of the original

tilled over.

feed dis-

I

The per cent of the feed distilled over in-

eludes that taken over both in the continuous

the analytical

still and

stant per cent of the bottoms

to a definite

in\

i

for a con- I

I

Each curve !

distilled

over.

per cent of the bottoms

distilled

over in the analytical still, the value of which is given

by the intersection

of the feed.

I

still.

Plots IX and X show this relationship

corresponds

I

of the curve with the true boiling

I

!

I

poitit

I

curve of the

feed is, in th~s

.

I

I

case, a plot of the true boiling point vs. per cent over fdr

a zero cut.

The true boiling

On this curve the .per cent over is,.therefore,

taken over only in the analytical

per cent of bottoms

Consider

still and must equal the

over since feed and bottoms

the casefhere

I

are identic'al.

high reflux has been used

I

lin

I

the analytical

still.

An example will probably

render these

points more clear.

Suppose that when 5% of the bottoms

over in the.analytical

Following

still, the boiling

the curve intersecting

I

point is 200 F.

the true boiling

curve at 5% over, we find that a temperature

responds

has been takdn

point

!

of 220 F. cor~I

to 40% of the original feed distilled

over.

The lowest curve shows the relationship

I'

between

the initial boiling point of the bottoms and the volume peJ

cent cut.

I

I

IX

PLOT

O;~:.::B'::j':"'~,"-O:,~'--ISi"';:C~:'~,' ttt"::

of gR'd,£:::-t::e:"bL:'I.~~.-I'N:~~n.~P:"O"JN~~L::

'A"

I~'j'---;:

320

30"

~80

U

,s,e;

r'"

,o,'=':~:=":-:3:::'~;~

f'"

~~~,•

F,i:.:p~;~Lfi'GHC~;~~,,~i~S~~.r~~-~'~.'.tl'

"~';',:,lr,;"t,~,,~:,~,.~,~,-,~,2[,~,:,'

::::::~~~T

_~F ~E.

; - CE~"

I

-

-t

[. ~~:

•

-,

,-pnIG~~~L _,._FEED

',OV~R-:-;-=~'HE::-.-P£-R:-=-:

.t-._~..

OF:; .BOTTOMS -. DVEB . :-

;-::-:-&f5jT+t:Effi-:

-

, '~~=--;.--~.

f

~-_.

:'.

__

•

t'

-; '~~~-.:.::_ - --.. - -

L_~~~~~.-.:_L~ON~!~~.T~:::::..._

.._: .._

.:

..

:~::~:t~:::=F-:.;t~.:~:~:,

- ~~7:-:-1-=_.

, ..,_. ,.: .... j ,.• '

_

I

••.

, ••.

t .....--

-"-'f-'

..~

~--',.-;"~.'_"'-~_"

.. - .• -~:

-

,

-=~1.:-~'-.,; -J~'~~-f~';!=:~i~:

..~

_.t-'~---f-~"'.:~.:.:~-t-,-

2.60

Z"40

P1t. F~RVE

~T~U~i_.8 ..

~ OF '-~EED-'

r- .- -.,.~

'" ;.....----..

'0

:;::.1",

I'

c-

, .. :\ :-:'.i.::-::J:::_.~.~:~:

'._' ; __ u== ----

2,00

180

r-'~

160

I.L,..:

-,......-l,-~-'j';" '~:: .,--~j,

"---4-+#--

,',

--I..--~L•'.l'"•.t-'•., l~.:<f'TI: t,i:~!

L:

'.

-f ..I

1

r;.:

.

1'--' --.----,,--'.-_

... -----....--'..-- :-'-'-'--~--''''--1---''----1''-'-1--'

j

,

I,

,40

_i,+_,

.' ~ :

1:

I .'

• r

I

.:

;lL

!,:,

t

:'

I

1

..

."

i

120

. _

j

I

~. , , ,

I

:

r

'.:

..

-

~

••

-.

; ';1

.

I,"l

'

,.; .., .. ~.:... 1. . '_ .. __~!_.... ; .

80

!

.,

I

••

•

'.-

••••..

eM<

I ,.':

;:

' . '"

r

' .

I

I ...

.i

:

J

I

40

i

I'

..... L_.I

'__

! : .:, .; "'.1 ~~:

I

.

;",f_'i

f

".'T- ",. :.;.::'

100

' ~ - .j .

'\'...

I. .:

: .: ' : '.

1...!'

__

~

..

. ' .'.

....

t.

- :,

';:

10

30

PER

~o

50

CE.NT

60

OVER

.70

f'~:-:

:;::;.j':l;~~

:i(l:;,~);

,i~"~~;.t~~:::

I::. !I'-~':'

'J:~, ~:

.

I '.': ..-,-:: ..

"i"~-:~

\

~.,'~~'':l

I

:...~~~.

.. J

Ell!IOTif' . land'

LEHNHAR.~!

,

o

1

80

90

." v,

:'

.,j

~

I

100

/tJo

140

I~O

100

80

60

I

.

~

..: ~- .... :::)

o

10

30

PER

So

C.ENT

60

OVER

70

80

9D

-

100

The effect of rectification

a comparison

of the two plots.

is-clearly

Reflux

shovm by

II

tends to increase

I

i

II

the slope~ of the curves and causes them to more nearly

approach