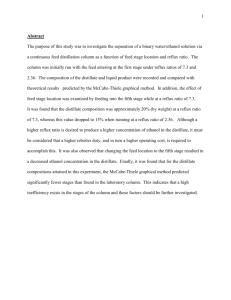

Set7ans

advertisement

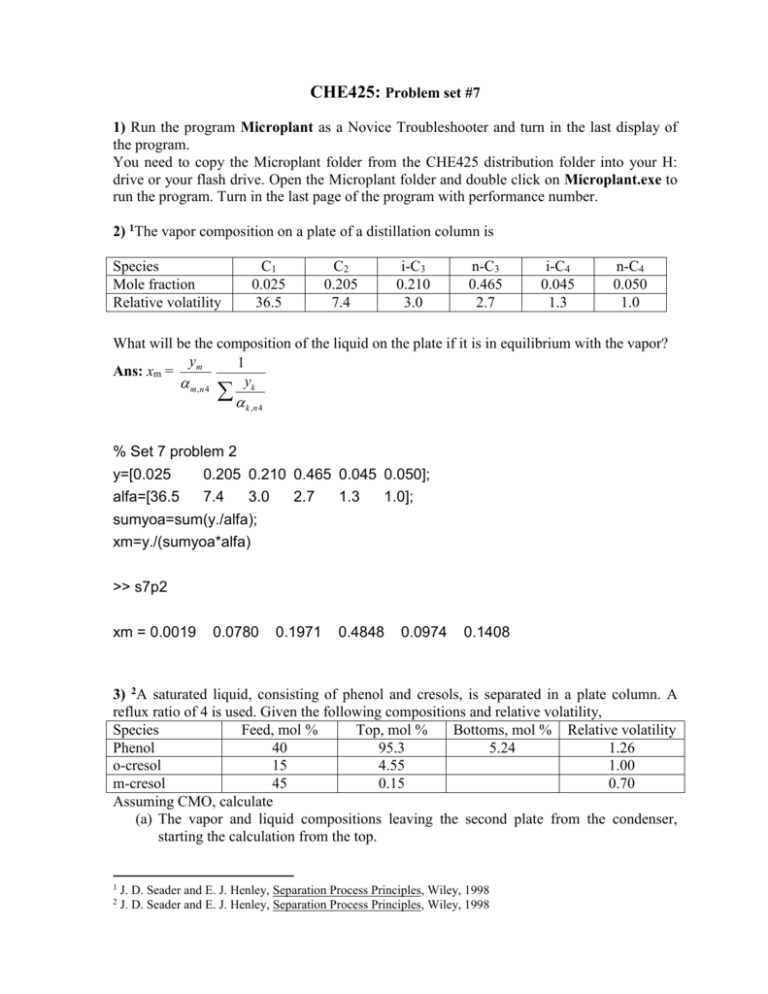

CHE425: Problem set #7 1) Run the program Microplant as a Novice Troubleshooter and turn in the last display of the program. You need to copy the Microplant folder from the CHE425 distribution folder into your H: drive or your flash drive. Open the Microplant folder and double click on Microplant.exe to run the program. Turn in the last page of the program with performance number. 2) 1The vapor composition on a plate of a distillation column is Species Mole fraction Relative volatility C1 0.025 36.5 C2 0.205 7.4 i-C3 0.210 3.0 n-C3 0.465 2.7 i-C4 0.045 1.3 n-C4 0.050 1.0 What will be the composition of the liquid on the plate if it is in equilibrium with the vapor? y 1 Ans: xm = m y m ,n 4 k k ,n 4 % Set 7 problem 2 y=[0.025 0.205 0.210 0.465 0.045 0.050]; alfa=[36.5 7.4 3.0 2.7 1.3 1.0]; sumyoa=sum(y./alfa); xm=y./(sumyoa*alfa) >> s7p2 xm = 0.0019 0.0780 0.1971 0.4848 0.0974 0.1408 3) 2A saturated liquid, consisting of phenol and cresols, is separated in a plate column. A reflux ratio of 4 is used. Given the following compositions and relative volatility, Species Feed, mol % Top, mol % Bottoms, mol % Relative volatility Phenol 40 95.3 5.24 1.26 o-cresol 15 4.55 1.00 m-cresol 45 0.15 0.70 Assuming CMO, calculate (a) The vapor and liquid compositions leaving the second plate from the condenser, starting the calculation from the top. 1 2 J. D. Seader and E. J. Henley, Separation Process Principles, Wiley, 1998 J. D. Seader and E. J. Henley, Separation Process Principles, Wiley, 1998 (b) The vapor and liquid compositions leaving the second plate above the reboiler, starting the calculation from the bottom. Ans: y2 = 0.9432 0.0544 0.0024 x2 = 0.9283 0.0674 0.0043 xNm1 = 0.1009 0.2909 0.6082 yNm1 = 0.1507 0.3448 0.5045 4. 3A feed mixture enters a distillation column at a rate of 200 moles/hr. The feed has the following composition: Compound Mole fraction Relative volatility Benzene 0.20 2.25 Toluene 0.30 1.00 Xylene 0.10 0.33 Cumene 0.40 0.21 The feed enters as a two-phase mixture that is 30% vapor. The column has a partial reboiler and a total condenser. Feed is returned to the column from the condenser as a saturated liquid. The specifications require that 99.8% of the cumene be recovered in the bottoms and 99.5% of the toluene be recovered in the distillate. The equilibrium data can be represented by constant relative volatilities. We have decided to operate at total reflux. What is the recovery of xylenes in the distillate? Ans: FR of xylene = 0.05313 5. 3We wish to separate three components A, B, and C. If B is picked as the reference component, A = 1.25 and C = 0.50. The feed rate is 100 moles/hr, and feed is saturated liquid. Feed compositions are zA = 0.3, zB = 0.5, and zC = 0.2. We desire 99.6% recovery of B in the distillate and a 98.3% recovery of C in the bottoms. The minimum L/D has been estimated as 1.04. The column has constant molal overflow, saturated liquid reflux, and equilibrium stages. If we wish to operate at (L/D) = 1.2(L/D)min, estimate the total number of stages needed and the optimum feed plate location. Ans: Ne + Ns = 32.8, Ne = 15.4 Feed tray = #15 from top. 6. 3A distillation column has a feed of 100 kmol/hr. Feed is saturated liquid with 10 mol% LNK, 55 mol% LK, and 35 mol% HK. Reflux ratio is (L/D) = 1.2(L/D)min. We desire a 99.5% recovery of the light key in the distillate. Mole fraction of the light key in the distillate should be 0.75. Determine the minimum number of trays, the minimum reflux ratio, and the number of tray at 1.2Rmin. Data: LNK = 4.0, LK = 1.0, HK = 0.75. Ans: Nmin = 22.49, Rmin = 2.47, N = 48 stages 3 J. D. Seader and E. J. Henley, Separation Process Principles, Wiley, 1998 7. For each of the following units with C components, determine NV (number of variables), NE (number of equation), and F (degree of freedom): (a) Equilibrium feed stage with heat transfer and feed (b) Stream mixer (two streams combined into one with heat transfer) (c) Stream divider (a stream is divided into two streams with heat transfer) Ans: (a) F = NV NE = (5C + 16) (2C + 8) = 3C + 8 (b) F = NV NE = (3C + 10) (C + 4) = 2C + 6 (c) F = NV NE = (3C + 10) (2C + 5) = C + 5 8. Construct the enthalpy concentration diagram using the following data for methanol-water system at 1 atm: x or y 0 5 10 15 20 30 40 50 60 70 80 90 100 H(Btu/lbmol) 20720 20520 20340 20160 20000 19640 19310 18970 18650 18310 17980 17680 17390 h(Btu/lbmol) 3240 3070 2950 2850 2760 2620 2540 2470 2410 2370 2330 2290 2250 Vapor liquid equilibrium data: x 0 2 4 6 8 10 15 20 30 40 50 60 70 80 90 95 100 y 0 13.4 23.0 30.4 36.5 41.8 51.7 57.9 66.5 72.9 77.9 82.5 87.0 91.5 95.8 97.9 100 T,oC 100 96.4 93.5 91.2 89.3 87.7 84.4 81.7 78.0 75.3 73.1 71.2 69.3 67.6 66.0 65.0 64.5 a) Use Matlab to construct the enthalpy concentration diagram with the tie lines from equilibrium data. Label the plot with your name using the Title command. You can draw the tie lines from the following Matlab codes: nt=length(xv); hlt=spline(xy,hl,xv); hvt=spline(xy,hv,yv); for i=2:nt-1; x1=xv(i);x2=yv(i); y1=hlt(i);y2=hvt(i); line([x1 x2],[y1 y2]) end b) One hundred lbmol/h of a mixture of 69 mol% methanol in water at 30oC and 1 atm is to be separated by distillation at the same pressure into a liquid distillate containing 98 mol% methanol and a bottoms liquid product containing 96 mol% water. The enthalpy of the feed mixture is 765 Btu/lbmol. Determine the minimum number of equilibrium stages, the temperatures of the distillate and the bottoms. The minimum number of stages is seen to be 6. The value is independent of the feed condition because at total reflux, there is no no feed. The temperature of the bottoms is 93.5oC. The temperature of the distillate is 64.7oC