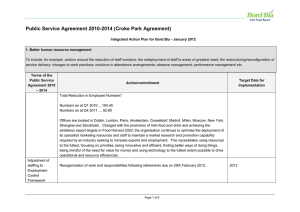

Meat Processor Quality Assurance Scheme Processor Standard Revision 01

advertisement