Revising the master production schedule in sequence dependent processes SCHILLINGI

advertisement

INT. J. PROD. Rhs.. 2003, VOL. 4 1 , NO. 9, 2021 - 2 0 3 5

_ Taylor & Francis

\^y

Revising the master production schedule in sequence dependent processes

JAMES A. HILLt*, WILLIAM L. BERRYt and DAVID A.

SCHILLINGI

Revising ihe master production schedule (MPS) in a roiling planning horizon

environment to improve plant performance is critical in process industries with

sequence dependeni changeovers. Plant performance is defined in terms of process

changeover time, total shortages, and finished goods inventory. Two heuristics for

revising the MPS are introduced and tested against a rolling horizon MPS thai

does not take sequence dependent changeovers into consideration. These two

heuristics represent two dilTerent approaches to heuristic design: local interchange

(SWAP) and global interchange (3OPT). Simulation experiments are reported

that test the performance of the two different approaches lo revising the MPS

in process industries with sequence dependent changeovers. The MPS designs

were tesled under plant conditions that are frequently encountered in process

industries. The results indicate that revising the MPS in process industries significantly improves plant performance. In addition, 30PT provides a major

improvement in changeover time, while SWAP provides improvement in total

shortages.

1.

Introduction

Changing markets are placing new business reqtiirements on many process industry plants, including the need for greater product variety wilh improved changeover

time and delivery performance (Leschke 1995. Olliff and Burch 1985). Supporting

these requirements is especially difticull in many process industry firms, such as firms

that manufacture chemical products, because such processes frequently involve long

product sequence dependent changeover times. As reported by Leschke (1995) changeover times represent a sizeable proportion of plant capacity, e.g. 47-92%. and are

not easily reduced through conventional changeover time reduction methods. One

means of supporting changeover time and delivery competitiveness in the high variety environment faced by such companies is through the development of improved

master production scheduling. In this paper we focus on improving plant performance by revising the master production schedule (MPS) in a make-to-stock process

industry environment.

The MPS specifies the timing and size of production quantities for each product.

The MPS links the firm's broad strategies, as expressed in the aggregate production

plan, to more specific tactical plans that will enable the firm to balance the product

demands of customers with the supply of products made available by plant schedules

and inventory. Process industry firms generally perform master production schedulRevision received June 2002.

tOwen Graduate School o\' Management. Vanderbilt University. Nashville. TN 37203.

USA.

J Fisher College of Btisiness. The Ohio State University. Columnbus. OH 43210, USA

*To whom correspondence should be addressed, e-maii: james.hill((( owen.vanderbilt.edu

liuenunioiiiil Jmirtiut oj Protluciioii Rt'.u-tmh ISSN 1)020 7543 prinllSSN 1366 5HKX online i; 2003 Taylor & hrancis Lid

http:,''www.landr.Lo.uk'j(.n]rnals

DOI; IO.I0K0/0020754O3IOO0I23BH6

2022

J. A. HilUt al.

ing differently from job shop industries. These firms tend to schedLile capacity first

belbre raw materials because of resource constraints within the chemical blending

and mixing process. If planning for capacity at the chemical mixing and blending

operations indicates potential infeasibilities. the master production schedule shouid

be revised to accommodate these capacity limitations. Most of the previous work on

master production scheduling does not consider process industry firms where changeovers are sequence dependent {Lin and Krajewski 1992. Sridharan et al. 1987. and

Zhao and Lee 1993). In this paper we address the problem of revising a rolling

horizon MPS in process industries with sequence dependent changeovers.

This paper has two objectives: (I) to present computationally efficient methods

to revise the MPS to improve plant performance in sequence dependent processes,

and (2) to determine the sensitivity of these methods to frequently encountered

differences in plant operating conditions. We begin by discussing previous literature

relative to the master production scheduling problem. In the next section, two heuristics are presented to revise the MPS under rolling horizons. Next, we present the

research questions to be examined and the research design used in the simulation

experiments. Finally, computational results are discussed that demonstrate the

improvements in master production scheduling performance.

2.

Literature review

Very little work has been reported on master production scheduling methods that

consider changeover time and product sequence restrictions often encountered in the

process industries. Product sequence restrictions and changeover costs were incorporated in a process industry model reported by Oliff and Burch (1985). They present a mixed integer programming model that determines lot sizes, line assignments

and inventory levels for 28 MPS products. However, because of the problem size and

computation requirements, a linear programming approximation that generates

near-optimal solutions is limited to small problem sizes. De Matta and Guignard

(1995) study lot-sizing and changeover decisions in production schedules that are

implemented on a rolling-horizon basis. Their results show that as the planning

horizon lengthens, the changeover and holding costs converge. These authors do

not include re-planning intervals within the planning horizon. Hill et al. (2000)

introduce a two-level approach to master production scheduling. The authors

show that master production scheduling should be done at the bottleneck process

(level two) not the end item (level one) in order to improve plant performance.

Some research has been done on re-planning the MPS under a rolling horizon.

Lin and Krajewski (1992) present a mathematical model for designing a MPS system

in an uncertain environment. The model can be used to estimate the expected cost

per period for any combination of the re-planning interval, the frozen interval and

the forecast window. Venkataraman (1996) addresses the problem of re-planning

frequency for a rolling horizon MPS in a process industry environment. The author

uses actual data from a paint company to determine the appropriate re-planning

frequency. Kern and Wei (1996) evaluate the relative effectiveness of rescheduling

policies in capacity-constrained, just-in-time production environments. The authors

found that higher demand variation, large forecast errors, and tight capacity led to

the degradation of system performance. Yang and Jacobs (1999) examine the use

of both frozen and re-planning intervals for planning the MPS for a capacityconstrained job shop. The results show that forecast error, demand lumpiness, set-up

time, and planned lead time have a greater impact on total inventory and mean total

Revising the master production schedule

2023

backlog than the frozen and re-pkinning intervals. None of these aulhors have

focused on master production scheduling in environments where changeovers are

sequence dependent. In this paper, we examine master production scheduling performance where heuristics are used to revise the MPS within the planning horizon.

We also determine operating conditions that effect MPS performance in a process

industry environment where changeover times are sequence dependent.

In the next section, we demonstrate two approaches to revising the MPS in a

process industry environment where changeovers are sequence dependent. Two

scheduling heuristics. SWAP and 30PT can be used to revise the MPS for maketo-stock sequence dependent products. Since the planning horizon may be sufficiently long to include multiple orders for an individual product, these heuristics

can be used to sequence a series of orders that includes both different products and

repeat orders for the same product. These computationally efficient heuristics, which

represent different approaches to revising the MPS. can be applied to large problems.

3.

Scheduling heuristics

The SWAP heuristic is a simple local search heuristic that has been tested extensively in the scheduling literature (Wilkerson and Irwin 1971. Hill ct al. 2000). It is an

improvement heuristic, which uses a neighbourhood search approach similar to that

used by Gupta and Darrow (1986). The heuristic begins with an initial MPS set of

orders and reduces the changeover time in the MPS through swaps of adjacent

orders until no further improvement is possible. The local switching of orders is

thought to be advantageous in master production scheduling because orders are

not moved far from their original due date generated by the initial MPS. thus

allowing for improvement in both process changeover time and delivery performance,

30PT is an adaptation of Lin and Kernighan's (1973) Three-Opt routine, which

seeks to improve a given MPS by examining interchanges of three orders at a time.

As an illustration, consider a sequence often orders in a master production schedule

(numbered from I to 10)

1.2,3,4,5,6,7,8.9.10.

A possible three-way interchange would be to take the orders and changeovers

represented by 1.2; 5,6; and 8, 9, and create a new sequence where I is followed

by 6; 8 is followed by 2; and 5 is followed by 9. All other changeovers in the original

sequence remain the same. Specifically, the resulting sequence would be:

1,6,7,8,2,3,4,5,9,10.

If the second sequence results in a smaller total changeover time, then it is retained in

place of the first.

There are a number of different ways to perform a three-way interchange. We

have chosen for simplicity to implement solely the swapping approach used in the

illustration above, which maintains the sequence of all orders that were not swapped.

This method provides a counterpoint to the SWAP heuristic.

4.

Research design

In this section, we present the research design for evaluating master production

scheduling performance under process industry environments. The research questions are provided first. A discussion of the environmental factors that impact

2024

J. A.

performance in process industries is then provided. Next, the experimental design

and performance criteria are described. Finally, the simulation model is outlined.

4.1.

Research questions

Previous research on replanning the master production schedule has not

addressed processes with sequence dependent changeovers. Nor has this research

addressed processes with multiple products. Our research attempts to address

some important issues relative to manufacturing plants that have multiple products

with sequence dependent changeovers. Three questions are examined in this research

to improve master production scheduling performance in process industries with

sequence dependent changeovers. These are:

(1) To what extent can performance he improved hy revising the rolling horizon

MPS with the SWAP and 3OPT scheduling heuristics in sequence dependent

processes?

(2) How is performance of the revised master production schedule affected by

changes in the replanning frequency?

(3) Is the relative performance of the revised master production schedule dependent on the interaction of the independent variables?

4.2. Experimental factors

4.2.1. Coefficient of variation of changeover times

The proportion of plant capacity explained by changeover time can be very large.

When such a large portion of the process capacity is devoted to changeovers. a

relatively small percentage reduction in changeover time can represent an important

improvement in operating performance. Given the sensitivity of many companies in

process industries to improving margins in a high product variety environment, the

design of the master production schedule to incorporate scheduling heuristics that

reduce changeover time can be very important in improving plant performance.

Furthermore, while previous research indicates that scheduling performance is

quite sensitive to changes in the coetticient of variation in changeover times, relatively small values have been used for this factor in evaluating sequence dependent

scheduling heuristics. Previous work by Gavett (1965) and Guinet (1993) report

results covering a range of 0.17-0.57 for the magnitude of changeover time coefficient of variation. While very little has been published concerning the actual magnitude of the changeover time coefficient of variation in plants, our field research

indicates values as large as 0.97. or nearly twice the maximum value studied in

previous research. Understanding plant performance at much higher levels for the

coefficient of variation in changeover times is important in understanding the implications of this factor in master production scheduling. This experimental factor

brings a new dimension to master production scheduling research because, in previous research, changeovers are considered to be either negligible or sequence independent. To understand how the revised MPS performs under different operating

conditions, we varied the changeover matrix to produce two levels of coefficiem of

variation (high = base level of 0.97; low = 0.32 one-third of the hase).

4.2.2. TBO {time between orders)

When scheduling a set of orders, several heuristics have been proposed in previous research to minimize changeover time in sequence dependent scheduling (Clark

Revising the master production seliedide

2025

and Ciark 2000. Haase and Kinims 2000). These authors provide efficient algorithms

10 reduce the amount of CPU lime. However, the rules are tested on relatively small

problem sizes and not under operating conditions outlined in this paper. With the

exception of Guinet (1993). much of the previous research on sequence dependent

single machine processes has been conducted using relatively small problem sizes,

involving 20 orders or fewer.

In master production scheduling the time between orders (TBO) is commonly

used to generate diflerent problem sizes (Sridharan et at. 1987, Sridharan and

LaForge 1994). The TBO is the ratio between the economic order quantity and

the average period demand. If the number of product items is fixed, a plant

having make-to-slock products with predominately small TBO values reflects the

frequent production of small lot sizes and relatively large MPS problem sizes.

Likewise, a plant with products having predominately large TBO values reflects a

situation where products are produced infrequently in large lot sizes, yielding relatively small MPS problem sizes. In our research, we have chosen levels for TBO

(high = 20; low = 4) which generate order sizes ranging from 20 to 100.

4.2.3. MFS method

The experimental factor master production scheduling method was set at three

levels. The first setting represents the results of the initial MPS without using replanning heuristics. The MPS is still updated and rolled forward, although without the

use of scheduling heuristics. From this point further we will refer to the MPS without

scheduling heuristics as the unrevised MPS. The second and third settings represent

results of the revised MPS using SWAP and 30PT respectively.

4.2.4. Demand uncertainty

Past research (Sridharan and Berry 1990. Lin and Krajewski 1992, Zhao and Lee

1993. Kern and Wei 1996. Yang and Jacobs 1999) has shown that demand uncertainty is an important factor affecting master production scheduling performance.

Demand uncertainty was modelled by generating actual demand for multiple

products. The forecast error was modelled using a normal distribution with a

mean of zero and a standard deviation with two experimental settings: I5yo and

30% of mean demand. The forecast requirements used in determining the MPS were

computed by adding the forecast error to the actual demand each period over the

simulation run. A critical assumption is thai the forecast is unbiased. Previous

research has shown that under conditions of demand uncertainty there is no clear

choice of lot-sizing rules (Wemmerlov and Whybark 1984). This .study uses the Fixed

Periodic Requirement (FPR) rule. Wemmerlov (1979) reported that most companies

prefer a FPR lol-sizing rule. The use of the FPR is also supported by Yang and

Jacobs (I999J.

4.2.5. Re-planning frequency

The main objective of this study is to examine the affect of revising the MPS in a

process industry environment. Sridharan and Berry (1990) have shown that the

length of the planning horizon has the least influence on system cost and customer

service. Therefore, it is not our intention to focus on the length of the planning

horizon. We consequently set the re-planning frequency (R) to be a fraction of the

fixed planning horizon (A'). The values of R for our experiments are 0.25, 0.50. 0.75

2026

/ A. ///7/et al.

and 1.0. When R is equal to 0.25, revising is done every 0.25A' periods. These are the

same levels used by Zhao and Lee (1993).

4.3.

Performance criteria

Customer pressure for improved delivery performance makes total shortages an

important measure. Delivery performance is defined as the degree to which manufacturing cannot meet the MPS due dates, i.e. order tardiness. Order tardiness is

measured in terms of the number of scheduling periods each MPS order is delivered

late. This measure is converted into total shortages by multiplying order tardiness by

the average sales forecast per scheduling period. Total inventory is similar to that for

total shortages, and reflects performance frequently reported in process industry

firms.

Changeover time is an important measurement because the MPS is often developed in an uncapacitated environment considering other criteria, such as customer

service inventory investment and instability, leaving changeover time to be considered in shop floor scheduling. Also, additional capacity can be used as a buffer

against demand variability. As a result, this measure reflects the potential improvement in capacity obtained by revising the MPS.

Based on our above discussion, we use three performance criteria to evaluate the

MPS performance; (I) the total amount of shortages in the MPS planning hori/.on.

(2) the total amount of finished goods inventory in the MPS planning horizon, and

(3) ihe total amount of changeover time in the planning horizon.

4.4.

Experimental design

Simulation experiments were conducted to examine the research questions presented earlier. A simulation model was developed using FORTRAN and run on a

Dell OptiPlex GXI desktop system. The SPSS statistical package was used to analyse

the data. A full factorial Analysis of Variance design with 40 replications was used to

examine the research questions.

The replications in these experiments were 40 different product sets. Each product set includes ten products, each having the following data; average period sales

forecast for the next 30 periods (in units), the MPS batch size (in units), the MPS

initial inventory and the run time processing rate (in units/hour). The changeover

time matrix data represent actual operating data collected from a chemical processing firm.

For all 40 replications, the following procedure was used to randomly generate

Ihe product structure data for each of the ten products. The parameter values listed

in this paragraph are representative of actual operating data. First, an average

period demand was randomly generated from a uniform distribution with a mean

of 12000, a lower limit of 4000 and an upper limit of 20000. Second, the experimental factor setting for the time between orders (TBO) value was used as the mean

of a TBO distribution. A TBO value for each product was randomly generated from

a uniform distribution having upper and lower limits of ±50% of the mean value

setting. Third, the formula product batch size was computed to be the average period

demand multiplied by the lime between orders value for each product. Fourth, the

changeover to proce.ssing time ratio value for each product was randomly generated

from a uniform distribution having upper and lower limits set at ±50% of ihe mean

value of 0.25. This setting implies that the average proportion of process capacity

explained by the changeover time is 25%. After the ratio value was set, the run time

Revising the master production schedule

2027

processing rate (in units/hour) was calculated for each product using the fixed value

for the ratio and the average changeover lime from the changeover time matrix.

Finally, the changeover time matrix having the appropriate level for the changeover

time coefficient of variation was used in the MPS.

Next, an MPS record v^as established for each product containing a forecast,

projected inventory, and MPS rows. These records were processed to develop a 30

period MPS. At the end of each replanning cycle, the MPS is revised using the

scheduling heuristic and rolled forward through time. This procedure was repeated

until all 30 periods of the requirements were processed. To eliminate the effect of

transient conditions upon the operating performance, the first five periods of operating performance data in each simulation run are discarded. The five-period initialization interval was selected after visual inspection of the inventory level data. In

these experiments, the initial inventory conditions were identical for all product sets.

Therefore, the differences in performance between the replications resulted from

differences in the randomly generated average period forecast, the product ratio

value, TBO values between product structures, and differences in the changeover

time coefficient of variation value.

5.

P.xperimental results and discussion

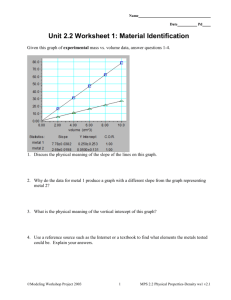

It is clear from the results in tables 1. 2 and 3 that the MPS scheduling method

and the replanning frequency have a large influence on performance in comparison

with the other parameters studied. In fact, their F-statistic ranks near the top in all

three performance measurements. Therefore the next two sections are focused

around these two parameters. The results showing the effect of experimental factors

F-

Source

MPS

CV

TBO

Demand

Replanning freq

CV X TBO

CV X MPS

TBO X MPS

Repl. X MPS

Repl, X CV

Repl. X TBO

60.2

50.8

108.9

41.3

57.5

31.7

22.9

28.9

20.8

48.1

27.0

Sig.

0.00*

0.00*

0.00*

0.00*

0.00*

0.00*

0.00*

0.00*

0.00*

0.00*

0.00*

* Signilicant al the 0.05 level

Table I.

(a) ANOVA results for total shortages.

Unrevised MPS

MPS-SWAP

MPS-3OPT

Unrevised MPS

MPS-SWAP

MPS-30PT

1.0

0.00*

0.00*

1.0

0.00*

1.0

iU al ihf l).()^ level

Table 1. (b) Tiikey multiple comparisons.

2028

/ . A. /////et al.

Source

F

Sig.

MPS

CV

TBO

187.3

6.3

33.0

46.1

94.2

0.084

0.00*

0.02*

0.00*

0.00*

0.00*

0.77

0.01*

0.00*

0.07

Demand

Replaniiing frcq

CV X TBO

CV X MPS

TBO X MPS

Repl. X MPS

Repl. X CV

Repl. X TBO

7.1

30.7

3.2

10.4

37.2

n.o2*

0.00*

* Sij