2006 Commercial Space Transportation Developments and Concepts: Vehicles, Technologies

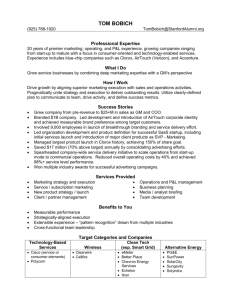

advertisement