IMPLOVEiENTS IN METHODS OF EXTRACTION, ARGON

advertisement

IMPLOVEiENTS IN METHODS OF EXTRACTION,

PURIFICATION, A1D 1ASUREIENT OF EADIO

GENIC ARGON IN MINEAiLS

by

LAWRENCE STRICKLLND

S.B., Massachusetts Institute of Technology

(1952)

SUBMITTED IN PARTIAL FULFILLIENT

OF THE REQUIREIENTS FOR THE

DEGREE OF DOCTOR OF

PHILOSOPHY

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June, 1956

Signature

of

Author.

......

*0.-..

.

4f

X,Of

Department

/

*a

*..

,

....

.

.

Geology and Geophysics

.I Septe;nber p3, 1955

Certified

Thepc SupgrvAsor

Accepted

by.\.........

.

.

.

.

4..................

....

.

.

Chairman, Departmental Committee

Students

on Gradua

-Ming==

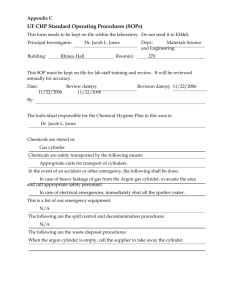

A CINOWLEDGEMvENTS

The author is

indebted to the many people who helped

in the completion of this research.

He wishes to thank

Dr. Leonard Herzog, who was always available for consultation

when problems arose involving mass spectrometry and who

was an invaluable help in the early stages of this research.

Professor Patrick Hurley, who suggested the

author undertake this research and who was always willing

to take time from his busy schedule to help.

He was a

source of inspiration whenever forward progress was slow.

The author will remember his association with Professor

Hurley for many years.

Mr. Milo Backus, whose companion-

ship made the many hours spent on this research seem short.

The typist, Joan Whitehouse, for her untiring efforts to

complete this manuscriot in a tight schedule.

His wife,

Shirley, without her unlimited confidence in the author,

and unselfish devotion, the successful completion of this

research would have been impossible.

the Geology Department.

The entire staff of

The research presented in this

thesis was a part of a program supported

by the Atomic Energy Commission urAer

Contract AT(30-1)-1381.

ABSTRACT

Title: Improvements in methods of extraction, purification,

and measurement of radio genic argon in minerals.

Author: Lawrence Strickland

Submitted in partial fulfillment of the requirements

of the degree of Doctor of Philosophy at Massachusetts Institute of Technology

Age measurements by the A40 /K4 0 method have shown

promising results in recent tests. It is important that

the possibility of small errors in analysis be investigated

and that the techniques of analysis be simplified and shortened.

In this investigation new instruments and facilities were

constructed and tested to these ends.

It was planned that isotope dilution analysis would be

used to monitor experiments leading toward a possible reliable volumetric method of analysis. For this purpose a

mass spectrometer was constructed, after Nier's design,

with a 60 magnet sector and 6 inch radius, and with changes

made in the method of collection and measurement. The

method of measuring the isotopes of argon was a dynamic one,

in order to allow most of the sample to be used during an

analysis. Molecular flow conditions exist throughout the

entire gas-flow sheet. The isotope ratios measured at time

intervals were then extrapolated to the time the sample

started to flow into the ionization chamber.

Experimentation showed that argon could be lost if the

sample was absorbed on charcoal at too low temoeratures for

too long a time. It was also found that quantities of gas

containing argon c8uld be purified by selective adsorption

on charcoal at -78 c.

The mass spectrometric procedures were checked for

discriminatio]0and reproducibility by measuring the atmosratio and the radiogenic argon content of

pheric argon

a sample of llpidolite of known age. Results of these

tests were as follows:

(measured)

310

311

A T1OSPHERIC ARGON 40 / 36

Nier (1950)

2 96+l

308

Fractionation and

Discrimination

1.047

1.050

1.042

or approximately 2 percent discrimination per mass unit.

This value is different for each spectrometer. The value

obtained is reasonable.

LEPIDOLITE SAIIPLE

A4 0 / gm sample (x103 cm3 )

.79 + .08

.74 + .03

.73 + .03

age (m. y. )

Aldrich (1954)

This work

1610

1710 + 90

The volumetric analysis apparatus was checked by

analyzing air for its argon content with .993 percent,

.990 percent, and .992 percent the values obtained. This

is to be comoared with a value of .993 percent obtained

by Paneth.

'BLE

OF CONTENTS

.page

Acknowledgements......*00

Abstract..........................

Section I.

*

**

* .........

............

o.*eoo

.0

000

Introduction.................0.0......00.0.

00

......

0

i

11

1

Methods of Determining Geologic Age

Lead

Strontium-Rubidium

Argon-Potassium

Comparison of age Methods

Research Problems

Section II. Mass Spectrometer........................... 7

Introduction

Isotope Analysis of Argon

Theory of Mass Spectrometer

Refocusing of Divergent Beams

Causes of Ion Beam Spread

Resolution

Physical Arrangement of the Equipment

Section III. Vacuum Techniques and Gas Flow Conditions

in the Mass Spectrometer.................. 45

Introduction

Gas Flow Through the Mass Spectrometer

Cold Traps Background Mass Spectre

Gas Flow into the Mass Soectrometer

Section IV. Production of Positive Ions................

59

Introduction

Methods and Workmanship

The Orthodox Source

Mass Discrimination of Ion Source

Emission Regulator

Sensitivity

Stability

Section V. Collection and Measurement of Ion Beams.....

70

Collector Design

Preamxolifier

D-C Current Amplifier

Measurement of Ion Beams

Treatment of Data

Section VI. Isotope Dilution Techniques................

77

Tracer Introduction System

Calibration of the Tracer

Possible Errors in Tracer Calibration

Isotope Dilution Measurements

Possible Errors in the Determination of Radiogenic

Argon

Section VII. Volumetric Analysis of Argon..............

Introduction

Separation Procedure (Introductory Remarks)

Description of Equipment

85

Calibration of Volumes

Problems to be Solved

Loss of Argon

Extraction of Small Quantities of Argon from Minerals

Atmospheric Argon Contamination

Hydrogen Removal

Operation of the Barium Furnace

Gas Circulation System

Results of Volumetric Analyses

Section VIII. Standardized Procedures..................

104

Volumetric-Analysis

Isotope Dilution Analysis

Section IX.Measurement of Age by the Potassium-Argon

Method.................

..........

...

.. *.

110

Section X. Recommendations for Future Research.........

115

Appendix I. Use of Radio Frequency Induction Heater

Appendix II. Condensed Procedure Sheet

Biographical Sketch

I

__:i

LIST OF ILLUSTRATIONS

Figure 1. Refocusing properties of magnet sector.

11.

2. Effect on refocusing by shifting magnet .1

inch upward from correct position.

13.

3. Effect on refocusing by shifting magnet

.2 inch down and .1 inch towards source

from correct oosition.

14.

4. Bean spread due to various aberrations.

17.

5. Gas inlet system.

19.

6.

21.

Magnet poles.

7. Right side view of mass spectrometer.

23.

8. Left side view of mass spectrometer.

24.

9. Schematic diagram of high voltage supply .

25.

10. Front panel view of high voltage supply.

2.

11. Bottom view of high voltage supply.

27.

12. Rear view of high voltage supply.

28.

13. Schematic diagram of ion current amplifier.

29.

14. Front panel view of ion current amolifier.

30.

15. Bottom view of ion current amplifier.

31.

16. Rear view of ion current amplifier.

32.

17. Schematic diagram of magnet current supply.

33.

18. Schematic diagram of balancing panel.

34.

19. Front panel view of balancing panel.

35.

20. Rear view of balancing panel.

36.

21. Schematic diagram of regulated D.C. power supply. 37.

22. Front panel view of regulated D.C. power supply.

38.

Figure 23. Bottom view of regulated D.C. power supply. 319.

24. Rear view of regulated D.C. power supply.

40,

25. Schematic diagram of emission regulator.

41.

26. Front panel view of emission regulator.

42.

27. Rear view of emission regulator.

43.

28. Diagram of mass spectrometer tube.

44.

29. Schematic diagram of mass spectrometer

with possible appropriate pressures.

47,

30. Residual spectra using solid carbon dioxide

as coolant.

50.

31. Residual spectra using liquid nitrogen

as coolant.

51.

32. Increase of background spectra with

time.

52.

Variation in 4 ratio with time.

40

Variation in 40 ratio with time.

57.

35. Schematic diagram of ion source.

61.

36. Schematic diagram of electron gun.

66.

37. Schematic diagram of ion gun.

67.

38. Peak height vs. electron accelerating

voltage.

69.

39. Design of collector.

72.

40. Characteristics of CK5886 tube.

75.

41. Typical recorded ion beams.

76.

33.

34.

56.

42. Percent error in Qh for 1 percent error

43.

in Rmn.

83.

Furnace for extraction of gases.

87.

89.

Figure 44. Gas separation system.

45. Adsorption of argon on charcoal at liquid

nitrogen temperature.

Clean up of sma 1 quantities o

presence of 1.20 x 10-3 and cm

40

47. Decay scheme of K .

46.

gas in

argon.

93.

100.

112.

LIST OF TABLES

Table Ak Comparison of Argon ratios (mass discrimination) 64.

Table B Calibration of spike

79.

Table C Percent error in volume of pure tracer

determined per E percent error in ratio or

quantity

79.

Table D Percent error in the determination of radiogenic argon for a given percent error in

ratio and quantity

81.

Table E Results of volumetric analysis

103.

Table F Branching ratio

111.

Table G Comparison of ages

113.

Section I

INTRODUCTION

It was the purpose of this research to construct and calibrate

equipment and techniques for the extraction and quantitative separation

and isotopic measurement of the argon from potassium bearing minerals,

the ultimate objective being to contribute data toward the establishment

of the potassium-argon method of age determination.

It was also the purpose of this research to determine if it is

possible to make contamination-free volumetric analysis of argon in minerals.

The section that follows will acquaint the reader with the recent

developments which prompted the present research, and will present an

introductory statement of the research problems.

Methods of Determining the Geological Age of Rocks and Minerals

Natural radioactivities have provided a means of studying absolute

time in earth history.

28

232

U2 3 8 , U25 , Th23,

The more important of these are the breakdowns of

Rb 87 and K40

Several excellent reviews of the methods of age determination have

appeared in recent years.

A detailed account of the historical develop-

ment of the potassium-argon decay has been published in a paper by Birch

(1951), while Faul (1954) has an excellent review of all methods of age

determination.

fields.

Kohman (1954) presents the most recent developments in all

In order to present this research in its proper prospective a

brief review of the development of the methods of age determination is

presented.

Lead

The fact that the three heavy radioactive elements U2 38 , U 2 3 5 and Th 2 3 2

produce the three lead isotopes Pb2 0 6 , Pb207 and Pb2 0 8 has led to the

possibility of determining the age of uranium and thorium bearing minerals

be measuring their Pb/U+Th ratios.

Early lead age measurements were made by determining, chemically, the

total lead and uranium plus thorium content of the mineral.

Although

several hundred age determinations were made by the chemical lead method,

progress was slow until Nier's (Nier, 1939) work appeared in 1939.

It

was not until the development of a simple mass spectrometer (Nier, 1940)

for isotope abundance measurements that analysis of the lead isotope content of minerals became the practice.

It was then possible to make correc-

tions for primary lead contamination and to study the effect of losses of

parent and daughter elements.

The decay schemes involved allow computation of three ages for each

mineral.

Since it is evident that the three computed ages seldom agree,

loss of parent or daughter elements may be quite common.

Enough discrep-

ancies in lead age determinations, when compared with other methods of age

determination, have been indicated in recent years to warrant a concentrated program of investigation (Kulp 1954),(Kohman

1954).

However, when

the computed ages agree the "age" may be considered as reasonably accurate

and is being used as a common base point.

Strontium - Rubidium

The use of Rb8 7 decay as a method of age determination was first

suggested by Goldschmidt (1937) but, after the initial work by Hahn,

Strassman and Walling (1937) little was done until the late 1940's and

early 1950's.

Then work by Mattauch (1947), Ahrens (1949), Ahrens and

Gorfinkle (19501 Herzog (1952), Aldrich, Doak and Davis (1952), and others

increased the available information on the use of the Rb87 decay.

The requirement that there should be a high Rb8 7 /Sr8 7 ratio in any

mineral used made the method applicable, initially, only to such minerals

as lepidolites.

The increased use of isotope dilution techniques has

made the determination of small quantities of Rb 87 and Sr8 7 very accurate.

Other minerals such as biotites and potassium feldspars can now be utilized.

Rb/Sr ages at the present time seem to be as reproducible as lead ages,

although, some doubt exists as to the correct half-life to be used for the

Rb87 decay.

The method seems to be consistent within itself and the ages

derived agree with lead ages for the same region if a half-life of about

+10

4.9x10 is correct for Rb8 7

Argon-Potassium

Evans (1940), and independently Thompson and Rowlands (1943) first

suggested the use of the potassium-argon decay as a possible method of age

determination.

Birch (1951) in a review of previous literature stated:-

"Since 1930 over one hundred papers or

letters have

been published concerning the radioactivity of potassium-40."

In the same review he says,

"Few determinations of a es have as yet been made by

use of the radioactivity of K 0, but the existence of reasonably reliable constants should encourage efforts to obtain

ages of potassium minerals."

The large terrestrial abundance and ubiquitous nature of potassium,

and intermediate half-life value of potassium-40, has made age determination by the argon-potassium method appear very promising.

Research must

be undertaken in two separate areas if the potassium-argon decay is to

become reliable as a method of age determination.

One, it must be estab-

lished whether the contamination reported by other workers is primary argon

or contamination argon introduced during an analysis; and two, the decay

constant must be more firmly established.

4.

The problems associated with these areas of investigation have made

it difficult to obtain reliable analytical results.

The first problem is

the difficulty of quantitatively extracting small volumes of argon from

the mineral.

The second is associated with the necessity of determining

the isotopic composition of the argon.

A third problem not connected with

analytical procedures but of prime importance in determining the age of a

mineral, is the doubt that exists regarding the correct value of the branching ratio.

The first problem is discussed more completely in section VII. However,

the author now believes that by direct fusion or with the use of fluxes

quantitative extraction of argon is possible.

The second problem is not so easily handled.

The literature gives

no information regarding the quantity and isotopic composition of

"contamination" argon.

1% to 10%".

It is usually reported as "varying from less than

If it is not possible to obtain contamination free argon

and if it is true that all minerals contain some "common" argon (Kohman,

1954), then corrections must be made and mass spectrometric measurements

are necessary.

Since few laboratories are equipped with mass spectrometers

which can be devoted exclusively to the isotope analysis of argon, the

application of methods of age determination to the solution of geological

problems will be considerably curtailed.

The third problem, that of establishing a reliable branching ratio,

received most of the early research effort.

Table F) may be determined in three ways.

The branching ratio (see

The first is by observation

of the x-rays produced in the K-capture process; the second is by analysis

of the argon 40 produced during a known period of geological time; and the

third is by comparison of the quantities of A 4 0 and Ca4 0 produced in the

same mineral.

Comparison of Age Methods

It now appears possible to make accurate analysis of the parent and

daughter elements associated with the different methods of age determination.

Kulp (1954) lists a set of lead 207/206 ages that were determined by

three different laboratories on specimens from the same locality.

The

agreement is very good and regardless of the accuracy of the calculated

207/206 ages the mass spectrometric analyses must not be contributing any

variation in lead age determination.

Further a few samples from the same

mineral and same locality have been measured, for strontium and rubidium,

by both the Carnegie Institution in Washington and Nuclear Geophysics

Section of the Department of Geology and Geophysics at the Massachusetts

Institute of Technology.

In two samples the quantities of Rb and Sr deter-

mined agreed to withint 5% (Herzog, 1954 and 1955).

A third sample had

to be discarded because of large rubidium contamination corrections.

Thus,

the few existing interlaboratory checks indicate that quantities of lead,

rubidium, and strontium in a mineral can be accurately measured.

Therefore, it is now necessary to assure that radiogenic argon can

be measured with the same accuracy.

Although few interlaboratory checks

have been made, accurate measurements appear possible at the present time.

With assurance that quantities of rubidium, strontium, argon and lead can

be accurately measured a concentrated program of age determination is

possible.

Few laboratories in the world are equipped to make accurate

analyses for all these elements.

An interlaboratory program is necessary.

With such a program the discrepancies now evident in the ages determined

by the various methods may be resolved.

6.

Research Problems

A concentrated program of research devoted to the potassium-argon

method of age determination requires the use of a mass spectrometer and

a system to extract, purify, and measure the gases in a mineral.

Initial research effort was devoted to the construction of a mass

spectrometer that could be used for isotope analysis of argon.

The many

problems connected with the construction and calibration of a mass spectrometer are fully discussed in later sections.

A background of information concerning the extraction and purification of helium was available in the Department of Geology and Geophysics.

The problems associated with atmospheric contamination and the separation

of small quantities of gas in the case of argon analysis, however, are

more severe.

It was necessary to design and construct a furnace to

extract argon from minerals since the furnace currently in use for helium

analyses could not be sufficiently outgassed.

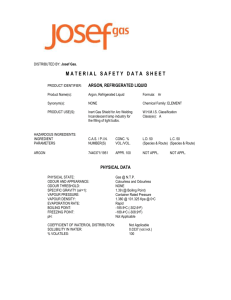

Argon, as well as other gases, is adsorbed on charcoal at liquid

nitrogen temperature.

Therefore, this method for the separation of gases,

commonly used in helium analysis, could not be employed.

The literature

contained little specific information regarding the separation and measurement of small quantities of argon.

Two papers, one by Soddy (1907) and

one by Arrol, Chackett, and Epstein (1949) provided the basic information

upon which the present separation system is built.

The many stages of

development through which this system went are discussed in Section VII.

7.

Section II

MASS SPECTROMETER

Introduction

The measurement of radiogenic argon in potassium bearing minerals

requires a knowledge of the isotopic composition as well as the quantity

of the gas.

A mass spectrometer was constructed similar to that described

by Nier (1947) with a six inch radius and 600 sector.

In selecting this

type of instrument thought had to be given not only to the problem of

argon analysis but to the availability of material, ease of construction,

and adaptability to other research problems that may arise after the

present research in completed.

Isotope Analysis of Argon

After the initial work of Aston and Dempster around 1918-1919, many

persons contributed to the development of mass spectrometry.

Several

excellent books have been written describing this development.

Among the

best are Ewald and Hinterberger (1954), Barnard (1952), and Aston (1942).

Aston (1920) first made use of the mass spectrometer to investigate

the isotopes of argon.

He gave 40.00

±

0.02 as the mass of the most

abundant argon isotope and reported the presence of "a faint line at mass

36, which may be about 3% of the total".

It was not until 1934 that

Zeeman and deGier (1934) announced the presence of an isotope of argon of

mass 38.

This was later confirmed by Nier (1936) when he also demonstrated

the lack of other isotopes with a high degree of precision.

the isotopes of 40 and 36 was estimated by Vaughn as 304112.

The ratio of

Nier (1936)

later gave 325 for this ratio and 5.1 for the ratio of the isotopes 38 and

36.

The latest determination of these ratios give 40/36 = 296t 1 and

38/36

= .188 t .001 (Nier 1950).

These later ratios are used throughout

this research.

Theory of the Mass Spectrometer

An analysis of the path of an ion beam in electrostatic and magnetic

fields has been carried out by Herzog (1934) and Stephens (1934).

Ewald

and Hintenberger (195 2 ) in their book "Methoden and Anvendungen Der Massenspectroscopic" have an excellent discussion of ion optics.

The discussion

here will be limited to applications of the general theory to the 600

sector spectrometer.

It is useful to write down, first, the equation for the passage of

a charged particle of mass m and charge e through a magnetic field of

intensity H.

velocity v.

The particle is projected into the magnetic field with a

The path of the particle will be a circle with the radius

dependent upon the velocity, mass, and charge of the particle and intensity

of the magnetic field.

The particle will experience a centrifugal force,

2

mv /r and for equilibrium this must be balanced by the force exerted by

magnetic field, Hev.

mv 2 /r = Hev

That is

or

r

= mv/eH

(1)

If (mv) and H are held constant then r is a constant.

particle has mass m (14-.m) and velocity v (1*

of my (1 + & m +- v).

If another

A v) it will have a momentum

If it is similarly projected into the magnetic field

it will have a radius of curvature of r = my (1+ A (mv))/eH

The magnetic field generates a momentum dispersion.

If it is now

assumed that the charged particle has acquired its velocity by falling

through an electrostatic potential V, the kinetic energy developed will be

equal to the potential energy of the particle eV, before acceleration, or

1/2 mv2 = eV/300

(2)

There will be a definite velocity associated with all particles having

the same energy (constant mV2 ) which is

root of their mass.

inversely proportional to the square

Each particle will, as a consequence,

describe a path

through the magnetic field with a radius of curvature proportional to the

square root of its mass.

The equations (1) and (2) can be combined into

a single equation eliminating v,

or

m/e = r2 H2 /2V.

(3)

If the radius is expressed in inches, the field intensity in gauss,

the mass in atomic mass units, the charge in terms of a single charge unit,

and V in volts, the equation (3) may be written,

m/e

=

3.09 x 10-4

r2 H2 /V

(4)

In the case of the mass spectrometer with a six inch radius this

equation becomes

m/e

= .0343 x H2 /V

Several points should be mentioned.

(5)

(1.) A more detailed discussion

of the focusing properties of a magnetic sector field follows, however,

it should be noted here that focusing is with respect to direction only.

(2.)

It has been assumed that each particle is monoenergetic.

The ion

source must be designed so that a small energy spread is achieved. (3.)

The mass spectrometer equation, (3),

is followed in the source region before

the ions have passed through the acceleration potential as well as in the

magnetic analyzer. (4.) More intense ion beams are possible if direction

focusing only is undertaken.

The mass spectrometer may be considered as

a constant deviation device.

Refocusing of Divergent Beams

The discussion may be extended now to include the refocusing properties

of the magnetic sector field.

Although the spectrometer was in use in 1918

10.

it was not until 1934 that a general discussion of the refocusing effects

of magnetic and electrostatic fields was published by Herzog (in Ewaldt&

Hintenberger, 1952).

A divergent beam of monoenergenic ions of one mass is directed into

the homogeneous magnetic field.

incident at an angle,6,

(See figure 1.)

The central ion ray is

, with the normal to the field boundaries and

emerges at an angle C. with the normal to the field boundary.

angle of divergence of the ion beam is

q

The semi-

The condition to be satisfied

.

in order that a beam divergent from point P1 should be refocused at point

P2 was given by Herzog (1934). (In Barnard, 1952).

r

sink

1

cos(-E 1)

12 cos(t2)

- 1,

sin( -6 -6 )

cos6 1

cos 2

r

cose 1

cosE 2 3

If a symmetrically arranged instrument has a radius of 6 inches, a

--

0(6)

magnetic field of 600, and an ion beam incident normal to the field

boundaries, the following equations are obtained,

+

rsin

with 4E

=6 2

ll(cos

)

+1,cos f

-

(11)

sinj: 0

(7)

0,

-

(1

= 12

1

r(cot4p 4- cosec#

)

(8)

with a symmetrically arranged instrument, and

1

=

6.00(

1

(3)6

2 )

(3)2

-

10.39 inches

with a six inch radius and 600 magnetic sector field.

The arrangement of

the source point, image point, and magnetic field for this case are shown

in figure 27.

An instrument of these dimensions was constructed for this

research.

Causes of Ion Beam Spread

Refocusing is not perfect even with correct alignment.

error if 2r(l-cosr).

of small e

.

The "focusing"

This may be written as rie 2 with the approximation

11.

K

P A= l1

P2B=12

General case of first-order focusing of ion beam

in homogeneous magnetic field with sharply defined

boundaries of any arbitrary shape.

12.

The minimum beam spread that can be achieved for first order focusing

2

is rCr .

To achieve this P

respect to Pm.

and P2 must be positioned correctly with

There are additional aberrations introduced if the source

and collector slits are not aligned parallel to each other and perpendicular

to the central plane of the magnet.

If the magnet is displaced from its correct position there are further

aberrations.

R. A. Davies (in Barnard, 1953) has derived the following

equations for beam spread due to three possible directions of misalignment.

(1)

Magnet displaced distance x1 along x axis.

Spread

(2)

= rr

2

1+

r4C (

2

~

2~*

2

2/2 - gxI/r + 4x /r2

Magnet displaced distance g, along the g axis

Spread = r d2

(3)

rC

+ 4

y + re (

-

42/2 - ffy/2r + 2y

2

.)

-

(10)

Magnet notated angle i about its nominal apex, Pm

Spread

= r 42

.r

e

+-re

(

2/2

+

rR

-

9/4 e

2

+

.)

(11)

Figures 3, 4 show diagrammatically the effect of the refocusing

properties of the magnet sector a displacement of the magnet from its

correct position.

The figures show that a displacement in the x direction,

for any given a and r, causes the greatest beam spread.

It has been assumed throughout the above discussion that the magnetic

field has well defined boundaries.

Barnard (1954) has a discussion of

fringing flux corrections and states that additional adjustments are

necessary after the magnet has been positioned on a theoretical basis.

A

good approximation is obtained then by considering that the boundaries of

the magnetic fields extend out to a distance of one gap width.

It has

been further assumed throughout the above discussion that the ions of each

mass are monenergetic with a velocity characteristic of that

mass.

However,

A

Ii'

ill

'II

'II

I'

.1-100I

-*100

-'-0

-*9

-

0l

100I

00

-K;Figure 2

'00,

/

'0

Effect on refocusing by shifting the magnet .1

inch upward from it- correct position.

I

III

IIII

I'i

I|

~/

/

//

//

--

,9000

0-000

--000

9

00

//

100

.00,1000

-.-

10000,-

'000,

-:: , .0001

Figure 3

-9

-;--

-O,

Effect on refocusing by shifting the magnet .2

inch down and .1 inch towards source from its

correct position.

15.

a small energy spread is unavoidable.

spread.

(1.)

There are three causes of energy

When ions are obtained by electron bombardment, a potential

gradient across the electron beam is necessary to withdraw the ions from

the beam.

Even with a beam of small cross-sectional area some ions acquire

potential of

6V

in excess of that acquired by other ions.

AR - 2r

introduced is 2

The aberration

SV/V. (2.) a broadening of the ion

S/%= r

beam can arise because of energy changes associated with collisions

between similar ions.

The pressure must be below 10-6, if collisions are

not to cause excessive broadening.

(3.)

Ions formed from molecular dis-

sociation products have associated with them a varying amount of energy

Aberrations arising from this source are a cause for

of dissociation.

concern in hydrocarbon analysis.

However, the gases encountered in this

research were monatomic and consequently have no energy of dissociation

associated with them.

Resolution

Ewaldtand Hintenberger (1952) have derived the following expression

for the resolution:

M

------

2(12)

M

v

K"

where, theoretically, for the spectrometer used in this research

=

K"

and

2r

G

=

-1.

The expression for the revolution then becomes

M

=

1

A V

V

+

.

Si f.. S2

r

(13)

16.

For the spectrometer used in this research values of 6.00, .008, .050

are observed for r, S, and S2,

for

dV/V.

respectively.

A value of 15/2300 is obtained

The resolution is

M/ 4A M

=

l/.0013 + .0096

92.

That is to say there is a separation of one mass unit at mass 92.

The resolution is sufficient for this research and can be improved, if

necessary, by reducing the width of the collector slit.

A picture of possible aberrations introduced is shown in figure

(Barnard).

.

This figure shows the effects of misalignment of source and

collector slits; of spherical aberration for r = 150 mm, r

of chromatic aberrations of

&V

=

0.5V, V

=

100OV, and r

=

1/30 radian;

150 mm; and

of non-uniformity in the z direction of the magnetic field for a pole gap

of 20 mm in relation to an ion ribbon width of 10 mm symmetrically disposed

abput the central plane.

Physical Arrangement of Equipment

The equipment used in this research to produce, analyze, and collect

positive ions consisted of:

(1)

Ion Source

(2)

Collector

(3)

Regulated high voltage supply

0

-5000V with taps for drawing out

and focusing potentials.

(4)

Regulated power supply 225V

(5)

Regulated magnet current supply 0-300ma.

(6)

Magnet

(7)

D-C Current Amplifiers

(8)

Preamplifier

(9)

Emission Regulator

17.

a

b

C

d

e

f

Figure 4

Beam spread due to various aberrations.

(a) Exact reproduction of source slit (0.2 x 10 mm) with

collector slit. Accurately aligned; no aberrations.

(b) Spherical aberration added.

(c) Chromatic aberration added.

(d) Curvature of image due to variation of magnetic flux

density across pole gap and to ion rays passing obliquely

through central plane.

(e) Image broadening due to oscillatory component in

acceleration potential.

(f) Distortion due to misalignment by 10 of collector slit

with source slit.

(g) Superposition of aberrations; for clarity each flank

considered separately; one flank shown extended by

aberrations (b). (c), (e) and (f); the other flank shown

extended by aberrations (d) and (f) only.

18.

(10)

Vacuum System

(12)

Spectrometer tube

(13)

Source magnets and aligning mechanism

The ion source (1) is discussed in Section IV.

The collector (2),

D-C current amplifier (7), and preamplifier (8) are discussed in section V.

Pictures and schematic diagrams of the electronic equipment are shown on

the following pages.

All the electronic equipment with the exception of

the magnet current supply and preamplifier were built by Dunn Engineering

Associates of Cambridge.

(10)

Vacuum System

The vacuum system consisted of an umbrella-type diffusion pump, a cold

trap and fore pump.

The diffusion pump was designed by Homer Priest of the

Research Laboratory for Electronics, and built by Ryan, Velluto and Anderson

who also did most of the glass work necessary on the spectrometer and the

gas extraction and analysis system.

two-stage rotory pump.

The fore pump was a Welch Duo-seal

It was possible to attain vacua of 3-5x10~ mm of

mercury after prolonged heating of metal parts and with liquid nitrogen

as a cold trap coolant.

It was necessary to use liquid nitrogen as a cool-

ant to reduce hydrocarbon background

(11)

(see section III).

Gas Inlet System

The gas inlet system consisted of an inlet to which the sample container could be attached, a small calibrated volume, a 50 cm3 sample

reservoir, a 5 liter sample reservoir, a cold trap, evacuating system and

variable gas leak.

A diagram of the inlet system is shown in figure 5.

All glassware was Pyrex and all stopcocks were mercury seal stopcocks with

a 4 mm bore.

- F j IMMOMMOOM

10,11M I- M

Gas Leak

Sample tube

To spectrometer

ITo

fore pump

Cold trap

Cold trap

Diffusion pump

Figure 5

Gas inlet system.

WIN

20.

The evacuating system consisted of a nozzle-type mercury diffusion

pump and a cold trap.

attainable.

Vacuums of less than 2-3x0~7 mm of mercury were

It was necessary to maintain liquid nitrogen on the cold

trap during sample analysis because of the presence of hydrocarbons in

the background spectra.

The variable leak was variable over a wide range.

With a small open-

ing it was possible to analyze air for atmospheric argon, although some

distortion of peak shape was observed due to the presence of large oxygen

and nitrogen beams.

It was also possible to accurately control the flow

rate of samples of the size encountered in this research.

All parts of the

leak were made of stainless steel and nickel-plated to prevent outgassing.

Some difficulty was experienced with air leaks developing around the pressfit connectors.

It is recommended that in a permanent installation these

be replaced by silver soldered connections.

(6)

Magnet

A diagram of the magnet poles is shown in figure 6.

were made of Armco ingot magnet iron.

The magnet poles

Each core was wound with 20,000

turns of #22 magnet wire covered with double formex coating.

With a gap

width of .625 inches, 100 ma magnet current produced a field intensity of

3060 gauss.

A plot of field intensity vs magnet current shows that the

field variation is linear in the region of interest.

Ion beams can be located approximately by the use of the mass spectrometer equation,

m/e

=

3.09 x 10~4

=

k

I2 /V

where I is in milliamperes and V in volts.

r2 H2 /V

(14)

The constant k is equal to 8.b6.

If one papameter is fixed the other may be found using equation (14) and

the ion beam located.

ALL dimensions in inches

Figure 6

Magnet poles.

||||||Il li

AI

-

~

22.

(12)

Spectrometer tube

The spectrometer tube was made from 2-inch copper tubing with all

joints being silver soldered.

stainless steel.

All flanges were made of non-magnetic

The diagram on page 44 shows the location of the source,

collector and vacuum outlets.

Copper is very gassy and it was necessary

to sandblast the inside of the tube and maintain periodic heating periods

to obtain an adequate vacuum.

In order to obtain satisfactory recorded

ion beam shapes the source and image points must be accurately located.

The tube was assembled and swedged by R. Thorness, machinist for A. 0.

Nier.

After the tube had arrived it was necessary to position the source

and collector flanges relative to each other and to the central plane of

the tube.

With the aid of a competent machinest and a larger optical

flat it was possible to locate these flanges accurately to within .01

inch.

Figures 7 and 8 show right and left sideviews of the spectrometer,

showing especially the method of mounting the spectrometer tube.

(13)

Source magnets and aligning mechanism

The source magnets were two 2xl inch rods of Alnico V magnetic

material.

They could be correctly aligned with the aid of the alignment

mechanism shown in figures 7 and 8.

Once correctly aligned it was

possible to lock them securely in position.

It was necessary to lock

them in position as any change in their position would make a redetermination of the discrimination value necessary.

Figure 7.

---

Right side view of the Mass Spectrometer

="W -

-WO

24.

Figure 8.

Left side view of the Mass Spectrometer

25.

Figure 9.

Schematic diagram of high voltage supply.

115V 60,,v

5000V REGULATED DC SUPPLY

26.

Figure 10.

Front panel view of high voltage supply.

27.

Figure 11.

Bottom view of high voltage supply.

28.

Figure 12.

Rear view of high voltage supply.

29.

Figure 13.

Schematic diagram of ion current amplifier.

CK5886

ION CURRENT AMPLIFIER

30.

Figure 14.

Front panel view of ion current amplifier.

31.

Figure 15.

Bottom view of ion current amplifier.

32.

A

a VP

ftftftwmw

Figure 16.

Rear view of ion current amplifier.

33.

Figure 17.

Schematic diagram of magnet current supply.

ZP

T, CHICAGO F-65

T2 STANCOR P-6134

5A

60oT3 T HORDARSON T-21F04

T4 UTC CG - 301

NEON

6.3V

T2

I Meg

50K

IPWW

8

TRIAD C-ISA

S

T3

6SF5

5V_

90V

I0K

15KW

8A-iJi

P3K1

MOTR

2______

1W

COILSERI

5

B

10 SEC TIME

7W

DELAY

TD

0.25

600V

V1

5U4

D

-~

5U

0

C05-

_ _ _j

-

2

9

lOK

50K

50K

50K

I~wCURN

C C

12P

3

IW

V2PW

*00

50K

2

51.14SU2_>30K

50W LINE ADJ.

20W

5 V5

_MICA

20WR

ID

--

COCL

C C

47K

loW

30K

15K

20W

.

R

WHITEUT

NEODN

0

NEON

TREEN

3AE

BODEi5A

ALLIED BUU 12A

MOMENTARY CONTACT

REVERSING

D

SWITCHES

SNHNSO

o____!______

REMOTE CONTROL

UNIT

REGULATED D.C.

MAGNET SUPPLY

2N

34.

Figure 18.

Schematic diagram of balancing panel.

INPUT

FROM AMPLIFIERS

*2

I

OFF

R17

1000

25K

RI6

500

15K

R13

200

Rii

Rg

Ry

7

R5

R3

-

-

R,

I

+

100

50

20

10

5

2

1

5K Io2.5K

5001

2500

50f

50i1

0-2MA DC 0-20MADC

50fl%

50f1±1%

ALL RESISTORS 1% PWWSW5

1.5K

A

-

-

INPUT *1

R2

R4

50n1

150nl

R6

Re

Rio

25010 500n0 1.5K

ALL RESISTORS

R12

2.5K

R24

5K

R516

15K

1% PWW

SW4

B

ODIRECT

10

2

2

DECADE +

3

DECADE

3

SW

R3 4

4

O BAT+

99K

R3 2

25BAT-

9K

R24

IOOK

2 2.5 V E

PUT S TAKE

DECADE

RESISTANCES

1%PWW

2

R33

R29

99n

04

OFF

I

nD2

BALANCING PANEL

Ri

25K

OFF

35.

Figure 19.

Front panel view of balancing panel.

36.

Figure 20.

Rear view of balancing panel.

37.

Figure 21.

Schematic diagram of regulated D.C. power supply.

LI STANCOR C-1003

TI UTC

R- 102

OUTPUT A5

Al

A2

A3

A4

GROUND CONNECTORS

REGULATED D.C. SUPPLY

225V, 180 M. A.

60-%

38.

Figure 22.

Schematic diagram of regulated D.C. power supply.

39.

Figure 23.

Bottom view of regulated D.C. power supply.

40.

Figure 24.

Rear view of regulated D.C. power supply.

trap

sheitd

filoment

Figure 25.

Schematic diagram of emission regulator.

Rl

150 ohm 50 watt rheostat

R2

150 ohm 50 watt adjustable

R3

250,000 ohm wire would potentiometer

R4

20,000 ohm precision wire wound

R5

50,000 ohm wire wound potentiometer

B1 , B2 , B, B

45 volt B batteries

M

mete', 0O10 amps. a.c.

meter, 0-1.5 milliamps d.c.

M3

meter, 0-500 microamps d.c.

T, filament transformer, secondary 2.5 volts

10 amps. 7500 ras volts insulation

SWi SPST toggle switch

SW2 two position selector switch, 2500 voLts

insulation

42.

Figure 26.

Front panel view of emission regulator.

43.

Figure 27.

Rear view of emission regulator.

44.

Figure 28.

Diagram of mass spectrometer tube.

NOTE:

2'Copper Tubing used throughout

unless otherwise specified

* 7 Drill(.201) thru

V4-20 N.C. Top 6 holes

equally spaced on

3.5" B.C.

* 25 Drill - 2 holes

'/"deep for i x 'W

long Dowel Pins

125

5"

.375

2.75

DETA I L OF 0OUTER FACE

OF FLI ANGES

.9"

0.D.

but central I"

I.D. ="

6"R

to be held parallel

to ±0.005"

li"Copper Tubing

Copper reducing nipple 2 "-l1"

(shave nipple O.D. and Tee

I.D. to snug fit for silver brazing)

Cut off"Tee"oand silver

91"

l7 g

-(

solder 2"-60* "Ell"

Stainless Steel

Flange

600 MASS SPECTROMETER TUBE

scale

j". i"

Scale tolerance on tube

dimensions except where

otherwise stated

45.

Section III

VACUUM TECHNIQUES AND GAS FLOW CONDITIONS IN THE MASS SPECTROMETER

Introduction

The gas handling system

required for introduction of the sample into

the mass spectrometer depends upon the type of gas to be analyzed.

If the

sample is a single gas introduced for isotope assay, fractionation may,

in general, be ignored and a simple handling system is sufficient.

If,

however, the gas to be analyzed is a complex mixture consisting of many

isotopes, it is necessary to meet several requirements in so far as possible.

First, there should exist a known relationship between the partial

pressures of each isotope in the sample reservoir and the ionization

chamber.

Second, the composition of the sample should not change during

the analysis.

Third, the total peak height at any mass should be the

linear sum of all contributing isotopes of the gas mixture.

Fourth, the

rate of gas flow should remain constant during the analysis.

Fifth, no

gas striking the filament should be allowed to re-enter the ionization

chamber.

Sixth, erratic behavior of the diffusion pump should not have

any effect on analysis.

Seventh, and last, it is desirable that gas enter-

ing the ionization chamber should have reached temperature equilibrium.

The above requirements are of prime importance in hydrocarbon analysis.

In the present research, however, the problem is one of introducing a

single gas for isotope analysis, complicated by the smallness of the

sample, so that detailed discussion of the above requirements is not

included.

The problems of gas flow can be grouped into two headings.

One,

gas flow through the spectrometer and two, introduction of the sample into

the spectrometer.

These problems are discussed in the present section.

46.

Gas Flow Through the Spectrometer

It is necessary that the pressure in the spectrometer be maintained

such that the mean free path of molecules is greater than

of any part of the spectrometer.

the dimensions

Figure 29 shows a schematic diagram of

the spectrometer with possible appropriate pressures for the various parts

of the spectrometer.

The rate of molecular flow between any two points is given by

Q

=

Km

dP/MA

(15)

where Q is the rate of flow, dP is the pressure difference, and M1 is a

constant depending on the geometry and temperature of the system.

the gas flow is proportional to 1/M

Since

fractionation must occur in the

source from which the gas is being withdrawn, once steady state conditions

have been established.

The peak height of any isotope is dependent directly

upon the partial pressure of that isotope in the ionization chamber.

To

determine the steady state partial pressure in the ionization chamber it

is necessary to know the rate at which the sample flows into the ionization chamber, v, expressed in litres/sec; the rate at which the sample

is withdrawn from the chamber, S, expressed in litres/sec; and the volume

of the ionization chamber, V, expressed in litres.

The ionization chamber gains v dt standard litres of gas in time dt,

and loses pSdt litres in time dt, where p denotes the partial pressure

of the gas expressed in atmospheres, in the ionization chamber.

The net

gain in gas then is

d(pV)

=

(v -

pS)dt

or

V

dp/dt

=

v -

pS.

(16)

Integration of this equation gives the partial pressure of the gas

entering the ionization chamber or also the partial pressure of the gas

10-1

mm of mercury

10-2

J

10~4

10-6

10- 7

10-8

Figure 29.

Schematic diagram of mass spectrometer with possible appropriate pressures.

48.

intersecting the electron beam at a time t after entering the ionization

chamber.

Pt

v/S

(1

exp(-St/V))

-

(17)

The steady state partial pressure then is v/S.

The time required

to reach steady state conditions for a given rate of inflow, v, is

dependent upon S and V.

when f/S is large.

The most efficient use of a gas sample is obtained

In order to reach steady state conditions within a

reasonable length of time S/V should be as large as possible.

The necessary

information regarding S is not known for the spectrometer used in this

research but some idea of the partial pressures attained may be gained from

an examination of the available information.

For example, for one particular

analysis, the sample size was 2.04 x 10-3 cm3S.T.P. and the rate of inflow

was .5 x 10~9 litres

sec~

1.

Experience has shown that steady state flow

conditions for mass 38 are reached in about 60 seconds.

The volume of the

ionization chamber is approximately

(2.54 cm x 1.27 cm x 1.27 cm)/1000

or 4.1 x 10-3 litres.

The factor exp(-St/V) should have reached a small

value, say .01, before steady state conditions are reached.

Therefore,

e-x is equal to .01 when x is equal to 4.6,or St/V is equal to 4.6.

S = 4.6 x (4) x 10-3

60

60

=

Then,

3 x 10~4 litres sec~1.

This is the pumping speed at the ionization chamber slit.

The partial

pressure of mass 38 then is

.5 x 10~9/s x 10~4

or

.16 x 10-5 atmosphere.

At this pressure the mean free path is 7.30/1.6, (Dushman 1949), approximately 4.6 cm. or about twice the longest dimension of the ionization chamber.

It should be noted that this is a minimum value since t = 60 secs is a

maximum value.

Although this is an approximation of the conditions existing

49.

in the ionization chamber, it is seen that molecular flow conditions do

exist in the spectrometer for samples of the size used in this research.

One important feature should be noted.

If any appreciable volume exists

between the leak and the ionization chamber, and if the conductance of this

volume is comparable with that of the leak, the time constant in attaining

steady-state pressures will become very large.

The leak must be the only

controlling factor finally in operation.

Cold Traps:

Background Mass Spectra

The diffusion pump used on the spectrometer is a mercury diffusion

pump designed by Homer Priest of Research Laboratory of Electronics at

M.I.T.

3

Since mercury has a vapor pressure of .185 x 10- mm mercury at 0QC

it is necessary to prevent mercury from entering the spectrometer.

It is

further desirable to keep mercury from diffusing into the interior of the

spectrometer to prevent deterioration of the silver soldered joints.

Diffusion of mercury and hydrocarbons into the spectrometer can be prevented

by cooling a trap with solid carbon dioxide in alcohol or with liquid

nitrogen.

A comparison of the residual background spectra using either

coolant is shown by comparing figures 30 and

31.

That hydrocarbons

do diffuse into the spectrometer can be seen by comparing figures 30 and

31..

(See also section II ). The hydrocarbons are probably vapors from

the oil used in the forepump and from the stopcock lubricant used on

stopcocks in the gas inlet system.

The forepump oils and stopcock lubric-

ant used have vapor pressures of 10-4

-

10- 6 mm of mercury at 20 0 C.

However,

the temperature of the oil is probably much higher than this due to

continuous operation in a hot room.

It is necessary, therefore, to insert

a cold trap immediately adjacent to the gas leak and mercury diffusion pump.

50.

10

w

5

C.

35

36

37

38 39 40 41

MASS NUMBER

42

43

44

Figure 30.

Residual spectra using solid carbon

daxide as a coolant.

51.

0

Y-O.5

A

Lu

0-

.

lI

.

35

36

37

.

I

38 39

40 41

MASS NUMBER

II

42

43

Figure 31.

Residual spectra using liquid nitrogen as coolant.

44

52.

36

37

38

39

40

41

42

43

44

10 MIN

36

37

38

39

40

41

42

43

30 MIN

Figure 32.

Increase of background spec-tra with tim,

44

53.

Figure 32 shows another source of background mass spectra.

The increase

in background mass spectra is probably due to outgassing of the filament

and electron bombardment of ionization chamber walls.. Note particularly

the increase in the carbon dioxide (44) peak.

Recommendations for Further Work

If further work is planned that requires a more sensitive instrument

it will be necessary to reduce the background spectra.

This can be achieved

by plating the spectrometer tube with chromium and by vigorous torching or

prolonged baking of glass parts.

It would also be desirable to degas all metal parts in the source and

collector by heating them in a vacuum furnace with an industion heater.

Control of Gas Flow Into the Ionization Chamber

In an earlier section reference was made to the existence of molecular

flow conditions in the ionization chamber.

It is necessary now to consider

how these flow conditions are established.

The physical arrangement of

the leak was discussed in section II.

Only the effect of the leak upon

the gas flow conditions is discussed here.

Suppose that the volume of the sample reservoir is V litres, and the

gas is withdrawn from the reservoir at molecular flow rates.

Since the

sample reservoir is a closed system there is a steady loss of gas.

Let

S be the rate of withdrawal of the gas at the pressure in the reservoir.

Then for any particular gas the loss per time dt is PS dt where P is the

partial pressure of the gas.

d(PV)= - PS dt

Therefore:

or

dp/p

=

- S/V dt.

54.

is the initial partial pressure in the system and Pt the

Hence, if P

partial pressure at time t,

Po

Pt

(18)

exp(-St/V)

Thus, the pressure time characteristic is different for each gas simply

because S

is proportional to 1/M.

If the reservoir contains a binary mixture, say argon 40 and argon

38, the relationships become

In

Pil

Pt

.948

(It

P

4

In- Pt 384

n( Pt)

Po0)40

(19)

-P

\/38

With molecular flow conditions, the gases in the mixture are mutually

independent and each ion current decays by a factor exp(-Smt/V) in

consequence of the pressure decay.

If measurements of the unknown mixture

and calibration mixture are taken at exactly the same time t, then the

percentage decay will be the same for each isotope in the unknown and

calibration mixture.

to be t = 0.

In this research the time of comparison was taken

This is the most easily reproducable time.

For most all

samples of the size encountered in this research the initial decay is

very approximately linear.

It is, therefore, easier and more accurate to

extrapolate to zero time than interpolate between measured points on an

exponential curve.

Fractionation Patterns

Molecular flow exists where the mean free path of molecules is long

with respect to the diameters of the tubes through which flow takes place.

The pressure in the ionization chamber of a mass spectrometer is always

low enough so that this condition prevails.

If the pressure in the sample

reservoir is also low enough to allow molecular flow, then molecular flow

55.

prevails throughout the spectrometer and regardless of the nature of the

leak the composition of the gas in the ionization chamber is the same

as that of the sample (Inghram 1954).

However, with this low pressure

in the sample reservoir, the leak must be fairly large to keep the pressure

in the analyzing region at an acceptably high value.

Thus there is a

fairly rapid depletion of the sample in the reservoir and because the

flow rate of a gas component in molecular flow varies inversely as the

square root of the mass of this component the sample reservoir, and hence

the ionizing region becomes in time depleted in the lighter components.

From equation 18 the following relations can be derived.

(1)

40

Pt

(2)

P38

=

40

Po

40

exp(-Sm t/V)

P3 8

e

38

(19)

t/V)

40

Dividing (1) by (2) and setting Sm '

(20)

38)

m equal to 1/40

and 1/382

respectively, we have:

P4 0 /P 3 8

(3)

t)

P40 p38

exp

/pf(8)'

(40)2

(40)2

_

-

3

(38)-

t/v

V

(21)

Therefore, the ratio argon 40/argon 38 increases with time at a

definite rate.

The variation of the ratio 40/38 in most analyses resembled

that shown in figure 33.

Since the peak height is proportional to the partial pressure in the

ionization chamber, the peak height measurement may be considered representative of

40

t

38

40

and P

0

,P

38

,

0

or

40 38

ht/ht

From the graph on page 56, we have 1.0525

=

40

h

38

/h0

ext(

t)

1.0400 exp( g t) and

2x 10- 5 sec-1.

The value of d

, theoretically is

(

1/(38)

-

1/(40)1) 1/V or 4.2x10-3/V.

A computation of the volume of the gas inlet system gives as the volume

approximately 200 cm 3 or theoretically

0- 2.lxlO-5sec~1 .

3

1.061

0

5

10

Figure 33.

Variation in 40/38 ratio with time.

15

MINS.

SNIH

SL

,

- -

-

OL

-

-

-I

,

,

,

E

CD

S

,

,

,

,

,

,O

LE

58.

A similar calculation can be made for the ratio 40/38 in atmospheric

argon.

40 36

ht /ht

-

40 38

ho0 /h8 exp( U

t)

From the graph in figure 34 we have 321.5

of

f

is 5.5x10-5sec~ .

(1/(36)1 - 1/(40)1)

The value of

1/V

f

=

311 exp(d

t).

The value

, theoretically, is

= 8.6x10-3/200

=

4.3x10-5sec -1

The agreement here is not as good but definitely indicates that molecular

flow conditions are established.

59.

Section IV

PRODUCTION OF POSITIVE IONS

Introduction

In section II it was shown that the mass spectrometer is a constant

deviation spectrometer in which focusing is in respect to direction only.

A spectrometer with adequate resolution is possible only if the positive

ions have a small energy spread.

be used.

This limits the type of source that may

For example, the gaseous discharge type of source has an ion

energy spread of 1000 ev.

There are two main types of sources; (1) the hot anode or solids

source and (2) the electron bombardment or gaseous source.

Use of hot

anode source requires that the sample can be applied to a filament in a

solid form, while the electron bombardment source requires that the sample

be introduced in a gaseous or vapor form.

The electron bombardment source was first used by Dempster (1922) and

subsequently developed by Bleakney (1932), Tate and Smith (1934), Nier

(1940, 1947), and others.

The Nier-type source has been called the orthodox

electron-bombardment source because of its almost universal use in routine

mass spectrometric application.

Materials and Workmanship

Careful selection of materials for construction of the ion source is

necessary.

Metals should be used which do not corrode or oxidize easily,

which have a permeability less than 1.005 and which are not gassy.

non-magnetic nichromes and tantanlum are very satisfactory.

The

Tantalum, how-

ever, should not be used in the presence of hydrogen since it becomes

brittle and weak.

Adequate insulation as well as mechanical stability have

60.

to be considered in selecting insulators.

Fused silica, glass or hydrogen

fired lavite have the best insulation and stability characteristics.

Three features should have careful consideration; (1) maintenance of

design geometry, (2) elimination, in so far as possible, of edges, and

(3) a surface finish.

In (1) where requires, alignment, parallelisms,

and squarenesses, should be held to

.001 inch.

In construction, elimin-

ation of sharp edges (2) is necessary to prevent the intense electrostatic

field disturbances that sharp edges exhibit.

Uncontrolled cold field

emission due to these high fields may give rise to background peaks in

the mass region of interest.

not fully considered.

A source will function if these points are

A more carefully constructed source, however, will

give more satisfactory over-all performance.

The Orthodox Source

An ion source of this type may be said to consist of four parts;

(1) a device for introducing the gas into the source; (2) an ionization

chamber; (3) an electron gun and (4) an ion gun.

In this section it is

assumed that the gas has been properly introduced into the ionization

chamber and is representative of the original sample.

Figure 35 shows the physical arrangement of the source used in the

present research.

(3)

The Electron Gun

In the source, the electron gun (see figure 36 ) consists of a heated

tungsten filament and an anode.

The potential applied to the ionization

chamber, the thermal energy, and the potential disturbances in the chamber

determine the energy of the electrons.

the use of source magnets.

The electon beam is collimated by

The poles of the magnet are aligned so that

the major component of the electron velocity is parallel to the lines of

61.

GA S

IONIZATION

CHAMBER

ELECTRON

BEAM

17

JJFILAMENT

CONTROL

TRAP

FOCUSING

PLATE

COLLiMNATING PLA TES

PLATESI

Figure 35.

Schematic diagram of ion source.

62.

force.

Those electrons with a velocity component transverse to the magnetic

lines of force experience a force causing them to rotate in circles whose

plane is perpendicular to the magnetic lines of force.

electron, therefore, is in a circular helix.

(1)

be noted.

The motion of each

Two important features should

The electron beam should be aligned so as to pass through

the ionization chamber and be collected without bombarding any slit edges.

A wider slit at the collecting end of the chamber does not help, since

excessive penetration of the collecting voltage into the ionization chamber

may cause serious deflections of the ion beam.

A larger source magnet is

the only solution.

(2)

Correct alignment may be made empirically from scale drawings,

but final small adjustments are necessary.

The best position is indicated

by a compromise between maximum trap current and maximum ion current.

Even this is no guarantee that secondary electrons do not contribute an

important percentage of the ionization.

(4)

The Ion Gun

The ion gun (see figure 37 ) consists of a drawing-out potential,

accelerating potential, and collimating system.

The drawing-out potential is variable up to 14% of the accelerating

potential.

In adjusting the drawing-out field care must be taken to avoid

extreme penetration of the field into the ion chamber.

This will cause

deviation of the electron beam with a resultant spreading of the ion beam.

The accelerating potential is variable from 0-5000 volts, with 2500

volts the voltage most commonly used.

The collimating system consists of two plates with eight-thousandths

inch slits.

2.25

0

The half angle of divergence of this system is approximately

63.

Mass Discrimination

Incorrect isotope abundances can arise from two main causes (1) fractionation in the gas handling system and (2) mass discrimination in the ion

source.

The former is discussed fully in the section III on gas flow in

the mass spectrometer.

The latter is caused by the presence of a magnetic

field in the source region.

Mass discrimination has also been observed

when electrostatic scanning is used.

Since magnetic scanning and not

electrostatic scanning is used, the latter is not a factor in this research.

The source magnets used in aligning the electron beam are a source of

mass discrimination.

Ions of lighter masses are made to move in circular

paths more easily than the heavier masses, hence the lighter masses will

appear in less than their true abundance.

The energy of the ion before

it has passed through the accelerating potential is low and as a consequence

the ion is easily made to move in a circular path.

Since the energies of all ions of the same mass may not be equal it is

impossible to predict the mass discrimination.

must be determined empirically.

The mass discrimination

It was determined by measuring the

atmospheric A4 0 /A36 ratio.

A comparison of the ratios of 40/38, 40/36, 48/36 by Nier (1950) and

the ratios obtained using the mass spectrometer employed throughout this

research are shown in Table A

.

The difference between the two is due to

the mass discrimination of the ion sources.

The discrimination values for

the ratios 40/38, 40/36, 38/36 may be computed by knowing only the 40/36

ratio.

This is standard procedure used by mass spectrometrists.

ratio is related to the 40/38 ratio as follows:

(40/36)A/(40/38)i

:

310/296

40/38

1575

The 40/36

64.

In the same manner the value for

The value 40/38 is computed as 1604.

the ratio 38/36 is computed as .192.

Table

RATIO

A

40/36

40/38

38/36

296 t 1

1575

.188

Nier (1950)

310 ±-3

1604

.192

This work

Emission Regulator

The physical arrangement of the emission regulator used in this research

has been discussed in Section II.

and Nier (1949).

figure

25.

It was patterned after a design by Winn

A schematic diagram of the emission regulator appears in

Regulation is achieved by control of the electric field at

the filament by a control plate placed in front of the filament.

known as a space-charge-controlled regulator.

This is

This is electrically

analogous to running a common triode vacuum tube with a positive grid.

Voltage for the control plate is obtained from battery B1 .

The electron

current to the control plate flows through the battery B1 and the resistors

Any variation in the electron emission current causes the

R3 and R 4 .

control plate voltage to vary which tends to oppose the change in electron

current.

The filament is a seven mil tungsten wire bent into the shape of a

hairpin.

It was necessary to use a filament of this shape to obtain an

intense electron beam.

With a flat or straight filament most of the electron

emission would go to the control plate.

The emission density from a hairpin-

shaped filament is considerably greater at the point than elsewhere.

When

the point is placed close to the hole in the control plate a considerable

65.

portion of the emission goes through the hole in the control plate while

still being subjected to the controlling field.

It was found by experimentation that the filament should be placed about

one-half millimeter from the control plate hole.

With too great a filament-

control plate spacing too much of the electron emission goes to the control

plate and not enough goes through the hole as ionizing electrons.

With too

close spacing more electrons go through the control plate hole, but not

enough current goes to the control plate to maintain good stability.

Sensitivity

In ion production two efficiencies are considered.

to the gas molecules and one with respect to electrons.

One with respect

The problem of gas

flow in the spectrometer and efficient use of gas molecules are discussed

in section III.

It should be mentioned here that the total gas flow through

the spectrometer, Q

,

is expressed in liters-micron-sec

1.

That is, the

number of liters of gas at one micron pressure flowing through the source

per sec.

The over-all sensitivity, then, is expressed as the number of

liters-micron-sec

collector.

1-needed to produce a given number of amps at the

The sensitivity of the spectrometer used in this research is

6.3xl0~ 4lit-micron-sec~

for 10-12 amps at mass 40.

This sensitivity is

limited only by the background at mass 40 which is generally below 10-12

amps.

(see section III for a more complete discussion of background).

The number of ions produced may be expressed as

i

-

noQisie

(21)

where n0 is the density of the gas molecules,

Q is the collision cross-

section of the molecules for a given electron energy, s is the path length

of the electron in the gas, and i

is the electron current.

small quantity and is taken to be the ionization probability.

n0sQi is a

(Barnard 1952).

66.

IONIZATION

CHAMBER

CONTROL

TRAP

PLATE

FILAME NT

45V

40"

454

Figure 36.

Schematic diagram of electron gun.

67.

CHAMBER

GAS

ELECTRON

BEAM

DRAWING-OUT

VOLTAGE

ACCELERATING

VOLTAGE

I

ION BEAM

-

I

.9-

1 I-10

if,"

Figure 37.

Schematic diagram of ion gun.

68.

A plot of the observed peak height vs. electron energy is shown in figure 38.

Stability

In all ion sources, adequate electronic equipment must be provided to

stabilize the voltages applied to the electrodes in the ion and electron

guns.

Of consideralbe importance is the use of proper insulation.

section II).

(see

A leaky insulator can result in an unstable ion beam.

This

type of instability is difficult to locate and can best be prevented by

adequate attention to cleanliness in the source.

If in equation (21) Qisn 0 is a constant for any given set of conditions

(as it usually is) the stability of the ion current depends upon the stability of the electron current, i e .

Since secondary electron emission is,

to some extent, always present, it is desirable to control the total

electron current immediately adjacent to the filament.

As discussed in

an above subsection this is the method used in the present research.

The density of gas molecules no, is directly proportional to the

rate of gas inflow Qgffl and inversely proportional to the pumping speed

S, or no

Cc Q9f 1/S.

It is necessary, therefore, to control not only the

rate of gas inflow but also the rate at which the gas is pumped from the

ionization chamber.

The pumping speed can be controlled by proper control

of the heating element in the diffusion pump and by proper design of the

ionization chamber.

1.0

+

++

.8-

. Os

5n

m

J0

+

4

.2-

0

10

20

30

40

50

60

70

80

90

ELECTRON ACCELERATING VOLTAGE

100

(VOLTS)

70.

Section V

COLLECTION AND MEASUREMENT OF ION BEAMS

Collector Design

Several different collector designs have been considered in the present

research.

The main decision to be made being that of selecting a single

or multiple collecting system.

The wide mass separation of the isotopes

of argon made null method measuring impractical without multiple collection.

This, however, would introduce unwanted mass discriminations. (Barnard 1952).

Further because of the smallness of the sample usually encountered in this