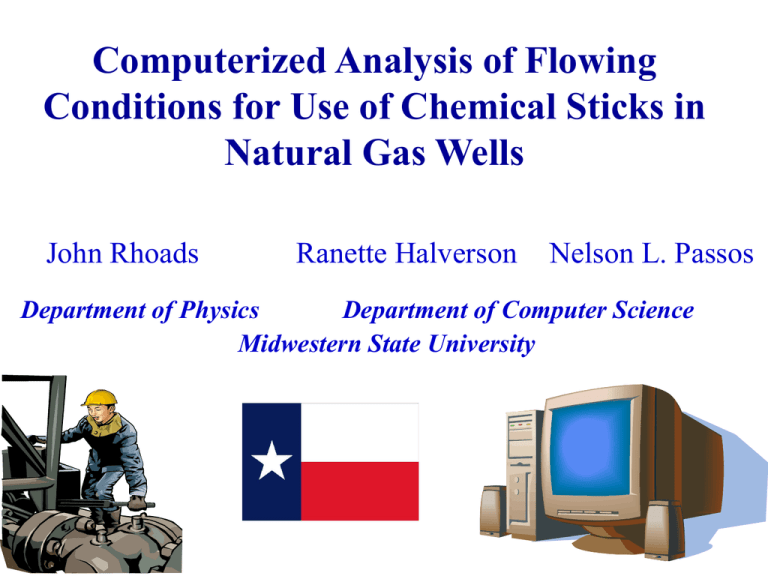

Computerized Analysis of Flowing Conditions for Use of Chemical Sticks in

advertisement

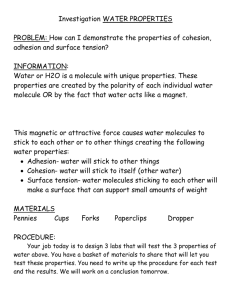

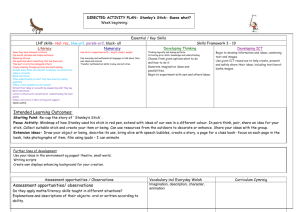

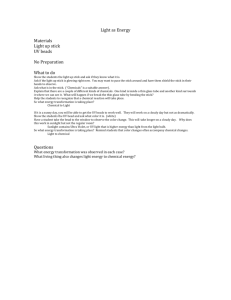

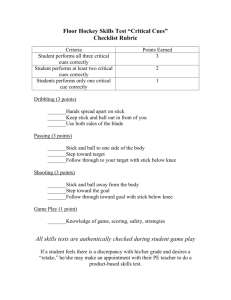

Computerized Analysis of Flowing Conditions for Use of Chemical Sticks in Natural Gas Wells John Rhoads Ranette Halverson Nelson L. Passos Department of Physics Department of Computer Science Midwestern State University Outline • Oil field applications • Chemical sticks • Required field computation • Results • Summary 2 OIL FIELD COMPUTER APPLICATIONS •STRUCTURAL DESIGN (OFFSHORE PLATFORMS) •RESERVOIR SIMULATION •SEISMIC ANALYSIS •FUTURE PRODUCTION FRECASTS •FINANCIAL MANAGEMENT 3 OIL FIELD COMPUTER APPLICATIONS USUAL REQUIREMENTS: •SUPERCOMPUTERS •PARALLEL SOFTWARE •HIGH COSTS •REMOTE DATA PROCESSING 4 OIL FIELD COMPUTER APPLICATIONS SMALL SOFTWARE TOOLS: •directional/horizontal drilling •water and CO2 flood prediction •tubing and casing design routines •tubular inventory •analysis of geological features • risk analysis 5 THE CHEMICAL STICK PROBLEM WELL-KNOWN PROBLEMS: • Internal corrosion of tubular products • Corrosion results cessation of production • Liquid chemical treatments cannot be dumped down tubing in a flowing gas well • Liquid treatment requires shut down of production operations 6 THE CHEMICAL STICK PROBLEM PROCEDURE: • Delivery of chemicals to the bottom of hole is made by dropping a solid chemical stick inside the tubing • Stick designed to fall to the bottom of the hole, become static, slowly dissolving over time to release active corrosion control ingredients • Question? whether or not a given size chemical stick will fall in a gas stream flowing inside a tube 7 FIELD COMPUTATION INPUT: • Flow rate from the well • Wellhead pressure • Chemical stick falls under the influence of gravity REQUIRED: • Impulse of gas stream incident on and normal to the cross sectional area of the bottom of the chemical stick. 8 FIELD COMPUTATION CALCULATIONS: • Assumptions were required due to lack of information on frictional data (dragging forces), bottom hole pressure, heat exchange (gas and environment), etc. REQUIRED ANSWER: • Will the stick fall to the bottom? 9 SOLUTION StickDrop Algorithm Estimate flowing bottom hole pressure Estimated bottom hole temperature Calculate the gas density at the bottom hole Compute the mass flow rate MFR (lbs/second) Calculate the velocity in feet per second Compute force per second impact on end of stick: Calculate the mass Calculate the buoyancy If weight is greater than the impulse force, the stick will drop. END 10 IMPLEMENTATION 11 IMPLEMENTATION 12 EXPERIMENTAL DATA Tubing dimensions Tubing 1.90" 2.375" 2.875" Area (square inches) 2.138 3.272 4.680 Chemical stick dimensions Stick Area Length Weight (lbs) 1.00" 1.25" 1.625" 0.785 1.227 2.074 15 15 18 0.55 0.75 1.50 13 EXPERIMENTAL DATA 1.90" 1.00" 90° F Chemical Stick Bottom hole temperature A 2.138 sq in Tubing Flow rate = 5,000 Mcfd (million cubic feet/day) 14 EXPERIMENTAL DATA Chemical stick not heavy enough 15 ~ Summary ~ • Computer applications availability • Field operation requirements • Computerized solution for the chemical stick drop • Benefits of a field solution Questions?? 16