The University of Georgia The Economic Feasibility of a Blueberry

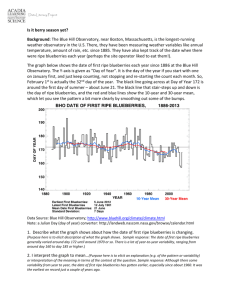

advertisement

The University of Georgia Center for Agribusiness and Economic Development College of Agricultural and Environmental Sciences The Economic Feasibility of a Blueberry Packing Facility in Southeast Georgia Prepared by: Audrey Luke-Morgan and Kent Wolfe September 2008 FR 08-06 The Economic Feasibility of a Blueberry Packing Facility in Southeast Georgia Page Introduction ................................................................................................................................................................. 2 Blueberry History .................................................................................................................................................... 2 Market Analysis ...................................................................................................................................................... 3 Georgia Blueberry Grower Prices ................................................................................................................................. 6 Fresh and Frozen Blueberry Grower Price Spread .................................................................................................... 7 Weighted Average Grower Price .............................................................................................................................. 8 Coffee County Projected Prices and Quantity ............................................................................................................... 9 Financial Feasibility .................................................................................................................................................... 11 Capital Cost ............................................................................................................................................................ 11 Variable Operating Costs........................................................................................................................................ 12 Labor and Benefits ............................................................................................................................................... 13 Other Variable Operating Expenses ............................................................................................................................ 14 Packaging Material ................................................................................................................................................. 14 Utilities and Communications .............................................................................................................................. 14 Pallets .................................................................................................................................................................... 15 Fuel and Oil ............................................................................................................................................................ 15 Interest on Operating Capital .................................................................................................................................. 15 Fixed Costs .................................................................................................................................................................. 16 Breakeven Analysis ................................................................................................................................................. 17 Summary .................................................................................................................................................................... 18 1 Coffee County Blueberry Packing Facility Feasibility Analysis Introduction This report examines the economic feasibility of constructing and operating a valueadded blueberry processing facility in the Coffee County area. The main focus of this report will focus on packing blueberries for the fresh and processed market. The industry has successfully added value to blueberries by further processing such as packing in clamshell containers, freezing, and juicing blueberries for convenience. These processes increase the value received by the farmer, cooperative, and retailer. However, the largest percentage of added value occurs in the packing component. Hence, the Coffee County group has requested the Center for Agribusiness and Economic Development (CAED) to research the feasibility of operating a value-added blueberry processing facility. This report examines the relevant economic issues surrounding the operation of a valueadded processing facility. All costs were taken into consideration, even a small direct cost to the producers for delivery of the blueberries to the facility. The majority of this report consists of the marketing, finance, and impact analysis sections. Together these sections explain the feasibility of operating the proposed blueberry packing facility. Blueberry History For centuries, blueberries were gathered from the forests and the bogs by Native Americans and consumed fresh and also preserved. The Northeast Native American tribes revered blueberries and much folklore developed around them. The blossom end of each berry, the calyx, forms the shape of a perfect five-pointed star; the elders of the tribe would tell of how the Great Spirit sent "star berries" to relieve the children's hunger during a famine. Parts of the blueberry plant were also used as medicine. A tea made from the leaves of the plant was thought to be good for the blood. Blueberry juice was used to treat coughs. The juice also made an excellent dye for baskets and cloth. In food preparation, dried blueberries were added to stews, soups and meats. The dried berries were also crushed into a powder and rubbed into meat for flavor. Blueberries were also used for medicinal purposes along with the leaves and roots. The US and Canada lead the world in blueberry production and account for an estimated 90% of world production. Blueberries have been in North America for centuries and were an important food, medicinal and dye used by Native Americans. For example, the leaves ere used to make a tea which was good for the blood. The juice was used to treat coughs as well as a dye. The blueberry was incorporated into various food products. Today, the popularity of blueberries continues to grow as new food products are introduced to the market. Driving the increased consumption of blueberries are the health benefits that have been associated with eating blueberries. 2 Market Analysis In 1992, there were 3,500 acres of blueberries in Georgia. Georgia’s blueberry acreage has increased to 7,000 acres in 2006. The late freeze in 2007 decreased the number of harvested acres of blueberries significantly to 4,500 acres. There is an upward trend in blueberry yields per acre over the past 15 years. This upward trend is prevalent from 2000 to 2006. Again, 2007 was an anomaly. Table1--Cultivated blueberries: Commercial acreage, yield per acre, production, and season-average grower price in Georgia, 1992-2007 State Value of and Acreage Yield per Utilized Utilization Grower price utilized year harvested acre production Fresh Processed Fresh Processed All production 1,000 dollars Acres Pounds ---- 1,000 pounds ----- Cents/pound -1992 3,500 3,430 12,000 3,000 9,000 108.0 65.0 75.8 1993 3,700 1,490 5,500 1,500 4,000 102.0 27.0 47.5 1994 3,700 2,030 7,500 2,000 5,500 110.0 35.0 55.0 1995 3,700 3,510 13,000 5,000 8,000 96.0 37.0 59.7 1996 3,500 1,570 5,500 2,000 3,500 121.0 57.0 80.3 1997 4,000 3,250 13,000 4,000 9,000 114.0 53.0 71.8 1998 4,400 1,700 7,500 4,000 3,500 98.0 53.0 77.0 1999 4,400 2,500 11,000 6,000 5,000 118.0 60.0 91.6 2000 4,600 4,130 19,000 6,000 13,000 145.0 75.0 97.1 2001 4,600 3,700 17,000 6,000 11,000 125.0 55.0 79.7 2002 4,600 3,700 17,000 8,000 9,000 157.0 54.0 102.0 2003 4,500 3,780 17,000 8,000 9,000 164.0 63.0 111.0 2004 4,800 4,380 21,000 10,000 11,000 164.0 67.0 113.0 2005 6,000 4,330 26,000 12,000 14,000 173.0 79.0 122.0 2006 7,000 4,500 31,500 16,000 15,500 237.0 141.0 190.0 2007 1/ 4,500 2,000 9,000 6,000 3,000 310.0 142.0 254.0 1/ Preliminary. Source: USDA, National Agricultural Statistics Service, Noncitrus Fruit and Nuts Summary, various issues. 9,090 2,610 4,125 7,760 4,415 9,330 5,775 10,080 18,450 13,550 17,420 18,790 23,770 31,820 59,775 22,860 Since 1995, the per capita availability of frozen blueberries have trended downward. Total per capita blueberry availability has trended upward from 1971 to the present. Interestingly, in 2002, consumption of fresh blueberries surpassed consumption of frozen blueberry on a per capital basis, Figure 1. Figure 1. Blueberry Per Capita Availability (fresh weight Equivalent) 0.6 0.5 0.4 0.3 0.2 0.1 0.0 Fresh Frozen 19 71 19 73 19 75 19 77 19 79 19 81 19 83 19 85 19 87 19 89 19 91 19 93 19 95 19 97 19 99 20 01 20 03 20 05 Pounds Blueberrie Per Capita Availability (Fresh Weight Equivalent) Year 3 The data in Table 2 presents the per capita availability for both fresh and frozen blueberries. The data series starts in 1971 and continues through 2007, which is an estimate. Table 2. Blueberries: Per capita availability (fresh weight equivalent) Year Total Fresh Processed1 Pounds Frozen 1970 0.2 0.2 1971 0.2 0.2 1972 0.2 0.2 1973 0.2 0.2 1974 0.1 0.1 1975 0.2 0.2 1976 0.1 0.1 1977 0.1 0.1 1978 0.1 0.1 1979 0.1 0.1 1980 0.4 0.2 0.2 1981 0.3 0.2 0.2 1982 0.3 0.2 0.1 1983 0.2 0.1 0.0 1984 0.5 0.2 0.3 1985 0.5 0.2 0.2 1986 0.6 0.2 0.4 1987 0.5 0.2 0.3 1988 0.5 0.2 0.2 1989 0.5 0.2 0.3 1990 0.4 0.1 0.3 1991 0.5 0.2 0.3 1992 0.6 0.2 0.4 1993 0.7 0.3 0.5 1994 0.8 0.3 0.5 1995 0.8 0.3 0.5 1996 0.7 0.3 0.4 1997 0.6 0.3 0.3 1998 0.7 0.3 0.4 1999 0.7 0.3 0.4 2000 0.6 0.3 0.3 2001 0.7 0.3 0.4 2002 0.6 0.4 0.3 2003 0.8 0.4 0.4 2004 0.8 0.5 0.3 2005 0.8 0.4 0.4 2006 0.8 0.6 0.3 NA = Not available. 1Frozen. Source: USDA/Economic Research Service. Data last updated 4 Figure 2 presents the upward trend in Georgia’s blueberry utilization. Over the past fifteen years, a larger percentage of Georgia’s blueberries have been going to the fresh market. The trend in fresh use increased significantly between 1997 and 1998 and then fell in 2000. In 2001 fresh use started trending upward again. The spike in 2007 represents an anomaly due to the reduction of total blueberries attributed to the late freeze. Figure 2. Georgia Fresh Blueberry Use as a Percent of Total Production Fresh Use as a Percent of Total Production 70% 60% 40% 30% 20% 10% 20 0 20 6 07 1/ 20 05 20 03 20 04 20 02 19 99 20 00 20 01 0% 19 92 19 93 19 94 19 95 19 96 19 97 19 98 Percentage 50% Year 5 Georgia Blueberry Grower Prices Figure 3 presents the prices that Georgia blueberry growers have received since 1992. The prices for both the fresh and frozen blueberries have been trending upward since 1992. A significant price spike occurred in 2006 and then again in 2007. The 2007 price spike can be attributed to the short supply created by the late freeze. The price spread between fresh and frozen appears to be fairly consistent until 2002 where fresh blueberry prices were valued almost $1.00 per pound. Georgia Fresh and Frozen Grower Prices 350.0 Cents per Pound 300.0 250.0 200.0 Fresh 150.0 Frozen 100.0 50.0 19 92 19 93 19 94 19 95 19 96 19 97 19 98 19 99 20 00 20 01 20 02 20 03 20 04 20 05 20 20 06 07 1/ 0.0 Yeasr Figure 3. Georgia Fresh and Frozen Blueberry Grower Prices 6 Fresh and Frozen Blueberry Grower Price Spread Figure 4 presents the price spread between fresh and frozen Georgia blueberries. The price spread was about $0.43 per pound in 1992. Over the past 15 years it has trended upward to $1.68 per pound in 2007. However, this price differential is an anomaly attributed to the late freeze and its impact on reducing the supply of blueberries in Georgia. The price differential shrank between 1994 and 1998 from $0.75 to $0.45 per pound. The price spread trend reversed itself in 1999 and has been trending upward since. Form 2002 to 2006, the price spread between fresh and frozen Georgia blueberries has hovered around $1.00 per pound. Georiga Price Spread between Fresh and Frozen Blueberries 180 160 Cents per Pound 140 120 100 80 60 40 20 1/ 20 07 20 06 20 05 20 04 20 03 20 02 20 01 20 00 19 99 19 98 19 97 19 96 19 95 19 94 19 93 19 92 0 Year Figure 4. Georgia Price Spread between Fresh and Frozen Blueberry Grower Prices 7 Weighted Average Grower Price The weighted average price is a means of expressing the price a Georgia grower would receive for all of their blueberries, both fresh and frozen. In 1992, Georgia growers received an average of $0.76 per pound for their blueberry production. Again, this factors both fresh and frozen. In 2007, the price Georgia growers received have increased to $2.54 per pound. Georgia Weighted Average Grower Price 300.0 Cents per Pound 250.0 200.0 150.0 100.0 50.0 20 0 20 6 07 1/ 20 05 20 04 20 03 20 02 20 01 20 00 19 99 19 98 19 97 19 96 19 95 19 94 19 93 19 92 0.0 Year Figure 5. Georgia Weighted Average (Fresh and Frozen) Blueberry Grower Prices The average price for Georgia blueberries has been increasing steadily since 1992 but prices jumped significantly in 2006 to $1.90 per pound. In 2007, the price increase significantly. However the $2.54 per pound figure can be attributed to the late freeze and reduced supply of Georgia blueberries. 8 Coffee County Projected Prices and Quantity The four members of the Coffee County Blueberry Growers group are all seasoned blueberry producers. The following outlines their estimated and quantity for 2009 to 2013, Table 3. Table 3. Coffee County Blueberry Grower and Outside Berry Usage Year Outside Berries Total Berry Usage Coffee Grower Berries 2009 750,000 5,250,000 6,000,000 2010 1,200,000 4,800,000 6,000,000 2011 2,000,000 4,000,000 6,000,000 2012 2,750,000 3,250,000 6,000,000 2013 3,500,000 2,500,000 6,000,000 Table 4 presents area blueberry production. It is estimated that there are over 21 million pounds of blueberries produced in the area. However, there is a packing facility in Bacon County that is currently handling blueberries. It appears that there is sufficient blueberry production in the area to provide the new proposed facility with the extra berries it needs to process 6 million pounds a year. Table 4. Area Blueberry Production County 2007 Blueberry Acres Atkinson 114 Bacon 3,900 Ben Hill Berrien 105 Coffee 118 Irwin 41 Jeff Davis 196 Ware 620 Total 5,094 Yield Per Acre 2006 4,500 5,000 1,014 5,200 4,269 5,500 4,400 4,269 Total Pounds 513,000 19,500,000 106,470 613,600 175,029 1,078,000 2,728,000 21,746,286 Competition There are now about 16 packing facilities for fresh berries and 8 packing facilities for frozen berries in the state. The new facility will have to compete to acquire additional berries to obtain their 6 million pounds annually. However, after talking with folks in the industry, the number of acres of blueberries in Georgia is growing faster than the current packing facilities capacity to process during the peak of the fresh blueberry season. Harvested blueberry acres in Georgia increased from over 4,000 in 2005 to approximately 7,000 in 2006. This number fell in 2007 due to the late frost. 9 Projected Revenue The projected Revenue is very simple to calculate simply the volume of blueberries multiplied by the price for the handling, Table 5. Thirty-five percent of the blueberries will be considered fresh berries and the remaining 65% will be processed. The handling charge for fresh blueberries is $0.45 per pound and the handling charge for the processed blueberries is $0.16 per pound. Table 5. Estimated Revenue from Packing Facility Pounds Handling Price Estimated Revenue Fresh 2,100,000 $0.45 $945,000 Processed 3,900,000 $0.16 $694,000 Total 6,000,000 $1,569,000 Given that the price of handling the blueberries is not expected to change over the next five years and that capacity of the facility is 6 million pounds of berries, the estimated revenue will be $1,569,000 for each of the next five years. 10 Financial Feasibility General Assumptions Blueberry Packing and Processing Facility This section investigates the costs of operating a blueberry packing and processing facility capable of handling six million pounds of blueberries per year. The economic analysis considers the projected operating and fixed costs associated with the packing and processing blueberries for the fresh and processed market. This economic analysis applies to full annual operation; it does not serve as a cash-flow, or start-up cost analysis. The figures cover a "normal" operating year including a "normal" sales year. The economic analysis is provided to determine the true profit or loss potential of the proposed operation. Cash flow analysis can be used to determine the feasibility of any particular financing plan. Equipment costs for the operation include all necessary components for sorting, grading, packing, and cooling the blueberries prior to delivery. The size investigated was a single line for fresh market and a single line for processed market with a capacity large enough to service six million pounds. It is estimated that 35% of the annual throughput will be for the fresh market and the remaining 65% will be for the processed market. Equipment costs were provided by the interested group in conjunction with the Coffee County Cooperative Extension Service and the CAED. Capital Cost Equipment lines include both a fresh line and processed line. The capital cost figures include the necessary equipment for sorting, grading, packing and cooling blueberries for fresh market before they are picked up for delivery. Also included is equipment to package and process blueberries for the processed market. The equipment required for the fresh line includes a blower, color sorter, soft sorter, inspection table, transfer conveyor, volume filler and packing table with a projected cost of $231,034. The processed line will require a blower, destemmer, water tank with elevating, dewatering shaker, grade belt, box filler and box making table. The projected total capital cost for the processed line is $145,766. The processing equipment for the facility for both fresh and processed line totals $376,800. Additional miscellaneous equipment including lugs, scales, air compressor, pallet jack, spare parts, etc. is estimated to total $50,000. An additional component of this venture is the inclusion of “cooling trailers” in the field to rapidly remove field heat. The group proposes to provide refrigerated transport trailers to the producers so that the blueberries can begin the cooling process upon harvest and before delivery to the packing shed. By employing rapid post-harvest cooling, the quality of the blueberry will be better maintained through to market. It is estimated that by cooling alone, a producer can gain an increase of 10 to 30 fold in potential shelf-life by lowering the respiration rate and reduction in pathogen growth. A total of 20 trailers at a cost of $40,000 each would be included for this venture resulting in additional capital cost of $800,000. In addition, the operation would own two semi trucks to have available to pick-up and deliver these trailers to and from the producers. A portion of this cost may be passed on to the producer in the form of a lease rental fee. 11 The building with all improvements including concrete, cold storage, electrical, plumbing, and all land prep costs are estimated at $680,000. The land cost is estimated to be $5,000 per acre based on conversations with the major investor group and parties interested in this project with a total of 2 acres required. Office equipment, furniture, and computers are estimated to cost $9,925 for this venture. Working capital is essential in starting and operating any new business. Working capital is defined as the resources used to support a business until it is able to generate resources to support itself, generally in the form of profits. Most working capital comes in the form of start-up, short-term loans. Working capital varies with production level since it is directly related to variable operating expenses. For this analysis the required working capital is assumed to be resources sufficient to cover half of the operating expenses since the venture is will operate for only 20 weeks per year. The total capital cost and working capital represent the total estimated capital to be raised through equity and/or debt financing. These costs are summarized in Table 6 for the blueberry packing and processing facility venture at full capacity. Table 6. Capital Cost Summary Building and Improvements Equipment Transportation Equipment (Trailers & Semis) Office Equipment Land Total Capital Cost Working Capital $ 680,000 $ 426,800 $ 900,000 $ 9,925 $ 10,000 $ 2,026,725 $ 281,103 Variable Operating Costs Operating and fixed costs were estimated for this venture based on prior feasibility studies for similar ventures and conversations with sales and service representatives in the industry. Operating costs utilized in this study are those directly associated with operating the business. Total variable operating costs represent 56.5% of the total costs of the operation. These costs include hourly labor and benefits, fuel and oil, utilities, repairs and maintenance, communication expense, forklift rental, pallets, packaging supplies and materials, miscellaneous office expense, and interest on operating capital. The total variable operating cost is estimated to be $584,693 or $0.10 per pound. It is important to point out that no direct product purchase price is included in this analysis. The proposed operation will not take ownership of the “commodity blueberries”. Instead, the function will be a service provided for blueberry producers. Individual producers will retain ownership of and be responsible for marketing their own blueberries. A detailed analysis of these costs can be seen in Table 7. This analysis considers the operation as a whole, i.e. both fresh and processed line and does not look at each line individually. 12 Table 7.Total Costs: Operating and Fixed Costs for Fresh and Processed Line Blueberries Operating Costs: Labor: Truck Drivers Line Laborers Forklift Operators Benefits Fuel & Oil Electricity Water Repairs/Maintenance Phone/Fax/Internet Forklift Rental Pallets Packaging Material Miscellaneous Office Supplies Interest on Operating Capital Total Variable Cost Fixed Costs: Manager Secretarial/Office Support Accountant & Attorney Misc. Co-op/Business Startup Expenses Contingency Fees Property Taxes (Mill Rate, Facility Value) Insurance--Property and Product Liability Depreciation Interest on LT Debt Total Fixed Cost Total Cost Annual $ 300 6,000 6,000,000 $ 281,103 $ $ $ $ $ $ $ $ $ $ 12 $ $ 8.00 $ 0.015 $ $ 8% $ $ 40,000 160,000 32,000 42,231 25,489 61,750 6,000 40,136 3,600 8,000 48,000 90,000 5,000 22,488 584,693 $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ 0.007 0.027 0.005 0.007 0.00 0.010 0.001 0.01 0.001 0.00 0.01 0.02 0.00 0.004 0.10 % of Total Cost 3.9% 15.5% 3.1% 4.1% 2.5% 6.0% 0.6% 3.9% 0.3% 0.8% 4.6% 8.7% 0.5% 2.2% 56.5% $ $ $ $ $ $ $ $ $ $ 50,000 8,000 5,000 3,000 5,847 18,095 25,000 172,893 162,138 449,972 $ $ $ $ $ $ $ $ $ $ 0.01 0.00 0.001 0.001 0.001 0.00 0.00 0.03 0.03 0.07 4.8% 0.8% 0.5% 0.3% 0.6% 1.7% 2.4% 16.7% 15.7% 43.5% $ 1,034,665 $ 0.17 100.0% 1% 22.32 $ 2,026,725 $/lb Labor and Benefits The largest expense for this venture is labor. Direct labor and benefits total about 26.5% of the total costs with an estimated annual expense of $274,231 or $0.046 per pound. It is assumed that the facility will operate an eight hour shift, five days a week, 20 weeks a year with an effective pay rate of $10.00 per hour. Full-time employees for the facility includes 20 full-time employees for operating the fresh and processed line, 5 truck drivers for delivery and pickup of cooling trailers to producers’ fields encompassing a 40 mile radius, and 4 forklift operators. Fixed labor costs related to this venture include a manager to oversee operations and one part-time employee for office and clerical duties with annual salaries of $50,000 and $8,000 respectively. Variable and fixed labor expenses represent about 32% of the total cost of the operation or about $0.06 per pound. Fringe benefits are estimated to be 12.7% of the gross wages. The labor expense, including benefits and payroll taxes, are included in Table 8. 13 Table 8. Labor Requirements for Blueberry Processing Operational Period (weeks) Hours per Week Wage Rate/Hr Effective Wage Rate/Hr (w/ OT) $ $ 20 40 10.00 10.00 Blueberry Only Cost/week/e'ee Manager Office Personnel Truck Drivers Line Laborers Forklift Operators Total Wages 1 1 5 20 4 Fringe Benefits Calculations: FUTA Taxable amount/e'ee FUTA Rate SUTA Taxable amount/e'ee SUTA Rate FICA Rate PAYROLL TAXES: FUTA SUTA FICA Workers Comp Health Insurance ($/month/e'ee) for Manager Total Fringe Benefits Total Labor Costs $ $ $ $ 400.00 400.00 400.00 400.00 Annual Expense Cost/lb $ 50,000.00 $ 0.01 $ 8,000.00 $ 0.00 $ 40,000.00 $ 0.01 $ 160,000.00 $ 0.03 $ 32,000.00 $ 0.01 $ 290,000.00 $ 0.05 7000 0.80% 8500 2.70% 7.65% $ 300 Annual Expense $ 1,736.00 $ 6,709.50 $ 22,185.00 $ 8,000.00 $ 3,600.00 $ 42,230.50 $ 332,230.50 Cost/lb $ $ $ $ $ $ $ 0.00 0.00 0.00 0.00 0.00 0.01 0.06 Other Variable Operating Expenses Other operating costs include fuel and oil, utilities, repair and maintenance, communication, forklift rental, pallets, packaging material, office supplies and materials, and interest on operating capital. These individual items range from less than 1% to 9% of the total costs for the venture and collectively account for about 30% of the total cost of the venture. Packaging Material The largest of the various other operating expenses is the expense for packaging material. This expense encompasses clamshell packing, labels, bags and boxes to package the blueberries for market. The estimated expense is $0.015/lb of blueberries for a total expense of $90,000 assuming 6,000,000 pounds of blueberry packaged annually. Expense for packaging materials represents almost 9% of the total cost for the blueberry packaging venture. Utilities and Communications The next largest operating expense for this venture is utilities, representing 6.6% of the total costs. Total annual expense for water and electric is estimated to be about $67,750, or $0.01/lb. For electrical usage, the analysis assumes 5 months of peak operation at a monthly fee of just over $12,000 and the remaining 7 months off-peak at a monthly charge of approximately $200 per month. The water usage fee is based on a seasonal usage estimate of 3 million gallons with a cost of $2 per 1,000 gallons, or $6,000 per year. Phone, fax and internet, or “communications” expenses total $3,600 per year or less than $0.001 per pound of product or 0.3% of the total expense. 14 Pallets Pallets are required to handle and transport blueberries in the packaging facility. The estimated cost is $8 per pallet with a pallet required for every 1,000 pounds of blueberries packaged. The resulting annual cost is $48,000 or $0.01 per pound representing 4.6% of the total cost. Repairs and Maintenance Total repair and maintenance is dependent on 2% of the total capital costs for building, improvements and equipment. For this operation repair and maintenance is estimated to be $40,136, or about $0.01 per pound. These costs represent about 3.9% of the total cost for the blueberry packing facility. Fuel and Oil Fuel and oil expense was estimated based on current market prices. Given recent volatility in this market, this expense can change significantly. It is estimated that fuel and oil account for only 2.5% of the total cost of the venture at $25,489 per year. Included in this expense is LP gas for forklift operation and fuel for the semi-trucks that will be transporting the blueberries in the refrigerated trailers to and from the fields and plant. Operating season was estimated to be 100 days. Forklift LP gas expense was estimated to be $9,571 based on a daily usage of 134 lbs which results in annual usage of 3,190 gallons with a current price of $3.00 per gallon. Delivery fuel use is estimated based on annual throughput of 6 million pounds over 100 operating days which results in an average daily throughput of 60,000 pounds. The refrigerated trailers could vary in size dependent on producer needs related to total production and logistics such as field size, transportation distance, etc. To standardize calculations, it was assumed each trailer would hold 7,500 lbs of blueberries. Therefore, the plant would handle 8 loads of blueberries per day. It was further assumed that the average miles per trailer would be 20 miles one way. Thus, the projected mileage per day would be 320 miles for 100 days of operation. It is assumed that the average fuel consumption is 10 miles per gallon. Thus the required fuel for the delivery of cooling trailers to and from the field and facility would be 3,200 gallons. Utilizing current market diesel prices of $4.25 per gallon, the resulting annual expense for delivery fuel is $13,600. An additional 10% of these costs, or $2,317, is included to cover lube expense. Interest on Operating Capital For this analysis the required working capital is assumed to be resources sufficient to cover half of the operating expenses since the facility operates only 20 weeks. Interest on operating or working capital is included at 8%. The estimated required working capital for the venture is $281,103 per year or less than $0.004 per pound of blueberries packaged. Interest on operating capital represents 2.2% of the total cost. The remaining variable operating expenses attributable to the packing venture, estimated at $13,000 per year, are for forklift rental at $8,000 and office supplies utilized in the business at $5,000. Collectively these items account for 1.3% of the total costs. 15 Fixed Costs Fixed costs are expenditures that remain the same regardless of production level. Items categorized as fixed costs for this analysis include manager and secretarial support salaries, accounting/legal fees, miscellaneous startup and contingency feels, taxes, insurance, interest on intermediate and long-term debt, and depreciation. Total fixed costs are estimated to be $449,972. Based on the assumption set forth and projected level of production for this analysis, an additional expense of $0.07 per pound is incurred for fixed costs. Fixed costs represent 43.5% of the total cost of this venture. Salaried employees are considered "fixed" for this analysis since their costs are not easily changed with production levels. As discussed in the direct labor section, annual expenses of $50,000 and $8,000 respectively are included as fixed costs for managerial salaries and secretarial support. Accounting, legal and consulting fees are estimated to total $5,000 per year for the facility and represent about 0.5% of the total cost. The resulting cost per pound is less than $0.001. Miscellaneous start-up fees and licenses are estimated to be $3,000. Contingency are estimated at 1% of the total variable costs, or $5,847. These costs relate to less than $0.001per pound each. Together they comprise less than 1% of the total cost of operation of the blueberry packing facility. The land, equipment and building related to processing (manufacturing) the product may be tax exempt for the first five years of operation if an application is filed with the county tax assessor claiming a manufacturing exemption. However, any real or personal property not directly related to processing will be taxable. A total expense of $18,095 is included in the model to cover these taxes, based on property value and mill rate. This expense represents worst case scenario, if NO exemptions are claimed and represents 1.7% of the total cost. Also included in the analysis is insurance expense estimated to be $25,000 per year for the business to cover both property and product liability. Insurance expense represents 2.4% of the total cost for packing blueberries at the annual level of 6 million pounds/ Annualized cost of the internal capital and return on investment is built into the economic analysis. Fixed cost include a return on all capital invested. Interest expense is included at a rate of 8% of the total investment for a cost of $162,138 or $0.03 per pound for this operation. Return on invested capital can be thought of as the average annual interest payment for a loan capitalized over the anticipated useful life of the facility. Return on capital or interest on long-term debt represents 15.7% of the total cost of the operation. Economic depreciation is used to cover physical deterioration and functional obsolescence of equipment and facility and can be thought of as the annual average principal debt payment occurring if a loan is structured for the entire capital costs for the anticipated useful life of the facility. The total annual depreciation is estimated to be $172,893, or 16.7% of the total cost, based on the capital cost estimates and economic life of the capital assets. Table 9 summarizes the fixed costs. 16 Table 9. Fixed Costs Manager Secretarial/Office Support Accounting/Legal Misc. Business Startup Expenses Contingency Fees Property Tax Insurance Interest Expense (8% Total Investment) Depreciation Total Fixed Cost Total $ 50,000 $ 8,000 $ 5,000 $ 3,000 $ 5,847 $ 18,095 $ 25,000 $ 162,138 $ 172,893 $ 449,972 Total Costs Total costs based on these estimates and assumptions are $1,034,665 or $0.17 per pound to package and cool 6 million pounds of blueberries for the fresh and processed markets. Break Even Analysis Break even analysis can be very helpful in the evaluation of a new venture. The break even point is the point where revenue equals cost—no profits are made and no losses are incurred. Knowing the price or volume necessary to cover all costs or break even is crucial to evaluate a new venture. Considering all costs for this venture, the break-even price per unit is $0.089 per pound. Considering the projected service demand of 35% fresh market packing at a fee of $0.45 per pound and 65% processed market packing at $0.16 per pound, the projected blended average revenue per pound is $0.262. The resulting break-even volume at this blended mix and price is just under 4 million pounds at 3,956,655 pounds of blueberries. If only fresh market packing is considered, the breakeven volume to be packed would drop to roughly 2.3 million pounds assuming the higher fee of $0.45 per pound. Conversely, if only processed market blueberries are packed, assuming a fee of $0.16 per pound, the volume required to breakeven would increase to almost 6.5 million pounds, which is greater than the projected annual throughput for the facility. Table 10 summarizes these findings. Table 10. Break Even Analysis Break Even Price (Total Value per Unit) Volume Break Even Volume at 100% Fresh Market Fee ($0.45/lb) Break Even Volume at 100% Processed Market Fee ($0.16/lb) Break Even Volume at Projected Average Fee ($0.262/lb) $/Lb $0.089 2,299,256 lbs 6,466,658 lbs 3,956,655 lbs 17 Summary Based on assumptions set forth in this analysis, a blueberry packing facility in South Georgia appears to be economically feasible. Projected net returns are $0.09 per pound above all costs for the services provided. Again, it is important to point out that the packing facility will not take ownership of the blueberries nor be responsible for final marketing of them. The venture will provide the opportunity for area growers to enhance quality and reduce loss through the rapid post harvest cooling with the refrigerated trailers provided by the facility. The facility will have the capability of handling both fresh market and processed market blueberries which should be an enticement for area producers. 18 The Center for Agribusiness & Economic Development The Center for Agribusiness and Economic Development is a unit of the College of Agricultural and Environmental Sciences of the University of Georgia, combining the missions of research and extension. The Center has among its objectives: To provide feasibility and other short term studies for current or potential Georgia agribusiness firms and/or emerging food and fiber industries. To provide agricultural, natural resource, and demographic data for private and public decision makers. To find out more, visit our Web site at: http://www.caed.uga.edu Or contact: John McKissick, Director Center for Agribusiness and Economic Development Lumpkin House The University of Georgia Athens, Georgia 30602-7509 Phone (706)542-0760 caed@uga.edu The University of Georgia and Fort Valley State University, and the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An equal opportunity/affirmative action organization committed to a diverse work force. Report Number: FR-08-?? September 2008 Issued in furtherance of Cooperation Extension Acts of May 8 and June 30, 1914, the University of Georgia College of Agricultural and Environmental Sciences, and the U.S. Department of Agriculture cooperating. J. Scott Angle, Dean and Director 19