Site Monitoring

For Business Critical Continuity

Liebert SiteLink™

Installation Manual - SiteLink-4 and SiteLink-12

TABLE OF CONTENTS

1.0

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1

Using the SiteLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0

MOUNTING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1

Enclosure Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.0

MAKING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.1

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2

IGM - Liebert Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3

ARCnet / CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4

Connecting to a Building Management System (BMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.1

Connection Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.2

EIA-232 Connection—3-Wire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.3

EIA-232 Connection—DB-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.4

EIA-485 Connection—2-Wire (Default). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.5

EIA-485 or EIA-422 Connection—4-Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.0

ADDRESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1

Set the Address for ARC156 CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2

Set the Address for Legacy CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3

Verify Communication on the CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1

Formatting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.0

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

i

FIGURES

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Module dimensions and layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Enclosure - Overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Enclosure - Wall mounting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Enclosure - Floor mounting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

IGM connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring the CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EIA-232 using 3-wire connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EIA-232 using DB-9 cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EIA-485 using 2-wire connection (SiteLink default). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

EIA-485 or EIA-422 using 4-wire connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using an ARC156 CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using a Legacy CMnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setting the module’s address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

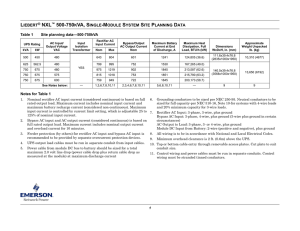

TABLES

Table 1

Table 2

LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Run & Error LED signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ii

Product Overview

1.0

PRODUCT OVERVIEW

1.1

Using the SiteLink

The Liebert SiteLink IGM Interface module is a BACnet router that provides the communications

link between Liebert units and other protocols and modules. The SiteLink module communicates with

Liebert IGMs that control devices such as environmental units, UPSs, frequency converters, and

power distribution units.

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case users will be required to correct the

interference at their own expense.

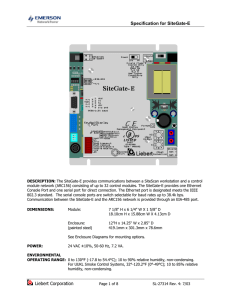

Figure 1

Module dimensions and layout

Format

Button

Rotary Address

Switches

Power

Switch

Gnd and

24VAC

Terminals

1"

25.4mm

Port A

Configuration

Jumpers

Keypad/

Display Port

Port A

CMnet Port

Port B

Access Port

LEDs

CMnet Baud

Rate Jumper

11.25"

285.8mm

1

7.5"

190.5mm

Mounting Instructions

2.0

MOUNTING INSTRUCTIONS

!

WARNING

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate equipment.

The SiteLink module comes with an enclosure that may be mounted on a wall or a floor. The module

must be secured to the enclosure as follows:

• Screw the SiteLink into an enclosed panel using the mounting holes provided on the cover plate.

To mount the enclosure:

• Choose an accessible area for mounting the enclosure, allowing clearance for wiring and service

access. Be sure to leave about 2 in. (51mm) on each side for wiring.

• Refer to the following diagrams in 2.1 - Enclosure Diagrams:

• Figure 2 - Overall dimensions

• Figure 3 - Wall mounting dimensions

• Figure 4 - Floor mounting dimensions

2.1

Enclosure Diagrams

Figure 2

Enclosure - Overall dimensions

14.25"

(362mm)

12"

(304.8mm)

2.85"

(72.3mm)

0.88" 9 places each end

(22.2mm)

3.55"

(90.1mm)

1.38"

(34.9mm)

1.12"

(28.6mm)

1.5"

(38.1mm)

1.12"

(28.6mm)

2

Mounting Instructions

Figure 3

Enclosure - Wall mounting dimensions

0.88"

(22.2mm)

0.88"

(22.2mm)

12.5"

(317.5mm)

1"

(25.4mm)

A

DETAIL A

12 places

12"

(304.8mm)

R 0.11"

(2.7mm)

0.4"

(10.2mm)

12

places

0.2"

(5.4mm)

R 0.19"

(4.7mm)

1"

(25.4mm)

0.88"

(22.2mm)

Figure 4

0.88"

(22.2mm)

Enclosure - Floor mounting dimensions

16"

(406.4mm)

0.16"

(4mm)

B

DETAIL B

14 places

9"

(228.6mm)

17.25"

(438.2mm)

0.88"

9 places each end

(22.2mm)

1.88"

(47.6mm)

4.05"

(102.8mm)

1.5"

(38.1mm)

2.62"

(66.7mm)

2.62"

(66.7mm)

3

R 0.11"

(2.8mm)

Making Connections

3.0

MAKING CONNECTIONS

3.1

Power Wiring

Whenever possible, make sure the module’s power and communications connections are working

properly before connecting any input or output points.

!

CAUTION

The SiteLink module is a Class 2 device (less than 30VAC). Take appropriate isolation

measures when mounting the SiteLink module in a control panel where non-Class 2 devices

(120VAC or greater) or wiring are present.

You can power several modules from the same transformer if you:

• maintain the same polarity

• use a transformer whose power rating is at least 20% greater than needed for the modules

For example, if the transformer is rated for 50VA and you connect it to two modules each rated at

20VA, the power trunk uses a recommended 80% of the transformer’s power (20+20=40).

!

CAUTION

Do NOT turn the module on. The module should be turned on by a factory trained specialist

only.

The SiteLink has an operating range of 21.6VAC to 26AVAC. If voltage measured at the module’s

power input terminals is outside this range, the module may not work properly.

Figure 5

Power connections

1. Turn the module’s power off. This prevents the module from being powered up before the proper

voltage is verified.

2. Make sure the 24VAC power source is off.

3. Connect the power wires to the module’s power terminals labeled Gnd and 24VAC (see

Figure 1).

4. Apply power to the transformer.

5. Make sure that 24VAC is present at the module’s power input terminals.

6. Set the module’s address. Refer to 4.0 - Addressing for details about setting the address.

7. Turn the module’s power switch on.

When the module turns on, the Run and Power LEDs turn on and the Run LED begins blinking. (See

Figure 1 for location of the LEDs.)

4

Making Connections

3.2

IGM - Liebert Equipment

Information Gathering Module Network is the protocol SiteLink uses to communicate to Liebert units

over the EIA-422 connection type. IGM is a point-to-point protocol, where one device connects directly

to another and only those two devices communicate with each other.

NOTE

If shielded cable is used, connect the shield wire to earth (ground) at the Liebert equipment. Do

not ground the shield at the SiteLink.

Figure 6

3.3

IGM connections

ARCnet / CMnet

The SiteLink module can connect to an EIA-485 CMnet through the CMnet port at 9600 bps,

38.4 Kbps or 156 Kbps. Use a baud rate of 156 Kbps to communicate on a BACnet over ARCNET

156 Kbps network. When communicating at 156 Kbps, the CMnet uses a unique implementation of

the industry standard ARCNET protocol called ARC156.

1. Be sure the module’s power is off before wiring it to the CMnet.

2. Check the network communication wiring for shorts and grounds.

3. Connect the CMnet wires to the module’s screw terminals as shown in Figure 7. Be sure to follow

the same polarity as the rest of the CMnet.

Figure 7

Wiring the CMnet

Optional Shield

CMnet

NETNET+

ARC156 CMnet

Shield

NETNET+

18-24 ga Twisted - Pair, Shielded,

Low Impedance, Low Capacitance.

Recommended wire: Magnum Cable A3-ARC-156-2

4. Set the CMnet’s baud rate on the module, as described in 4.0 - Addressing. All modules on the

CMnet must use the same baud rate.

5

Making Connections

3.4

Connecting to a Building Management System (BMS)

3.4.1

Connection Considerations

Port A on the SiteLink is capable of several types of connections:

• EIA-232

• 2-wire EIA-485

• 2-wire or 4-wire EIA-485/EIA-422

Differences Between EIA-485 and EIA-422

Third-party manufacturers sometimes specify a device as either EIA-485 or EIA-422.

EIA-485 and EIA-422 terminology is interchangeable for the following reasons. Both can have 2-wire

or 4-wire connections, but an EIA-422 connection needs 4 wires to achieve two-way communication.

An EIA-422 4-wire network actually consists of two EIA-422 2-wire one-directional networks communicating between the same devices.

The reason for the one-directional limitation is that an EIA-422 transmitter cannot turn off automatically after transmission. An EIA-422 transmitter that is on—even when not sending data—will prevent another transmitter from effectively sending data.

An EIA-485 transmitter, by contrast, can turn on and off between transmissions. This feature makes

a 2-wire connection possible and preferable for many reasons, including the fact that 2-wire networking allows for daisy-chaining with no need to designate any devices as master, as 4-wire requires.

The only advantage of 4-wire over 2-wire is that 4-wire allows full duplex communications; however,

since very few protocols need full duplex communications, there is little practical reason to run 4-wire

EIA-485. Although technically there are voltage and driver load differences between EIA-485 and

EIA-422, the differences are indistinguishable in normal use.

Liebert recommends using a 2-wire connection unless:

• you are communicating with a device that uses EIA-422 or

• the third-party device does not support 2-wire EIA-485.

Use of the two terms—EIA-422 and EIA-485—can be confusing in engineering drawings. When drawings include SiteLink wiring details, Liebert suggests labeling any occurrences of EIA-422 as

“EIA-422 (EIA-485 4-wire).”

Termination

You can reduce reflections that cause communication and data errors on EIA-485/EIA-422 networks

by terminating a data cable with a value equal to its characteristic impedance. Although termination

is often unnecessary on networks where the baud rates are slow or the cables are short, termination

becomes important as the baud rate increases.

Resistors acting as terminators typically have 120-130 ohms, although twisted-pair cable impedances

can be as low as 100 ohms. Liebert recommends 120 ohm terminating resistors on EIA-485/EIA-422

networks. You must apply a value that closely matches the cable impedance as near as possible to the

ends of the network segment.

NOTE

Some third-party manufacturers provide a resistor within a device, using a jumper to disable

the termination option if termination is not required. If you are using one of these devices,

make sure that only devices that require termination are set to have termination.

6

Making Connections

Bias

Data collisions occur when two devices enable their transmitters at the same time; these are likely to

occur on EIA-485/EIA-422 networks. A master/slave protocol has one master and many slaves. The

slaves are always listening and respond only when they hear their address in the master’s request for

information. When the master is not transmitting, the network will float, enabling noise to falsely

trigger one of the slaves’ receivers, since the receiver’s output is undefined when the receiver’s input

voltage is between 200mV and -200mV (known as the undefined state).

You can apply bias to the network to ensure that the network assumes a defined state even when all

device transmitters are off.

When bias is used with terminators, the float network state’s voltage exceeds 200mV. This means

that:

• The receivers are biased in the mark state (OFF, logic 1) when the network is idle or when the

transmitter sends a logic 1.

• During the transmission of a logic 0 (less than -200mV), the network will be in the space state

(ON, logic 0).

Liebert’s DIAG boards can serve as bias on EIA-485/EIA-422 networks. Apply bias in the middle of

the network, and apply termination only at the two end devices.

7

Making Connections

3.4.2

EIA-232 Connection—3-Wire

NOTE

Either Port A or Port B may be used for EIA-232.

When connecting the SiteLink to a BMS that uses EIA-232:

• The recommended wiring is 18-28AWG.

• Most EIA-232 cables are not twisted pair, but twisted pair wiring is acceptable.

• The distance from the SiteLink to the EIA-232 BMS interface should not exceed 50 ft. (15.2m).

Figure 8

EIA-232 using 3-wire connection

EIA-232 Modbus or BACnet

18-22 ga twisted pair

Recommended wire: Belden 88761

BMS

Interface

(Rx)

—————

(Tx)

—————

(Signal

—————

Ground)

3.4.3

2 wire 4 wire EIA-232

Net+ Tx +

Tx

NetTx Rx

Communications

n/c

Rx +

DTR

Port A

n/c

Rx DCD

Signal

Ground

SiteLink

Port A

Tx

Rx

Open Protocol

Communications

Port B

Gnd

EIA-232 Connection—DB-9

NOTE

Either Port A or Port B may be used for EIA-232.

When connecting the SiteLink to a BMS that uses EIA-232:

• A standard DB-9M to DB-9F cable can be connected to Port B on the SiteLink.

• The distance from the SiteLink to the EIA-232 BMS interface should not exceed 50 ft. (15.2m).

Figure 9

EIA-232 using DB-9 cable

2 wire 4 wire EIA-232

Net+ Tx +

Tx

NetTx Rx

Communications

n/c

Rx +

DTR

Port A

n/c

Rx DCD

Signal

Ground

EIA-232 Modbus or BACnet

Standard DB-9 pin

Open Protocol

Communications

Port B

8

Making Connections

3.4.4

EIA-485 Connection—2-Wire (Default)

NOTE

Port A is recommended for 2-wire EIA-485—the default setting for the module.

When connecting the SiteLink to a BMS that uses 2-wire EIA-485:

• The recommended wiring is shielded, 18-24AWG twisted pair.

• The distance from the SiteLink to the first EIA-485 device depends on the communications baud

rate; on average, this distance should not exceed 3,000 ft. (914.4m) at 9600 baud.

• Keep in mind that repeaters are often required when connecting 32 or more EIA-485 devices or

when using long runs of wire. Refer to your BMS documentation for information on when to use

repeaters.

Figure 10 EIA-485 using 2-wire connection (SiteLink default)

EIA-485 Modbus or BACnet

18-22 ga twisted pair

Recommended wire: Belden 88761

BMS Interface

2 wire 4 wire EIA-232

Net+ Tx +

Tx

NetTx Rx

Communications

n/c

Rx +

DTR

Port A

n/c

Rx DCD

Signal

Ground

SiteLink Port B

(Net +) ——————————

(Net -) ——————————

+

-

Master configuration using EIA-485 (2-wire)

3.4.5

Open Protocol

Communications

Port B

EIA-485 or EIA-422 Connection—4-Wire

NOTE

Port A may be used for EIA-485/EIA-422 (4-wire).

When connecting the SiteLink to a BMS that uses 4-wire EIA-485/EIA-422:

• The recommended wiring is shielded, 18-24AWG twisted pair.

• EIA-485 and EIA-422 networks are intended to be configured as a linear bus with daisy-chained

connections (star topologies are not recommended), and termination is usually applied to both

ends of the network.

• The distance from the SiteLink to the first EIA-485/EIA-422 device depends on the communications baud rate; on average, this distance should not exceed 3,000 ft. (914.4m) at 9600 baud.

• Keep in mind that repeaters are often required. Refer to your BMS documentation for information

on when to use repeaters.

Figure 11 EIA-485 or EIA-422 using 4-wire connection

EIA-485 Modbus or BACnet

18-22 ga twisted pair

Recommended wire: Belden 88761

BMS

Interface

Rx+

RxTx+

Tx-

———

———

———

———

SiteLink

Slave #1

Tx+

TxRx+

Rx-

2 wire 4 wire EIA-232

Net+ Tx +

Tx

NetTx Rx

Communications

n/c

Rx +

DTR

Port A

n/c

Rx DCD

Signal

Ground

SiteLink

Slave #2

———

———

———

———

Tx+

TxRx+

Rx-

Open Protocol

Communications

Port B

Slave configuration using EIA-485 (4-wire)

9

Addressing

4.0

ADDRESSING

4.1

Set the Address for ARC156 CMnet

On an ARC156 CMnet (156 Kbps), set the CMnet Mode jumper to ARC156. See Figure 12 for location of the jumper.

Figure 12 Using an ARC156 CMnet

CMnet Mode

9600/

38.4k

ARC156

ARC156

9600/38.4k

4.2

Set the Address for Legacy CMnet

On a legacy CMnet (9600 bps or 38.4 Kbps), set the CMnet Mode jumper to 9600/38.4k and use the

baud rate DIP switch to determine the baud rate. See Figure 13 for location of the jumper and the

DIP switch.

Figure 13 Using a Legacy CMnet

Options

Format

10's

1's

Module

Address

Baud rate

DIP switch

CMnet Mode

38.4k

9600

9600/

38.4k

ARC156

9600/38.4k

10

ARC156

Addressing

4.3

Verify Communication on the CMnet

To verify that the SiteLink is communicating on the CMnet, make sure the CMnet transmit and

receive LEDs are active.

NOTE

Before setting or changing the address, make sure the SiteLink’s power is Off. The SiteLink

reads the address only when the module is turned On. After changing the address, you must

transfer memory to the module.

The SiteLink has two rotary switches for assigning the module’s CMnet address, as shown in

Figure 14. The switch at left corresponds to the tens (10s) digit, the one at right to the ones (1s) digit.

For example, if the module’s address is three (3), set the tens switch to zero (0) and the ones switch to

three (3).

Figure 14 Setting the module’s address

Tens (10s) switch

EXAMPLE:

Setting the module address to 03

9

0

1

8

7

6

5

Ones (1s) switch

4

11

9

2

8

3

7

0

1

2

3

6

5

4

Troubleshooting

5.0

TROUBLESHOOTING

5.1

Formatting the Module

When you are unable to communicate with a module, you can, as a last resort, manually format the

module to try to restore communication. Formatting the module erases all memory, so you need to

transfer memory back to the module once it is formatted.

1.

2.

3.

4.

5.

5.2

Turn the module’s power off. Make sure the module’s address switches are not set to “0 0”.

Press and hold the Format button (see Figure 1 for location).

While continuing to hold the Format button, turn the module’s power on.

Continue to hold the button until the Error LED flashes three times in sync with the Run LED.

Release the Format button.

Diagnostic LEDs

The SiteLink module has LED indicators that show the status of certain functions, as Table 1 shows.

Table 1

LED indicators

Indicator

Description

Power

Lights when power is being supplied to the module

Run

Flashes to indicate a normal condition

Error

Lights when an error is detected

CMnet Receive

Lights when the SiteLink receives data from the CMnet/ARCnet

CMnet Transmit

Lights when the SiteLink transmits data over the CMnet/ARCnet

Port A Receive

Lights when SiteLink receives data over Port A

Port A Transmit

Lights when SiteLink transmits data over Port A

Port B Receive

Lights when SiteLink receives data over Port B

Port B Transmit

Lights when SiteLink transmits data over Port B

Unit Transmit

Lights when SiteLink transmits data over an IGM Port

Unit Receive

Lights when SiteLink receives data from an IGM Port

The Run and Error LEDs indicate error conditions, shown in Table 2, to assist in troubleshooting.

Table 2

Run & Error LED signals

Run LED

Error LED

2 flashes per second

Off

Condition

Normal

2 flashes per second

1 flash per second

Normal, but module is alone on the CMnet

2 flashes per second

2 flashes per second

Five-minute auto-restart delay after system error, or module is

configured for a different baud rate from the rest of the CMnet

2 flashes per second

4 flashes per second

Two or more items in the database have the same node ID

2 flashes per second

On

Exec halted after frequent system errors

5 flashes per second

On

Exec startup aborted; boot is running

5 flashes per second

Off

Firmware transfer in progress

7 flashes per second

7 flashes per second

Ten-second recovery period after brownout

14 flashes per second

14 flashes per second

Brownout

12

Specifications

6.0

SPECIFICATIONS

POWER

24VAC ± 10%, 50-60 Hz, 7.2VA power consumption

(120/24VAC 40VA Transformer available)

DIMENSIONS, W xD x H, in. (mm)

Module

6 x 2-5/16 x 7-1/20 (152.4 x 58.7 x 179.1)

Enclosure

(Painted steel)

14.25 x 2.85 x 12 (362 x 72.4 x 304.8)

See 2.1 - Enclosure Diagrams for mounting options.

ENVIRONMENTAL

Operating Range

0°F to 130°F (-17.8°C to 54.4°C), 10 to 90% relative humidity, non-condensing

CMnet EIA-485 port - control module network screw terminals

Switch-selectable baud rates ARC156 / 9600 bps or 38.4 Kbps

Recommended wire: MAGNUM Cable P/N A3-ARC-156-2

Communications

2 portal interfaces - one EIA-232, one EIA-485 2-wire/4-wire

(for third-party software; selectable baud rate, 9600 bps or 38.4 Kbps)

1 access port for diagnostics

4 to 12 unit ports for Liebert unit connection - screw terminal

MEMORY

1024 kB Flash memory and 1024 kB non-volatile battery-backed RAM

PROTECTION

Voltage, current and ESD protection on incoming power and ARC156 network

BATTERY

Seven-year lithium battery provides a minimum of 10,000 hours of data

retention during power outages

AGENCY LISTINGS

UL 916 (PAZX)

cUL C22.2 No. 205-M1983 (PAZX7)

FCC Part 15 - Subpart B - Class A

13

Specifications

14

Ensuring The High Availability

0f Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical

continuity, ensures network resiliency and adaptability through

a family of technologies—including Liebert power and cooling

technologies—that protect and support business-critical systems.

Liebert solutions employ an adaptive architecture that responds

to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility and

reduced capital equipment and operating costs.

Technical Support / Service

Web Site

www.liebert.com

Monitoring

800-222-5877

monitoring@liebert.com

Outside the US: 614-841-6755

Single-Phase UPS

800-222-5877

upstech@liebert.com

Outside the US: 614-841-6755

Three-Phase UPS

800-543-2378

powertech@liebert.com

Environmental Systems

800-543-2778

Outside the United States

614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

7/F, Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 2572220

Fax: 852 28029250

While every precaution has been taken to ensure the accuracy

and completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use of

this information or for any errors or omissions.

© 2006 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change

without notice.

® Liebert and the Liebert logo are registered trademarks of Liebert

Corporation. All names referred to are trademarks

or registered trademarks of their respective owners.

SL-27211 (6/06) Rev. 0

Emerson Network Power.

The global leader in enabling Business-Critical Continuity™.

AC Power Systems

Embedded Computing

Embedded Power

Connectivity

DC Power Systems

Integrated Cabinet Solutio ns

EmersonNetworkPower.com

Services

Outsid e Plant

Power Switching & Controls

Site Monitoring

Precision Cooling

Surge & Signal Protection

Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co.

©2006 Emerson Electric Co.