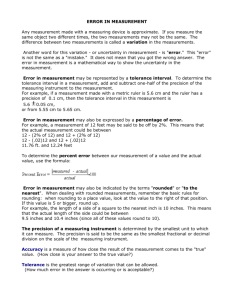

Jl O S M E TT E™ Model 5004 Automatic Osmometer

advertisement