ERROR IN MEASUREMENT

advertisement

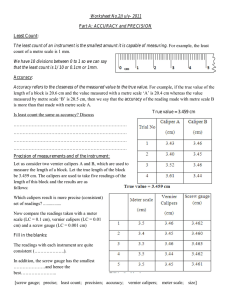

ERROR IN MEASUREMENT Any measurement made with a measuring device is approximate. If you measure the same object two different times, the two measurements may not be the same. The difference between two measurements is called a variation in the measurements. Another word for this variation - or uncertainty in measurement - is "error." This "error" is not the same as a "mistake." It does not mean that you got the wrong answer. The error in measurement is a mathematical way to show the uncertainty in the measurement. Error in measurement may be represented by a tolerance interval. To determine the tolerance interval in a measurement, add and subtract one-half of the precision of the measuring instrument to the measurement. For example, if a measurement made with a metric ruler is 5.6 cm and the ruler has a precision of 0.1 cm, then the tolerance interval in this measurement is 5.6 0.05 cm, or from 5.55 cm to 5.65 cm. Error in measurement may also be expressed by a percentage of error. For example, a measurement of 12 feet may be said to be off by 2%. This means that the actual measurement could be between 12 - (2% of 12) and 12 + (2% of 12) 12 - (.02)12 and 12 + (.02)12 11.76 ft. and 12.24 feet To determine the percent error between our measurement of a value and the actual value, use the formula: Error in measurement may also be indicated by the terms "rounded" or "to the nearest". When dealing with rounded measurements, remember the basic rules for rounding: when rounding to a place value, look at the value to the right of that position. If this value is 5 or bigger, round up. For example, the length of a side of a square to the nearest inch is 10 inches. This means that the actual length of the side could be between 9.5 inches and 10.4 inches (since all of these values round to 10). The precision of a measuring instrument is determined by the smallest unit to which it can measure. The precision is said to be the same as the smallest fractional or decimal division on the scale of the measuring instrument. Accuracy is a measure of how close the result of the measurement comes to the "true" value. (How close is your answer to the true value?) Tolerance is the greatest range of variation that can be allowed. (How much error in the answer is occurring or is acceptable?) Parallax To understand the errors involved in parallax, consider the speed reading on an automobile's speedometer as "seen" by the driver directly in front of the speedometer and a front seat passenger on the right. What each person sees can disagree by as much as 5 miles per hour. The passenger makes a reading from an angle, involving parallax, and therefore makes a less accurate reading. Ways to Improve Accuracy in Measurement 1. Make the measurement with an instrument that has the highest level of precision. The smaller the unit, or fraction of a unit, on the measuring device, the more precisely the device can measure. The precision of a measuring instrument is determined by the smallest unit to which it can measure. 2. Know your tools! Apply correct techniques when using the measuring instrument and reading the value measured. Avoid the error called "parallax" -always take readings by looking straight down (or ahead) at the measuring device. Looking at the measuring device from a left or right angle will give an incorrect value. 3. Repeat the same measure several times to get a good average value. 4. Measure under controlled conditions. If the object you are measuring could change size depending upon climatic conditions (swell or shrink), be sure to measure it under the same conditions each time. This may apply to your measuring instruments as well.