Operating Manual and User’s Guide S2000 Miniature Fiber Optic Spectrometers and Accessories

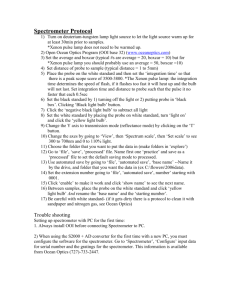

advertisement