NRG FACT SHEET

CO2 Capture Technology/KM CDR Process®

Background

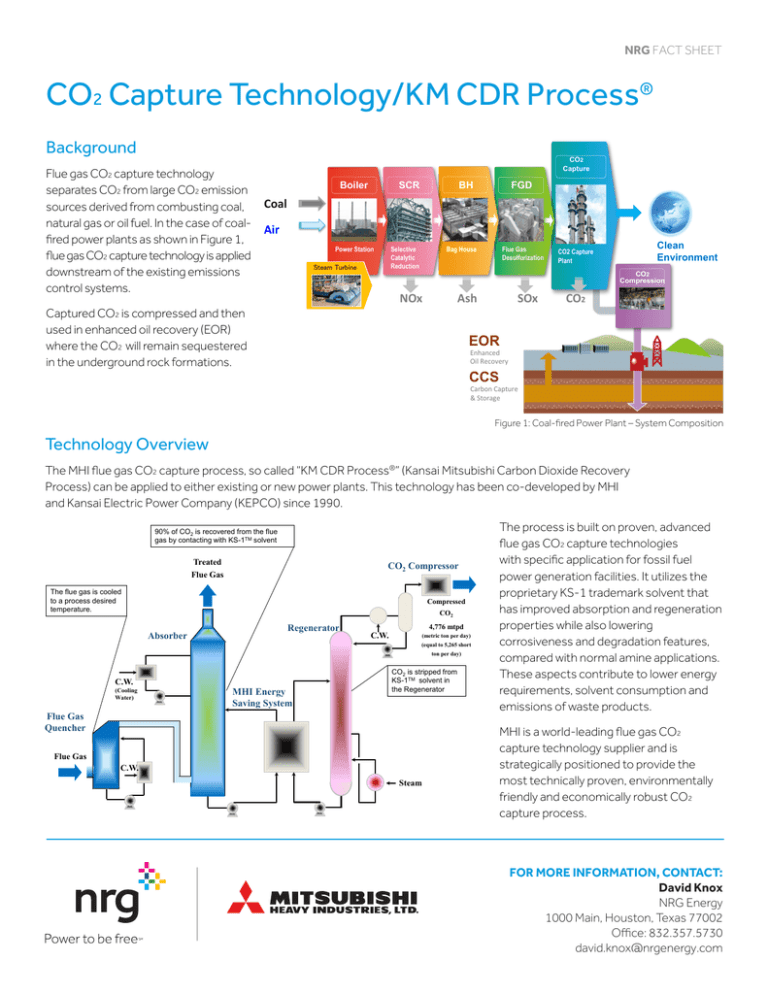

Flue gas CO2 capture technology

separates CO2 from large CO2 emission

sources derived from combusting coal,

natural gas or oil fuel. In the case of coalfired power plants as shown in Figure 1,

flue gas CO2 capture technology is applied

downstream of the existing emissions

control systems.

CO2

Capture

Boiler

SCR

FGD

BH

Coal

Air

Selective

Catalytic

Reduction

Power Station

Steam Turbine

Clean

Environment

CO2 Capture

Plant

CO2

Compression

NOx

Captured CO2 is compressed and then

used in enhanced oil recovery (EOR)

where the CO2 will remain sequestered

in the underground rock formations.

Flue Gas

Desulfurization

Bag House

Ash

SOx

CO2

EOR

Enhanced

Oil Recovery

CCS

Carbon Capture

& Storage

Figure 1: Coal-fired Power Plant – System Composition

Technology Overview

The MHI flue gas CO2 capture process, so called “KM CDR Process®” (Kansai Mitsubishi Carbon Dioxide Recovery

Process) can be applied to either existing or new power plants. This technology has been co-developed by MHI

and Kansai Electric Power Company (KEPCO) since 1990.

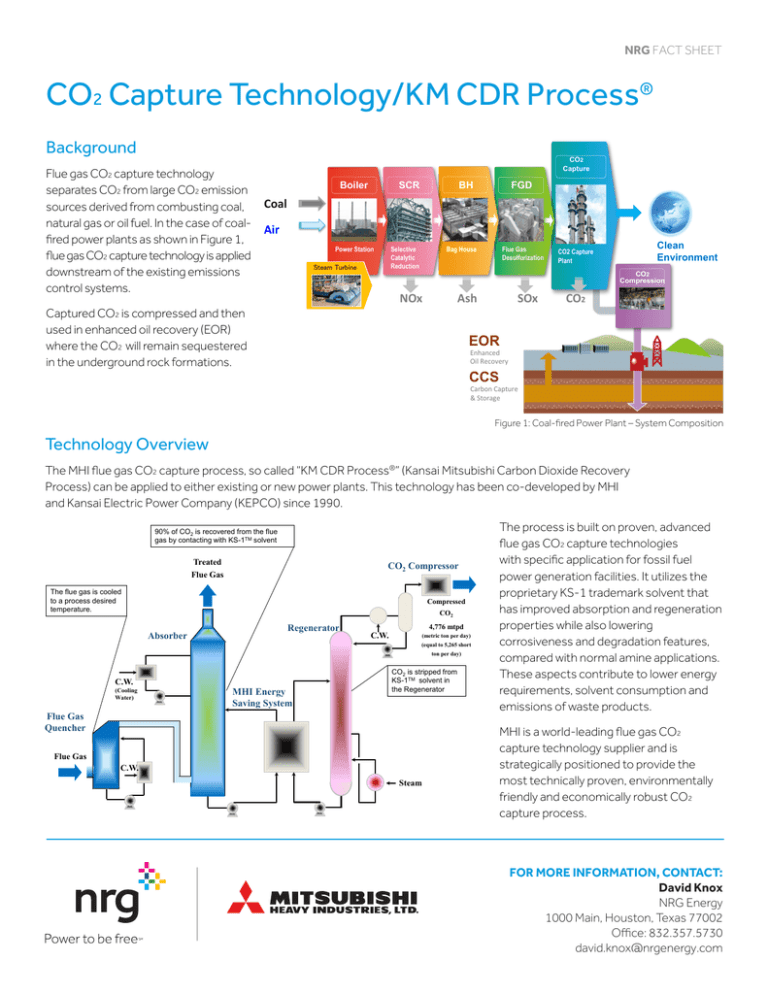

90% of CO2 is recovered from the flue

gas by contacting with KS-1TM solvent

Treated

Flue Gas

CO2 Compressor

The flue gas is cooled

to a process desired

temperature.

Compressed

CO2

Absorber

Regenerator

C.W.

4,776 mtpd

(metric ton per day)

(equal to 5,265 short

ton per day)

C.W.

(Cooling

Water)

MHI Energy

Saving System

CO2 is stripped from

KS-1TM solvent in

the Regenerator

Flue Gas

Quencher

Flue Gas

C.W.

Steam

The process is built on proven, advanced

flue gas CO2 capture technologies

with specific application for fossil fuel

power generation facilities. It utilizes the

proprietary KS-1 trademark solvent that

has improved absorption and regeneration

properties while also lowering

corrosiveness and degradation features,

compared with normal amine applications.

These aspects contribute to lower energy

requirements, solvent consumption and

emissions of waste products.

MHI is a world-leading flue gas CO2

capture technology supplier and is

strategically positioned to provide the

most technically proven, environmentally

friendly and economically robust CO2

capture process.

FOR MORE INFORMATION, CONTACT:

David Knox

NRG Energy

1000 Main, Houston, Texas 77002

Office: 832.357.5730

david.knox@nrgenergy.com

NRG FACT SHEET

KM CDR Process :

• World’s largest operating flue gas CO2 capture plant – eleven operating plants for various flue gas sources

including the largest post combustion CO2 capture plants in the world (as of June, 2014)

• World’s most energy efficient process with KS-1 solvent – leading to reduced costs

• World’s most advanced and comprehensive industrial R&D programs for more than 20 years – deployment of

multiple R&D pilot plants and research facilities led to significant process and technology improvements

• More than 207 patents pertaining to the KM CDR Process® all over the world (as of June, 2014)

• Widespread commercial experience with large scale various Air Quality Control Systems (AQCS) equipment

®

Experiences

The experience gained from the deployment of eleven operating plants has been invaluable in

strengthening operation and reliability in CO2 capture plants. Eleven major MHI CO2 capture plants

are currently under operation as shown in Figure 3.

3

8

CO2 Recovery (CDR) Plant –

IFFCO AonlaUnit (India)

1999

200 t/d Malaysia

2005

330 t/d Japan

2006

450 t/d India

CO2 Recovery (CDR) Plant –

IFFCO Phulpur Unit (India)

11

2006 India (Aonla)

450 Mt/d

2009

450 t/d Bahrain

2010

400 t/d UAE

2

2005 Japan

330 Mt/d

2011 U.S.A(SOCO)

500 t/d

2006

450 t/d India

2010

240 t/d Vietnam

2006 India (Phulpur)

450 Mt/d

2011 Pakistan

340 Mt/d

12

2014 Qatar

500 Mt/d

7

2009 Bahrain

450 Mt/d

10

2012 India (Vijaipur)

450 Mt/d

9

KEY

2009

450 t/d India

4

6

Plants under operation

Plants under construction

2010 UAE

400 Mt/d

1

5

2010 Vietnam

240 Mt/d

1999 Malaysia

210 Mt/d

2009 India (Kakinada)

450 Mt/d

Figure 3: MHI CO2 capture plant - Worldwide experience

2011

340 t/d Pakistan

2012

450 t/d India

2011

500 t/d USA

2014

500 t/d Qatar

Technology Demonstration

Coal-fired power plants are the largest producer

of CO2 emissions. The 500 mtpd (metric ton per

day) CO2 capture and sequestration project at Plant

Barry in Alabama is currently the world’ s largest

start-to-finish carbon capture and storage project

from coal fired flue gas. The CO2 produced from

the capture plant is transported via a pipeline and

sequestered at the Citronelle oil field.

The capture plant began successful operation on

June 2, 2011 and achieved a 100,000 ton of CO2

injection until October, 2013.

(Remark) KM CDR Process is a registered trademark of Mitsubishi Heavy

Industries, Ltd., in Japan, the United States of America, European Union (CTM),

Norway, Australia, and China.

NRG is a registered servicemark of NRG Energy, Inc. The plus signs and plus clusters are servicemarks of NRG Energy, Inc. © 2014 NRG Energy, Inc. All rights reserved.

Figure 4: The 500 mtpd CO2 capture plant at Plant Barry / Overview