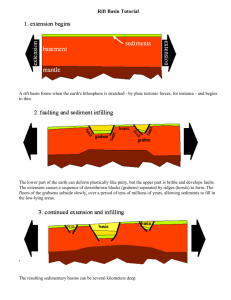

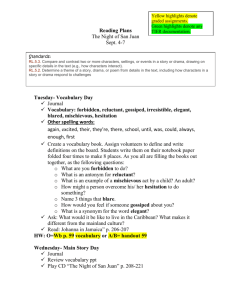

BACKGROUND GEOLOGY OF THE SAN JUAN BASIN

advertisement